#Fully Automatic Bottle Blowing Machine

Text

Mineral Water Bottling Plant, Mineral Water Bottling Plant Manufacturer - kceindia.com

Mineral Water Bottling Plant : We are Mineral Water Bottling Plant Manufacturer, Mineral Water Bottling Plant Supplier in Navi Mumbai, India. Call Now.

Mineral Water Bottling Plant, Industrial Water Bottling Plant, Mineral Water RO Plant, Mineral Water Plant, Mineral Water Plant Machine, Mineral Water Packaging Plant, Mineral Water System, Industrial Mineral Water Plant, Mineral Water Treatment Plant, Packaged Drinking Water Plant, Fully Automatic Bottle Filling Machine, Fully Automatic Bottle Blowing Machine, SS Vessel, SS Storage Tanks, SS Housing For Filter, SS Membrane Housing, SS Piping, Dosing Pump, Roller Conveyor, Ozonation Generator, Post Filtration System, Leather Softeners, Water Softeners in Sanpada, navi mumbai, mumbai, india.

#Mineral Water Bottling Plant#Industrial Water Bottling Plant#Mineral Water RO Plant#Mineral Water Plant#Mineral Water Plant Machine#Mineral Water Packaging Plant#Mineral Water System#Industrial Mineral Water Plant#Mineral Water Treatment Plant#Packaged Drinking Water Plant#Fully Automatic Bottle Filling Machine#Fully Automatic Bottle Blowing Machine#SS Vessel#SS Storage Tanks#SS Housing For Filter#SS Membrane Housing#SS Piping#Dosing Pump#Roller Conveyor#Ozonation Generator#Post Filtration System#Leather Softeners#Water Softeners in Sanpada#navi mumbai#mumbai#india

0 notes

Text

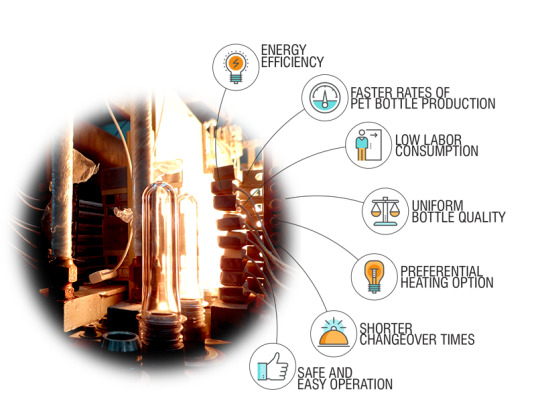

Semi Automatic Pet Bottle Blowing Machine | Seppasolutions

Seppasolutions semi automatic pet bottle blowing machine is a crucial investment for beverage and pharmaceutical businesses, enhancing production efficiency, product integrity, and cost-effectiveness. This technology creates bottles and containers by heating and stretching preforms in two stages. Investing in a Seppasolutions PET blowing machine offers benefits like enhanced production efficiency, precision, flexibility, cost-effectiveness, quality assurance, and excellence. The machine ensures uniform bottle dimensions, wall thickness, and neck finishes and accommodates various bottle sizes, shapes, and designs.

#semi automatic pet bottle blowing machine#semiautomatic pet blowing machine#semiautomatic machine#semi automatic bottle blowing machine#semi automatic pet blowing machine#semi automatic pet bottle filling machine#semi automatic pet bottling plant#fully & semi automatic pet bottle blowing machine

0 notes

Text

PET Blow Moulding Machines for PET/PP Bottles

Blow Machines Manufacturer in India – Explore our range of Automatic and Semi-automatic Water Bottle Blowing Machine and get the Price for them. Call now.

Explore more - PET Blow Moulding Machines for PET/PP Bottles.

#blow moulding machines#pet blow moulding machine#fully automatic blow moulding machine#Semi-automatic Water Bottle Blowing Machine

0 notes

Text

Choosing the Right Semi-Automatic PET Blowing Machine for Your Business

When choosing a semi automatic PET blowing machine for your business, there are several factors to consider. Firstly, the capacity of the machine should match your production requirements. Secondly, the type of PET preform that the machine can handle should be suitable for your product. Additionally, the ease of use, maintenance, and availability of spare parts are crucial factors. You should also consider the level of automation and the associated cost, as well as the machine's energy efficiency. Finally, it is essential to choose a reliable manufacturer with a good track record in the industry. Careful consideration of these factors will ensure that you choose the right semi-automatic PET blowing machine for your business.

#pet bottle blowing machine#automatic pet stretch blow molding machine#pet plastic bottle blowing machine#semi-automatic pet bottle blowing machine#pet bottle making machine#pet preform blowing machine#fully automatic pet bottle blowing machine#pet blow molding machine cost

0 notes

Text

Where do you think any impact begins

Where do you think any impact begins? You might be thinking, action! Or planning. It's true, both planning and action are ingredients for impact. But in the beginning? Impact begins with an idea. A vision. In the last article, we started looking at the meaning of being impactful and the habits of highly impactful people. Habits you can embrace to be fully automatic plastic bottle stretch blow moulding machines impactful too. The second habit that you, Highly Impactful Person (HIP - can you just see your name tag? lol), can adopt is to have an impact vision. A vision is a high level image of the impact you want to create. Your impact vision helps to clarify the influence you want to have in your business, your community, and the larger world. Focusing on impact doesn't mean you have to ignore money and making a profit. Impact and financial success go hand in hand. Businesses that focus on all the areas they have impact do 12-14 times better financially.

Ready to get a handle on your impact vision? Here are 3 ways to begin: Dream Big This is the place for dreaming big. Figuring out how you will do it comes later. First,open up to possibility, and free up your thinking. What if money, time, and resources were not an issue? What if you could do whatever you imagine here? Think about it in an unlimited and unrestricted way. That is how people expand their impact in the world. Pick an Area Next, pick an area where you want to begin to create your impact vision and start writing down the first thing that pops up in your mind about your desired impact vision. A vision is not something that you create fully formed out of the blue. It's an evolving process. Then move through every other area of your business. Include your team, your clients, your products/services, your marketing, and your systems. You Decide on the Scale Having a big vision doesn't mean being grandiose. Your impact vision should have a scale that is perfect for you. Not everybody wants a big company or an empire. Don't make it bigger than what you want.

Do stretch yourself so you grow, and your impact grows. In your impact vision, you don't have to stop at your business. How else might your values ( Habit #1 of Highly Impactful People ) be calling you to benefit others? How do you want to show up in these areas, what contribution or positive effect do you want to have with: · Your community: That can mean both a physical place you live and your business is, and also your online community · The environment: Are there ways your business can be a positive influence in maintaining a healthy environment? Even small ways matter. · Your family and friends: How do you want to show up for them? How do you want to contribute to their lives? · The larger world: If your vision reaches farther, what impact do you want to have in other communities or even other countries? It's worth allowing your thinking to stroll along those lines too. When you picture the ways that your higher purpose could unfold, it makes your work even more meaningful. Does this feel energizing? Then you go! Keep up the impact vision process, and keep returning to your vision to help you stay focused and aligned with your impact vision. If you're feeling a little overwhelmed right now, it's OK! Stretching can feel so darn uncomfortable. It's all part of the process. When you do stretch yourself to create an impact vision, you'll find that it can carry you and help you conquer those fears and move beyond them. Every business starts with an idea, a vision. Make your vision one that aligns with your values and how you want to contribute.

0 notes

Text

#Fully Automatic All Electric machine#fully automatic pet blowing machines#water bottle-making machine#PET bottle-making machine#automatic blow molding machine#PET Blow Molding Machine#Plastic Bottles Blowing Machine#Handfeed Automatic Pet Blowing Machine#plastic can-making machine#Plastic Bottle Maker#pet bottle blowing machine manufaturer#pet blowing machine#pet blowing machine in usa#pet blowing machine in america

1 note

·

View note

Text

The key point is that specific thigh lifting and firming exercises

For many ladies any type of safe workout, including exercises for lifting and firming the thighs, are going to help improve the body - regardless of age. Whether your top goal is to enhance the appearance of your nasty trouble spots or your overall health and wellness, the proper thigh lifting and firming exercises can definitely help you get the best results in the shortest amount of time - with minimal risk of injury.You were built to walk and move - you were built to for physical activity. But, most modern jobs require a lot of sitting at a desk - especially for ladies. This leads to long list of unwanted health conditions and negatively affects your appearance - and attractiveness (loose flabby, saddle-bag hips and big, thick thighs).Since we can't fully automatic PET bottle blow moulding machine Factory all leave our regular jobs and earn a living by walking/jogging through the streets, a regular fitness program is an ideal solution. Specific thigh lifting and firming exercises are an essential part of that targeted workout routine.So, what should you do for your problem thighs?Brisk walking (especially hill waking) or jogging, 3 - five times each week is a great start.

Do things that prompt you to walk more (use your body), such as parking your car further away from your workplace and taking the stairway as opposed to the easy elevator (yes, I know you've heard that one before - but are you doing these simple things?).2 to 3 times per week, do specifically targeted thigh lifting and firming exercises, if your thighs, buttocks and hips are stubborn problem areas for you. If you don't like looking at your lower body in the mirror when you are naked - then this means you.Beneath, you'll read the written instructions of an exercise that works well, but it truly helps to have a video, e-guide or detailed photos to insure that you are doing the exercises properly. For some ladies, it is also helpful to exercise in front of a mirror - to check for proper positioning and movement.Bad form can lead to unnecessary injuries and negate the effectiveness of the exercise - leaving you with disappointing results - and long term frustration.

Here is a great thigh lifting and firming exercise to include your workout.'Slow Burn' Hip and Thigh Lifts (Hip & Thigh Abduction)Lie down on your right side (preferably on a soft fitness mat), with your head resting on your arm or the palm of your hand. Bring your knees forward - so your hip joint is at a 90 degree angle.Straighten your left leg (the one on top) so your left foot is out in front of your body, on the floor. Slowly lift your left foot from the floor to the sky (about 3 feet off the floor) - pause for 1 second at the top and then slowly lower your foot, lightly touch the floor and repeat the move. Do 10 - fifteen repetitions and then turn over onto the opposite side and do the same number on the other side.Are you confused yet?Typed instructions of bodyweight thigh lifting and firming movements can be hard to follow, especially to the first time user. A woman that has performed this type of lower body lifting and firming exercise in the past, understands the movement, almost instantly.But any female who is new to this exercise can quickly become frustrated and helpless.Thigh abductions are very targeted thigh lifting and firming exercises, but they must be executed properly.

And they must be done in conjunction with a series of other lower body exercises in order to give you the body enhancing results you deserve and desire.Its quite possible that you may either need the help of a fitness professional, a good instructional guide with photos or a video.Truthfully there's actually no point in doing just this one thigh exercise, if you are not doing it properly and you are not combining it with the right support exercises. When the right exercises are combined in the correct sequence - you get the body changing benefits of muscle movement synergy and stimulation.Also - you want to get this right because you could easily injure yourself and cause unnecessary setbacks - that would delay your positive results even longer - and nobody wants to wait longer to improve their body?The key point is that specific thigh lifting and firming exercises are extremely effective, but you've got to be certain you are following a well-structured program that consists of the group of critical exercises you need - and not just one single exercise.A well planned grouping and sequence of butt, thigh and hip exercises can visibly transform your lower body problem spots into an eye-catching work of art - that you'd certainly be proud of displaying in your favorite swimsuit.

0 notes

Text

White Boi Training Program: Training Dan

My uptight friend Barry is so pushy I had way more time today to deal with for so long.

He enters my apartment in a nicely iron suit, grey shirt and perfectly shined shoes to fully complete the look.

I hate that stringy white people straight hair but on him it is splendid combing it to his own specification.

I can see him with that cool expression on his face thinking how good his life and all go his success.

I sigh dreaming of him I offer him a beer one that I have brew that makes all of my dream can come true.

I pop open a beer bottle top throwing it to the side and slipping off the counter I pour out the contents of the bottle.

I drop a pill in the bottle fill up the bottle with tap water and shake it up till oh fizzles up the top layer.

It transform in to the perfect beer in look, smell and taste so excellent he will never know the difference.

I replace the top heading back out I hand it to him then sit on the other side as he pop the cork.

Something goes off in his mind as he read the label of the bottle then took in the scent of it.

His mouth curls up loving the bottle closer up to his nose inhaling more and more then places it in his mouth.

Taking one huff of the bottle hitting his taste bud, tickling his senses out of control all of his nerves are on high.

He stops cold galloping down the hole thing in to his throat he freaks out his throat cools down.

I can see the explosion blow up his happier expression takes over, he calms down with excitement

His body automatically also down the couch laying back and his feet open up spreading over the space.

His eyes open wide stalling back and forth brimming with energy he is so hyper active in his movements.

Taking advantage of the situation I say let’s watch television grabbing the remote from my table.

His eyes follow my hand lifting in to face the screen and press play clicking it the remote a buzzing sound erupts.

The device comes on automatically a red light beam shoots out to the middle of his forehead.

“What’s going on dude? I can’t think right now.”

“The head is so groggy, what’s in this?”

“Ssssshhhhh…relax…it’s all good”

“It’s all good”

“We need to speak.”

“Watch the screen stare in to the spiral and let go.”

“The beam shoots in to his head causing a electrical reaction.”

“People like you need to be broken down.”

“You need to be humbled”

“You are not special, who cares about how good you look?”

“It’s time to pay the piper”

“Commence downgrading Dan”

“Woah! What’s happening”

“Right now you are being stripped mentally, emotionally and physically.”

“You see this machine, feel the cold air as your clothes are ripped off.”

“The smooth body airing as your armpits and cock are shaved.”

“Nnnnnnooooo! Stop”

“Pppppllllleeeeaaaasssseee”

“Fuck No!”

The television screen spiral out of control to control him his body shifting one side to side .

He can’t believe himself as he falls back on to the couch his head falls back on to the couch.

I laugh a bit standing behind him I retrieve a comb digging it in to his hair I start to lather him up.

He drops back as shirt the chair turning on the faucet, I dig my hands in letting the soap

over take him.

The detachable shower head comes off as I wash the lather out and wrap his head with a towel.

I the towel is put throw a work our drying his hair and then I grab the comb in one hand to his hair.

Applying grease to his hair as I comb threw

It placing his hair to appear the way I choose for it.

I get some spray hardening it till it is perfect for me, I wash his face then shave it for a bit.

His face now cleanse covering it with cream I work over his body to gleam beautifully.

“Wow! You are glowing in the bask of the sunlight.”

“You are so damn fine my love.”

“How are you feeling my slave”

“Blank and empty”

“The way all good bois are”

“Yyyyyeeeesssss”

“Yes Master Lawrence “

“Mwahahahahaha “

“I bright some clothes for you, go iron them and get dressed.”

“Yes, Master Lawrence “

“Enter the living room and take a seat when

you finish.”

“Yes Master”

“We are at the half way point”

“Just a bit more and I will push him over the edge.”

“I am here sire”

“Do you understand what you are?”

“I am your slave”

“I am your property “

“I belong to you “

“Focus on me”

“Sir Yes Sir”

“What can I do for you?”

“Go prepare dinner”

“Then make drinks for me”

“I’ll be in the living room”

“As you wish Master Lawrence “

The end

#grant gustin#Barry#slave#property#Hypno slave#white slave#hypnosis#mind control#White Boi Training Program

30 notes

·

View notes

Text

Discover the Versatility and Efficiency of Fully Automatic Injection Blow Machines

Are you in need of a reliable and efficient manufacturing partner for your plastic products? Look no further than Ningbo Sanshun Machinery & Technology Co. Ltd. With over 30 years of experience in the industry, we are a global leader in providing high-quality plastic injection molding machines.

At Sanshun Machinery, we understand the importance of precision and speed when it comes to manufacturing plastic products. This is why we have invested in state-of-the-art technology and expertise to produce the best fully automatic injection blow machines and high-speed plastic injection molding machines.

Our fully automatic injection blow machines are designed to produce hollow plastic products with high precision and efficiency. These machines have a wide range of applications, from producing bottles, containers, and jars, to more complex products such as medical devices and automotive parts. With our advanced technology and strict quality control measures, you can trust that every product coming out of our fully automatic injection blow machines will meet your exact specifications.

One of the advantages of our fully automatic injection blow machines is their versatility. They are capable of producing a variety of plastic products in different sizes, shapes, and colors. This allows our clients to have more flexibility in their production processes and meet the demands of their customers.

Similarly, our high-speed plastic injection molding machines are designed to produce plastic products with unparalleled speed and accuracy. These machines are equipped with high-performance servo motors and advanced control systems, allowing for faster injection and mold opening/closing cycles. With a production speed of up to 470mm/s, our high-speed plastic injection molding machines can significantly improve your production efficiency and reduce costs.

We take great pride in our commitment to quality. All of our machines are manufactured in compliance with international quality standards, including CE and ISO. We also have a dedicated team of engineers who conduct thorough testing and inspection before any machine leaves our factory. This ensures that our machines perform at the highest levels and have a longer lifespan.

Aside from our advanced technology and high-quality machines, another factor that sets us apart is our global reach. We have established a strong presence in over 100 countries and regions, providing our clients with reliable and timely support. Our team of experts is always available to provide technical assistance and after-sales support, ensuring that our client's production processes run smoothly and efficiently.

Ningbo Sanshun is your go-to partner for all your plastic injection molding needs. We aim to exceed your expectations in terms of quality, speed, and reliability. Contact us today at 0086-13857882024 and visit our website at https://www.china-sanshun.com/ to help you take your plastic manufacturing to the next level.

#injection blow molding machine#led bulb cover making injection blow machine#plastic auxiliary machine#high speed machine#injection moulding machine

0 notes

Text

Maruti Machines' Carbonated Soda Plant: Empowering Beverage Brands with Excellence in Manufacturing

Introduction :

Maruti Machines, a leading name in the beverage industry, introduces its revolutionary product, the Carbonated Soda Plant. Built on precision engineering and cutting-edge technology, this state-of-the-art plant sets new standards for carbonated soda manufacturing. Maruti Machines' commitment to delivering exceptional solutions is evident in the design and functionality of the Carbonated Soda Plant. In this article, we will explore the remarkable features and advantages of Maruti Machines' plant, highlighting its ability to enhance production efficiency, product quality, and market competitiveness for beverage brands.

Streamlined Production Process :

The Carbonated Soda Plant by Maruti Machines streamlines the entire production process, ensuring seamless operations and optimal efficiency. From precise ingredient handling and mixing to carbonation and packaging, this plant integrates advanced automation and intelligent controls to eliminate bottlenecks and reduce human intervention. The plant ensures consistent taste and quality by accurately measuring and dispensing ingredients, guaranteeing the perfect balance of flavors. With state-of-the-art carbonation technology, the plant controls the carbonation levels precisely, resulting in a refreshing and effervescent soda experience for consumers.

Enhanced Quality Control :

Maruti Machines' Carbonated Soda Plant places a strong emphasis on maintaining impeccable quality standards. The plant incorporates robust quality control mechanisms throughout the production cycle, ensuring that each bottle of soda meets the highest standards of taste, consistency, and safety. Advanced sensors and monitoring systems constantly track variables such as temperature, pressure, and quality parameters, allowing for immediate detection of any deviations. This meticulous quality control system enables swift corrective actions, ensuring that only the finest carbonated sodas are produced under the Maruti Machines brand. We also offers Automatic Carbonated Soft Drink Plant, Fully Automatic Pet Blow Molding Machine, Automatic Soda Soft Drink Packaging Machine, Carbonated Soda Soft Drink Plant, Automatic Soda Drink Packaging Plant for futher details visit our Website.

Flexibility and Customization :

Maruti Machines understands the importance of flexibility and customization in the beverage industry. The Carbonated Soda Plant offers unparalleled versatility to accommodate a wide range of flavors, bottle sizes, and packaging formats. Whether a brand desires classic cola or wishes to experiment with unique flavor profiles, Maruti Machines' plant can adapt to cater to diverse consumer preferences. The modular design of the plant allows for easy customization based on specific brand requirements, empowering beverage brands to create distinctive products that resonate with their target markets.

Sustainability and Efficiency :

Maruti Machines' Carbonated Soda Plant prioritizes sustainability and efficiency in its design and operation. The plant incorporates energy-efficient components and optimized power consumption, reducing environmental impact while maintaining high production output. Additionally, the plant integrates advanced recycling and waste management systems, minimizing material wastage and promoting responsible production practices. By embracing sustainable measures, the plant enables beverage brands to align with eco-conscious consumer preferences, enhancing brand reputation and market positioning.

Cost-Effectiveness and Scalability :

For beverage brands, cost-effectiveness and scalability are vital considerations. Maruti Machines' Carbonated Soda Plant offers significant cost savings through streamlined processes, reduced labor requirements, and optimized resource utilization. The plant's modular design allows for easy scalability, enabling beverage brands to expand their production capacity as their business grows. This flexibility ensures that the Carbonated Soda Plant is a long-term investment that can adapt to changing market demands and support the brand's future growth.

Conclusion :

Maruti Machines' Carbonated Soda Plant represents a game-changing solution for beverage brands. With its streamlined production process, enhanced quality control, flexibility, sustainability features, and cost-effectiveness, this plant empowers brands to achieve excellence in carbonated soda manufacturing. By choosing Maruti Machines, beverage brands can benefit from cutting-edge technology, precision engineering, and unmatched efficiency, ultimately positioning themselves as leaders in the competitive market. The Carbonated Soda Plant by Maruti Machines is poised to transform the industry, helping brands deliver exceptional carbonated sodas and meet the evolving preferences of consumers.

0 notes

Text

Natural Mineral Water Plant, Manufacturer, Exporter in India

Manufacturer, Supplier, and Exporter of Fully Automatic Bottle Filling Machine, Automatic Bottle Filling Machine, Bottled Water Filling Machine in Navi Mumbai, India.

Mineral Water RO Plant, Mineral Water Plant, Mineral Water Plant Machine, Mineral Water Packaging Plant, Mineral Water System, Industrial Mineral Water Plant, Mineral Water Treatment Plant, Packaged Drinking Water Plant, Fully Automatic Bottle Filling Machine, Fully Automatic Bottle Blowing Machine, SS Vessel, SS Storage Tanks, SS Housing For Filter, SS Membrane Housing, SS Piping, Dosing Pump, Roller Conveyor, Ozonation Generator, Post Filtration System, Leather Softeners, Water Softeners in Sanpada, navi mumbai, mumbai, india.

0 notes

Text

Semi Automatic Pet Blowing Machine | Seppasolutions

Seppasolutions is a leading manufacturer of energy-efficient pet blowing machines that prioritize eco-friendliness and cost savings. An easy-to-use maintenance strategy makes basic operations like mold changes and troubleshooting simpler with their semi automatic pet blowing machine. They also boost operational efficiency by offering thorough servicing and support. These machines connect to digital platforms for real-time monitoring, data analytics, and predictive maintenance, enabling businesses to raise production standards and achieve long-term success in a dynamic market.

#semiautomatic pet blowing machine#semi automatic pet blowing machine#semi automatic pet bottle blowing machine#semi automatic bottle blowing machine#semiautomatic machine#fully automatic pet blowing machine#fully & semi automatic pet bottle blowing machine

0 notes

Text

SP Pristine Series-II PET Blow Moulding Machine.

SP Pristine Series-II is a Fully Automatic Electric Pet Stretch Blow Moulding Machine by Shaym Plastic with 9000-18000 BHP & 7-12000 bottles per hour.

Explore more - SP Pristine Series-II PET Blow Moulding Machine.

0 notes

Text

An Overview of Different Types of Plastic Automation Systems

Plastic automation machines are essential tools for the manufacturing industry. They automate the production of plastic products, making it easier and faster to produce high-quality plastic parts. We have many plastic automation machine systems, each with unique features and capabilities.

This article will provide an overview of the 7 different types of plastic automation machines and their applications.

1. Injection moulding machines

Injection moulding machines are one of the most popular plastic automation machine systems. They produce a wide range of plastic parts, from small components to large industrial parts.

The process begins with melting plastic pellets and injecting the melted plastic into a mould. Once the mould cools off, you can eject the solid end product.

Injection moulding machines are highly customisable, allowing manufacturers to produce parts in many shapes and sizes. They proved their efficiency in various industries, from automotive, medical and consumer goods to electronics.

There are several types of injection moulding machines, such as:

Hydraulic: The most common type, and these machines are capable of high production speed and durability.

Electric: These are becoming more popular due to their energy efficiency and precision.

Hybrid: These machines combine the best of both hydraulic and electric machines, providing high production speed and energy efficiency.

2. Extrusion machines

Extrusion machines produce plastic products with a continuous cross-section, such as tubing, pipes, and profiles. The process involves melting plastic pellets and pushing them through a die to create a continuous shape, such as a tube or a sheet.

These machines come in various sizes and types, from small tabletop models to large industrial machines. They can produce a range of products, including packaging materials, pipes, and profiles.

Some extrusion machines have features like co-extrusion, which allows for multi-layered products and in-line cutting. It reduces the need for additional processing steps.

Overall, extrusion machines play a crucial role in the plastic manufacturing process.

3. Blow moulding machines

Blow moulding machines are plastic manufacturing equipment that creates hollow plastic parts, such as bottles, containers, and tanks.

The process involves melting plastic pellets and extruding them into a hollow tube. The machine clamps the tube between two halves of a mould, then blows air into the tube, which causes it to expand and take the shape of the mould. Once the plastic has cooled and solidified, you open the mould and remove the finished part.

Blow moulding machines also come in different sizes and types:

Extrusion blow moulding

Injection blow moulding

Stretch blow moulding

Industries widely use these plastic automation machine systems for packaging, automotive, and consumer goods. They are efficient and cost-effective, allowing for high-volume production with minimal labour.

4. Thermoforming machines

Thermoforming machines create various products by heating and forming a plastic sheet over a mould. The process involves placing a heated plastic sheet over a mould, which is then drawn into the cavity using vacuum pressure.

After the plastic cools and solidifies, the machine opens the mould and removes the finished product. Thermoforming machines are available in various sizes and types — manual, semi-automatic, and fully automatic.

These plastic automation machine systems can produce food packaging, medical trays, automotive components, and consumer goods. Thermoforming machines are cost-effective, fast, and flexible, making them ideal for small to medium-scale production.

5. Rotational moulding machines

The next type of plastic automation machine system is the rotational moulding machine. They create large, hollow products such as tanks, containers, and playground equipment. The process involves placing plastic resin in a mould that heats and rotates on multiple axes to distribute the molten plastic evenly. The mould then cools, and the finished product is ready.

We have rotational moulding machines in various sizes, from small tabletop models to large industrial machines. They are efficient, cost-effective, and can produce complex shapes with consistent wall thickness.

You commonly see this equipment in industries such as agriculture, automotive, and construction due to its ability to produce large, durable products.

6. Compression moulding machines

Compression moulding machines create high-strength and high-precision products, such as electrical, automotive, and aerospace components.

The process involves placing a pre-measured amount of plastic material into a heated mould cavity and applying pressure to compress the material into the desired shape.

Its sizes and types include hydraulic, pneumatic, and electric models. They are not only efficient and reliable but also offer high-quality products with minimal waste.

7. Transfer moulding machines

Transfer moulding machines produce high-precision parts with complex geometries, such as electrical components, medical devices, and automotive parts. It involves melting plastic material in a chamber and then transferring the molten material to a heated mould cavity using a plunger or piston.

Transfer moulding machines offer advantages such as high production rates, consistent part quality, and the ability to use a wide range of materials.

Industries use these plastic automation machine systems for processes where precision and quality are essential, such as aerospace, medical, and automotive.

Conclusion

Whether you are looking to produce small components, large industrial parts, or high-precision plastic products, there is a system that can meet your needs. By understanding these several types of plastic automation machine systems available, you can choose the right one for your manufacturing process and improve your productivity and efficiency.

Talk to an expert at Mitchell Industries for more information regarding plastic automation machines.

#Granulation Moulding Machines#Blow Moulding Machine Alphamac#blow moulding machines#injection moulding machines#injection moulding

0 notes

Text

This surgery procedure will eliminate your discomfort

From plastic surgery to beauty treatments, cosmetic medical care spans a large range of procedures that helps men and women look and feel their best. A cosmetic surgeon can help you choose the best cosmetic procedure for you. Read this article if you want to find out what a viable plastic surgeon can do for you.Breast Augmentation: Breast augmentation is a plastic surgery procedure that was designed to enlarge the breasts with the use of breast implants such as silicone or saline breast implants. Liposuction: Liposuction is a wonderful plastic surgery procedure that was designed to remove fully automatic PET bottle blowing machine Factory localized fat deposits from the body. Liposuction can help you get the extra fat off your body and it will boost your self-confidence.Tummy Tuck: Tummy tuck surgery is a cosmetic surgery procedure that is used to flatten the stomach. During this cosmetic surgery procedure, excess fat is removed from the stomach and the underlying abdominal muscles are tightened.

This magnificent procedure will reduce the size of your bulging belly. Arm Lift: Arm lift surgery removes excess fat and skin from the upper arms. This procedure will make your arms slimmer and sexier.Breast Lift: Breast lift surgery will raise your breasts to a higher level. If your breasts are sagging, you are a viable candidate for breast lift surgery.Breast Reduction: A breast reduction will reduce the size of your breasts. If you are experiencing back pain, shoulder pain, or neck pain because of the size of your breasts, you are a viable candidate for breast reduction surgery.

This surgery procedure will eliminate your discomfort.Brow Lift : A brow lift is also known as an eyebrow lift and forehead lift. This procedure corrects problems in the upper facial region such as drooping brows and sagging skin on the forehead. Ear Surgery : Ear surgery reshapes the ear for reconstructive or cosmetic purposes.Eyelid Surgery: Eyelid Surgery corrects bags and drooping eyelids. Facelift : Facelift surgery raises sagging skin of the neck and face and reduces the appearance of wrinkles. Facelift surgery can take 10 to 15 years off your face.Gastric Bypass: Gastric Bypass or gastrointestinal surgery was designed to eliminate excess amounts of fat from the human body. Gastric bypass surgery is also known as weight loss surgery.

Lip Augmentation: The lip augmentation procedure was designed to plump up the lips and make them bigger and more beautiful. Lip augmentation uses facial fillers such as collagen or Restylane. This procedure can also be performed with the use of lip implants such as Advanta or Gore-tex implants. Male Breast Reduction: Male breast reduction is a plastic surgery procedure that reduces the size of male breasts.Nose Surgery: Nose surgery is also known as rhinoplasty, nose reshaping, or nasal reconstruction. This procedure reshapes and resizes the nose.If you want to improve your appearance and fix your physical flaws with plastic surgery, you should consult with a board-certified cosmetic surgeon today. Because it isnt about beauty for a week or a month, its about beauty for the rest of your life.

0 notes

Text

Purpose of a Blow Molding Machine

Companies dealing with packaging services often use a bottle capping machine to serve their purpose. The same size fits all dogma does not apply here. Instead, individual clients try to source the right machine depending on specific requirements. Indeed there are multiple components to check and approve before placing the final order to have the machine installed. It is always better to be well-informed about the requirement instead of depending on the manufacturer or dealer to provide the right device.

It is not weird to be flabbergasted by the available variety or asked about the range of machines that fit the purpose perfectly. It is advisable to research the types of machines available for handling the capping suitably. The end-user can choose based on the working principle of the devices or opt for the best machine according to its application. Other customers may decide to look at various machines that support different kinds of automation too.

Whatever may be the process of selection, the following criteria need to be met before giving assent for a particular capping machine:-

· Accuracy- The right way to place the caps without wasting time is important. Sure, both an automatic and a semi-automatic machine can cap the bottles efficiently, but one needs to consider the accuracy of the capping and the speed simultaneously to ensure a good buy. The bigger plants prefer fully automatic machines as the caps get placed and fitted into the mouth of the bottle with a satisfying snap. The line moves on speedily, improving workplace productivity as well.

· Cross Contamination- Reducing or eliminating human error during this process is most important. The worker capping bottles manually is sure to be fatigued and make careless mistakes. This will not only cause leakage of valuable liquid from the bottle but there may also be cross-contamination of the product. This is a health hazard for plants capping bottles containing milk, water, or other food items. It is best to eliminate this possibility once and for all by opting for an automatic machine.

· Adaptability- the modern-day automatic bottle capping machines are perfect in all aspects. Most of the machines allow switching between different types of bottles/containers, with the shape and size of caps varying accordingly. Specifying the need to the manufacturer will result in customization that not only enhances the speed of capping but ensures accuracy too.

· Reliability- Locating a manufacturer and/or dealer that scarifies all criteria without charging exorbitantly can be a Godsend. It is essential to find one with a proven track record of shipping the machine to the plant at the earliest. Often, the dealer or manufacturer will dispatch a technician to oversee the bottling line and help with the installation.

The companies engaged in the task of manufacturing bottles and containers according to specifications must invest in the best possible machine capable of producing bottles rapidly. Souring a top blow molding machine can ensure meeting the demand easily.

0 notes