Text

Agrochemical Liquid Filling Machine

Shiv Shakti Machtech is a leading Manufacturer, Exporter, and Supplier of Agrochemical Liquid Filling Machine in Ahmedabad, Gujarat, India.

Our high-quality Agrochemical Liquid Filling Machine is tailored to meet the precise needs of the agrochemical industry.

Designed for efficient and reliable filling, it accommodates liquid agrochemical products such as pesticides, fertilizers, herbicides, insecticides, and chemical formulations.

Key Features:

Superior Filling Accuracy: Utilizes advanced technology for precise and consistent filling.

Versatile Container Compatibility: Can handle various container sizes and shapes.

Efficient Operation: A User-friendly interface allows for quick adjustments and changeovers, ensuring high-speed filling capability.

Hygienic and Safe: Constructed with food-grade and corrosion-resistant materials, with advanced safety features.

Robust and Durable Construction: Built to withstand demanding operating conditions, with minimal maintenance requirements.

Customizable Solutions: Offers options for tailoring the machine to specific needs.

Benefits:

Ensures precise and accurate filling, minimizing product waste.

Provides flexibility in packaging requirements.

Maximizes productivity with efficient operation and high-speed filling capability.

Prioritizes the safety and hygiene of agrochemical products.

Offers long-lasting performance and cost savings.

Customizable to meet unique requirements.

Geographical Coverage:

Shiv Shakti Machtech serves Agrochemical Liquid Filling Machine in Ahmedabad, Gujarat, India, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#AgrochemicalLiquidFillingMachine#AgrochemicalLiquidFillingMachineinAhmedabad#AgrochemicalLiquidFillingMachineinGujarat#AgrochemicalLiquidFillingMachineinIndia#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofAgrochemicalLiquidFillingMachine#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofAgrochemicalLiquidFillingMachine

0 notes

Text

Front and Back Labeller Machine

Shiv Shakti Machtech is a leading Manufacturer, Exporter, and Supplier of Front and Back Labeller Machine in Ahmedabad, Gujarat, India.

Manufacturers utilize a front and back labeller machine as a specialized device in packaging and labeling processes. It applies labels to both the front and back surfaces of products simultaneously.

Functionality:

Engineers design the machine to accurately and efficiently apply labels to both the front and back surfaces of products like bottles, jars, containers, or packages.

It can handle various types of labels, including paper labels, adhesive labels, or shrink sleeves, depending on the specific requirements of the product and packaging.

Operation:

The machine's conveyor system feeds products, positioning them for labeling.

The machine applies labels to the front and back of each product as it moves along the conveyor, ensuring precise placement and alignment.

Advanced sensors and labeling mechanisms ensure consistent label application, even at high speeds.

Features:

Dual Labeling: Capable of applying labels to both the front and back of products in a single pass, saving time and labor.

Adjustable Settings: Allows for customization of label placement, size, and orientation to accommodate different product sizes and shapes.

High-Speed Operation: Can label products at high speeds, making it suitable for large-scale production environments.

User-Friendly Interface: Intuitive controls and touchscreen displays simplify operation and setup, minimizing training requirements for operators.

Robust Construction: Built with durable materials and components to ensure long-term reliability and minimal maintenance requirements.

Geographical Coverage:

Shiv Shakti Machtech serves Front and Back Labeller Machine needs worldwide, including Algeria, Angola, Argentina, Australia, Austria, Azerbaijan, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Chile, Colombia, Congo, Cuba, Cyprus, Denmark, Ecuador, Egypt, Ethiopia, Fiji, Finland, France, Georgia, Germany, Ghana, Hungary, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kuwait, Lebanon, Malawi, Malaysia, Mauritius, Morocco, Mozambique, Namibia, Nepal, Netherlands, New Zealand, Nigeria, Norway, Oman, Philippines, Poland, Portugal, Qatar, Romania, Rwanda, Saudi Arabia, Serbia, Singapore, Slovakia, Slovenia, Somalia, South Africa, Spain, Sri Lanka, Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Turkey, Uganda, Ukraine, United Arab Emirates, United Kingdom, United States, Uruguay, Uzbekistan, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#Ahmedabad#Algeria#Angola#Argentina#Australia#Austria#Azerbaijan#Bahrain#Bangladesh#Belarus#Belgium#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#Chile#Colombia#Congo#Cuba#Cyprus#Denmark#Ecuador#Egypt

0 notes

Text

Six Head Bottle Capping Machine

Company Overview:

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Six Head Bottle Capping Machine in Ahmedabad, Gujarat, India.

A six-head bottle capping machine is specialized equipment utilized in the packaging industry for efficient bottle capping.

It automatically caps bottles with caps or closures, commonly made of plastic or metal materials.

The machine is equipped with six capping heads, allowing for simultaneous capping and enhancing production efficiency.

Also known as Rotary Six Head Bottle Capper Machine, Rotary Six Head Chuck Capper machine, and Rotary Bottle Capper Machine.

Salient Features:

No bottle, no cap system.

Made of stainless steel for durability and hygiene.

Minimal changeover and setting time, ensuring time effectiveness.

Easy dismantling of parts for cleaning.

Equipped with safety features like a Clutch System to prevent glass breakage.

User-friendly main operating panel for easy operation.

Applications:

Beverage Industry: Capping bottles of water, soft drinks, juices, and other beverages.

Pharmaceutical Industry: Capping bottles containing medications, supplements, and pharmaceutical products.

Cosmetics Industry: Capping bottles of lotions, creams, shampoos, and other cosmetic products.

Food Industry: Capping bottles of sauces, dressings, condiments, and edible oils.

Geographical Coverage:

Shiv Shakti Machtech serves Six Head Bottle Capping Machines in Ahmedabad, Gujarat, India, and across various states and territories including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can contact Shiv Shakti Machtech for further details and inquiries.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofSixHeadBottleCappingMachine#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya#Nagaland#Odisha#Puducherry#Punjab

0 notes

Text

Edible Oil Bottle Packaging Line

Shiv Shakti Machtech is a leading Manufacturer, Exporter, and Supplier of Edible Oil Bottle Packaging Line in Ahmedabad, Gujarat, India.

Edible oil bottle packaging lines are crucial in the food and beverage sector, comprising several machines that efficiently fill, cap, and label bottles of edible oil.

The primary machines in edible oil packaging lines include servo motor controlled gear pump filling machines, screw capping machines, and round bottle sticker labeling machines.

A servo motor controlled gear pump filling machine uses a gear pump to manage the flow of oil and a servo motor to accurately dispense the correct amount into each bottle, ensuring consistent fill levels and minimizing waste.

Screw capping machines are employed to secure caps on bottles, typically using a rotating chuck to hold and spin the bottle while applying various types of caps like snap-on, twist-off, and screw-on.

Round bottle sticker labeling machines utilize a conveyor system to move bottles through the labeling process, where labels are precisely dispensed and applied, accommodating different sizes and shapes of labels.

When choosing equipment for an edible oil packaging line, factors such as production requirements, space availability, and budget should be taken into account.

It is crucial to select a reputable manufacturer capable of providing equipment that adheres to industry standards and regulations.

Specification:

Bottle Packing Line: Includes filling, capping, and labeling machines.

Capping: Single head for securing caps.

Filling Head: Equipped with 4 heads for efficient oil filling.

Labeling: Designed for round bottle labeling.

Speed: Capable of processing up to 28 bottles per minute.

Total Length: The complete line spans 18 feet, with each machine occupying 6 feet.

Container Type: Specifically designed for bottles.

Warranty: Comes with a 1-year warranty.

Filling Material: Intended for use with oil.

Country of Origin: Made in India.

I Deal In Available in new condition only.

Automation Grade: Fully automatic operation.

Application:

Cooking Oil, Mustard Oil, Soybean Oil, Cottonseed Oil, Vanaspati Ghee, Rice Bran Oil, Sesame Oil, Palm Oil, Mustard Oil, Kachi Ghani Mustard Oil, Refined Oil, Coconut Oil, Sunflower Oil, Corn Oil, Olive Oil, Soya Oil, Canola Oil, Safflower Oil, Oil Spray, Avocado Oil, Rapeseed Oil, Nut Oils, Organic Safflower Oil, Palm Oil, Groundnut Oil, Edible Oil, Vegetable Oil,

Geographical Coverage:

Shiv Shakti Machtech serves Edible Oil Bottle Packaging Line in Ahmedabad, Gujarat, India, including

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and

Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand,

Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha,

Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#EdibleOilBottlePackagingLineinAhmedaabad#EdibleOilBottlePackagingLineinGujarat#EdibleOilBottlePackagingLineinIndia#EdibleOilBottlePackagingLineMachineManufacturerinAhmedabad#ExporterofEdibleOilBottlePackagingLine#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofEdibleOilBottlePackagingLine#Meghalaya

0 notes

Text

Automatic Labeling Machine for Food Containers

Shiv Shakti Machtech is a leading Manufacturer, Exporter, and Supplier of Automatic Labeling Machine for Food Containers in Ahmedabad, Gujarat, India.

We offer an advanced solution, our Automatic Labeling Machine for Food Containers, tailored to efficiently apply labels with precision and speed.

This machine, equipped with cutting-edge technology, seamlessly integrates into food packaging lines, ensuring accurate label placement.

An Labeling Machine for Food Containers is designed to label various types of food packaging efficiently and accurately.

Key Features:

High-Speed Labeling: Labels food containers quickly to meet high production demands.

Precision Label Placement: Ensures accurate label alignment, reducing waste.

Versatile Label Compatibility: Accommodates various label types for diverse packaging needs.

Adjustable Labeling Parameters: Customizable settings for label size, position, and pressure.

User-Friendly Interface: Intuitive touchscreen interface for easy operation and monitoring.

Automatic Container Feeding: Integrates with conveyor systems for automated container feeding.

Quick Changeover: Enables swift transitions between label types and container sizes.

Robust Construction: Durable materials withstand continuous operation in food processing environments.

Compliance with Food Safety Standards: Meets regulatory requirements for hygienic food labeling.

Applications:

Food Container, Food Package, Plastic Container, Pastic Punnet, Transparent Punnet, Fruits Punnet, Storage Container, Lunchbox, Compass Box, Packed Food Container, Bag, Pouch, Filled Pouch, Big Bag, Paperbag, Food Carton, Food Box, Bakery Box, Bakery Carton.

Geographical Coverage:

Shiv Shakti Machtech serves Automatic Labeling Machine for Food Containers in Ahmedabad, Gujarat, India, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#AutomaticLabelingMachineforFoodContainers#AutomaticLabelingMachineforFoodContainersinGujarat#AutomaticLabelingMachineforFoodContainersinIndia#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofAutomaticLabelingMachineforFoodContainers#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#ManufacturerofAutomaticLabelingMachineforFoodContainersinAhmedabad#ManufacturerofAutomaticLabelingMachineforFoodContainersinIndia#Meghalaya

0 notes

Text

Rotary Chuck Capper Machine

Shiv Shakti Machtech:

Shiv Shakti Machtech Manufacturer, Exporter, and Supplier of Rotary Chuck Capper Machine in Ahmedabad, Gujarat, India.

The Rotary Chuck Capper Machine is a versatile and efficient solution designed for capping bottles with various types of caps.

It is equipped with rotary chuck capping heads that securely tighten caps onto bottles as they pass through the machine's rotary mechanism.

Features:

Rotary Chuck Capping Heads: Utilizes rotary chuck capping heads to securely grip and tighten caps onto bottles.

Adjustable Capping Speed: Allows for adjustable capping speed to accommodate different production rates and bottle sizes.

Quick Changeover: Designed for quick and easy changeover between different cap sizes and types.

Flexible Cap Handling: Capable of handling a wide range of cap styles, including screw caps, snap-on caps, and press-on caps.

Gentle Handling: Ensures gentle handling of bottles to prevent damage during the capping process.

Stainless Steel Construction: Constructed from stainless steel for durability, corrosion resistance, and compliance with hygiene standards.

User-Friendly Interface: Equipped with an intuitive interface for easy operation, monitoring, and adjustment of machine settings.

Benefits:

Efficient Capping: Ensures fast and efficient capping of bottles, maximizing production output.

Versatile Cap Compatibility: Compatible with various types and sizes of caps, offering flexibility in production.

Easy Operation: A simple and user-friendly interface facilitates easy operation and maintenance.

High-Quality Capping: Delivers consistent and reliable capping results, ensuring product quality and integrity.

Space-Saving Design: A compact footprint saves valuable floor space in production facilities.

Robust Construction: Durable construction ensures long-term reliability and performance even in demanding industrial environments.

Applications:

Bottling lines in the food and beverage industry.

Pharmaceutical and cosmetic packaging facilities.

Chemical and household cleaning product manufacturing plants.

Contract packaging and bottling services.

Any production line requires efficient and reliable bottle capping.

Geographical Coverage:

Shiv Shakti Machtech serves Rotary Chuck Capper Machine in Ahmedabad, Gujarat, India, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofRotaryChuckCapperMachine#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofRotaryChuckCapperMachine#Meghalaya#Nagaland#Odisha#Puducherry

0 notes

Text

Phenyl Bottle Filling Machine Servo Based

Shiv Shakti Machtech:

Shiv Shakti Machtech Manufacturer, Exporter and Supplier of Phenyl Bottle Filling Machine Servo Based in Ahmedabad, Gujarat, India.

The Phenyl Bottle Filling Machine (Servo Based) is an advanced solution designed for precise and efficient filling of phenyl bottles. It incorporates servo motor technology, offering enhanced accuracy and control over the filling process.

Components:

Turn Table: Facilitates the smooth transition of bottles through the filling line.

Gear Pump Filling Machine: Utilizes high-precision gear pump technology for accurate measurement and dispensing of phenyl into bottles.

Single Head Screw Capping Machine: Efficiently secures bottle caps with precision, ensuring a tight seal to maintain product integrity.

Round Bottle Labeling Machines: Automatically applies labels to bottles, enhancing brand visibility and compliance with labeling standards.

Features:

Fully automatic operation streamlines the bottling process with precision and efficiency.

Tailored to meet the specific needs of phenyl manufacturing.

Ensures consistent fill levels and eliminates wastage, contributing to cost-effectiveness.

Tight seal on bottle caps maintains product integrity.

Automatic labeling enhances brand visibility and compliance with labeling standards.

Intuitive control system allows operators to set parameters, monitor production, and make adjustments easily.

Equipped with sensors and safety features for smooth and error-free operation.

Reduces the need for manual labor, increasing overall production output.

Applications:

Disinfectant Chemicals, Cleaning Chemicals, Liquid Cleaning Chemical, Cleaning Agent, Floor Cleaner, Phenyl, Tile Cleaner, Utensil Cleaner, Bathroom Cleaners, Surface Cleaner, Household Cleaners, White Phenyl, Black Phenyl, Liquid Bleach, Car Shampoos, Car Polish, Liquid Polish, Glass Cleaners, Turpentine, AdBlue, Diesel exhaust fluid.

Geographical Coverage:

Shiv Shakti Machtech serves Phenyl Bottle Filling Machine Servo Based in Ahmedabad, Gujarat, India, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofPhenylBottleFillingMachineServoBased#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofPhenylBottleFillingMachineServoBased#Meghalaya#Nagaland#Odisha#PhenylBottleFillingMachineServo

0 notes

Text

Automatic Sleeve Label Inserting with Heating Tunnel

Shiv Shakti Machtech, based in Ahmedabad, Gujarat, India, is a Manufacturer, Exporter, and Supplier of Automatic Sleeve Label Inserting with Heating Tunnel.

The Automatic Shrink Sleeve Applicator with Electric Tunnel seamlessly integrates sleeve labeling into production lines, ensuring high efficiency and precision. It accurately applies labels onto containers of various shapes and sizes, with the advanced tunnel feature shrinking the labels onto the containers for a professional finish.

Benefits:

Enhanced Productivity: Experience enhanced productivity and cost-effectiveness in packaging operations.

Automated Functionality: The equipment's automated functionality reduces manual labor requirements, minimizing errors and increasing output capacity.

Versatility: Seamlessly integrates into existing production lines across different industries.

Product Integrity: The precise application of labels and efficient sealing by the shrink tunnel ensure product integrity and brand consistency.

Consumer Satisfaction: The integrated solution elevates the aesthetic appeal of the final product, meeting modern industry demands for efficient and visually appealing packaging solutions.

Commitment to Quality: Shiv Shakti Machtech's commitment to innovation and quality shines through in

this advanced packaging solution, empowers businesses to meet market demands with efficiency and excellence.

Geographical Coverage:

Shiv Shakti Machtech serves Automatic Sleeve Label Inserting with Heating Tunnel in Ahmedabad, Gujarat, India,

covering regions across the country including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra Nagar Haveli, Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh,

Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab,

Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#AutomaticSleeveLabelInsertingwithHeatingTunnel#AutomaticSleeveLabelInsertingwithHeatingTunnelinAhmedabad#Bihar#Chandigarh#Chhattisgarh#DadraNagarHaveli#DamanandDiu#Delhi#Exporter#ExporterofAutomaticSleeveLabelInsertingwithHeatingTunnel#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofAutomaticSleeveLabelInsertingwithHeatingTunnelinAhmedabad#Meghalaya

0 notes

Text

Four Head Bottle Capping Machine

Shiv Shakti Machtech:

Shiv Shakti Machtech Manufacturer, Exporter, and Supplier of Four Head Bottle Capping Machine in Ahmedabad, Gujarat, India.

The four-head bottle capping machine efficiently seals bottles in manufacturing and packaging processes

A versatile industrial equipment designed to cap bottles with various types of caps, including ROPP caps, lug caps, and crown caps.

Four Head Bottle ROPP Capping Machine:

This machine is specifically designed to apply ROPP (Roll-On Pilfer-Proof) caps onto bottles. ROPP caps provide a tamper-evident seal and are commonly used in the pharmaceutical, food, and beverage industries.

Four Head Lug Capping Machine:

The four head lug capping machine applies lug caps onto bottles. Lug caps have a twist-off design, commonly sealing jars with jams, pickles, and sauces.

Four Head Crown Capping Machine:

The machine applies crown caps onto bottles, typically sealing glass bottles containing carbonated beverages like beer and soda. Crown caps provide a secure seal and are easy to open with a bottle opener.

Specifications:

Fast product changeovers.

Low power consumption.

Integrated fault light and alarm system.

Accurate and repeatable performance.

Adjustable conveyor guide rails.

No bottle no capping system.

Motorized height adjustment of capping heads.

Cap Feeder Auto On/Off system.

Clutch System in feed worm to avoid bottle damage.

Smooth and accurate container handling.

Fully interlocked guarding for safety.

Applications:

Pharmaceutical industry.

Food and beverage industry.

Cosmetics industry.

Chemical industry.

Household products industry.

Geographical Coverage:

Shiv Shakti Machtech serves Four Head Bottle Capping Machine in Ahmedabad, Gujarat, India, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

Interested parties can reach out to Shiv Shakti Machtech for further details.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chemicalindustry#Chhattisgarh#Cosmeticsindustry#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofFourHeadBottleCappingMachine#foodandbeverageindustry#FourHeadBottleCappingMachine#FourHeadBottleCappingMachineinAhmedabad#FourHeadBottleCappingMachineinGujarat#FourHeadBottleCappingMachineinIndia#Goa#Gujarat#Haryana#HimachalPradesh#Householdproductsindustry#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh

1 note

·

View note

Text

Mustard Oil / Edible Oil Bottle Filling Line

Company Overview:

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Mustard Oil / Edible Oil Bottle Filling Line in Ahmedabad, Gujarat, India.

Shiv Shakti Machtech's Mustard Oil Bottle Filling Machine is crafted from top-notch materials, adhering to hygiene standards and facilitating easy cleaning.

A Mustard Oil or Edible Oil Bottle Filling Line comprises a series of machines designed for filling, capping, and labeling bottles containing mustard oil or other edible oils.

Filling Machine:

Equipped to precisely fill bottles with desired quantities of mustard oil or edible oil.

Features a conveyor belt system for bottle transportation, precision filling nozzles, and volume adjustment controls.

Ensures uniform filling levels and reduces spillage or wastage of oil.

Capping Machine:

Responsible for securely sealing filled bottles with caps or lids.

Utilizes various capping mechanisms (e.g., screw caps, press-on caps, snap-on caps) based on bottle and cap types.

Ensures tight and consistent sealing to prevent oil leakage or contamination.

Labeling Machine:

Applies labels onto filled and capped bottles, providing product information, branding, and regulatory details.

Operates with precision and consistency, even at high production speeds.

Features may include label applicators, sensors, and controls for accurate label placement and alignment.

Application:

Food and beverage industry: Used in edible oil processing plants, bottling facilities, and packaging operations for Cooking Oil, Mustard Oil, Soybean Oil, Cottonseed Oil, Vanaspati Ghee, Rice Bran Oil, Sesame Oil, Palm Oil, Mustard Oil, Kachi Ghani Mustard Oil, Refined Oil, Coconut Oil, Sunflower Oil, Corn Oil, Olive Oil, Soya Oil, Canola Oil, Safflower Oil, Oil Spray, Avocado Oil, Rapeseed Oil, Nut Oils, Organic Safflower Oil, Palm Oil, Groundnut Oil, Edible Oil, Vegetable Oil.

Geographical Coverage:

Shiv Shakti Machtech serves as the Manufacturer and Supplier of Mustard Oil / Edible Oil Bottle Filling Line in Ahmedabad, Gujarat, India, and various locations across the country, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

For further details, interested parties can contact Shiv Shakti Machtech.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya#MustardOil/EdibleOilBottleFillingLine#MustardOil/EdibleOilBottleFillingLineinGujarat#MustardOil/EdibleOilBottleFillingLineinIndia#Nagaland#Odisha

2 notes

·

View notes

Text

Flat Bottle Double Side Sticker Labeling Machine

Company Overview:

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Flat Bottle Double Side Sticker Labeling Machine in Ahmedabad, Gujarat, India.

Designed specifically for flat-shaped bottles, such as cosmetic containers and pharmaceutical vials.

Offers an efficient and reliable solution for applying labels on both sides of flat bottles.

Key Features:

Dual Labeling Heads: Equipped with two heads for simultaneous labeling on both sides, enhancing productivity.

Accurate Servo-Driven Technology: Utilizes advanced servo motors for precise label positioning, reducing errors and wastage.

Flexible Label Compatibility: Accommodates various label materials, including pressure-sensitive and transparent labels, offering versatility.

Adjustable Conveyor System: Easily adjustable to handle bottles of different sizes and shapes, ensuring seamless integration into production lines.

User-Friendly Interface: Intuitive interface simplifies operation and reduces training requirements for operators.

Integration Capabilities: Can be integrated with other packaging equipment for a streamlined production process.

Benefits:

Increases production efficiency by reducing labeling time.

Minimizes errors and wastage, leading to cost savings.

Enhances flexibility to meet diverse labeling requirements.

Streamlines production lines and improves overall efficiency.

Reinforces brand identity through consistent label placement.

Geographical Coverage:

Shiv Shakti Machtech serves as the Manufacturer and Supplier of Flat Bottle Double Side Sticker Labeling Machine in Ahmedabad, Gujarat, India, and various locations across the country, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

For further details, interested parties can contact Shiv Shakti Machtech.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofFlatBottleDoubleSideStickerLabelingMachine#FlatBottleDoubleSideStickerLabelingMachine#FlatBottleDoubleSideStickerLabelingMachineinAhmedabad#FlatBottleDoubleSideStickerLabelingMachineinGujarat#FlatBottleDoubleSideStickerLabelingMachineinIndia#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya

1 note

·

View note

Text

Liquor Glass Bottle High Speed Ropp Capping Machine

Company Overview:

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of a Liquor Glass Bottle High Speed Ropp Capping Machine in Ahmedabad, Gujarat, India.

The Liquor Glass Bottle High-Speed ROPP (Roll-On Pilfer-Proof) Capping Machine efficiently seals liquor glass bottles with ROPP closures.

Tailored specifically for the liquor industry, the machine securely caps glass bottles with ROPP closures, ensuring product integrity and tamper resistance.

Engineered to operate at high speeds, the machine enables rapid capping of large volumes of bottles to meet production demands.

Functionality:

Utilizes a roll-on mechanism to apply ROPP closures onto the necks of liquor glass bottles.

Ensures tight and uniform sealing of caps to prevent leakage and tampering.

Operates with precision to maintain product quality and consistency.

Key Features:

High-Speed Operation: Capable of capping bottles at a rapid pace, enhancing production efficiency.

ROPP Closure Compatibility: Designed to accommodate ROPP closures specifically tailored for liquor bottles.

Adjustable Settings: Allows for adjustment of capping pressure and speed to suit different bottle sizes and closure types.

Robust Construction: Constructed from durable materials to withstand continuous operation in demanding industrial environments.

User-Friendly Interface: Equipped with an intuitive control panel for easy operation and monitoring of machine parameters.

Benefits:

Increases production throughput by automating the capping process and reducing manual labor.

Ensures consistent and reliable sealing of bottles, minimizing product wastage and rework.

Enhances product security and authenticity by providing tamper-evident closures.

Supports efficient inventory management and distribution by facilitating faster packaging operations.

Geographical Coverage:

Shiv Shakti Machtech serves as the Manufacturer and Supplier of Liquor Glass Bottle High Speed Ropp Capping Machine in Ahmedabad, Gujarat, India, and various locations across the country, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

For further details, interested parties can contact Shiv Shakti Machtech.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofLiquorGlassBottleHighSpeedRoppCappingMachine#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#LiquorGlassBottleHighSpeedRoppCappingMachine#LiquorGlassBottleHighSpeedRoppCappingMachineinAhmedabad#LiquorGlassBottleHighSpeedRoppCappingMachineinGujarat#LiquorGlassBottleHighSpeedRoppCappingMachineinIndia#LiquorGlassBottleHighSpeedRoppCappingMachineinIndiia#MadhyaPradesh#Maharashtra#Manipur#Manufacturer

1 note

·

View note

Text

Mustard Oil Filling Machine Servo Based

Company Overview:

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Mustard Oil Filling Machine Servo Based, in Ahmedabad, Gujarat, India.

Specializes in providing servo-based mustard oil filling machines designed for accurate filling of mustard oil into containers or bottles.

Functionality:

Operates using servo motors to control the filling mechanism, ensuring precise measurement and filling of mustard oil into containers.

Mustard oil is fed into the machine's reservoir, and the servo motor regulates the flow of oil into containers, maintaining accurate filling levels.

The servo-based system offers adjustable filling speeds and volumes to accommodate various container sizes and production needs.

Advantages:

Precision: Ensures accurate filling volumes, reducing product giveaway and wastage.

Efficiency: Improves production efficiency by automating the filling process and reducing manual labor.

Quality Assurance: Maintains product quality by consistently filling containers to the desired level.

Cost-Effectiveness: Optimizes the filling process, minimizing operating costs and product loss.

Compliance: Meets industry standards and regulatory requirements for filling accuracy and hygiene.

Applications:

Specifically designed for filling mustard oil into containers, suitable for bottles, cans, and jars.

Widely used in the food and beverage industry, pharmaceutical industry, and chemical and cosmetic industries for filling various liquids, including Cooking Oil, Mustard Oil, Soybean Oil, Cottonseed Oil, Sesame Oil, Palm Oil, Refined Oil, Coconut Oil, Sunflower Oil, Corn Oil, Olive Oil, Soya Oil, Avocado Oil, Groundnut Oil, Edible Oil, and Vegetable Oil.

Geographical Coverage:

Shiv Shakti Machtech serves as the Manufacturer and Supplier of Mustard Oil Filling Machine Servo Based in Ahmedabad, Gujarat, India, and various locations across the country, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

For further details, interested parties can contact Shiv Shakti Machtech.

Read the full article

#Ahmedabad#andchemicalandcosmeticindustriesforfillingvariousliquids#AndhraPradesh#ArunachalPradesh#Assam#AvocadoOil#Bihar#Chandigarh#Chhattisgarh#CoconutOil#CornOil#CottonseedOil#DadraandNagarHaveliandDamanandDiu#Delhi#EdibleOil#Exporter#ExporterofMustardOilFillingMachineServoBased#foodandbeverageindustry#Goa#GroundnutOil#Gujarat#Haryana#HimachalPradesh#includingCookingOil#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh

1 note

·

View note

Text

Front and Back Labeling Machine

Front and Back Labeling Machine:

Company Overview:

Shiv Shakti Machtech operates as a Manufacturer, Exporter, and Supplier of Front and Back Labeling Machine in Ahmedabad, Gujarat, India.

These versatile machines cater to sectors such as pharmaceuticals and food packaging, among others.

Specifically designed for labeling bottles, boxes, or containers, they ensure consistent results in diverse manufacturing environments.

The Front and Back Labeler Machines are known for their innovative design and reliability, crafted with meticulous attention to detail.

The machines combine precision and efficiency, employing advanced sensors and servo motors for accurate label placement.

Customizable settings allow adaptation to different product shapes and sizes.

Streamlined process execution from product entry to label application embodies operational excellence.

Features:

Adjustable settings accommodate various product dimensions.

The user-friendly design ensures seamless operation.

Robust construction ensures longevity.

Precision label placement underscores commitment to excellence.

Technical Specifications:

Programmable Logic Controller (PLC): Yes

Gap between Two Labels: Maximum 3mm

Country of Origin: Made in India

Brand: Shiv Shakti Machtech

Direction Of Movement: Left to Right

Dispensing Motor: Servo Motor

Label Roll Diameter: Outer Roll Dia - Maximum 300mm

Conveyor Height: 850mm

I Deal In: New Only

Bottle Type: Flat Bottles and Containers

Automation Grade: Automatic

Usage/Application: Sticker Labeling

Shiv Shakti Machtech is the Supplier of Front and Back Labeling Machines in Ahmedabad, Gujarat, India, and various locations across the country, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal.

For further details, please feel free to contact Shiv Shakti Machtech

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#FrontandBackLabelingMachine#FrontandBackLabelingMachineManufacturerinAhmedabad#FrontandBackLabelingMachineSupplierinGujarat#FrontandBackLabelingMachineSupplierinIndia#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya#Nagaland

1 note

·

View note

Text

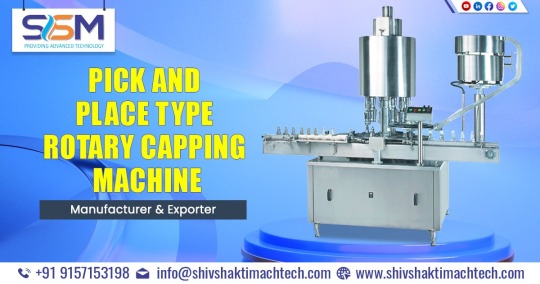

Pick and Place Type Rotary Capping Machine

Shiv Shakti Machtech: Overview

Shiv Shakti Machtech operates as a Manufacturer, Exporter, and Supplier of Pick and Place Type Rotary Capping Machine in Ahmedabad, Gujarat, India.

A specialized machine, the Pick and Place Type Rotary Capping Machine, caps containers with caps or closures in a rotary motion.

The machine employs a pick and place mechanism to accurately pick caps from a supply and place them onto containers moving along a rotary conveyor.

The machine picks and precisely places caps onto containers as they move through, ensuring secure sealing.

Features:

Rotary Motion: Operates on a rotary platform, allowing continuous capping of containers in a circular motion.

Pick and Place Mechanism: Utilizes a pick and place system to handle caps and containers with precision.

Adjustable: Can be adjusted to accommodate different container sizes and cap types.

High Speed: Capable of high-speed capping to meet production demands efficiently.

Versatile: Suitable for various industries requiring capping of containers, including food and beverage, pharmaceuticals, cosmetics, and more.

User-friendly: Designed with user-friendly controls for easy operation and adjustment.

Benefits:

Increases production efficiency by automating the capping process.

Ensures uniform and secure sealing of containers, reducing the risk of leaks or contamination.

Saves labor costs and time compared to manual capping methods.

Enhances overall packaging quality and consistency.

Applications:

This Capping Machine finds applications in industries such as pharmaceuticals, food and beverage, cosmetics, and chemical manufacturing, where efficient and precise capping of containers is essential for product quality and integrity.

Shiv Shakti Machtech is Supplier of Pick and Place Type Rotary Capping Machine in Ahmedabad, Gujarat, India and including locations like Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

For further details, please feel free to contact us.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofPickandPlaceTypeRotaryCappingMachine#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofPickandPlaceTypeRotaryCappingMachine#Meghalaya#Nagaland#Odisha#PickandPlaceTypeRotaryCappingMachine

1 note

·

View note

Text

Jerry Can Filling Machine

Shiv Shakti Machtech operates as a Manufacturer, Exporter, and Supplier of Jerry Can Filling Machine in Ahmedabad, Gujarat, India.

Shiv Shakti Machtech is a leading manufacturer of packaging machinery, specializing in liquid filling machines.

The Positive Displacement Jerry Can Filling Machine is engineered for precise and efficient filling of jerry cans with liquids.

Constructed from high-quality stainless steel, ensuring durability and longevity.

Features a positive displacement pump for accurate dispensing into jerry cans of varying sizes.

Product Details:

Product Name: Positive Displacement Jerry Can Filling Machine

Manufacturer: Shiv Shakti Machtech

Country of Origin: Made in India

Machine Type: Automatic

Driven Type: Electric

Weight: 350kg

Power Supply: 440V, 50Hz, 3 Phase

Frequency: Variable Frequency Drive

Fill Range: 5 liters to 35 liters

Application: Jar Filling

Filling Material: Free flowing liquid and Oils

Advanced Features:

Equipped with automatic shut-off system to halt filling process upon reaching desired liquid amount, minimizing waste.

User-friendly touchscreen interface for easy control and adjustment of filling parameters.

Suitable for companies requiring high-speed and high-precision filling of jerry cans with liquid products.

Benefits:

Accurate filling capabilities at high speeds due to positive displacement pump technology.

Ensures consistent filling and prevents overfilling, leading to efficient usage of liquid resources.

Reliable investment for businesses needing precise and rapid filling of jerry cans with liquid products.

Shiv Shakti Machtech is Supplier of Jerry Can Filling Machine in Ahmedabad, Gujarat, India and including locations like Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

For further details, please feel free to contact us.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#ExporterofJerryCanFillingMachine#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#JerryCanFillingMachine#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofJerryCanFillingMachine#Meghalaya#Nagaland#Odisha

1 note

·

View note

Text

Round Bottle Labeling Machine Servo Model

Shiv Shakti Machtech: Overview

Shiv Shakti Machtech operates as a Manufacturer, Exporter, and Supplier of Round Bottle Labeling Machine Servo Model in Ahmedabad, Gujarat, India.

This Machine is designed with a robust construction, featuring a conveyor system that ensures smooth transportation of bottles.

Equipped with a high-speed labeling head, the machine ensures accurate placement of labels and can accommodate various sizes and shapes of labels.

A user-friendly control panel allows for easy adjustments to label positioning, speed, and other settings, enhancing operational flexibility.

Constructed with high-quality materials, the machine is reliable, durable, and compliant with industry safety standards.

Product Specifications:

Programmable Logic Controller (PLC)

Human-Machine Interface (HMI)

Maximum Gap between Two Labels: 3mm

Country of Origin: Made in India

Brand: Shiv Shakti Machtech

Capacity: Up to 120 bottles per minute

Direction of Movement: Left to Right

Bottle Diameter: Up to 100mm

Dispensing Motor: Servo Motor

Maximum Label Roll Diameter: 300mm

Control: HMI

Conveyor Height: 850mm

Weight: Approximately 150 kg

Electrical Load: 1.5 kW

Bottle Type: Round

Model Name/Number: SSM-SL-120

Usage/Application: Labeling

Machine Type: Single Side Labeling

Application:

The Round Bottle Labeling Machine serves as a versatile tool across various industries.

It efficiently labels round bottles of different sizes and materials, making it suitable for pharmaceuticals, cosmetics, food and beverage, and more.

It is ideal for labeling small vials, jars, or larger bottles, ensuring compliance with labeling regulations and enhancing the appearance of products.

Shiv Shakti Machtech is Supplier of Round Bottle Labeling Machine Servo Model in Ahmedabad, Gujarat, India and including locations like Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

For further details, please feel free to contact us.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya#Nagaland#Odisha#Puducherry#Punjab#Rajasthan

1 note

·

View note