#AACBlockPlant

Text

Exporter of AAC Block Plant in Kenya

Company Overview:

Excellent En-Fab Incorporation, based in Ahmedabad, Gujarat, India, specializes in industrial plants and equipment.

Since 2010, they have been Manufacturer, Supplier and Exporter of AAC Block Plant in Kenya.

Production Process of AAC Blocks:

AAC blocks are manufactured by mixing sand or fly ash, cement, lime, gypsum, aluminum powder, and water.

The mixture is poured into molds and cured in autoclaves under high pressure and temperature.

This process triggers a chemical reaction, creating millions of tiny air bubbles throughout the material, resulting in a lightweight and porous structure.

Benefits of AAC Blocks:

Lightweight: AAC blocks are significantly lighter than traditional concrete blocks, reducing structural load and enabling easier handling and installation.

Thermal Insulation: The porous structure of AAC blocks provides excellent thermal insulation, maintaining comfortable indoor temperatures and reducing energy costs.

Fire Resistance: AAC blocks offer high fire resistance, enhancing building safety and meeting fire code requirementsSound Insulation: Air-filled voids in AAC blocks contribute to superior sound insulation, reducing noise transmission between rooms and buildings.

Eco-Friendly: Made from abundant natural materials, AAC blocks consume less energy in production compared to traditional concrete blocks, making them environmentally friendly.

Applications of AAC Blocks:

Residential buildings: Used for walls, partitions, and other structural elements.

Commercial buildings: Including offices, hotels, schools, hospitals, and shopping complexes.

Industrial buildings: For warehouses, factories, and storage facilities.

Infrastructure projects: Such as bridges, tunnels, and retaining walls.

Specialized constructions: Such as swimming pools, sound barriers, and fire-rated walls.

Excellent En-Fab Incorporation is Exporter of AAC Block Plant in Kenya Including Naragoi, Bungoma, Dadaab, Eldoret, Killfi, Kisil, Lamu, Litein, Lodwar, Lokichoggio, Mombasa, Moyale, Ruiru, Voi, Mumias, Nairobi, Nanyuki, Narok, Wajir, Watamu, Watamu, Webuye, Wote, Wundanyi.

For inquiries or further information, please don't hesitate to contact us.s

Read the full article

#AACBlockPlant#AACBlockPlantinKenya#aluminumpowder#Bungoma#cement#CommercialBuildings#Dadaab#Eldoret#Exporter#ExporterofAACBlockPlant#gypsum#India#Industrialbuildings#InfrastructureProjects#Killfi#Kisil#Lamu#lime#Litein#Lodwar#Lokichoggio#Manufacturer#Mombasa#Moyale#Mumias#Nairobi#Nanyuki#Naragoi#Narok#Residentialbuildings

0 notes

Photo

1000 CM #aacblockplant supplied by Laxmi En Fab Pvt. Ltd.

For more information contact

Mitesh Patel

- +91 8980800839

- www.laxmienfab.com, www.aacplant.co.in

0 notes

Text

Exporter of AAC Block Plant in Zambia

About Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation is one of the leading Manufacturer and Exporter of AAC Block Plant in Zambia.

Excellent En-Fab Incorporation is a leading manufacturer of AAC Block Plants in India, producing plants that meet the highest engineering standards and comply with international regulations.

They offer AAC plants with capacities ranging from 30 cubic meters per day to 750 cubic meters per day, providing versatile solutions for various project sizes.

AAC blocks are made primarily from fly ash (pond ash or sand), cement, gypsum, lime, and aluminum powder.

The manufacturing process involves material crushing, measuring, mixing, pouring, curing, cutting, and steaming.

The company boasts a team of qualified and experienced experts dedicated to delivering high-quality products tailored to meet the unique needs of customers.

With extensive experience in designing various building material plants and equipment, they ensure the finest engineering quality.

Excellent En-Fab Incorporation offers comprehensive technical support, including planning, design drawing, construction guidance, installation, commissioning, and technical training, providing customers with a one-stop service solution.

AAC Block Plant Benefits:

Fire Resistant

Pest Resistant

Sound Proof

Earthquake Resistant

Faster Construction

Long-lasting

Cost Saving

Versatile

Non-toxic

Thermal Insulation

Environment-Friendly

High Resistance to Water Penetration

Excellent En-Fab Incorporation is Exporter of AAC Block Plant in Zambia like Lusaka, Kitwe, Ndola, Kabwe, Chingola, Mufulira, Livingstone, Luanshya, Kasama, Chipata, Lusaka, Ndola, Mazabuka, Chipata, Chingola, Kasama, Luangwa, Mumbwa, Mufulira, Mongu, Mansa, Choma.

For additional information or inquiries, interested parties are encouraged to contact Excellent En-Fab Incorporation.

Read the full article

#AACBlockPlant#aluminumpowder#cement#CostSaving#crushing#curing#cutting#ExporterofAACBlockPlant#ExporterofAACblockplantinZambia#gypsum#India#lime#Long-lasting#Manufacturer#measuring#mixing#PestResistant#pouring#Supplier#Zambia

0 notes

Text

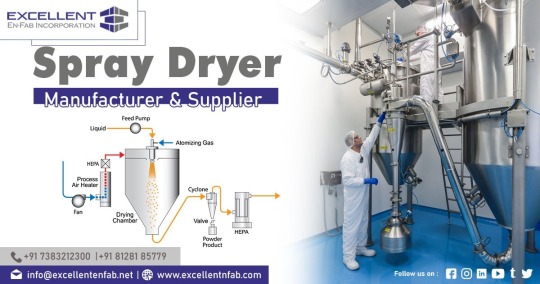

Exporter of Spray Dryer in Sri Lanka

Exporter of Spray Dryer in Sri Lanka:

Company Overview:

Excellent En-Fab Incorporation, operating since 2010, is a Manufacturer, Exporter, and Supplier of Spray Dryer.

Their product range includes AAC Block Plant, Flash Dryer, Dry Mix Mortar Plant, Storage Equipments, Autoclave, Rotary Dryer/Kiln, Wall Putty Plant, Spray Dryer, Agro Waste Pyrolysis Plant, Hot Air Generators, Spin Flash Dryer, and more.

Specializes in manufacturing premium-quality spray dryers in India, meeting international standards.

Offers various types of spray dryers customized to meet individual customer needs.

Utilizes hot air to swiftly dry atomized liquid feedstock into fine droplets, producing dry particles or powders ready for subsequent processing or packaging.

Offers spray dryers in different configurations, including nozzle atomizers, rotary atomizers, and fluidized bed dryers, designed to suit specific applications and accommodate diverse requirements.

Features:

A high aspirator rate reduces the product’s remaining moisture.

Excellent results are achieved when temperature and other parameters are properly controlled.

Minimum maintenance is required for a long working life.

Long-term dependability guaranteed.

Continuous drying methods enable faster production while maintaining and managing product quality.

Application:

Food Industry

Pharmaceuticals

Chemicals

Ceramics

Export Focus:

Excellent En-Fab Incorporation Exporter of Spray Dryer in Sri Lanka, covering regions such as Colombo, Moratuwa, Dehiwala-Mount Lavinia, Jaffna, Negombo, Sri Jayawardenepura, Kalmunai, Kandy, Vavuniya, and others.

Interested parties are encouraged to contact the company for further details and inquiries.

Read the full article

#AACBlockPlant#Agrowastepyrolysisplant#Autoclave#Ceramics#chemicals#Colombo#Dehiwala-MountLavinia#DryMixMortarPlant#Exporter#ExporterofSprayDryerinSriLanka#FlashDryer#FoodIndustry#HotAirGenerators#Jaffna#Kalmunai#Kandy#Long-termdependability#Manufacturer#ManufacturerofSprayDryer#Minimummaintenance#Moratuwa#Negombo#properlycontrolled#RotaryDryer/kiln#SpinFlashDryer#SprayDryer#SprayDryerinSriLanka#SriJayawardenepura#SriLanka#StorageEquipments

0 notes

Text

Exporter of AAC Block Plant in Russia

Company Profile:

Excellent En-Fab Incorporation is a leading Manufacturer, Supplier, and Exporter of AAC Block Plant in Russia.

Established in 2016, the company specializes in providing turnkey solutions for AAC Block Making Plants.

Their focus lies in manufacturing AAC Block Plants, AAC Plant, and Autoclave Aerated Concrete Block Making Plants, offering comprehensive solutions to clients.

The company produces AAC blocks, which are lightweight and versatile building materials made from sand, cement, lime, gypsum, and aluminum powder.

Utilizing autoclaving, they create cellular concrete blocks with excellent thermal insulation properties.

Process Overview:

Raw Material Preparation: Sand, cement, lime, and aluminum powder are mixed in predetermined proportions to form a slurry.

Molding: The slurry is poured into molds where it undergoes a chemical reaction and expands to form aerated concrete blocks.

Curing: Autoclaves steam cure green blocks, allowing them to cure and harden.

Cutting and Finishing: Cured blocks are cut into desired sizes using wire-cutting machines and finished as per requirements.

Key Equipment:

Mixer: Mixing raw materials to form the slurry.

Molds: Shaping AAC blocks during molding.

Autoclaves: Steam curing for strength and durability.

Cutting Machines: Cutting cured blocks into precise dimensions.

Finishing Equipment: Surface finishing such as grinding machines and painting equipment.

Applications:

Residential Construction: Used for building walls, partitions, and roofs.

Commercial Construction: Applied in offices, hotels, schools, hospitals, and shopping malls.

Industrial Construction: Suitable for industrial facilities, warehouses, and manufacturing plants.

Infrastructure Projects: Utilized in projects such as bridges, retaining walls, and sound barriers.

Supply Locations in Russia:

Excellent En-Fab Incorporation provides Exporter of AAC Block Plant in Russia, covering cities such as Moscow, Saint Petersburg, Novosibirsk, Samara, Omsk, Veliky Novgorod, Seversk, Norilsk, Murmansk, Belgorod, Novorossiysk, Arzamas, Kineshma, Derbent, Novoshakhtinsk, Shakhty, Vladimir, Velikiye Luki, and Kovrov.

The company encourages interested parties to contact them for further details and inquiries.

Read the full article

#AACBlockPlant#AACBlockPlantinRussia#Arzamas#Belgorod#CommercialConstruction#Derbent#Exporter#ExporterofAACBlockPlantinRussia#ExporterofAACBlockPlantorterofAACBlockPlant#IndustrialConstruction#InfrastructureProjects#Kineshma#Kovrov#Manufacturer#ManufacturerofAACBlockPlant#Moscow#Murmansk#Norilsk#Novorossiysk#Novoshakhtinsk#Novosibirsk#Omsk#ResidentialConstruction#Russia#SaintPetersburg#Samara#Seversk#Shakhty#SupplieerofAACBlockPlant#Supplier

0 notes

Text

AAC Block Plant in Sri Lanka

About Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation is a Manufacturer, Supplier, and Exporter of AAC Block Plant in Sri Lanka.

Established in 2016, Excellent En-Fab Incorporation specializes in AAC Block Making Plants and offers turnkey projects in this field.

Focuses on manufacturing AAC Block Plants, AAC Plant, and Autoclave Aerated concrete-making Plants, providing comprehensive solutions.

Produces AAC blocks, a lightweight and versatile building material made from sand, cement, lime, gypsum, and aluminum powder.

Utilizes autoclaving to create cellular concrete blocks with excellent thermal insulation properties.

Process Overview:

Raw Material Preparation: Sand, cement, lime, and aluminum powder mixed in predetermined proportions to form a slurry.

Molding: Slurry poured into molds undergoes a chemical reaction and expands, forming aerated concrete blocks.

Curing: Green blocks allowed to cure and harden in autoclaves through steam curing.

Cutting and Finishing: Cured blocks cut into desired sizes using wire cutting machines and finished as per requirements.

Key Equipment:

Mixer: Mixing raw materials to form the slurry.

Molds: Shaping AAC blocks during molding.

Autoclaves: Steam curing for strength and durability.

Cutting Machines: Cutting cured blocks into precise dimensions.

Finishing Equipment: Surface finishing such as grinding machines and painting equipment.

Applications:

Residential Construction: Building walls, partitions, and roofs.

Commercial Construction: Offices, hotels, schools, hospitals, and shopping malls.

Industrial Construction: Industrial facilities, warehouses, and manufacturing plants.

Infrastructure Projects: Bridges, retaining walls, and sound barriers.

Supply Locations in Sri Lanka:

Excellent En-Fab Incorporation Providing AAC Block Plant in Sri Lanka, covering regions such as Colombo, Moratuwa, Dehiwala-Mount Lavinia, Jaffna, Negombo, Sri Jayawardenepura, Kalmunai, Kandy, Vavuniya, and others.

For further details and inquiries, interested parties are encouraged to contact the company.

Read the full article

#AACBlockPlant#AACBlockPlantinSriLanka#AutoclavedAeratedConcretePlant#Autoclavedaeratedconcreteplantinsrilanka#Colombo#CommercialConstruction#Dehiwala-MountLavinia#Exporter#ExporterofAACBlockPlant#ExporterofAACBlockPlantinSriLanka#IndustrialConstruction#InfrastructureProjects#Jaffna#Kalmunai#Kandy#Manufacturer#ManufacturerofAACBlockPlant#Moratuwa#Negombo#ResidentialConstruction#SriJayawardenepura#SriLanka#Supplier#SupplierofAACBlockPlant#Vavuniya

0 notes

Text

AAC Block Plant in Kenya

AAC Block Plant in Kenya:

About Excellent En-Fab Incorporation:

Established in 2016, Excellent En-Fab Incorporation specializes in AAC Block Making Plants and offers turnkey projects in this field.

Focuses on manufacturing AAC Block Plants, AAC Plant, and Autoclave Aerated Concrete Block Making Plants, providing comprehensive solutions.

AAC Block Plant Overview:

Produces AAC blocks, a lightweight and versatile building material made from sand, cement, lime, gypsum, and aluminum powder.

Utilizes autoclaving to create cellular concrete blocks with excellent thermal insulation properties.

Process Overview:

Raw Material Preparation: Sand, cement, lime, and aluminum powder mixed in predetermined proportions to form a slurry.

Molding: Slurry poured into molds undergoes a chemical reaction and expands, forming aerated concrete blocks.

Curing: Green blocks are allowed to cure and harden in autoclaves through steam curing.

Cutting and Finishing: Cured blocks are cut into desired sizes using wire-cutting machines and finished as per requirements.

Key Equipment:

Mixer: Mixing raw materials to form the slurry.

Molds: Shaping AAC blocks during molding.

Autoclaves: Steam curing for strength and durability.

Cutting Machines: Cutting cured blocks into precise dimensions.

Finishing Equipment: Surface finishing such as grinding machines and painting equipment.

Applications:

Residential Construction: Building walls, partitions, and roofs.

Commercial Construction: Offices, hotels, schools, hospitals, and shopping malls.

Industrial Construction: Industrial facilities, warehouses, and manufacturing plants.

Infrastructure Projects: Bridges, retaining walls, and sound barriers.

Supply Locations in Kenya:

Providing AAC Block Plant in Kenya including Naragoi, Bungoma, Dadaab, Eldoret, Killfi, Kisil, Lamu, Litein, Lodwar, Lokichoggio, Mombasa, Moyale, Ruiru, Voi, Mumias, Nairobi, Nanyuki, Narok, Wajir, Watamu, Webuye, Wote, and Wundanyi.

Contact us to discuss your requirements for high-quality products.

Read the full article

#AACBlockPlant#Bungoma#Dadaab#Eldoret#Exporter#ExporterofAACBlockPlantinKenya#Killfi#Kisil#Lamu#Litein#Lodwar#Lokichoggio#Manufacturer#ManufacturerofAACBlockPlantinKenya#Mombasa#Moyale#Mumias#Nairobi#Nanyuki#Naragoi#Narok#Ruiru#SupplerofAACBlockPlantinKenya#Supplier#SupplierofAACBlockplants#Voi#Wajir#Watamu#Webuye#Wote

0 notes

Text

AAC Block Plant in Africa

AAC Block Plant in Africa:

Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation, established in 2016, specializes in AAC Block Making Plants and offers turnkey projects in this field.

The company focuses on manufacturing AAC Block Plants, AAC Plant, and Autoclave Aerated Concrete Block Making Plants, providing comprehensive solutions.

We manufacture and supply the finest engineering quality AAC Block Plants in Africa, meeting all international standards.

AAC plants with capacities ranging from 30 cubic meters per day to 750 cubic meters per day can be installed.

The main raw material of AAC blocks is fly ash (pond ash or sand), with cement, gypsum, and lime serving as cementing materials, and aluminum powder acting as the foaming agent.

The main forming procedures include Material crushing, measuring, mixing, pouring, curing, cutting, and steaming.

Consists of Cement Silo, Lime Silo, Gypsum Silo, Fly ash Silo, or Pond Ash Loading Screening and Transfer system.

AAC Block Machines manufactured by us are designed as per the capacity of each plant to ensure accurate mix preparation.

Benefits of AAC Block Plant:

Fire Resistant

Pest Resistant

Sound Proof

Earthquake Resistant

Faster Construction

Long-lasting

Cost Saving

Versatile

Non-toxic

Thermal Insulation

Environment-Friendly

High Resistance to Water Penetration

Export Focus:

We Provide AAC Block Plant in Africa, supplying products to various locations including Ghana, Kenya, Cameroon, Burundi, Angola, Chad, Algeria, Egypt, Burkina Faso, Comoros, Benin, Senegal, Ethiopia, South Africa, Nigeria, Mali, Gabon, Morocco, Uganda, Kampala, Jinjha, and Zambia.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#AACBlockPlant#AACBlockPlantinAfrica#Algeria#Angola#AutoclaveAeratedConcreteBlockMakingPlants#Benin#BurkinaFaso#Burundi#Cameroon#CementSilo#Chad#Comoros#Egypt#Ethiopia#Exporter#ExporterofAACBlockPlantinAfrica#FlyashSilo#Gabon#Ghana#GypsumSilo#Jinjha#Kampala#Kenya#LimeSilo#Mali#Manufacturer#ManufacturerofAACBlockPlant#Morocco#Nigeria#Senegal

0 notes

Text

AAC Block Plant in Bangladesh

AAC Block Plant in Bangladesh:

Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation, established in 2016, specializes in AAC Block Making Plants and offers turnkey projects in this field.

The company focuses on manufacturing AAC Block Plants, AAC Plant, and Autoclave Aerated Concrete Block Making Plants, providing comprehensive solutions.

The company produces AAC Block Plants in India, adhering to international standards, with capacities ranging from 30 cubic meters per day to 750 cubic meters per day.

AAC blocks are made primarily from fly ash, cement, gypsum, lime, and aluminum powder. The manufacturing process includes material crushing, measuring, mixing, pouring, curing, cutting, and steaming.

This section consists of Cement Silo, Lime Silo, Gypsum Silo, Fly ash Silo, or Pond Ash Loading Screening and Transfer system to ensure accurate batching and mixing.

AAC Block Plant Benefits :

Fire Resistant

Pest Resistant

Sound Proof

Earthquake Resistant

Faster Construction

Long-lasting

Cost Saving

Versatile

Non-toxic

Thermal Insulation

Environment-Friendly

High Resistance to Water Penetration

Excellent En-Fab Incorporation exports AAC Block Plant in Bangladesh, serving various locations such as Bhairab, Bogra, Brahmanbaria, Chandpur, Chowmuhani, Chudanga, Comilla Sadar Dakshin, Faridpur, Feni, Jessore, Jhenaidah, Kadam Rasul, Kaliakair, Kushitia, Naogaon, Narsingdi, Pabna, Saidpur, Satkhira, Savar, Tangail, Tarabo, and Tongi.

For inquiries and information, interested parties are encouraged to contact Excellent En-Fab Incorporation.

Read the full article

#AACBlockPlant#Bangladesh#Bhairab#Bogra#Brahmanbaria#Chandpur#Chowmuhani#Chudanga#ComillaSadarDakshin#Faridpur#Feni#Jessore#Jhenaidah#KadamRasul#Kaliakair#Kushitia#Manufacturer#Naogaon#Narsingdi#Pabna#Saidpur#Satkhira#Savar#Supplier#Tangail#Tarabo#Tongi

0 notes

Text

Top AAC Block Plant Manufacturer

Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation is a Manufacturer and Supplier of the Top AAC Block Plant in Kerala.

Situated in Ahmedabad, Gujarat, India, we operate from our headquarters.

Excellent En-Fab Incorporation is a recognized hub for Process & Construction Equipment Manufacturing in India.

The company has a primary focus on supplying high-pressure autoclaves to AAC block plants.

Excellent En-Fab Incorporation takes pride in being a leading manufacturer of Autoclaved Aerated Concrete Plant (AAC Plant) in India.

Engineers specially design the AAC Plant to produce AAC Blocks, renowned for their exceptional heat, fire, and sound resistance.

Innovative AAC Block Manufacturing Process: The AAC block manufacturing process involves several key steps:

Raw Material Preparation: The mixing process precisely combines silica sand, cement, lime, and aluminum powder.

Batching and Mixing: The mixture, combined with water, is placed in molds.

Curing: Molded blocks undergo curing in autoclaves with steam and high pressure, forming air bubbles that give AAC blocks their lightweight and insulating properties.

Cutting and Shaping: Based on project requirements, workers cut cured blocks into various sizes and shapes.

Final Curing: Blocks undergo final curing to strengthen their structure.

Packaging: Workers package and prepare finished AAC blocks for distribution.

Export Excellence Across Sectors: Excellent En-Fab Incorporation has demonstrated commendable export performance across sectors,

including pharmaceuticals, chemicals, food processing, minerals, and more.

Supplying AAC Block Plant in Kerala:

The company provides the Top AAC Block Plant Manufacturer in Kerala, serving cities such as Thiruvananthapuram, Kochi, Kozhikode, Thrissur, Kollam, Alappuzha, Kannur, Palakkad, Kottayam, and Malappuram.

Read the full article

#AACBlockPlant#Alappuzha#Exporter#India#Kannur#Kochi#Kollam#Kottayam#Kozhikode#Malappuram#Manufacturer#Palakkad#Supplier#Thiruvananthapuram#Thrissur

0 notes

Text

Manufacturer of AAC Block Plant in Maharashtra

Manufacturer of AAC Block Plant in Maharashtra:

Excellent En-Fab Incorporation, based in Ahmedabad, Gujarat, is a well-known Process & Construction Equipment Manufacturing Hub in India.

Established in 2010, the company specializes in supplying high-pressure autoclaves to AAC block factories.

AAC Block Plant Overview:

An AAC Block Plant is a specialized manufacturing facility designed for the production of AAC (Autoclaved Aerated Concrete) blocks.

AAC blocks are lightweight, precast building materials made from sand, cement, lime, and aluminum powder.

The distinctive feature of AAC blocks is their cellular structure, created through a process known as autoclaving.

Working Process:

Raw Material Preparation: A team precisely mixes sand, cement, lime, and aluminum powder to form a slurry.

Molding: The slurry is poured into molds of varying sizes and shapes based on the desired dimensions of the AAC blocks.

Curing: Molded blocks cure naturally, gaining initial strength during a specific period.

Autoclaving: Cured blocks undergo a high-pressure steam-curing process in autoclaves. The reaction of aluminum powder with other materials forms hydrogen gas, creating tiny air bubbles in the blocks, resulting in their cellular structure.

Cutting and Packaging: After autoclaving, the team cuts blocks to the desired size and packages them for distribution and use in construction projects.

Geographical Coverage in Maharashtra:

Excellent En-Fab Incorporation provides Manufacturer of AAC Block Plant in Maharashtra, catering to locations such as Mumbai, Pune, Nagpur, Nashik, Vasai-Virar, Solapur, Bhiwandi, Amravati, Kolhapur, Akola, Latur, Jalna, Panvel, Navi Mumbai, Parbhani, Dhule, Nanded, Jalgaon, Ahmednagar, and Chandrapur.

For more details, please have a professional conversation with you / your team.

Read the full article

#AACBlockPlant#Ahmednagar#Akola#Amravati#Bhiwandi#Chandrapur#Dhule#India#Jalgaon#Jalna#Kolhapur#Latur#Maharashtra#Manufacturer#Mumbai#Nagpur#Nanded#Nashik#NaviMumbai#Panvel#Parbhani#Pune#Solapur#Supplier#Vasai-Virar

0 notes

Text

AAC Block Plant Manufacturer in Haryana

AAC Block Plant Manufacturer in Haryana

Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation was established in 2016.

Specialization:

Specializes in AAC Block Making Plants, AAC Plant, Autoclave Aerated Concrete Block Making Plants, and offers turnkey projects.

Operates as a manufacturer, exporter, and supplier, with its setup located in India.

AAC Block Plant Overview:

An AAC (Autoclaved Aerated Concrete) Block Plant produces lightweight, high-strength construction blocks made from cement, fly ash, lime, gypsum, aluminum powder, and water.

The autoclave cures blocks formed by mixing raw materials and pouring the mixture into molds, resulting in distinctive features.

Benefits of AAC Blocks:

The construction industry widely uses AAC blocks for their lightweight nature, good insulating capabilities, fire resistance, and durability.

Considered a greener alternative to traditional building materials like brick, concrete, and wood.

Components of AAC Block Plant:

Common components include a ball mill, batching plant, pouring mixer, cutting machine, autoclave, and packing machine.

Fully automating the facility enhances production efficiency and reduces labor expenses.

Geographical Presence:

Provides AAC Block Plant Manufacturer in Haryana, covering areas such as Udyog Vihar, Gurugram, Faridabad, Kundli, Rai, Barhi, Bahadurgarh, Dharuhera, Karnal, Manakpur, Yamunanagar, Sonepat, Panipat, Narnaul, Barwala, Ambala, Tohana, Jind, Samalkha, Kalka, Kutana, Murthal, and Jagadhri.

Encourage individuals to reach out to Excellent En-Fab Incorporation for further details or inquiries.

Read the full article

#AACBlockPlant#Ambala#Bahadurgarh#barhi#Barwala#Dharuhera#Faridabad#Gurugram#Haryana#India#Jind#Kalka#Karnal#Kundli#Kutana#Manakpur#Manufacturer#Murthal#Narnaul#Panipat#Rai#Samalkha#Sonepat#Supplier#Tohana#UdyogVihar#Yamunanagar

0 notes

Text

AAC Block Plant in Assam

AAC Block Plant in Assam:

Excellent En-Fab Incorporation:

Based in Ahmedabad, Gujarat, it is a prominent player in India's Process & Construction Equipment Manufacturing Hubs.

Established in 2010, with a focus on supplying high-pressure autoclaves tailored for AAC (Autoclaved Aerated Concrete) block plants.

AAC Block Manufacturing Process:

A unique process produces AAC blocks, involving the mixing of finely ground sand, cement, lime, and aluminum powder.

Autoclaving, a high-pressure steam curing process, results in the formation of aerated concrete with a porous structure.

Plant Components:

Mixing and Casting Section: Precise blending of raw materials to create a homogenous slurry, poured into molds for block formation.

Curing Section: Blocks undergo autoclaving, a high-pressure steam curing process, enhancing their strength and durability.

Cutting and Packaging Section: After curing, blocks are cut into specific sizes using specialized equipment and then packaged for distribution.

Advantages of AAC Blocks:

Lightweight: Significantly lighter than traditional concrete blocks, facilitating easier handling during construction.

Thermal Insulation: The porous structure provides excellent thermal insulation, contributing to energy-efficient buildings.

Fire Resistance: Exhibits high fire resistance, enhancing structural safety.

Sound Insulation: Porous nature contributes to effective sound insulation.

Applications of AAC Blocks:

Find applications in various construction projects, including residential, commercial, and industrial buildings.

Commonly used for load-bearing walls, partitions, and as a substitute for traditional bricks.

Excellent En-Fab provides AAC Block Plant in Assam, covering key locations such as Dhuburi, Dibrugarh, Dispur, Guwahati, Jorhat, Nagaon, Sivasagar, Silchar, Tezpur, and Tinsukia.

Read the full article

#AACBlockPlant#Assam#Dhuburi#Dibrugarh#Dispur#Exporter#Guwahati#Jorhat#Manufacturer#Nagaon#Silchar#Sivasagar#Supplier#Tezpur#Tinsukia

0 notes

Text

Manufacturer of AAC Block Plant in Kerala

Manufacturer of AAC Block Plant in Kerala:

Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation was established in 2016.

Specializing in AAC Block Making Plants, AAC Plant, Autoclave Aerated Concrete Block Making Plants, and providing turnkey projects.

The company operates as a manufacturer, exporter, and supplier, with its setup located in India.

AAC Block Making Plant Overview:

The AAC Block Making Plant produces thermally insulating concrete-based blocks designed for internal and external construction.

Known for quick installation and excellent insulation properties, AAC is particularly suitable for urban areas with high-rise buildings and temperature variations.

Advantages of AAC Blocks in Construction:

Quick and easy installation facilitated by routable material.

Lower density reduces the reliance on steel and concrete in high-rise buildings.

Specifications of AAC Blocks:

Maximum Block Size: Various sizes available.

Density: 650 - 700 kg/m3.

Compressive Strength: 30 - 35 kg/cm2.

Thermal Conductivity: 0.24.

Production Capacity: 50 / 75 / 100 / 150 / 200 Cubic meters per 24 hours.

Feeding of Raw Material: Automatic.

Manpower: 7 to 8.

Electrical Power Connection: 65Hp.

Applications of AAC Blocks:

Suitable for construction in various sectors, including buildings, hospitals, cold storage, educational institutes, office buildings, multi-family and single-family projects, auditoriums, and theaters.

Service Locations:

Excellent En-Fab Incorporation provides Manufacturer of AAC Block Plant in Kerala, covering areas like Thiruvananthapuram, Kochi, Kozhikode, Thrissur, Kollam, Alappuzha, Kannur, Palakkad, Kottayam, and Malappuram.

Read the full article

#AACBlockPlant#Alappuzha#Kannur#Kerala#Kochi#Kollam#Kottayam#Kozhikode#Malappuram#Manufacturer#Palakkad#Supplier#Thiruvananthapuram#Thrissur

0 notes

Text

AAC Block Plant in Hyderabad

AAC Block Plant in Hyderabad:

Excellent En-Fab Incorporation

Excellent En-Fab Incorporation, based in Ahmedabad, Gujarat, is a prominent player in India's Process and Construction Equipment Manufacturing Hubs.

Established in 2010, Excellent En-Fab is dedicated to supplying high-pressure autoclaves tailored for AAC (Autoclaved Aerated Concrete) block plants.

An AAC Block Plant is a specialized facility for manufacturing lightweight AAC blocks, a popular building material. It involves machinery for raw material processing, AAC slurry mixing and casting, and block cutting and curing.

AAC Block Production Process:

Raw Material Preparation: Precisely mix silica sand, cement, lime, and aluminum powder to form base materials.

Batching and Mixing: The mixture, along with water, is placed in molds.

Curing: Autoclaves cure blocks using steam and high pressure, creating air bubbles that impart lightweight and insulating properties.

Cutting and Shaping: After curing, cut blocks into various sizes and shapes as per project requirements.

Final Curing: Apply additional curing to strengthen the block structure.

Packaging: Finished AAC blocks undergo packaging for distribution.

Applications of AAC Blocks:

AAC blocks find application in diverse construction projects, including residential and commercial buildings, schools, hospitals, and industrial structures. Construction firms, builders, and developers utilize AAC block facilities for production.

Service Coverage in Hyderabad:

Providing AAC Block Plant in Hyderabad, Telangana, and various locations including Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, and Jangaon.

Read the full article

0 notes

Text

AAC Block Plant in Kerala

AAC Block Plant in Kerala:

Situated in Ahmedabad, Gujarat, Excellent En-Fab Incorporation is a recognized hub for Process and Construction Equipment Manufacturing in India.

Established in 2010, the company has a primary focus on supplying high-pressure autoclaves to AAC block plants.

Excellent En-Fab Incorporation takes pride in being a leading manufacturer of Autoclaved Aerated Concrete Plant (AAC Plant) in India. The specially designed AAC Plant produces AAC Blocks, known for their exceptional heat, fire, and sound resistance.

Innovative AAC Block Manufacturing Process:

The AAC block manufacturing process involves several key steps:

Raw Material Preparation: Operators mix precise proportions of silica sand, cement, lime, and aluminum powder.

Batching and Mixing: The mixture, combined with water, is placed in molds.

Curing: Molded blocks undergo curing in autoclaves with steam and high pressure, forming air bubbles that give AAC blocks their lightweight and insulating properties.

Cutting and Shaping: Operators cut cured blocks into various sizes and shapes based on project requirements.

Final Curing: Blocks undergo final curing to strengthen their structure.

Packaging: Operators package and prepare finished AAC blocks for distribution.

Export Excellence Across Sectors:

Excellent En-Fab Incorporation has demonstrated commendable export performance across sectors, including pharmaceuticals, chemicals, food processing, minerals, and more.

Supplying AAC Block Plant in Kerala:

The company provides AAC Block Plant in Kerala, serving cities such as Thiruvananthapuram, Kochi, Kozhikode, Thrissur, Kollam, Alappuzha, Kannur, Palakkad, Kottayam, and Malappuram.

Read the full article

#AACBlockPlant#Alappuzha#India#Kannur#Kerala#Kochi#Kollam#Kottayam#Kozhikode#Malappuram#Manufacturer#Palakkad#Supplier#Thiruvananthapuram#Thrissur

0 notes