#IndustrialApplications

Text

Mica Band Heaters emerge as the pinnacle of industrial heating innovation, designed to withstand temperatures as high as 900⁰F. Crafted with precision and ingenuity, these heaters boast a construction that combines high-temperature mica sheets, Nickel-chrome resistance wire, and a resilient steel sheath. Their versatility spans across industries, catering seamlessly to the needs of plastic molding, medical laboratories, and various industrial processes. Engineered for efficiency, reliability, and tailored performance, these heaters embody technological brilliance, ensuring uniform heating and optimal functionality across a wide spectrum of applications.For more Information visit https://heatersandsensors.ca/

#IndustrialHeatingInnovation#MicaBandHeaters#TemperatureVersatility#PrecisionEngineering#EfficientHeatingSolutions#TechInnovation#IndustrialApplications#UniformHeating#TailoredPerformance#ReliableHeatSupply

2 notes

·

View notes

Text

How to choose the right aluminum laser welding machine

#laserweldingmachine#laserwelder#weldingmachine#MaterialIdentification#AluminumAlloys#MetalCharacteristics#LaserAbsorption#ThermalImpact#MaterialThickness#LaserPower#WeldingThickness#MetalProperties#AluminumWelding#AlloyWelding#MetalThickness#PowerRequirements#PenetrationDepth#WeldingTechnology#MaterialScience#Metalworking#LaserWelding#IndustrialApplications

0 notes

Text

Elevate your industrial processes with our Fast Hydration Guar Gum Powder! Engineered for efficiency and reliability, it's the perfect solution for enhancing viscosity, stability, and performance in various applications. Experience the difference in your production today!

For more details, visit- https://www.agrogums.com/product/guar-gum-powder

0 notes

Text

"Experience the power of precision with our high vacuum pump. Elevate your processes to new heights of #efficiency and #reliability"!

🌐 www.yashblower.com

☎️ +91 9971006400

#yashblower#industrial equipment#vacuumpum#highvacuumpump#manufacturer#pump#industrialapplications#industrialequipments#vacuum#vacuumtechnology#air pressure#air blower#quality#performance#durability#efficiency#printingindustry#pharmaindustry

0 notes

Text

The Power of Wire Rods

the versatility and strength of wire rods! From reinforcing concrete structures to powering electrical systems, wire rods are essential components across industries.

0 notes

Text

#PPMultifilamentYarn#IndustrialMaterials#Manufacturing#FormosaSynthetics#Textiles#Automotive#GeoTextiles#CostEffective#Durability#Versatility#MaintenanceTips#IndustrialApplications#Performance#Reliability#Polypropylene#Craftsmanship#Innovation#Sustainability#IndustrialEngineering#QualityAssurance#BusinessSolutions

0 notes

Text

Aluminum Extrusion Market - Emerging Trends, Market Players, and Environmental Considerations

The global aluminum extrusion market size is anticipated to reach USD 146.82 billion by 2030, expanding at a CAGR of 8.2% from 2024 to 2030, according to a new report by Grand View Research, Inc. Growing infrastructure and residential construction activities, particularly in the booming Asia Pacific, Latin America, and MENA regions, are poised to be major growth drivers in the coming years. Rapid urbanization, rising disposable incomes, and population surge are fueling massive investments in infrastructure and construction sectors. In the budget for 2023 - 2024, the Indian government allocated INR 16,000 crores (~USD 1931.5 million) to develop “sustainable cities of tomorrow”. Such initiatives are anticipated to transform multiple cities in India by improving their infrastructure and mobility and creating urban sustainability. There exists a substantial deficit in infrastructure investment on a global scale, prompting governments worldwide to actively address and reduce this gap. This concerted effort is anticipated to have a positive impact on this market through 2030.

Aluminum Extrusion Market Report Highlights

Shapes dominated the product segment with more than 79.0% revenue share in 2023, owing to excellent malleability properties and rising demand for aluminum shapes in prominent end-use industries

In terms of product, the rods & bars segment is expected to register a significant CAGR over the forecast period

Buildings & construction application held the largest revenue share of over 60.0% in 2023. Aluminum extrusion products find a wide range of applications in the construction sector and are anticipated to witness significant demand growth over the forecast period, owing to infrastructural developments

Increased spending on R&D activities in the automotive industry by leading players has led to a substantial spike in demand for lightweight aluminum parts in electric vehicle segment

Asia Pacific dominated the market for aluminum extrusion in 2023, owing to factors such as growing construction & automotive industry in this region due to the presence of rapidly developing economies such as China, India, and other Southeast Asian countries

In November 2023, Norsk Hydro ASA announced an agreement with Watt Electric Vehicles (WEVC), an automotive start-up in the UK, to deliver low-carbon and recycled aluminum extrusion chassis for the latter’s upcoming commercial electric vehicle to be produced from the beginning of 2025

For More Details or Sample Copy please visit link @: Aluminum Extrusion Market Report

The construction sector’s boom is not the only driver for market expansion. Aluminum's flexibility, strength, and rust resistance make it popular application in automotive industry, especially with the changing dynamics of automotive vehicles. The booming automotive & transportation application segment is expected to drive the demand for aluminum extrusion over the coming years.

Stringent environmental regulations, particularly around carbon emissions, are driving automakers to embrace aluminum over steel. Car manufacturers face a mounting pressure to comply with laws like those from the EPA, CARB, and NHTSA, pushing them to adopt lighter and more fuel-efficient materials. Aluminum extruded parts offer an enticing solution here by significantly reducing vehicle weight, thereby lowering emissions and meeting regulatory requirements. This, in turn, is expected to reduce weight and drive significant demand for aluminum extruded parts.

#AluminumExtrusionMarket#Construction#Manufacturing#BuildingMaterials#Engineering#Design#Sustainability#SupplyChain#Architecture#IndustrialApplications

0 notes

Text

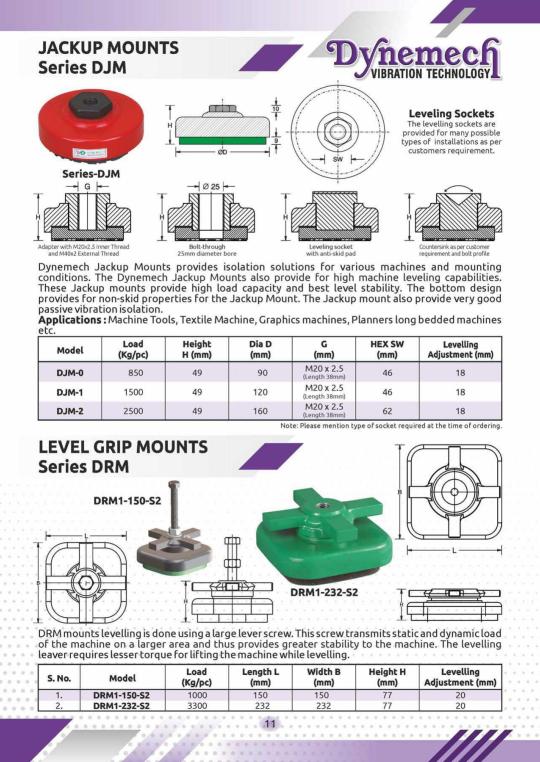

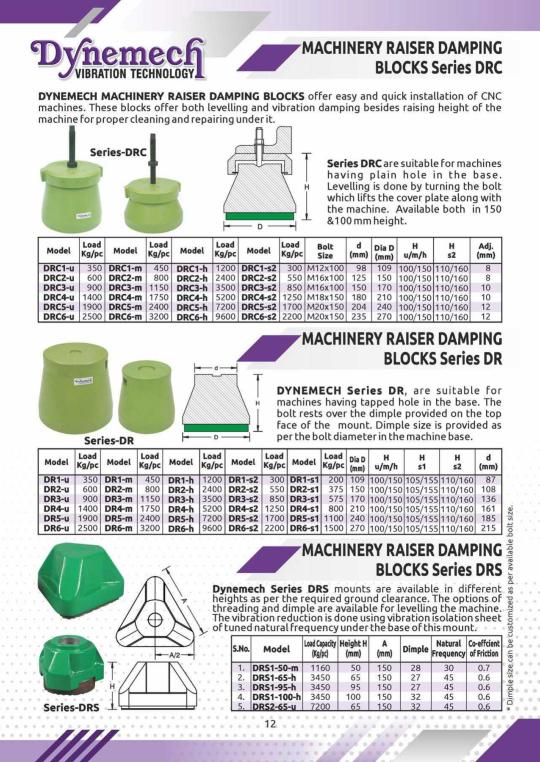

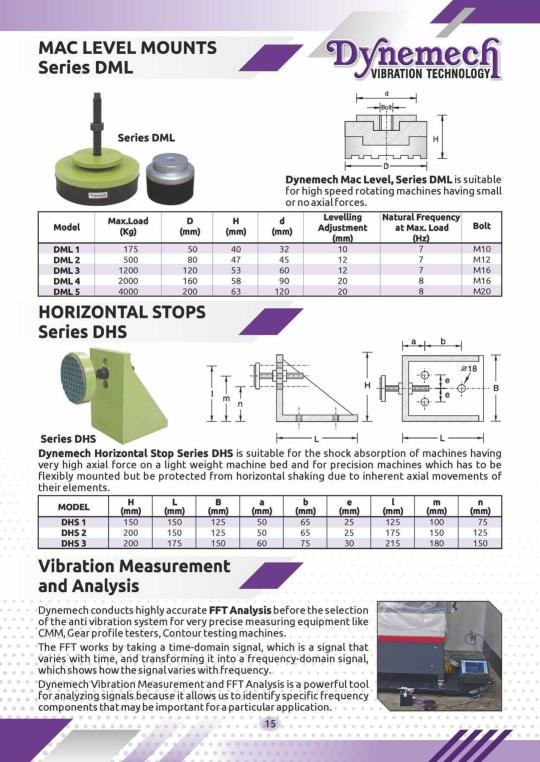

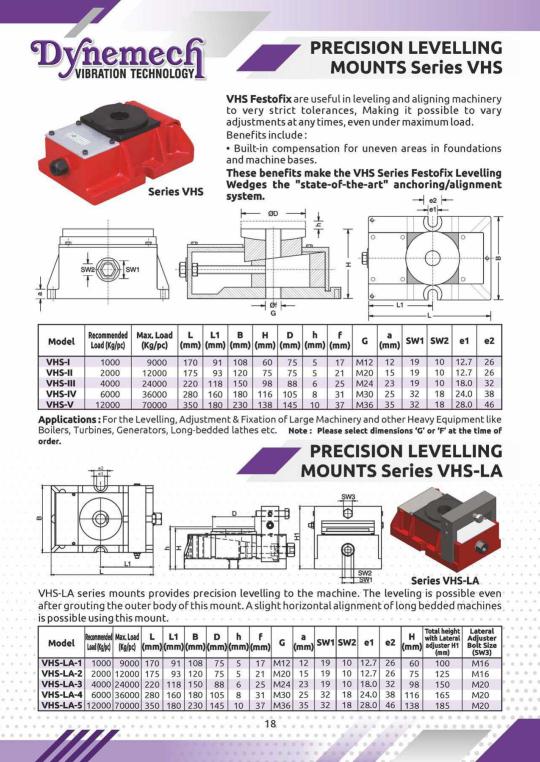

Dynemech Anti-Vibration Mounts: Essential Solutions for Vibration Control

Vibrations provide a substantial obstacle in several industrial and mechanical contexts. They have the potential to cause equipment failure, structural damage, and pose threats to worker safety. Nevertheless, by utilising appropriate anti-vibration solutions, such as those offered by Dynemech, these difficulties may be efficiently resolved.

Dynemech provides a wide variety of anti-vibration mounts that are customised to fit individual requirements.

1. Elastomeric mounts:

Synthetic elastomeric compounds of nitrile, neoprene or natural rubber mounts are frequently employed to isolate vibrations in machinery and equipment. They efficiently absorb and attenuate vibrations, hence minimising their influence on nearby infrastructure.

2. Spring Mounts:

Spring mounts employ metallic springs to dampen vibrations, providing a superior level of isolation. They are ideal for situations that need strong vibration control.

3. Spring mounts with viscous damping

Spring mounts with viscous damping are frequently employed in mechanical and automotive engineering to mitigate the propagation of vibration and shock from a source to its surrounds.

4. Pneumatic mounts:

Pneumatic mounts employ pressurised air to isolate and attenuate vibrations. These devices provide customisable degrees of vibration regulation, making them well-suited for dynamic settings.

5. Anti-Vibration Tables & Platforms for Controlling Vibrations in Operation:

Anti-vibration tables and platforms are specifically engineered to regulate and reduce vibrations in a range of activities, particularly in laboratory, industrial, and precision measurement environments. These surfaces are specifically designed to minimise the effects of external vibrations on delicate equipment and processes, hence guaranteeing precision, steadiness, and dependability in operations.

Advantages of Utilising Anti-Vibration Mounts

Vibration Isolation Machinery Protection: By preventing damage to sensitive equipment caused by excessive vibration, anti-vibration mounts increase the equipment's operational lifespan and decrease maintenance expenses.

Enhanced Performance: The implementation of these mounts maintains optimal performance and accuracy, particularly in precision equipment and measurement instruments, by effectively isolating machinery and equipment from external vibrations.

Mitigated Wear and Tear: The implementation of vibration isolation effectively reduces the deterioration and replacement expenses associated with apparatus and components.

Enhanced Comfort and Safety in the Workplace

Occupational Safety: Anti-vibration mounts safeguard personnel against the adverse consequences of extended vibration exposure, including hand-arm vibration syndrome and whole-body vibration effects, through the mitigation of vibration transmission to the surrounding environment.

Comfort and Productivity: The utilisation of anti-vibration installations by personnel operating apparatus or equipment results in enhanced comfort and decreased fatigue, which may potentially boost morale and productivity.

Precision and Stability

Enhanced Accuracy: Anti-vibration mounts guarantee stability and precision in various applications, including microscopy, metrology, and precision manufacturing, through the reduction of external disturbances.

Reliable and Consistent Outcomes: In procedures that demand precision and accuracy, these mounts contribute to dependable and consistent outcomes by establishing a vibration-free and stable environment.

Supplementary products and solutions provided by Dynemech

Dynemech offers a range of machine bases and vibration dampening solutions, which include anti-vibration mounts.

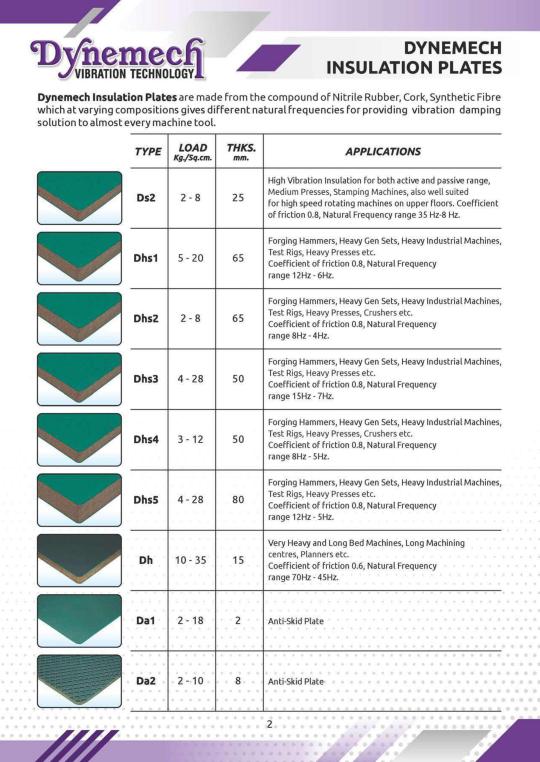

Vibration Isolation Plate

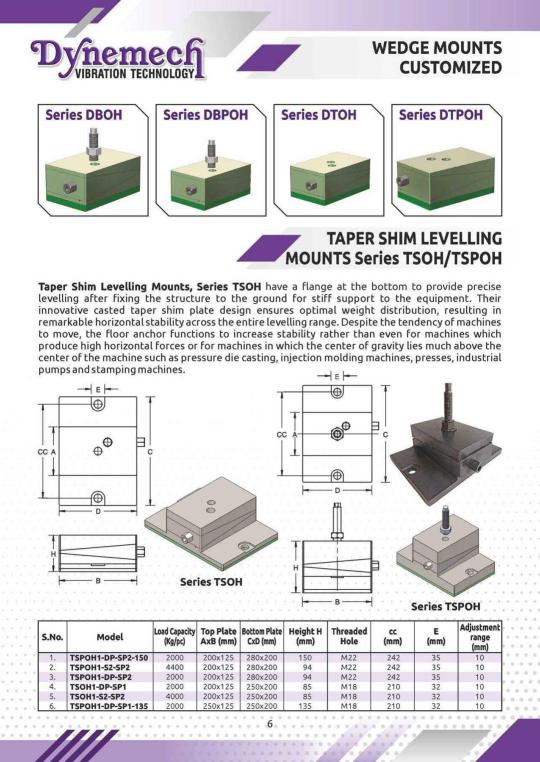

Mounting Wedge

Shim levelling mounts for taper applications

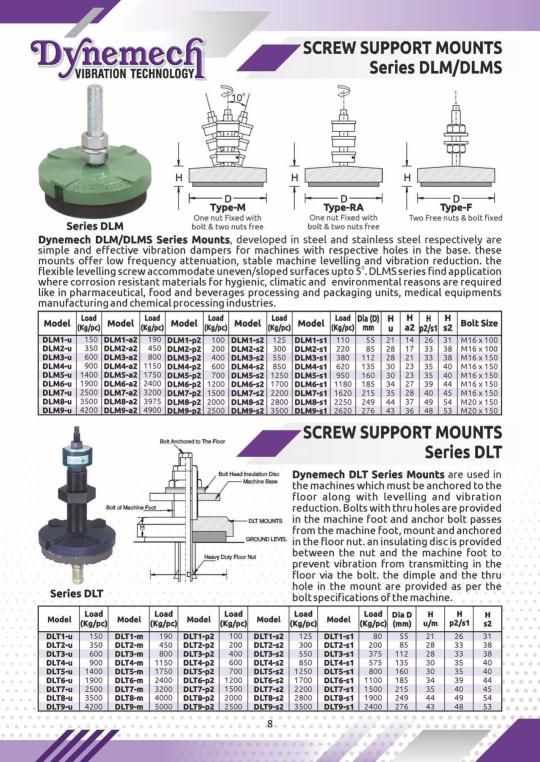

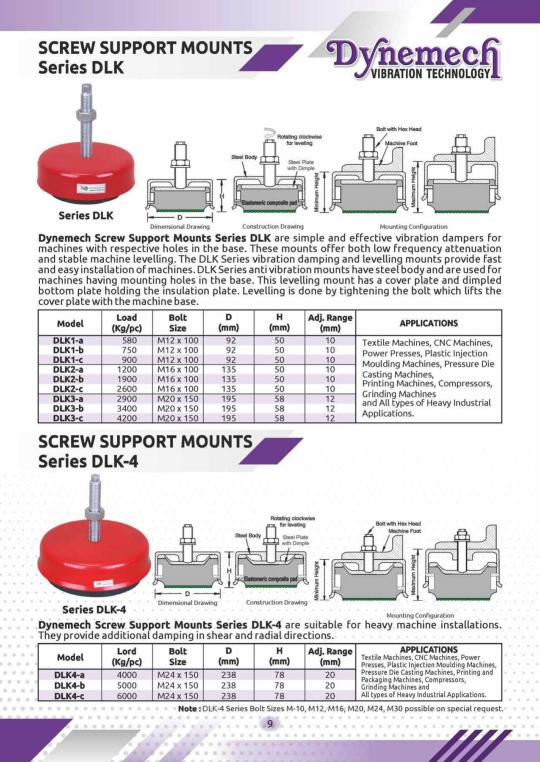

Cylindrical Screw Support Mounts

Damping blocks for Raising machinery

Precision Levelling Mounts

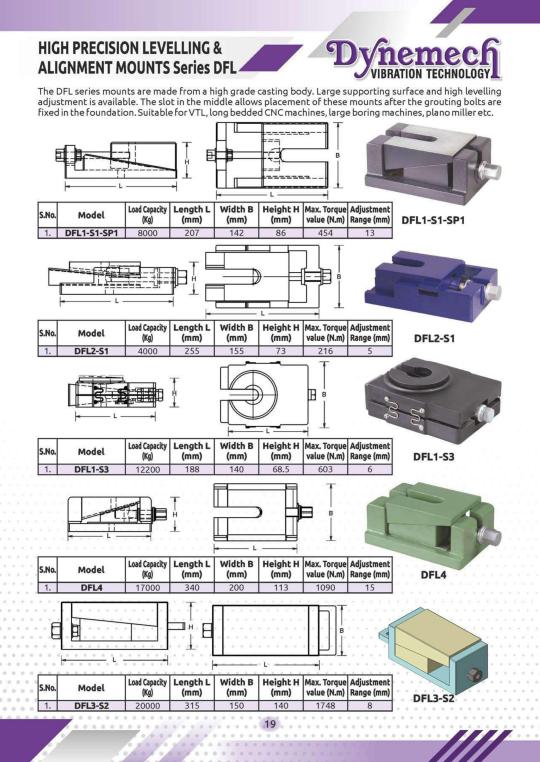

High Precision Levelling & Alignment Mounts

Flexifoot Generator Mounts

Rubber Air Springs

Membrane Air Springs

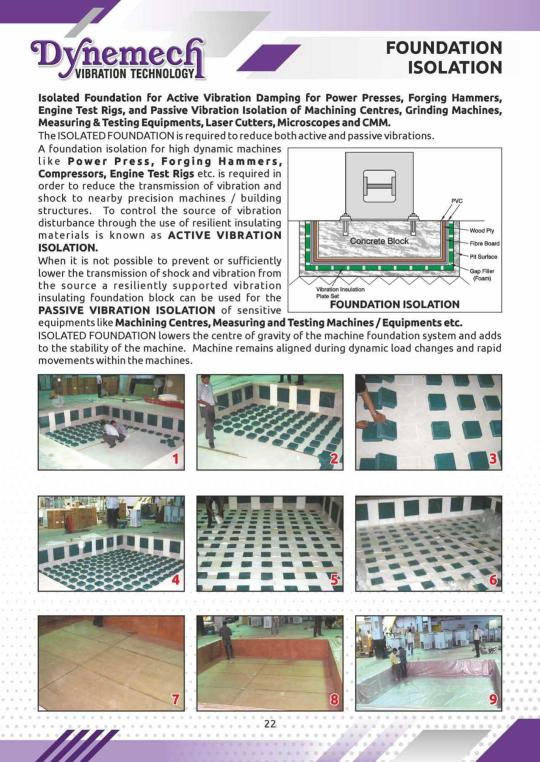

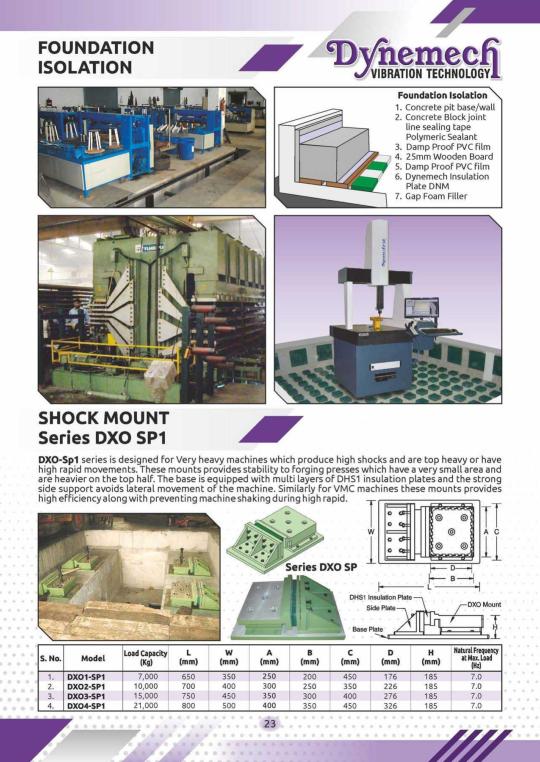

Foundation Isolation and many more …

Uses of Anti-Vibration Mounts

Anti-vibration mounts are used in several industries, such as:

• Manufacturing

• Automotive

• Aerospace

• Electronics

• Life sciences

• And more...

Furthermore...

In conclusion

Ultimately, anti-vibration mounts are crucial in minimising the harmful impacts of vibrations in industrial and mechanical settings. Businesses may enhance productivity, save expenses, and provide safer work conditions by selecting the appropriate mount type and implementing efficient vibration control measures.

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: Salе[email protected]

www.vibrationmountsindia.com | www.vibrationdampingpads.com

#VibrationControl#AntiVibrationMounts#ElastomericMounts#SpringMounts#PneumaticMounts#ViscousDamping#AntiVibrationTables#MachineryProtection#OccupationalSafety#PrecisionEquipment#IndustrialApplications#MechanicalSettings#SupplementaryProducts#Dynemech

1 note

·

View note

Text

THE SCIENCE IN VALVE FLOW : HOW VALVE DESIGN OPTIMIZES FLUID FLOW AND PRESSURE CONTROL

Learn how valve design optimizes fluid flow and pressure control for efficient industrial operations. Explore key techniques and benefits.

Whether it is the case that valves are needed for a new construction project, a plant expansion or even daily maintenance, a reliable Butterfly valve supplier will always be vital for the proper running and long-term trustworthiness of industrial systems.

Industrial owners and valve sellers both count on these suppliers to make sure they get the valves they need in the quality they are searching for. A valve stockist in UAE is well-informed and experienced in the local market specificities and requirements and is able to deliver customized products that meet to the demands of its customers in the region.

#Controlvalvessuppliers#Europeanvalvemanufacturers#Industrialapplications#industrialvalvesuppliers#ValveDesign#valveflow#ValveManufacturers#valvemechanism#ValveSuppliers

0 notes

Text

#PhenolicResins#ChemicalIndustry#PolymerTechnology#ResinMarket#GermanyChemicals#Manufacturing#CompositeMaterials#IndustrialApplications

0 notes

Text

Silicone Rubber Heaters, designed to endure temperatures up to 450 ⁰F, boast premium quality features like exceptional dielectric strength and resilience to moisture, chemicals, and acids in industrial settings. These heaters, constructed with a heating element vulcanized between two layers of silicone rubber, ensure top-notch insulation with fiberglass reinforcement, providing a flame-retardant, moisture-proof, and flexible structure. Their adaptability spans across industries, excelling in freeze protection, condensation prevention, medical equipment, aerospace, semiconductor and processing equipment, automotive, heated press machinery, and various other applications due to their remarkable ability to maintain temperatures and adapt to diverse conditions, marking them as a pivotal innovation in the field of heating solutions. For More Information Go To Our Site https://heatersandsensors.ca

#SiliconeRubberHeaters#HeatingInnovations#IndustrialHeating#FlexibleHeatingSolutions#TemperatureControl#InnovativeTechnology#IndustrialApplications#VersatileHeaters#AdvancedHeating#HighQualityMaterials

2 notes

·

View notes

Text

How to choose the right aluminum laser welding machine

#laserweldingmachine#laserwelder#weldingmachine#MaterialIdentification#AluminumAlloys#MetalCharacteristics#LaserAbsorption#ThermalImpact#MaterialThickness#LaserPower#WeldingThickness#MetalProperties#AluminumWelding#AlloyWelding#MetalThickness#PowerRequirements#PenetrationDepth#WeldingTechnology#MaterialScience#Metalworking#LaserWelding#IndustrialApplications

0 notes

Text

Flywheel Ring Gears

Ring gears are essential components in various mechanical systems and machines, playing a crucial role in the transmission of power and torque. At Bright Industries, we take pride in manufacturing high-quality ring gears that meet the diverse needs of industries such as automotive, aerospace, agriculture, and more. Our ring gears are precision-engineered to deliver exceptional performance, durability, and reliability, making them a preferred choice among engineers and manufacturers worldwide.

#FlywheelRingGears#PrecisionEngineering#ReliablePerformance#IndustrialApplications#AutomotiveIndustry

0 notes

Text

"Elevate your industrial game with our powerful ring blowers! 💨 Perfect for boosting efficiency and productivity."

🌐 www.yashblower.com

☎️ +91 9971006400

#yashblower#air blower#industrial equipment#ringblower#blower#aquaculture#fish farming#wtp#water treatment plant#industrialairblower#industrialapplications#ventilation

0 notes

Text

Wire rod Manufacture

Wire rods are long, thin metal rods produced through hot rolling processes, typically made from carbon steel or other materials like aluminum or copper. They serve as essential raw materials in a variety of industries, including construction, automotive, manufacturing, and telecommunications.

#WireRods#SteelIndustry#Manufacturing#ConstructionMaterials#IndustrialApplications#MetalProducts#VersatileMaterials

0 notes

Text

The Complete Guide to PP Multifilament Yarn: Uses, Manufacturing, and Maintenance

Introduction

PP multifilament yarn is a key material in various industries, offering strength, durability, and flexibility. It's manufactured by spinning multiple fibers into a single thread, resulting in exceptional tensile strength. Used in textiles, automotive parts, geotextiles, and more, its versatility is unmatched. Proper maintenance is crucial for maximizing its benefits and longevity in industrial settings.

Know About PP Multifilament Yarn:

PP multifilament yarn, meticulously crafted by Formosa Synthetics Pvt. Ltd., is a cornerstone of modern industrial materials. Through advanced manufacturing techniques, multiple strands of polypropylene fibers are intricately woven to create a seamless, durable thread. This exceptional craftsmanship ensures unparalleled strength and resilience, making it ideal for diverse applications such as geo textiles and automotive components, where reliability is paramount. Businesses worldwide rely on Formosa Synthetics Pvt. Ltd.'s PP multifilament yarn for superior performance and durability in demanding environments, making it a top choice across industries.

Benefits of Using PP Multifilament Yarn:

PP multifilament yarn offers a wide array of benefits, making it highly desirable across industries. Its superior braking power, scratch resistance, and water absorption capabilities ensure suitability for diverse applications. Furthermore, its cost-effectiveness compared to alternatives such as nylon or polyester, along with its excellent thermal insulation properties, adds to its appeal.

Enhanced Braking Power

Greater Scratch Resistance

Superior Water Absorption Capabilities

Cost-Effectiveness

High Thermal Insulation Properties

PP multifilament yarn stands out for its exceptional performance and versatility across various industries. Its combination of strength, durability, and cost-effectiveness makes it a preferred choice for a wide range of applications.

Where PP Multifilament Yarns are Mostly Used?

PP multifilament yarn finds extensive usage across diverse sectors and applications.

Geo Textile Items

Channel Fabrics

Woven Sacks

Webbings and Tapes

Braids and Ropes

Sports Devices

Marine and Nautical Applications

Fishing Industry

Chemical Handling

Considerations When Opting for the Right Multifilament Yarn:

Required Characteristics

Manufacturing Practices

Cost Evaluation

Availability

Conclusion:

PP multifilament yarn emerges as a versatile and indispensable material with a myriad of applications across industries. Its exceptional strength, durability, and cost-effectiveness make it a preferred choice for various manufacturing needs. With proper care and maintenance, PP multifilament yarn products can withstand the rigors of industrial use and deliver long-lasting performance.

Read More

#PPMultifilamentYarn#IndustrialMaterials#Manufacturing#FormosaSynthetics#Textiles#Automotive#GeoTextiles#CostEffective#Durability#Versatility#MaintenanceTips#IndustrialApplications#Performance#Reliability#Polypropylene#Craftsmanship#Innovation#Sustainability#IndustrialEngineering#QualityAssurance#BusinessSolutions

0 notes