#High Voltage (HV) Cable

Text

High Voltage (HV) Cable Market Growth Analysis

High Voltage (HV) Cable Market research report identifies, assesses, and analyses the up-and-coming trends along with major drivers, restraints, challenges and opportunities in the market for Energy industry. The High Voltage (HV) Cable Market report contains estimations of CAGR values, market drivers and market restraints about the Energy industry which are helpful for businesses in deciding upon numerous strategies. The market type, organization size, availability on-premises, end-users’ organization type, and the availability in areas such as North America, South America, Europe, Asia-Pacific and Middle East & Africa are kept into view while formulating this global High Voltage (HV) Cable Market analysis report.

Download Free Sample Report: https://www.delvens.com/get-free-sample/high-voltage-hv-cable-market

High Voltage (HV) Cable Market by Product Type (Cables (XLPE, EPR, HEPR, MI), Accessories (Joints, Termination, Fittings & Fixtures), Conductor Type (Aluminum, Copper), Installation, Voltage, End User and Region (North America, Europe, Asia-Pacific, Middle East and Africa and South America). The global High-Voltage (HV) Cable market size was estimated at USD 40.5 billion in 2023 and is projected to reach USD 59.3 billion in 2030 at a CAGR of 5.6% during the forecast period 2023-2030.

High Voltage (HV) Cable Market Competitive Landscape:

Prysmian Group

Sumitomo Electric Industries Ltd.

Nexans

LS Cable & System Ltd.

NKT A/S

Furukawa Electric

Taihan Cable & Solution Co., Ltd.

ZTT

Elsewedy Electric Company

Wuxi Jiangnan Cable

Riyadh Cables

PFISTERER Holding AG

DUCAB

TE Connectivity

Brugg Kabel AG

KEI Industries Ltd.

Tratos

Southwire Company,

Tele-Fonika Kable SA

Synergy Cables

High Voltage (HV) Cable Market Recent Developments:

In May 2023, The Prysmian Group has issued an announcement pertaining to the triumphant acquisition of a contract with an estimated worth exceeding USD 864.9 million. This contractual agreement is in reference to the initiation of a new power interconnection project between France and Spain, which is set to be implemented for the benefit of INELFE. It should be noted that INELFE is a joint venture that is co-owned by Red Electrica, the Spanish grid operator, and Réseau de Transport d’Électricité (RTE), the French grid operator.

In April 2023, Nexans finalized the purchase of Reka Kaapeli Oy, for a total of USD 57.29 million. The integration of Reka Cables into Nexans' Distribution & Usage business group was included in the acquisition. Being a part of Nexans presents Reka Cables with the chance to enhance its growth and development, while also enabling increased investments in renewable energy solutions.

For Purchase Inquiry at: https://www.delvens.com/Inquire-before-buying/high-voltage-hv-cable-market

High voltage cables are utilized for the transmission and distribution of power at elevated voltages. These cables possess structural components comprising of one or more conductors, protective jackets, and insulators. An important structural divergence that sets high voltage cables apart from other cable types is the existence of additional internal layers within the insulation jacket that facilitate the control of electric flow surrounding the conductor. This attribute assists in mitigating power losses during long-range transmissions, thereby rendering high voltage cables more efficient than their counterparts in power transmission. High voltage cables may be installed as overhead cables, buried cables in industrial settings, or even submarine cables for power transmission between different states and countries.

The market for high voltage power cables is ultimately dependent on electricity demand across the world. The increasing demand for electricity is further anticipated to bring lucrative growth opportunities for the market. The replacement of the aged grid infrastructure and transmission lines is another factor that drives the growth of the market. Also, the increasing penetration of renewables such as solar energy and wind energy requires setting up new utility grids with new transmission & distribution networks. Therefore, the growing penetration of renewables acts as the market driver for high voltage cables.

High Voltage (HV) Cable Market Key Findings:

On the basis of installations, the worldwide high voltage cables market is divided into three segments, namely overhead, submarine, and underground, based on the type of installation. The proliferation of overhead installation is primarily attributed to its convenient installation process and low transmission losses across extended distances. Furthermore, the economic benefits of these cables, which do not entail complex technologies, account for their widespread adoption.

On the basis of Analytics, the market is categorized into three segments, namely 100 kV – 250 kV, 251 kV – 400 kV, and above 400 kV. Currently, the 251 kV – 400 kV segment holds the largest market share due to the extensive application of high voltage cables within this voltage range. In developing countries, the power transmission industry is still flourishing, resulting in the increased use of low and medium voltage cables. Consequently, the above 400 kV segment in these countries possesses a relatively minor presence. However, during the forecast period, the 251 kV – 400 kV segment is expected to grow in various regions owing to the substantial installation of these voltage lines. In North America and Europe, the above 400 kV segment is anticipated to witness a rise in their market share, primarily due to technological advancements that support their installation.

On the basis of end-user, the global market for high voltage cables is bifurcated into two segments, namely utility and industrial, wherein the former serves as the primary source of power for most sectors across the nation, consequently constituting a significant proportion of the market. With the escalation of rural electrification plans, population growth, and urbanization, the end-user demand for electricity has substantially increased. This augmented demand for power has led to the integration of renewable energy sources for power generation, thereby facilitating the installation of new grids required to cater to power needs across distant locations. The industrial sector, particularly the exploration and railways industry, also leverages high voltage cables for their operations. Moreover, the market is expected to experience a positive growth trajectory owing to the proposed plans and presence of metros in diverse parts of the world.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. North America possesses a limited market share within the industry. However, due to the prevailing replacement of antiquated grids throughout the region, the high voltage cable market is anticipated to experience gradual growth within the area.

High Voltage (HV) Cable Market Regional Analysis:

North America to Dominate the Market

North America possesses a limited market share within the industry. However, due to the prevailing replacement of antiquated grids throughout the region, the high voltage cable market is anticipated to experience gradual growth within the area.

The exploration endeavors of the oil and gas industry have significantly contributed to the expansion of the industrial sector of the market.

Get Direct Order of this Report: https://www.delvens.com/checkout/high-voltage-hv-cable-market

Browse Related Reports:

Heat Shrink Tubing (HST) Market

Next Generation Biofuels Market

Power Grid Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-3290-6466

#High Voltage (HV) Cable Market#High Voltage (HV) Cable#HV Cable#HV Cable Market#Energy#consulting company#strategic advisory firm#best market reports#market analysis reports#trending reports#syndicated reports

0 notes

Link

"Are you looking for a trusted high voltage cable supplier? Contact WWC. We are an experienced wire and cable manufacturer and supplier with more than 24 years of experience. We have served Australian industries such as power stations, utilities, mining and more. Learn more about us here https://www.wwcables.com.au/products/mv-hv.html

or call 1800 008 799 for obligation free quote. "

0 notes

Text

"Beneath the Surface: The Underground Cable Revolution" 🌟

In the ever-evolving landscape of energy transmission and distribution, the MV (Medium Voltage) and HV (High Voltage) Underground Cables and Accessories Market stand at the forefront of innovation and sustainability. Traditionally, overhead power lines dominated the scene, sprawling across landscapes and marking the skyline. However, as the world seeks more resilient and visually unobtrusive solutions, underground cables have emerged as a game-changer, offering a host of benefits from improved reliability to reduced environmental impact.

#UndergroundCables #EnergyTransmission #Sustainability #RenewableIntegration #GridModernization #GreenTechnology #FutureofEnergy #ClimateAction #SmartGrid #ResilientInfrastructure #CleanEnergy #Innovation #EnergyEfficiency #GlobalEnergy #ElectricalEngineering

The MV and HV Underground Cables and Accessories Market is experiencing a renaissance, driven by the need to modernize aging infrastructure, integrate renewable energy sources, and enhance grid resilience. Underground cables offer a range of advantages over overhead lines, including lower transmission losses, reduced exposure to weather-related disruptions, and minimal visual impact on landscapes. With advancements in cable technology and installation techniques, underground cable networks are becoming increasingly cost-effective and efficient, enabling utilities to meet the growing demand for reliable and sustainable energy transmission.

As nations worldwide commit to decarbonization and pursue ambitious climate goals, the MV and HV Underground Cables and Accessories Market is poised for substantial growth and investment. By embracing underground cable solutions, utilities can not only enhance grid reliability and efficiency but also contribute to the preservation of natural landscapes and ecosystems. It's time to delve beneath the surface and explore the potential of underground cables to shape a cleaner, greener, and more resilient energy future for generations to come.

0 notes

Text

Partial Discharge Detector Market Analysis, Regional Segmented, Outlook & Forecast till 2033

The competitive analysis of the Partial Discharge Detector Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Partial Discharge Detector Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Receive the FREE Sample Report of Partial Discharge Detector Market Research Insights @ https://stringentdatalytics.com/sample-request/partial-discharge-detector-market/8129/

Market Segmentations:

Global Partial Discharge Detector Market: By Company

• APM Technologies

• Siemens

• High Voltage Partial Discharge

• ALTANOVA GROUP

• OMICRON Electronics

• Prysmian Group

• Protec Equipment

• Megger

• Qualitrol Company

• Doble Engineering Company

• Eaton

• Power Diagnostix

• Dimrus

• SNSK Company

• EA Technology

• LS Cable and System

• Dynamic Ratings

• HV Hipot Electric

Global Partial Discharge Detector Market: By Type

• Desktop

• Portable

Global Partial Discharge Detector Market: By Application

• Gas Insulated Switchgear (GIS)

• Transformers

• Power Cables

• Others

Regional Analysis of Global Partial Discharge Detector Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Partial Discharge Detector market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Partial Discharge Detector Market Research Report @ https://stringentdatalytics.com/purchase/partial-discharge-detector-market/8129/

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the Partial Discharge Detector?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Partial Discharge Detector?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Electrical Product Power Mould

Electrical product moulds or power moulds are critical components in the production of high-quality electrical components and devices for power transmission and distribution systems. YF POWER is a leading brand that offers reliable electrical product moulds/power moulds designed to meet the specific requirements of electrical components and systems. These moulds are made of high-grade materials, including steel, aluminium, and copper alloy, and are manufactured with advanced production technologies such as CNC machining, EDM, and wire cutting. The use of these moulds ensures the optimal production of electrical components with precise dimensions, complex shapes, and high-repeatability rates.

YF POWER's electrical product moulds/power moulds are engineered to meet the highest quality standards, ensuring the longevity and reliability of the products manufactured using these moulds. These moulds are widely used in the power industry, including the production of insulators, bushings, and surge arresters, among others. YF POWER's electrical product moulds/power moulds provide efficient and cost-effective solutions for the production of high-quality electrical components, ensuring safe and reliable power transmission and distribution systems.

Types of Electrical Product Power Mould

Arrester Mould

10kV Arrester Mold (1-8)

36kV Arrestor Mold (1-6)

Insulator Mould

3kV Insulator Mold (R-1-8)

24kV Insulator Mold (R-1-6)

35kV Insulator Mold (R-1-6)

66kV Insulator Mold(1-2)

500 kV Insulator Mold

1000 kV Insulator Mold

Hollow Core Mould

110kv Hollow Core Mould

150kv Hollow Core Mould

Portable Variable Frequency Test System

Impulse Voltage Test System

AC Test Transformer System (Oil Insulated Type)

HV DC Generator Test System

AC Resonance Test System (Variable Inductance)

AC Test Transformer System (GAS Insulated Type)

Variable Frequency Resonance Test System(Gas Insulated Type)

Cable Accessory Mould

Cold Shrinkable Mould

Hot Shrinkage Mould

Cut-Out Insulator Mould

Benefits of Electric Product Mould/Power Mould

Precision and Consistency

Electric product molds are engineered with precise specifications, ensuring that each finished product meets consistent requirements. This reduces the possibility of defects and inconsistencies in the manufacturing process.

Longevity and Durability

Electric product molds are created using high-quality materials, ensuring a durable and long-lasting lifespan. As a result, this helps reduce costs for businesses in the long run through fewer replacements and more consistent outputs.

Customization

Power moulds can be customized to fit the specific needs of a product client, allowing for increased flexibility in manufacturing processes. Custom design renders improved performance, distinct shape, and innovation that helps products stand out from others in the market.

Cost-Effectiveness

Electric product moulds can be designed and produced at scale, reducing costs for businesses in the long run through options to use existing non-standard molds or to develop standard mold sizes, making them a cost-effective solution for businesses that produce high-volume parts. The cost-effectiveness in mould production allows manufacturers to make their products affordable while maintaining quality standards.

Working Principle of Electric Product Mould/Power Mould

Electric product moulds or power moulds are tools used to create a specific shape or design for an electrical product. The moulds are created with the customer's specifications in mind and are designed to accurately produce parts and components that meet precise requirements. The working principle of electric product moulds is straightforward. The mould is created with a cavity or a set of cavities that match the desired shape of the final product. Once the mould is in place, the liquid material is injected into the cavity, taking up the space occupied by the mould.

Once the material cools or solidifies, the mould is removed, leaving a finished part with the exact shape and design specified by the client. Using electric product moulds helps ensure that the quality and consistency of electrical products remain uniform in every production batch. Moreover, power moulds can now be designed and customized to provide automation, reduction in human errors, and a high level of precision in production processes.

0 notes

Text

The high voltage wiring harness is a critical component in the operation of an electric vehicle.

The high voltage wiring harness is used to connect the high voltage battery pack to the rest of the vehicle's electrical system. It consists of several components that are designed to handle high voltages and provide reliable performance. The most important part of a high voltage wiring harness is its insulation system. This must be able to withstand the heat generated by the current flow without melting or becoming brittle. The insulation must also provide adequate protection against short circuits, preventing sparks from reaching other components such as electronics and fuel tanks.

0 notes

Text

Techniques for Building and Maintaining High and Low Voltage Infrastructure

These "conductor routeing configurations" are often implemented by professionals known as "installers" in the industry. When putting any of these concepts into effect, builders must keep in mind the geometric restrictions imposed by conductor routeing. Extremely adaptable operators are required, in particular at the level of connection between different usage zones, due to the specific challenges presented by the design and maintenance of high-voltage and low-voltage equipment. (including a lot of reconnection or switching around). Protection of HV&LV systems is greatly aided by this.Always Look to the Skies

The conductivity of electrical and electronic components is what determines their ratings, thus the phrase "Conductors' Rating," but other variables, such as the product's adaptability and tolerance of mechanical stress, also play a role in determining the best installation approach. The infrastructure for HV/LV systems may be installed and maintained. Choose that spot to set up HV & LV infrastructure installation and repair.

Although there are drawbacks to using pre-made systems and cable assemblies, they have several benefits over starting a power transmission network from scratch. Vehicles used in the installation and maintenance of HV&LV infrastructure must be parked in a space free of obstructions (such as pillars or walls) to ensure the safety of all workers. (such as walls, fire barriers, doors, and such objects). Accuracy is essential for the installation and maintenance of HV and LV infrastructure.

Before beginning construction, it's crucial to scope out the area and identify any possible routeing issues. It is possible to use a cable tray or prefabricated system for cable management, but this will rely on the overall design and the specifics of the cable routeing, such as the presence or absence of obstacles and the necessity for additional accessories to control cable height. If this cannot be done, then a study "by design" must be carried out. This resulted from the installation and upkeep of a high- and low-voltage electrical transmission and distribution network. assisting in the development of HV and LV systems.

Prefabricated busbars and cable trays must be assembled according to the schematic.

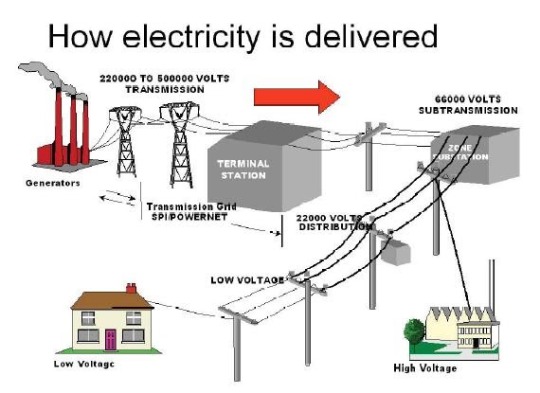

After deciding on the size and weight of cable trays and prefabricated systems, the quality and pattern installation of floor and wall tiles (for example, reinforced concrete) may be established. Power is either transmitted through transmission networks or distributed to consumers via distribution networks. Electricity may be generated, transmitted, and distributed to users through transmission, which is a kind of energy infrastructure. From production to distribution, transmission plays a critical role in the whole energy value chain. The transmission and distribution systems are essential to the delivery of power to residences.

Cable ladders and duct systems are two examples of the specialised solutions needed to sustain insulated conductors or cables.Buildings may vary greatly in form, purpose, and construction according on their surroundings. Every construction job necessitates the use of mechanical equipment for the installation of electrical wiring and connections. Cable ladders and ducting are examples of tools in this category. Because of their modular design, these mechanical aids may be used in a wide variety of contexts.

0 notes

Text

HV Substation Design: Powering the Future

High Voltage substations play a crucial role in the transmission and distribution of electrical power. These substations serve as key nodes in the power grid, facilitating the efficient and reliable transfer of electricity from generating stations to end-users. The design of HV substations is a complex and multifaceted process that requires careful planning, engineering expertise, and adherence to safety standards. In this blog, we will explore the essential elements of HV substation design under four subheadings: Site Selection, Equipment Selection, Layout Design, and Safety Considerations.

Site Selection:

Choosing the right location for an HV substation is vital to ensure optimal functionality and accessibility. Several factors need to be considered during site selection, including proximity to load centers, availability of land, environmental impact, and future expansion potential. Substations should be strategically located to minimize power losses during transmission and distribution, while also considering the environmental and social aspects. Thorough assessments and studies are conducted to determine the most suitable site, taking into account geological conditions, land availability, and the potential impact on nearby communities.

Equipment Selection:

The selection of equipment for an HV substation is a critical aspect of the design process. The chosen equipment must meet specific technical requirements, including voltage levels, load capacity, and operational efficiency. Common components found in HV substations include transformers, circuit breakers, switchgear, busbars, and protection systems. These components must be carefully selected based on the substation's anticipated load, the type of power generation being connected, and the overall network configuration. Advanced technologies, such as gas-insulated switchgear (GIS) and intelligent electronic devices (IEDs), are increasingly being integrated into substation designs to enhance substation testing and commissioning

Layout Design:

The layout design of an HV substation encompasses the physical arrangement of equipment, structures, and connections within the substation compound. Efficient layout design ensures ease of operation, maintenance, and future expansion. The layout should consider factors such as clearances, accessibility for maintenance personnel, and proper segregation of high voltage and low voltage areas. Additionally, safety measures, such as fencing, grounding systems, and fire suppression systems, should be incorporated into the layout. Careful consideration is given to the routing of cables, ensuring minimal interference and optimal signal integrity.

Safety Considerations:

Safety is of paramount importance in HV substation design to protect both personnel and the surrounding environment. Substations operate at high voltage levels, presenting inherent risks such as electric shocks and fire hazards. Adequate safety measures are implemented to mitigate these risks. Protective equipment, such as insulating gloves, safety clothing, and grounding systems, are used to safeguard workers during maintenance and operation. Moreover, the layout design should incorporate clear modern power system analysis signage, emergency exits, and proper fencing to restrict unauthorized access.

Conclusion:

HV substation design is a complex and interdisciplinary process that requires careful consideration of multiple factors. As the demand for electricity continues to grow and renewable energy integration becomes more prevalent, the importance of well-designed HV substations becomes increasingly evident. By embracing advancements in technology and adhering to international standards, we can ensure that HV substations continue to power the future with efficiency, reliability, and safety.

1 note

·

View note

Text

𝐓𝐑𝐀𝐍𝐒𝐌𝐈𝐒𝐒𝐈𝐎𝐍 𝐋𝐈𝐍𝐄𝐒

A transmission line is an essential component of the electrical power system that transfers electrical energy from the power source to the load. It is a type of high voltage power cable that is used to transmit large amounts of power over long distances. Transmission lines are critical to the functioning of the electrical grid as they help in maintaining the reliability and stability of the system.

The basic structure of a transmission line consists of three components – conductors, insulators, and supporting structures. The conductors are made of aluminum or copper and are arranged in a specific configuration to minimize the losses due to resistance. The insulators are used to support the conductors and provide insulation between them and the supporting structures. The supporting structures, usually made of steel or concrete, provide the necessary mechanical strength to hold the conductors in place.

One of the critical parameters that define the performance of a transmission line is its impedance. The impedance of a transmission line is the ratio of the voltage drop across the line to the current flowing through it. The impedance of a transmission line depends on several factors such as the length of the line, the type of conductor used, the frequency of operation, and the distance between the conductors. A transmission line with low impedance has a higher power transfer capability and lower losses.

Transmission lines are classified based on the voltage level they operate at. Extra high voltage (EHV) transmission lines are used to transmit power over long distances at voltages exceeding 230 kV. High voltage (HV) transmission lines are used to transmit power over shorter distances at voltages ranging from 66 kV to 230 kV. Medium voltage (MV) transmission lines are used for local distribution of power at voltages ranging from 1 kV to 69 kV.

One of the primary challenges associated with the transmission of electrical power is the losses that occur due to various factors such as resistance, capacitance, and inductance of the transmission line. These losses can result in a significant reduction in the efficiency of the power system. To overcome this problem, advanced technologies such as High Voltage Direct Current (HVDC) transmission have been developed that can transmit power over long distances with lower losses.

In conclusion, transmission lines are critical components of the electrical power system that help in the efficient transmission of electrical energy over long distances. With advancements in technology, the performance and efficiency of transmission lines have improved significantly, resulting in a more reliable and stable power grid. As the demand for electrical power continues to grow, transmission lines will play an increasingly important role in meeting the energy needs of the world.

Transmission lines are also vulnerable to various external factors such as lightning strikes, high winds, ice, and other extreme weather conditions, which can cause significant damage to the lines and interrupt the power supply. To mitigate these risks, transmission lines are designed and constructed to withstand these external factors.

Benefits:

Entire transmission system can be simplified to a two port network for the sake of easier calculations

The behavior of transmission lines and its voltage and current under normal and abnormal conditions depends on A, B, C, D, Z and H parameters

Transmission line parameter simplifies the model and gives quite accurate result

Load flow study in transmission line

Analyzing protection schemes

Increase the system efficiency

Avoide any danger in complete system.

How we get electriciy through transmission lines .

Electricity is generated at power plants and then transmitted over long distances through transmission lines to reach the load centers where it is needed. The electricity generated is usually in the form of high-voltage alternating current (AC) or direct current (DC).

In an AC transmission system, the electricity generated at the power plant is first stepped up to high voltage levels using transformers. The high-voltage AC power is then transmitted over long distances through transmission lines to the load centers where it is required. At the load centers, the voltage is stepped down to the required levels using transformers, and the electricity is distributed to the consumers.

In a DC transmission system, the electricity generated at the power plant is first converted to high-voltage direct current using a converter station. The high-voltage DC power is then transmitted over long distances through transmission lines to the load centers where it is needed. At the load centers, the DC power is converted back to AC using an inverter station, and the electricity is distributed to the consumers.

The transmission lines are made of high conductivity materials such as copper or aluminum, which have low resistance, to minimize the losses due to resistance and capacitance during transmission. The conductors used in transmission lines are often bundled together or arranged in a specific geometry to reduce the distance between them and to minimize the losses due to capacitance.

The electricity transmitted over the transmission lines can experience losses due to various factors such as resistance, capacitance, and inductance. These losses can cause a reduction in the efficiency of the power system and result in significant power wastage.

To minimize these losses, the transmission lines are designed to operate at high voltages and to have low resistance, low capacitance, and low inductance. The transmission lines are also designed to withstand various external factors such as high winds, ice, and lightning strikes.

In conclusion, electricity is transmitted over long distances through transmission lines from the power plants to the load centers where it is needed. The transmission lines are designed to minimize losses and to withstand various external factors. The efficient operation of the transmission lines is critical to the reliability and stability of the electrical power system.

1 note

·

View note

Text

Partial Discharge Testing: Need, Testing, and Addressing Defects

Did you know that more than 85% of disruptive failures in MV (medium voltage) and HV (high-voltage) equipment are related to partial discharge (PD)? This is why partial discharge testing is crucial for early detection and to keep your electrical infrastructure in good condition.

Studies have proven that PD activity can deteriorate assets, resulting in insulation being unable to withstand electrical stress. Over time, it can lead to flash-over and equipment failure. Testing is conducted to analyze the health of electrical insulation.

One of the effects of flash-over is the high-frequency current pulse traveling through the insulation’s capacitance (C1 and C3). The short, microsecond duration makes it a low-energy pulse, but it negatively impacts insulation and eventually results in catastrophic failure. Partial discharge breakdown also produces heat, light, sound, smell, HF electric current, and electromagnetic waves.

Understanding partial discharge

PD occurs when an aspect of an insulation system fails to withstand an electrical field it comes in contact. It is typically the result of poor workmanship or design, aging, contamination, or defective materials. Of all the available methods, partial discharge testing is the widely recognized practice for analyzing the health of electrical assets.

How is it done?

Online non-destructive and non-invasive techniques for surveying and monitoring are proven to deliver sufficient details for condition assessment without interrupting system operations. Modern techniques make it easier to test a wide range of assets from 3KV to 700KV and greater.

Partial discharge testing can identify all types of PD:

Surface PD – The most common phenomenon that occurs across the surface of the insulation. It is affected by humidity and salt air.

Internal PD – This occurs in voids, cavities, or defects within solid insulation.

Corona PD – Occurs in gaseous dielectrics with inhomogeneous fields, usually from the conductor, directly into the air, and in outdoor electrical assets.

Professionals can test air-insulated assets, GIS switchgear and busses, extruded cables, and paper-insulated cables online without causing an outage. They use various techniques, such as ultrasonic technology, HFCT/RFCT online cable testing, and transient earth voltage (TEV) methods. Some companies can perform partial discharge testing using UHF for non-contact detection with electromagnetic PD signals in cable systems, open terminal switchyards, and distribution networks.

About the Company:

Elegrow Technology is eminent for providing international standard design and technical assistance in the field of electrical, mechanical & power systems with utmost professional transparency.

0 notes

Text

Power engineering services offers complete electrical testing solutions

Power engineering services offers great electrical test equipment hire as well as the best electrical testing services in Australia. We cover earth testing with the best electrical test equipment and we make sure our clients have functional and safe electrical systems regardless of the projects they own.

Engineering design, commissioning, testing, upkeep, as well as maintenance of high voltage (HV) but also low voltage (LV) power components and related devices are areas of expertise for our team.

The business has a staff of electrical engineers, technicians, electricians, trade support staff, and electrical apprentices, all with one goal in mind: to convey the alternatives our consumers require efficiently and properly, and to do so on time. We work in most areas of the electrical industry, such as extraction, oil and gas, utility services, heavy manufacturing, production, construction, and marketing.

The electrical testing services we use is the best on the market and the most efficient, providing quick and accurate results. Our team will pinpoint the exact location of the cable fault so that we can repair it on the spot, reducing the overall hassle of the procedure. We offer earth testing and any other adjustments our clients may require based on their specific situation, ensuring that they have a safe and functional power service. Our experts are certified and have extensive experience working with both low and high voltage issues to find the best solution in the shortest amount of time. Our clients come from a wide range of industries, including commercial and construction, as well as manufacturing, utilities, oil and gas, and heavy and light industry. When you contact our team, we will identify the problem you are experiencing as well as the best and safest solution for your situation. We intend to address power issues in the long run so that you do not have to deal with them again anytime soon.

Regardless of the fact that our company is based in Perth, Australia, our team travels all over the country to assist anyone who requires our services. So, regardless of your location, don't hesitate to contact us because we will schedule an appointment and arrive as soon as possible. If you require assistance or support with power engineering services, you can find us at 130 Radium Street Welshpool WA 6106 or call us at (08) 9356 5304. Our team will be at your disposal, so you won't have to worry about the electrical aspect or design of your project. Please keep in mind that we also provide equipment for testing electricity and determining the cause of your power outage. Power Engineering Services prioritizes quality and safety in all of our projects. Our team will accommodate all your needs in the fastest time and at a cost that considers your budget. We will exceed your expectations as we are always focused on reaching the highest level of performance in our field and we always put our clients’ needs and safety first among our priorities.

#electrical earthing system#electrical test equipment#electrical testing services#earth testing#cable fault location#site acceptance testing#lightning protection system#factory acceptance testing

1 note

·

View note

Text

Buy Top-Quality High Voltage Cables For All Your Industrial Needs

Are you looking for reliable high-voltage cables in Australia? World Wire Cables is your go-to supplier. We provide top-quality wires and cables that meet all safety standards.

World Wire Cables offers a wide range of high-voltage cables that have been tested for quality assurance and meet all safety standards. Our products include instrumentation through to extra high voltage cables with flexible 110c fire-rated options available too! We also offer technical support so you can get expert advice on which cable will best suit your needs.

How to Find a Suitable HV Cable For You?

When it comes to selecting high-voltage cable, there are several factors to consider. The most important is the type of insulation material used. Insulation materials must withstand the high voltages and temperatures associated with these types of cables. Common insulation materials include polyethylene (PE), cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR) and silicone rubber (SR).

In addition to insulation material, other factors such as cable size, conductor type, and jacketing should also be taken into account when selecting a cable. Cable size is determined by its current carrying capacity; larger cables can handle more current than smaller ones. Conductor type refers to the material used for the wire itself; copper is the most common choice, but aluminium or steel may also be used depending on application requirements. Finally, jacketing protects the cable from external damage such as abrasion or moisture ingress; common jacketing materials include PVC and neoprene rubber.

Shop With World Wire Cables

If you’re looking for reliable high-voltage cables in Australia, look no further than World Wire Cables! With our extensive range of products and technical support services, you can rest assured that your electrical system will be safe and efficient no matter what application you need!

0 notes

Text

Wire and Cable Market Evaluation Targets Advancement Anticipated until 2032

Fact.MR clients will get a flawless understanding of the marketplace along with industry insights, possible actions, technological advancements, and strategic inputs using this Wire and Cable Market research report. This market report considers several factors that have an inordinate consequence on the growth of the business which includes historic data, present market trends, environment, technological innovation, impending technologies, and the technical progress in the industry. For reaching accomplishment at local, regional as well as international levels, a high-quality Wire and Cable Market research document is a decisive solution.

Request Sample: https://www.factmr.com/connectus/sample?flag=S&rep_id=7315

Moreover, an excellent Wire and Cable Market report has crucial aspects of the market that contains industry research, market sizing & forecast, competitive intelligence, market entry strategy, pricing trends, sustainability trends, customer insights, technology evolution, innovation trends, and distribution channel assessment. Also, before presenting it to the end users, all the information is assessed and validated by the expert team members. By attaining an actionable market insight via this market research report, sustainable and profitable business strategies can be built. All the data and information involved in the large-scale WIRE AND CABLE MARKET business report is taken from incredibly trustworthy sources such as websites, annual reports of the companies, white papers, journals, newspapers, and mergers.

Key Players

Prysmian Group

Furukawa Electric Co., Ltd.

Southwire Company, LLC

General Cable Corporation

Hengtong Optic-Electric Co Ltd.

TPC Wire & Cable Corp

LS Cable & System Ltd.

Sumitomo Electric Industries, Ltd.

Polycab Wires Private Limited

Key Segments Covered in Wire and Cable Industry Research

Wire and Cable Market by Type :

Low Voltage (LV) Wires and Cables

Medium and High Voltage (MV & HV) Wires and Cables

Optical Fiber Cables

Wire and Cable Market by Material :

Copper Wires and Cables

Aluminum Wires and Cables

Glass Wires and Cables

Others

Wire and Cable Market by End User :

Aerospace & Defense

Construction

IT & Telecommunications

Energy & Utilities

Oil & Gas

Consumer Electronics

Automotive

Wire and Cable Market by Region :

North America Wire and Cable Market

Europe Wire and Cable Market

Asia Pacific Wire and Cable Market

Latin America Wire and Cable Market

Middle East & Africa Wire and Cable Market

Key Highlights

Sales of Wire and Cable Market in 2020

Competitive Analysis of Wire and Cable Market

Demand Analysis of Wire and Cable Market

Key Trends of Supply Side Analysis of Wire and Cable Market

Outlook of Wire and Cable Market

Insights of Wire and Cable Market

Analysis of Wire and Cable Market

Survey of Wire and Cable Market

Size of Wire and Cable Market

A short viewpoint offered in the report elucidates the macro-economic aspects that influence the growth drivers of Wire and Cable Market which includes global GDP of Wire and Cable Market growth rate, various industries growth rate, such as cosmetics, pharmaceuticals, food and others.

This newly published and insightful report compounds sheds light on key dynamics, Key Trends of Wire and Cable Market and their impact on the overall value chain from Wire and Cable Market to end-users, which are expected to transform the future of the Wire and Cable Market sales.

0 notes

Text

HV & EHV Underground Cables Market Report, Demand, Key Vendors, Segment, Growth Opportunities by 2017 to 2032

Overview: The HV & EHV Underground Cables Market is a segment of the electrical power industry that focuses on the production and distribution of high voltage (HV) and extra high voltage (EHV) underground cables. These cables are designed to transmit electricity at higher voltage levels underground, providing efficient and reliable power transmission and distribution. HV & EHV Underground Cables Market, Global Outlook and Forecast by 2029, at a CAGR of 4.9% during the forecast period(2023-2029)

The HV & EHV Underground Cables Market has been experiencing significant growth in recent years, driven by the increasing demand for efficient and reliable electricity transmission and distribution infrastructure. HV and EHV underground cables offer advantages such as reduced transmission losses, improved power quality, and reduced environmental impact compared to overhead transmission lines.

Trends and Growth Drivers:

Increasing Energy Demand: The growing global energy demand, driven by population growth and industrialization, has led to the expansion of power transmission and distribution networks. HV and EHV underground cables enable efficient and secure power transmission over long distances, supporting the growth of the market.

Renewable Energy Integration: The integration of renewable energy sources, such as wind and solar power, into the electricity grid requires efficient transmission infrastructure. HV and EHV underground cables play a vital role in transmitting renewable energy from remote generation sites to load centers, facilitating the integration of clean energy sources.

Urbanization and Undergrounding Initiatives: The increasing urbanization and aesthetic concerns have led to undergrounding initiatives, where overhead power lines are replaced with underground cables. This trend is driving the demand for HV and EHV underground cables in urban areas, improving the visual impact and reducing the risk of power outages due to weather-related incidents.

Technological Advancements: Ongoing technological advancements in cable design and materials are driving the growth of the HV & EHV underground cables market. These advancements focus on enhancing cable performance, increasing transmission capacity, improving insulation properties, and reducing installation and maintenance costs.

Industry Analysis: The HV & EHV Underground Cables Market is characterized by the presence of major cable manufacturers and suppliers operating globally. Market participants offer a wide range of HV and EHV underground cables, including XLPE (cross-linked polyethylene) and MI (mass-impregnated) cables, tailored to meet the specific requirements of power transmission and distribution projects.

The market is highly competitive, with a focus on product innovation, quality assurance, and project execution capabilities. Collaboration between cable manufacturers, power utilities, and engineering firms is common to ensure seamless integration and reliable performance of underground cable systems.

Demand Outlook: The demand for HV and EHV underground cables is expected to witness substantial growth in the coming years. Factors such as increasing energy demand, renewable energy integration, urbanization trends, and technological advancements drive the market.

Additionally, government initiatives promoting undergrounding of power infrastructure, grid modernization efforts, and investments in smart city projects contribute to the market's growth potential. The need for reliable and resilient power transmission and distribution infrastructure further fuels the demand for HV and EHV underground cables.

In conclusion, the HV & EHV Underground Cables Market is experiencing significant growth due to the increasing demand for efficient and reliable power transmission and distribution infrastructure. Trends such as renewable energy integration, urbanization, and technological advancements drive the market. Collaborations and government initiatives further contribute to the market's expansion.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/hv-&-ehv-underground-cables-market/9736/

Market Segmentations:

Global HV & EHV Underground Cables Market: By Company

• Prysmian Group

• Nexans

• Southwire

• Hengtong Group

• Furukawa Electric

• Sumitomo Electric Industries

• Qrunning Cable

• LS Cable & System

• Taihan Electric

• Riyadh Cable

• NKT Cables

Global HV & EHV Underground Cables Market: By Type

• HV

• EHV

Global HV & EHV Underground Cables Market: By Application

• Direct Current

• Alternative Current

Global HV & EHV Underground Cables Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global HV & EHV Underground Cables market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/hv-&-ehv-underground-cables-market/9736/

Reasons to Purchase HV & EHV Underground Cables Market Report:

Comprehensive Insights: Market research reports provide in-depth and comprehensive insights into the ULSFO market. They typically cover various aspects such as market size, growth trends, competitive landscape, regulatory environment, technological developments, and consumer behavior. These reports offer a holistic view of the market, saving time and effort in gathering information from multiple sources.

Data and Statistics: Market research reports often include reliable and up-to-date data and statistics related to the ULSFO market. This data can help in analyzing market trends, understanding demand and supply dynamics, and making informed business decisions. Reports may include historical data, current market figures, and future projections, allowing businesses to assess market opportunities and potential risks.

Market Segmentation and Targeting: Market research reports often provide segmentation analysis, which helps identify different market segments based on factors such as vessel type, application, end-users, and geography. This information assists businesses in targeting specific customer segments and tailoring their marketing and business strategies accordingly.

Competitive Analysis: Market research reports typically include a competitive analysis section that identifies key players in the ULSFO market and evaluates their market share, strategies, and product offerings. This information helps businesses understand the competitive landscape, benchmark their performance against competitors, and identify areas for differentiation and growth.

Market Trends and Forecast: Market research reports provide insights into current market trends and future forecasts, enabling businesses to anticipate changes in the ULSFO market. This information is valuable for strategic planning, product development, investment decisions, and identifying emerging opportunities or potential threats in the market.

Decision-Making Support: Market research reports serve as a valuable tool in decision-making processes. The comprehensive insights, data, and analysis provided in the reports help businesses make informed decisions regarding market entry, expansion, product development, pricing, and marketing strategies. Reports can minimize risks and uncertainties by providing a solid foundation of market intelligence.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Cable Market#Underground Cable Installation#Cable Accessories#Cable Protection#HV Cable Industry Trends#EHV Cable Market Analysis.

0 notes

Text

How Does an Insulation Piercing Connector Work?

An insulation piercing connector is one of the main components of an AB cable system, and it can accept a proper tap connection. This particular connection will further distribute a good line in the street lighting and all the domestic utility connections. This design enables the system to seal all the connections against water penetration properly. Thus, the connector is then turned into a waterproof connector. With these connectors, you can orchestrate a semi-permanent and metal-to-metal contact between the insulation piercing connector and the wire conductor. Several factors tend to affect the dependability and performance of the connectors, such as contact type, tip design, and connection method.

Functioning of An Insulation Piercing Connector

Insulation piercing connectors have four main applications, which we will name and explain one by one.

1. Street Light Connections

For this application, the IPCs are used to tap the AB cable and then connect it properly to the service line, which will aid in powering the streetlights and other applications.

2. Tap off/Multi-Tap Connection to Households

Another one of the main applications of the IPCs is to make sure that the AB cables are properly tapped so that the power can be restored in households. With the help of a multiport insulation piercing connector, it is possible to set up a one-tap connection from the mainline to bring connections to different homes.

3. Distribution Box Charging Connection

In this case, the Insulation Piercing Connector will tap the main AB cable line to properly charge the Low Voltage Distribution Boxes connected to various applications like street lights, residential connections, and much more.

4. Jumper Connection

The Insulation Piercing Connectors can also be used with similar cable sizes on each side to facilitate a connection or any other high-angle turn properly.

Important Applications of IPCs

Following are some of the applications of insulation piercing connectors:

· Insulated HV and LV lines with proper interconnectors can provide efficient insulation and robust strength for different terminal ports and adjacent options.

· IPCs can also create and establish a connection between the service cables and the LV network.

· The IPCs invaluable when it comes to creating low-voltage insulation household wire T connections, creating power distribution system T connections, ordinary cable field branch and street lam distribution systems, line connections, and so much more.

Benefits of Using Insulation Piercing Connectors

· You can adequately fasten them with the proper pole structures.

· The connection that is established by the insulation piercing connector will be completely dependable, and the construction is pretty robust as well.

· The connections are incredibly long-lasting and durable for the AB cable systems.

· There is no need for proper conductor insulation stripping in the first place

· Based on the size of the connector, you can also use them for certain non-tension lines with a voltage above 600 volts.

· There is no need to use post-installation tape, making the installation smoother.

Wrapping Up,

The reasons mentioned above make Insulation Piercing Connectors an invaluable part of the electrical industry. The ability of the component to create a solid and lasting connection in the AB cable system is reliable.

About the author:

Axis Electricals is a leading manufacturer and exporter of high-quality electrical components including ABC Accessories, cable lugs, grounding rods, lightning protection, and other ranges.

0 notes

Text

ALL ABOUT VPI TRANSFORMERS

VPI transformers are vacuum pressure impregnated with a high temperature polyester stain which has phenomenal intensity safe and surface wettability capacity. It is not difficult to introduce and keep up with, lessens cost of cabling, and has ability to help over-burden of current. Quite possibly of the best vacuum pressure impregnated transformers in Hyderabad.

Rising interest for energy circulation all around the globe has extended as of late because of advancement of different businesses in creating economies. Substance, drug, steel, treatment facilities, mining, hostage power projects, hydropower undertakings, and wind-factory cultivates all require a particular voltage result to work gainfully and securely. The tension vpi transformers in hyderabad is a proper fit to accomplish security and voltage requests of these enterprises.

Contingent upon the country's asset base, hierarchical and mechanical skill, strategy system, accessibility of funding for cost varieties, and compromises, the World Bank Gathering will empower and back all wellsprings of environmentally friendly power. These drivers are supposed to support the market income development. Be that as it may, mechanical progressions has expanded the expense of transformers. Moreover, the VPI transformer neglects to perform over 2000 KVA which restricts its utilization.

vpi transformer suppliers in Hyderabad market income development is fuelled by the worldwide extension of energy appropriation organizations and quick industrialization in monetarily agricultural countries.

Expansion in the overall populace has expanded utilization of electric energy supply which might be a central point expected to drive income development of the VPI market. Likewise, state run administrations of different nations are intending to grow their power age plants, which will prompt popularity of transformers for energy dispersion. Moreover, mechanical headways, for example, nook mounted High Voltage (HV) and Low Voltage (LV) link boxes, 40% expansion in constrained air cooling, and others are the central point anticipated to drive interest for vacuum pressure impregnated transformers. Moreover, there are new open doors for central members in the VPI transformer market to foster 3D center VPI transformers for electric vehicles, which are the eventual fate of auto industry.

KEY Advantages FOR Partners:-

This report gives a quantitative investigation of the market portions, latest things, assessments, and elements of the vacuum pressure impregnated (VPI) transformer market examination from 2021 to 2030 to distinguish the predominant vacuum pressure impregnated (VPI) transformer market open doors.

The statistical surveying is presented alongside data connected with key drivers, restrictions, and open doors.

Watchman's five powers investigation features the intensity of purchasers and providers to empower partners create gain situated business choices and fortify their provider purchaser organization.

Inside and out examination of the vacuum pressure impregnated (VPI) transformer market division helps to decide the overall market open doors.

Significant nations in every locale are planned by their income commitment to the worldwide market.

Market player situating works with benchmarking and gives an unmistakable comprehension of the current place of the market players.

0 notes