#SteelIndustry

Text

TMT Bar Manufacturer and Distributor in Kanpur | RHL Profiles limited

Savings & Other Benefits to Construction in Use of High Strength TMT Steel Bars

Steel is an essential element of any civil or construction activity like Houses, Multi Storey, Townships, Malls, Airports, Ports, Dams, Bridges, etc. Steel not only provides strength to any construction but also provides durability and long life.

Each transformation of the steel industry was driven by the growing market need for steel bars with higher strength and elongation. The 21st century has witnessed a rapid increase in the cost of steel products and also brought greater focus on safety and quality norms of construction. This has spurred the demand for the development of TMT bars with properties of high strength and elongation to provide cost savings in the construction by reducing consumption.

Steel researchers across the world have been working hard to develop steel products to meet these specific market needs. This research has led to the development of TMT steel Bars with yield strengths of 500 N/mm 2, 550 N/mm2, and 600 N/mm2. These bars, because of their higher strength than traditional steel bars, are required in lesser quantities, thus, reducing the overall cost of the structure significantly.

The BIS code for IS 1786 (High Strength Deformed Steel Bars And Wires for concrete Reinforcement Specification), IS 13920 (Ductile Detailing of Reinforced concrete structures subjected to Seismic forces - Code of Practice), and IS 456 (Plain And Reinforced Concrete – Code of Practice) incorporated necessary changes to include these latest developments in the field of steel technology.

IS 1786 under its latest revision groups the Steel Bars under the following grades:

Fe 415, Fe 415D, Fe 415S

Fe 500, Fe 500D, Fe 500S

Fe 550, Fe 550D

Fe 600

Reinforcing steel is produced through one or a combination of processes like hot rolling after microalloying, hot rolling followed by cold working, or hot rolling followed by Thermo Mechanical Treatment (TMT process).

TMT Technology

TMT technology involves rapid cooling of hot-rolled bars rolled out of a finishing rolling mill from a temperature of 950-1050°C to 550-600°C using a high-pressure cool water spray system. The bars after quenching are cooled under controlled atmospheric conditions to impart properties based on the size and grade being rolled. The three major steps of the TMT process are as under :

1. QUENCHING: The hot rolled bar coming out of the finishing rolling mill stand is passed through a quenching box where it is rapidly quenched using a high-pressure cool water spray system. The surface of the bar gets hardened to the depth optimized for each section through the formation of a 'Martensitic' rim while the core remains hot and 'Austenitic'.

2. SELF TEMPERING: The bar coming out of the quenching box thus has a hot core compared to the cool outer surface thus allowing the heat to flow from the inner core to the outer surface causing tempering of the outer martensitic rim into "Tempered Martensitic" structure. The core remains "Austenitic" at this stage.

3. ATMOSPHERIC COOLING: The bar is then finished on an Automatic rake type controlled Cooling Bed where uniform atmospheric cooling of each bar takes place under controlled conditions resulting in the transformation of the hot "Austenitic" core of the bar into "Ferrite Pearlite" structure. The resultant final structure of the Bar thus produced consists of a hard and strong outer layer (Tempered Martensitic) with a soft and ductile inner core (Ferrite Pearlite) structure.

Importance of branded steel manufacturer -

Steel Billet of appropriate chemical composition - Right raw material procurement and selection.

Accurate rolling within close tolerances - Robust and Accurate manufacturing equipment.

Quenching under appropriate water pressure, water temperature, and water volume depending on finishing mill speed, chemical parameters, size, and grade of finished steel - Trained manpower.

Uniform atmospheric cooling on Automatic rake type cooling bed - Right technology.

Testing for Mechanical, and Physical properties in the laboratory - Quality Assurance.

Bundling, tagging, and dispatch as per grade and size of finished TMT Steel - Complete customer service and satisfaction.

2 notes

·

View notes

Text

Finding Reliable TMT Bar Manufacturers

Choosing the right TMT (Thermo-Mechanically Treated) bar manufacturer is paramount for any construction project aiming for structural integrity and longevity. TMT bars are the backbone of reinforced concrete structures, providing strength and durability against various environmental and load conditions. However, with numerous manufacturers in the market, finding a reliable one can be daunting. It's essential to consider factors such as quality standards, reputation, and customer satisfaction when selecting TMT bar manufacturers. By partnering with a reputable manufacturer, construction projects can ensure the consistent supply of high-quality TMT bars that meet industry standards and exceed performance expectations.

0 notes

Text

Navigating Market Dynamics in the Long Steel Products Industry

The global long steel products market size is expected to reach USD 1,012.11 billion by 2030, expanding at a CAGR of 5.1% from 2024 to 2030, according to a new report by Grand View Research, Inc,. Products such as rebars and wire rodsare of vital importance in today’s world with their growing emphasis in the building and construction industry. Based on product, the market is segmented into rebars, wire rods, sections, and tubes, of which rebars are extensively used in the construction of infrastructure and buildings. Wire rods are manufactured by drawing hot metals through shafts to develop wires with reduced diameters. Wire rods represent the most ductile form owing to their high ductility and easy availability in different diameters. They are widely used in construction and fencing applications which is positively impacting their growth.

Long Steel Products Market Report Highlights

Based on product, rebars held a revenue share of more than 34.0% in 2023 of the global market. Rebars are embedded in the concrete or used along with it so that the concrete can withstand the compressive forces in the structure and sustain against the tensile forces formed in the structure. The demand for rebars is expected to propel in developing nations owing to the growing construction activities

In terms of revenue, wire rods is anticipated to register a CAGR of 5.9% across the forecast period owing to their rising use in the automotive industry

Asia Pacific accounted for the highest share of over 66.0% in 2023, in terms of revenue, and this trend is anticipated to continue over the forecast period. As the region is characterized by a growing population and surging housing requirements, countries such as China and India, are witnessing an increasing number of residential construction projects. This is expected to result in significant product demand in the Asia Pacific in the coming years

The market is characterized by intense competition. Several of players are entering into long term supply contracts with end-users. ArcelorMittal, Emirates Steel Arkan and Emirates Rebar Limited are among the leading players of the market in the world

For More Details or Sample Copy please visit link @: Long Steel Products Market Report

Based on region, Asia Pacific is one of the leading markets in the world. The growth is attributable to China which is the largest producer and consumer of long steel products in the Asia Pacific. Other major markets in the region include Japan, South Korea, India, and Southeast Asian countries such as Indonesia, Vietnam, and Thailand. In recent years, the Asia Pacific market has faced challenges due to a global oversupply of raw materials, increased competition from other steel-producing countries, and the impact of the COVID-19 pandemic on the region's economies.

Further, various growth strategies such as new product development and capacity expansions by the market players are likely to benefit the industry growth. For instance, in February 2023, ArcelorMittal introduced a new blast oxygen furnace LD (Linz-Donawitz) converter in Bosnia with a capacity of 125 tons. This converter has been supplied by Primetals Technologies. Thus, this investment ramps up the production and processing of steel into billets, bars, blooms, and ingots.

#LongSteel#SteelMarket#ConstructionMaterials#BuildingIndustry#SteelIndustry#Manufacturing#SteelProduction#IndustrialMaterials#StructuralSteel#MarketAnalysis#SteelDemand#Metallurgy#BuildingMaterials#ConstructionTrends#SteelPrices#IndustryInsights

0 notes

Text

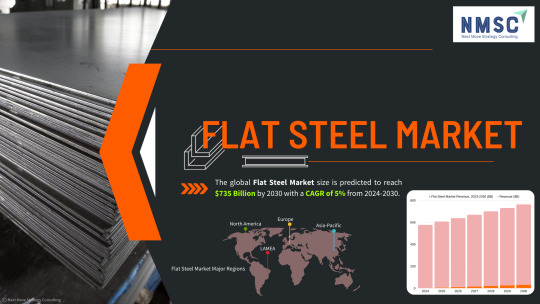

The flat steel market refers to the industry involved in the production, distribution, and consumption of flat-rolled steel products. These products include sheets, strips, and plates of steel that are manufactured through rolling processes.

Get a FREE sample: https://www.nextmsc.com/flat-steel-market/request-sample

The market encompasses various sectors such as construction, automotive, manufacturing, and infrastructure. Factors influencing the flat steel market include economic conditions, technological advancements, government regulations, and global demand trends.

Overall, the flat steel market plays a vital role in numerous industries due to the versatility, strength, and durability of flat-rolled steel products.

0 notes

Text

Hot Rolled Coil Manufacture

Hot Rolled Coil (HRC) is steel processed through hot rolling, enhancing its formability and strength for use in automotive, construction, and manufacturing sectors.

#HotRolledCoil#SteelIndustry#Manufacturing#ConstructionMaterials#MetalProcessing#SteelProduction#IndustrialMaterials#Formability#Strength#SteelProducts

0 notes

Text

Stainless Steel 409M Coils Manufacturers

Padmavati Steel & Engg.Co.

Advancing Industrial Excellence: Stainless Steel 409M Coils Manufacturers Leading the Way

Introduction: In the landscape of stainless steel production, precision, resilience, and innovation are vital. Among the spectrum of stainless steel alloys, Stainless Steel 409M coils shine as exemplars of quality and performance, valued for their robust mechanical attributes and resistance to corrosion. Pioneering advancements and setting new standards in manufacturing, producers of Stainless Steel 409M coils are pivotal in propelling industrial capabilities and addressing the evolving needs of various sectors.

Unveiling Leading Manufacturers of Stainless Steel 409M Coils:

Innovative Production Enterprises:

With a focus on cutting-edge technology and superior craftsmanship, Innovative Production Enterprises stands at the forefront of Stainless Steel 409M coil manufacturing. Utilizing state-of-the-art facilities and a team of skilled professionals, they fabricate coils that surpass industry benchmarks in mechanical strength, corrosion resistance, and dimensional precision. Their dedication to research and development ensures continuous enhancement and alignment with emerging market dynamics.

Precision Metal Fabricators:

Precision Metal Fabricators are renowned for their meticulous production of Stainless Steel 409M coils, precisely tailored to meet diverse industrial requirements. Employing a methodical manufacturing approach and stringent quality checks, they deliver coils renowned for exceptional performance and longevity. Their client-centric ethos and unwavering commitment to excellence have established them as a trusted source in the stainless steel manufacturing sphere.

Reliable Stainless Steel Industries:

Reliable Stainless Steel Industries specialize in crafting high-caliber Stainless Steel 409M coils, addressing the needs of sectors ranging from automotive to construction. Armed with advanced technology and a culture of innovation, they manufacture coils distinguished by superior mechanical properties, formability, and surface finishing. Their agility in production and unwavering focus on customer satisfaction position them as preferred partners for discerning clientele.

Technotron Fabrication Solutions:

Technotron Fabrication Solutions are experts in producing precision-engineered Stainless Steel 409M coils, precisely tailored for critical applications. Adhering rigorously to quality standards and continuous improvement principles, they uphold international benchmarks throughout the manufacturing process. Their nimble production capabilities and commitment to customer-centricity make them indispensable allies for enterprises seeking top-tier stainless steel coil solutions.

Conclusion: Manufacturers of Stainless Steel 409M coils epitomize excellence in stainless steel production, setting new standards for quality, reliability, and innovation. Through cutting-edge manufacturing processes, rigorous quality controls, and a steadfast commitment to customer satisfaction, these manufacturers empower industries to achieve unprecedented levels of performance and efficiency. As cornerstones of the stainless steel supply chain, they play a pivotal role in propelling industrial advancement and shaping the future of manufacturing across diverse sectors.

#CoilManufacturing#StainlessSteelCoils#IndustrialCoils#CoilProduction#MetalCoils#CoilSuppliers#SteelIndustry#ManufacturingExcellence#CoilSolutions#QualityCoils#CoilTechnology#EngineeringSolutions#SteelFabrication#PrecisionCoils#InnovationInCoils

0 notes

Text

Tie rod manufacturer | Bush plate manufacturer

Our state-of-the-art manufacturing facility is equipped with cutting-edge technology, positioning us as a reliable Tie Rod manufacturer and Bush Plate manufacturer. The meticulous craftsmanship that goes into each product ensures durability, reliability, and superior performance. As a trusted Tie Rod manufacturer, we understand the pivotal role these components play in providing structural stability, making them an integral part of construction and engineering projects. Simultaneously, our expertise as a Bush Plate manufacturer extends to creating robust components crucial for absorbing shocks and vibrations in heavy machinery.

Strips India’s legacy as a Tie Rod and Bush Plate manufacturer goes beyond just producing components; we offer solutions tailored to meet the unique requirements of our clients. Whether it’s tie rods for construction projects or bush plates for heavy machinery, our commitment to customization ensures that our clients receive products that perfectly align with their specifications.

Contact us at +91-9811152476 +91-9354813338 or mail us [email protected]

Do visit our site sitplindia.com/ . . . .

#StripsIndia#TieRodManufacturer#IndustrialEngineering#SteelManufacturing#QualityRodProducts#InfrastructureSolutions#ConstructionMaterials#StructuralEngineering#TieRodSystems#EngineeringExcellence#BuildingMaterials#SteelIndustry#InfrastructureDevelopment#ConstructionHardware#TieRodSuppliers#SteelInnovation#ManufacturingLeadership#StructuralComponents#BuildWithStrength#InnovativeEngineering#RodSolutions#ConstructionSupplies#InfrastructureMaterials#TieRodExperts#SteelCraftsmanship#QualityConstruction#BuildingWithIntegrity#StripsIndiaQuality

0 notes

Text

Best TMT Bar supplier In India | Nakoda TMT Group

NAKODA TMT embodies strength, flexibility, ductility, and reliability, ensuring the durability of buildings and homes over time. Our TMT steel is designed for long-lasting durability, showcasing the enduring strength we provide and the confidence you have in our products.

https://www.nakodagroup.com/

https://www.nakodagroup.com/tmt.html

#NakodaTMT#NakodaGroup#TMTBars#Chhattisgarh#iron#CorrosionResistant#NoCorrosion#LongLastingTMT#buildingwithtmt#qualitysteel#durableconstruction#rulingtmt#reinforcement#structuralsteel#highquality#reliable#steelindustry#buildingconstruction#civilengineering#structuralintegrity#robustness#lastingbuildings#tmtbars#construction#strength#strong#flexible

0 notes

Text

Round Bars Manufacturer in Mandi Gobindgarh

Mandi Gobindgarh, a city in Punjab, India, is known as a hub for steel production. It houses numerous manufacturers specializing in various steel products, including round bars. But with so many options, how do you find the top quality round bars manufacturer in Mandi Gobindgarh?

Factors to Consider:

✦Material: Choose between mild steel, high-carbon steel, or alloy steel rounds manufacturer in Mandi Gobindgarh depending on the required strength, durability, and corrosion resistance.

✦Size and Tolerance: Ensure the manufacturer offers the desired diameter and length with the specific tolerance requirements for your project.

✦Quality and Certifications: Look for manufacturers with established quality control procedures and certifications like ISO 9001, ensuring consistent product quality.

✦Experience and Reputation: Opt for manufacturers with a proven track record and a positive reputation in the industry.

✦Price and Service: Compare prices and consider factors like minimum order quantity, delivery timelines, and customer service offered by different manufacturers.

why choose Surya Steel Industries?

We Are the Best Alloy Steel Rounds Manufacturer in Mandi Gobindgarh. At our company, we understand the importance of quality in every aspect of our business. We are proud to be the best alloy steel rounds manufacturer in Mandi Gobindgarh, consistently delivering high-quality, well-built, and long-lasting round bars to meet the demanding needs of the automotive and construction industries.

Our Commitment to Quality:

✦Ideal for Fastener Applications & Cold Drawing: Our alloy steel rounds are meticulously crafted to excel in fastener applications and cold drawing processes, ensuring exceptional performance and reliability.

✦Unwavering Quality Focus: Delivering quality is paramount to us. We uphold stringent standards throughout our entire process, from the initial consultation through to delivery and after-sales support.

✦Quality Embedded in Every Step: Our commitment to quality permeates every activity, encompassing product design, manufacturing, sales, and service. This dedication ensures consistent excellence and superior performance in every round bar we produce.

✦Foundation for Success: We believe that unwavering quality is the cornerstone of our business success and market sustainability. It drives every initiative and decision we make, ensuring long-term customer satisfaction and industry leadership.

Partner with the Best:

Choose the Best Square Bar Manufacturer in Mandi Gobindgarh Contact us today to discuss your specific requirements and experience the difference that our commitment to quality can make for your project.

#mandigobindgarhmanufacturer#roundbarssupplier#steelindustry#highqualitybars#metalmanufacturing#industrialmaterials#steelproduction#roundbarspecialist

#mandigobindgarhmanufacturer#roundbarssupplier#steelindustry#highqualitybars#metalmanufacturing#industrialmaterials#steelproduction#roundbarspecialist

0 notes

Text

Explore innovative approaches and sustainable practices in secondary steel manufacturing that contribute to reducing pollutants in the steel industry. Learn how embracing transformative strategies can enhance environmental sustainability while maintaining steel production efficiency. Dive into the realm of eco-friendly steel manufacturing solutions and their positive impact on our environment. Read more.

1 note

·

View note

Text

What are the key properties and applications of P20 Steel Grade, and how does it compare to other tool steel grades in terms of performance and versatility?

P20 Steel, also known as P20 tool steel, is a versatile and widely used mold steel with several key properties and applications:

Key Properties of P20 Steel:

1. Excellent Machinability: P20 Steel exhibits good machinability, allowing for easy shaping and fabrication of molds and components.

2. High Hardenability: It has high hardenability, meaning it can be hardened throughout its cross-section when properly heat-treated, resulting in excellent wear resistance.

3. Good Polishing Ability: P20 Steel can be polished to a high surface finish, making it suitable for applications requiring fine detail and aesthetic appeal.

4. Good Toughness: P20 Steel offers good toughness, which helps prevent cracking and chipping during use, enhancing the durability of molds and components.

5. Excellent Dimensional Stability: It maintains its shape and size even under high temperatures and pressures, ensuring precision and consistency in molded products.

Applications of P20 Steel:

1. Injection Molding: P20 Steel is widely used for manufacturing injection molds for plastic components due to its excellent polishability, wear resistance, and dimensional stability.

2. Extrusion Dies: It is also used in the production of extrusion dies for plastic and rubber processing, where high wear resistance and toughness are required.

3. Die Casting: P20 Steel finds applications in die casting dies for non-ferrous metals, providing good thermal conductivity and resistance to thermal fatigue.

4. Forming Tools: P20 steel is used to manufacture forming tools, such as bending and stamping dies, where high wear resistance and toughness are essential.

Comparison with Other Tool Steel Grades:

1. Compared to H13 Steel: While H13 Steel offers higher heat resistance and hardness retention at elevated temperatures, P20 steel is preferred for applications requiring polishability, ease of machining, and excellent wear resistance at lower temperatures.

2. Compared to D2 Steel: D2 Steel offers higher wear resistance and edge retention compared to P20 steel, but it may be more difficult to machine and polish. P20 steel is often chosen for applications where polishability and machinability are critical.

3. Compared to S7 Steel: S7 Steel provides superior impact resistance and toughness compared to P20 steel, but P20 steel offers better wear resistance and dimensional stability, making it more suitable for applications requiring high precision and surface finish.

In summary, P20 Steel stands out for its excellent combination of machinability, polishability, wear resistance, toughness, and dimensional stability, making it a preferred choice for a wide range of tooling and mold-making applications in the manufacturing industry.

Sandeep Enterprises stands as a respected entity within the Steel Industry, underscored by its unwavering dedication to excellence, quality, and customer satisfaction. With a steadfast commitment to delivering superior products and services, Sandeep Enterprises has established itself as a trusted partner for clients across various sectors. From stringent quality control measures to innovative solutions tailored to meet diverse industry needs, Sandeep Enterprises consistently strives to exceed expectations. This dedication to excellence permeates every aspect of its operations, cementing its reputation as a leader in the Steel Industry.

#SandeepEnterprises#P20Steel#ToolSteel#Engineering#MoldMaking#InjectionMolding#ExtrusionDies#DieCasting#FormingTools#SteelIndustry#Manufacturing#PrecisionEngineering#P20PlasticMouldSteel#MouldMaking#Tooling#InjectionMoulding#PlasticManufacturing#SteelAlloy#MouldDesign#P20#PlasticIndustry

0 notes

Text

Driving Industrial Growth with Wire Rods Manufacturers in Punjab

Punjab, known for its vibrant industrial landscape, hosts several prominent wire rods manufacturers contributing significantly to the region's economic development. These manufacturers play a pivotal role in supplying high-quality wire rods, essential components in various industries such as construction, automotive, infrastructure, and manufacturing. With state-of-the-art facilities, advanced technology, and a commitment to excellence, wire rods manufacturers in Punjab cater to the diverse needs of their clientele, offering a wide range of products tailored to specific applications. Through innovation, quality assurance, and customer-centric approaches, these manufacturers bolster Punjab's industrial prowess while upholding the highest standards of reliability and performance in their products.

0 notes

Text

Iron Ore Pellets Market: Trends, Technological Advancements, and Investment Strategies

The global iron ore pellets market size is expected to reach USD 63.52 billion by 2027, expanding at a CAGR of 3.7% from 2020 to 2027, according to a new report by Grand View Research, Inc. The product demand is predicted to be largely driven by rising steel production in Asia Pacific. Iron ore pellets are an important source for steel manufacturing. Rapid industrialization and urbanization in emerging economies of Asia Pacific since the past few years have stimulated the production of steel. This has caused a surge in demand for iron ore pellets in the region.

Iron Ore Pellets Market Report Highlights

Asia Pacific acquired the largest volume share of 52.3% in 2019. This can be attributed to a large steel production base in China

By product, direct reduced pellet is anticipated to exhibit the fastest CAGR of 3.8% from 2020 to 2027 in terms of revenue owing to rising penetration of direct reduction production method

Based on trade, the captive segment dominated the market with a volume share of 70.8% in 2019 owing to a large number of integrated steel plants across the globe

Middle East and Africa is expected to expand at a significant CAGR of 3.1% from 2020 to 2027 in terms of revenue owing to several economic diversification programs implemented by Middle Eastern and North African countries

The global market is highly competitive with Vale and Rio Tinto leading in terms of production capacity and market share.

For More Details or Sample Copy please visit link @: Iron Ore Pellets Market Report

The product is mainly used in captive form by large integrated steel producers. However, there is ample potential for seaborne trade of the product as cross country trade is expected to rise over the coming years owing to rising demand from Asia Pacific and Middle East and Africa.

China dominates the market owing to huge steel production capacity in the country. However, emerging economies such as India, Vietnam, Myanmar, Philippines, and Indonesia are expected to witness significant growth as these countries are posing a significant challenge to the Chinese steel producers owing to their comparatively lower labor costs and supportive government policies.

Major players in the industry include multinational companies such as Vale, Rio Tinto, and BHP Billiton. Rio Tinto surpassed Vale as the leading global supplier of iron ore as well as its pellets in the first quarter of the year 2020 as Vale witnessed a sharp decline in iron ore output due to a deadly dam burst owned by Vale in 2019.

#IronOre#PelletsMarket#SteelIndustry#RawMaterials#MiningSector#IronOreMining#SteelProduction#MetalIndustry#OreProcessing#IronOreSupply#IronOreDemand#PelletizingPlant

0 notes

Text

Duplex Steel S31803 Flanges Manufacturers in India

Duplex Steel Flanges are solidified compounds and furthermore astoundingly erosion safe. Microstructures of this steel are comprise of Ferrite and Austenite stages' blend. Accordingly, they comprise of the highlights of both ferritic and austenitic treated Steel. It has a high-strength and superb protection from erosion. Duplex Stainless Steel Flanges have astounding intergranular consumption. It has an exceptional high protection from erosion breaking pressure even in sulfide and chloride conditions.

At the temperatures, in excess of 300 degree Celsius Duplex Steel Flanges is as yet shielded from the consumption causes embrittlement. Channel capacity is magnificent in low temperatures too. The manufacture work is done exclusively through the devices doled out for materials of Stainless Steel. Before they utilized should be cleaned appropriately. Saving the treated steel from the cross-defilement from the consumed metals is finished.

#aerospace#DuplexSteel#S31803#Flanges#Manufacturers#India#IndustrialSuppliers#SteelIndustry#Metalworking#Engineering#Exporters#QualityFlanges#CustomFabrication#Wholesale#SupplyChain#ConstructionMaterials

0 notes

Text

#AmitSinha#Management#Consultant#Industries#International#Industrial#Ethiopia#AddisAbaba#Targedo#Targedopvtltd#TargeroInternationalManagementCompany#Amit#Brand#Industry#Steel#SteelIndustry#HospitalityIndustry#Contact +251915700149#[email protected]#[email protected]#Dear Friends#Greetings of the day!#My name is Amit Sinha#Profession: Industrial Management Consultant#We are Approved Management Consultant from F.D.R.E#We Reorganize and Manage Industrial manufacturing projects in Different countries#100% guarantee to turn profitable company in 6 to 12 Months.#Based in Addis Ababa#Ethiopia. Email: [email protected]#direct 🤙 0915700149

0 notes

Text

Stainless Steel 310S Coils Stockists In India

Title: Stainless Steel 310S Coils Stockists In India

Introduction:

Stainless steel coils are indispensable in various industries, offering durability, corrosion resistance, and versatility. Among these, Stainless Steel 310S Coils stand out for their exceptional performance in high-temperature environments and corrosive atmospheres. In this article, we delve into the characteristics, applications, and advantages of Stainless Steel 310S Coils, highlighting their significance in modern industrial settings.

Characteristics of Stainless Steel 310S Coils:

Stainless Steel 310S is a high-alloy austenitic stainless steel known for its excellent resistance to oxidation and sulfidation at high temperatures. The addition of chromium and nickel enhances its corrosion resistance, making it suitable for applications involving elevated temperatures and harsh environments. Some key characteristics include:

High Temperature Resistance: Stainless Steel 310S retains its mechanical properties at temperatures up to 2000°F (1093°C), making it ideal for furnace parts, heat treatment equipment, and other high-temperature applications.

Corrosion Resistance: The alloy's composition offers superior resistance to oxidation, sulfidation, and carburization, ensuring longevity and reliability in corrosive environments.

Excellent Formability: Stainless Steel 310S Coils exhibit good formability and weldability, allowing for easy fabrication into various shapes and sizes to meet specific industrial requirements.

Strength and Durability: With a high chromium and nickel content, Stainless Steel 310S maintains its strength and toughness even at extreme temperatures, contributing to long-term performance and structural integrity.

Applications of Stainless Steel 310S Coils:

The versatility and robustness of Stainless Steel 310S Coils render them indispensable across diverse industrial sectors, including:

Chemical Processing: Used in reactors, piping, and heat exchangers for handling corrosive chemicals and high-temperature reactions.

Petrochemical Industry: Employed in refinery equipment, such as furnaces, boilers, and catalytic crackers, where resistance to sulfidation and oxidation is crucial.

Power Generation: Utilized in turbine parts, boiler tubes, and exhaust systems for power plants, ensuring reliability and efficiency under extreme conditions.

Aerospace and Automotive: Applied in exhaust systems, engine components, and structural parts, benefiting from its high temperature and corrosion resistance.

Food Processing: Employed in equipment for cooking, sterilizing, and processing food products, maintaining hygiene and preventing contamination.

Advantages of Stainless Steel 310S Coils:

Investing in Stainless Steel 310S Coils offers several advantages for industrial applications:

Longevity: The alloy's resistance to oxidation and corrosion ensures prolonged service life, reducing maintenance costs and downtime.

High Temperature Performance: Stainless Steel 310S maintains its mechanical properties at elevated temperatures, providing reliability in demanding thermal environments.

Versatility: Suitable for a wide range of applications across various industries, offering flexibility and adaptability to diverse manufacturing processes.

Cost-Effectiveness: Despite initial investment, Stainless Steel 310S Coils prove cost-effective over time due to their durability, reliability, and low maintenance requirements.

Environmental Sustainability: Stainless steel is fully recyclable, contributing to sustainable practices and reducing the environmental footprint of industrial operations.

Conclusion:

Stainless Steel 310S Coils play a crucial role in modern industrial applications, offering unparalleled performance in high-temperature and corrosive environments. With their exceptional characteristics, wide-ranging applications, and numerous advantages, they continue to be the material of choice for engineers and manufacturers striving for reliability, durability, and sustainability in their processes. As industries evolve, Stainless Steel 310S Coils remain at the forefront of innovation, driving progress and efficiency across diverse sectors.

For More Information :

Email : [email protected]

Call Us : +91-9930388308

Website : https://www.padmavatisteel.com/

#StainlessSteelCoils#StainlessSteelManufacturers#StainlessSteel304#CoilManufacturers#MumbaiManufacturers#SteelIndustry#IndustrialCoils#CorrosionResistance#DurableCoils#HighQualitySteel#VersatileCoils#StainlessSteelProducts#MetalCoils#SteelProduction#SteelManufacturing

0 notes