#PTFE Lined Flush Bottom Valves

Text

Supplier of PTFE Lined Flush Bottom Valves in Telangana

Company Overview:

Flowline Valve is a prominent Manufacturer and Supplier of PTFE Lined Flush Bottom Valves in Telangana, India.Committed to quality, the company adheres to ISO 9001:2015 standards and has been in operation since 2013.

These valves, also known as tank bottom valves, facilitate the draining or emptying of liquids, slurries, or powders from tanks and vessels.

Specifically lined…

View On WordPress

#Adilabad#Agriculture Industry#Bhadradri-Kothagudem#Bhoopalpally#Cement Industries#Exporter of Supplier of PTFE Lined Flush Bottom Valves#Exporter of Supplier of PTFE Lined Flush Bottom Valves in Telangana#Hyderabad#Jagtial#Jangaon#Jayashankar#Jogulamba-Gadwal#Kamareddy#Karimnagar#Khammam#Komaram Bheem Asifabad#Mahabubabad#Mahabubnagar#Mancherial#Manufacturer of Supplier of PTFE Lined Flush Bottom Valves in India#Manufacturer of Supplier of PTFE Lined Flush Bottom Valves in Telangana#Medak#Medchal#Nagarkurnool#Nalgonda. Nirmal#Nizamabad#Oil & Gas Industries#Peddapalle#PTFE Lined Flush Bottom Valves#PTFE LINED FLUSH BOTTOM VALVES in gujarat

0 notes

Text

Pipe Fittings

This chapter presents various types of pipe fittings. Of all the fittings, the elbow is the one most often used. Simply put, the elbow, or ell, is used when a pipe changes direction. Elbows can turn up, down, left, right, or any angle in between. When one finds it necessary to draw a 90° elbow or calculate how much space it will occupy in a routing configuration, knowing its length becomes essential. An elbow's length is commonly referred to as the center-to-end dimension and is measured from the centerpoint of its radius to the end of either opening. Dimensional sizes of fittings are typically provided by the manufacturer of the fitting. Manufacturers issue dimensioning charts containing lengths for a particular fitting. Another elbow that may be used under certain circumstances and with permission from the customer is the 90° short-radius elbow. The 90° short-radius ell makes a much sharper turn than does the long-radius ell.

Emissions from Pipe Fittings and Gaskets

Threaded pipe fittings in the seal flush line can be significant leak sources, with readings above 1,000 ppm.4,17 Similar emission levels may be measured near the gasket region on the seal chamber face. Any leakage from these areas may drift into the emission measurement area for the mechanical seal. The mechanical seal may then be erroneously implicated as a leaker. It should be standard practice to sniff nearby hydraulic fittings and the flange gasket area if excessive VOC concentrations are detected adjacent to the mechanical seal.

Leak-tight threaded pipe fittings can be more easily attained using anaerobic paste-type sealants rather than PTFE tape. The seal chamber face must be smooth to be emission tight. Gaskets and O-rings must be free of nicks and scratches.

32.16.2 Thermoplastic Fittings Manufacturing

Thermoplastic pipe fittings may be injection-molded, fabricated, rotomolded, or thermoformed. Injection-molded fittings are generally made in sizes through 12-in. nominal diameter. Typical molded fittings are tees, 45-degree and 90-degree elbows, reducers, couplings, caps, flange adapters, stub ends, branch saddles, service saddles, and self-tapping saddle tees. Electrofusion couplings and fittings are either made by injection molding or machined from pipe stock. Electrofusion fittings and couplings are made with a coil-like integral heating element incorporated into the fitting. Joining with other fittings uses an electrical fusion device that provides electricity into the heating element, which melts the adjacent thermoplastic material and creates a fusion-welded joint.

Larger-diameter fittings exceed the capabilities of injection molding and are typically fabricated. Rotomolding is used for the manufacture of polyethylene large-diameter (up to 60 in.) and custom fittings for polyethylene corrugated drainage piping applications.

Thermoformed fittings are made by heating a section of pipe and then using a forming tool to reshape the heated area. Examples of thermoformed fittings are sweep elbows, swaged reducers, and forged stub ends. Some polyethylene corrugated pipe fittings and appurtenances are also thermoformed.

All proprietary joints shall be made in accordance with the manufacturer’s instructions. Care shall be taken to establish satisfactory jointing techniques for all water service pipework. When making joints by welding, brazing, or soldering, precautions shall be taken to avoid the risk of fire. All burrs shall be removed from the ends of pipes and any jointing materials used shall be prevented from entering the waterways. All piping and fittings shall be cleaned internally and free from particles of sand, soil, metal filings, and chips, etc.

8.19.3 Cast iron pipes

Flexible mechanical joints shall be made in accordance with the manufacturer’s instructions.

For molten lead joints, the spigot and socket shall be centered with rings of dry yarn caulked tightly into the bottom of the spigot to prevent the entry of lead into the bore of the pipe and to prevent contact of lead with the water.

Synthetic yarns that do not promote the growth of bacteria shall be used to prevent contamination of the water. The remainder of the joint space shall be filled with molten lead (taking care that no dross enters the joint), cold wire, strip, or spun lead (lead wool). The joint shall be caulked to a smooth finish with pneumatic tools or a hand hammer of mass not less than 1.5 kg. When working with spun lead, caulking tools shall be of a thickness to fill the joint space, ensuring thorough consolidation of the material to the full depth of the socket.

Lead joints shall be finished about 3 mm inside the face of the socket.

Flange joints shall be made with screwed or cast on flanges.

8.19.4 Steel pipes

Welded joints shall not be used where a protective lining would be damaged by heat, or where the pipework is employed as a primary circulation to an indirect hot water heating system.

Screwed joints in steel piping shall be made with screwed socket joints using wrought iron, steel, or malleable double crimping fitting. A thread filler shall be used. Exposed threads left after jointing shall be painted or, where installed underground, thickly coated with bituminous or other suitable corrosion preventative agent.

Flange joints shall be made with screwed or welded flanges of steel or cast iron using jointing rings and, if necessary, a suitable jointing paste. The nuts shall be carefully tightened, in opposite pairs, until the jointing ring is sufficiently compressed between the flanges for a watertight joint.

8.19.5 Unplasticized PVC pipes

8.19.5.1 Mechanical joints

Mechanical joints in unplasticized PVC piping of sizes 2 and upwards shall be made in accordance with BS4346: Part 2, by the use of push-fit integral elastomeric sealing rings which are compressed when the plain ended pipes are inserted into the adjoining sockets. The plain pipe ends shall be chamfered and the surfaces cleaned and lubricated.

The chamfered pipe end shall be inserted fully into the adjoining socket (except where provision is to be made for expansion), or as far as any locating mark put on the spigot end by the manufacturer. The sealing rings shall comply with BS2494.

8.19.5.2 Compression joints

Compression joints shall only be used with unplasticized PVC piping of size 2 and smaller. The joints shall be of the nonmanipulative type. Care shall be taken to avoid overtightening.

8.19.5.3 Solvent cement welded joints

Solvent cement welded joints in unplasticized PVC piping shall be made using solvent cement complying with BS4346: Part 3 recommended by the manufacturer of the pipe. The dimensions of the spigots and sockets shall comply with BSEN1452: Part 1–5.

Joints may also be made using integral sockets formed in the pipes and solvent cemented.

8.19.5.4 Flanged joints

Flanged joints used for connections to valves and fittings shall use full-face flanges or stub flanges, both with corrosion resistant or immune backing rings and bolting.

8.19.5.5 Polyethylene pipes

Mechanical joints shall be either plastics or metal proprietary compression fittings, for example, brass, gunmetal, or malleable iron. These shall include insert liners to support the bore of the pipe except where the manufacturer of the fitting instructs otherwise.

To ensure satisfactory jointing of the materials from which the pipe and transition elbow are made compatibility shall be established. The manufacturer’s instructions shall be carefully followed.

No attempt shall be made to joint polyethylene piping by solvent cement welding.

Large pipe fittings and valve components must be press forged and will require extensive machining. Whereas small parts such as the flange previously described can be quickly heated and cooled, and given optimum process conditions, should exhibit microstructure and properties similar to pipe and tube, the properties of large forgings will be location and thickness dependent. While no large forged part has yet been made from 740H, the properties of a solution-annealed, water-quenched and aged 343-mm-diameter bar shown in Table 14.2 are informative. Yield strength near the surface is comparable to that of thin wall tube, but yield strength at the bar center, while meeting ASME minimum, is significantly lower. Ductility and toughness were good. A hardness traverse taken on the as quenched bar showed VHN 170 at the surface and VHN 290 at the center. This is indicative of strong auto-aging in the bar center. Because the γ′ that forms on slow cooling is relatively coarse, after the final aging treatment, the bar center will have lower strength than the surface. The microstructure and creep strength at the center of the bar has not been evaluated.

A calculated continuous cooling transformation diagram for alloy 740H is shown in Fig. 14.26. This diagram supports the notion that significant γ′ hardening will occur even during water quenching of a large forging. A cooling simulation was conducted for the bar heat treatment using DEFORM software [49]. The cooling rate at a depth of 25 mm was 315°C/min and at the bar center was 30°C/min. Based on the calculated CCT diagram, there should be about 10% γ′ in the center and no γ′ at the surface. That is consistent with the experimental results.

Filament-wound pipe fittings, such as elbows and tees have been used in the chemical, and oil industry since the 1980s.9 Traditionally, composite pipe fittings were produced manually or semi-manually, but the development of CNC winders with six or more axes has allowed automated production of pipe fittings since the 1990s. The efficiency of these advanced machines depends on methods and software to determine winding patterns and perform fabrication of the complex shape within manufacturing specifications. Winding pattern generation is particularly challenging since a substantial amount of data storage/processing is required to meet manufacturing requirements (e.g., fiber tension and full-coverage) of non-axisymmetric patterns, which are required for filament-wound elbows or tees.72 On the other hand, it is worth noting that CAM software capability, rather than hardware, is considered the limiting factor for improving the performance of automated winders of non-axisymmetric parts. Consequently, general-purpose filament winding systems for pipe fittings are currently deemed impractical due to the lack of universal mathematical models and design software for CAM.9,73 Although some progress has been made to determine closed-form solutions for efficient winding patterns on specific shapes, such as elbows,74,75 most CAM systems still implement approximate methods to design and produce specific pipe fitting geometries.73 An illustration of a software-generated winding pattern, and the resulting wound elbow, is included in Fig. 11.75

Leaking valves and pipe fittings are the next concern when pressure is dropping during a test. Test sections should be isolated at pipeline block valves by using slip blinds to insure no leakage. If the test section cannot be blinded but the valves are double blocked instead, the operator must measure pressure increase in the adjacent section between the double-blocked valves to insure a tight seal exists. You need to be careful when using a thin “fire blind” at an isolation valve because under pressure the thin blind will deform and the blind cannot be removed without removing the entire valve. This often requires calling in vacuum trucks to remove product on the opposite side of the test valve being removed.

So, leakage through valves and fittings jeopardizes the chances for a successful test and may lead to data that cannot be correlated, and in that situation, the pipeline must be retested.

Tree piping is defined as all pipe, fittings, or pressure conduits, excluding valves and chokes, from the vertical bores of the tree to the flowline connections. The piping may be used for production, pigging, monitoring, injection, servicing, or testing of the subsea tree. Inboard tree piping is upstream of the first tree wing valves. Outboard tree piping is downstream of the first tree wing valve and upstream of the flowline connector.

Tree piping is normally designed in accordance with ASME B31.3. The guidelines in the API specifications are general and, in many cases, open to interpretation. It is up to the manufacturer to apply his engineering judgment.

0 notes

Text

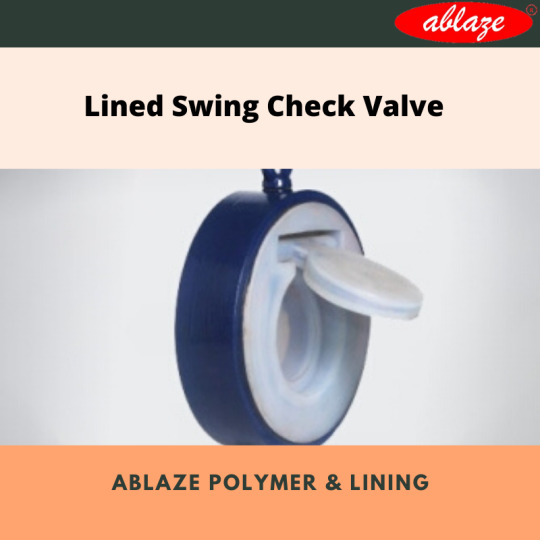

Do You Have These Products?

The industry type we are talking about will never do anything with our requirement.

Thus, it becomes a deal that we learn through and expect the things to go the way expected.

Thus, have you ever needed Lined Pipes, Fittings, Valves and other such customized products?

Do share your thoughts, and now – We are going to share the product types you should have in place for the operations to get going.

Below are the products you can directly get out from AblazeLining!

Ball Valve

Ball Check Valve

Butterfly Valve

Lined Globe Valve

Diaphragm Valve

Flush Bottom Valve

Lined Swing Check Valve

Plug Valve

Full View Sight Glass

Double Window Type Sight Glass

Dip Pipe

PTFE Stirrer & Agitators

Feed Pipe

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined EQUAL TEE

Lined Concentric Reducer

Lined Equal Cross

Lined Unequal Cross

Lined Blind Flanges

Solid Spacer

Lined Spacer

If you are the person and need these products to conducting business operations at an ease, just make sure that you are switching to Ablaze Lining! They have been a leading and trustworthy Lined Pipes, Fittings, Valves and Customized Products’ manufacturer and supplier. They will also manage to serve you as per your requirement and needs. Make sure that you are filling in their contact form, and get to the every detail they have mentioned on their website. It will ensure you are having everything you need to have reasonable decision in place. On top of everything – They have served countless customers and always ensure the requirements clients use their products for taking on everything in the best possible manner. So, visit the recommendation for sure!

Final Thoughts

Thus, in case you are still looking for the Lined Swing Check Valve Manufacturer, the recommendation we talked about will do the best.

Just ensure to stick with the guide and take it as a reference.

These are the products we shared are what Ablaze Lining offers!

On a sweeter note – Thanks for the read, though!

0 notes

Text

The Best Thing You Will Learn About PTFE Lined Pipes & Fittings Is This

www.ablazelining.com

The Best Thing You Will Learn

About PTFE Lined Pipes & Fittings Is This

We do not want this guide to be super technical, though!

However, it becomes an important subject to discuss about PTFE Lined Pipes and Fittings at the same time.

We have the questions up and ready – Are you the user of PTFE Lined Pipes & Fittings?

Are you the person who uses Fluoropolymer Lined Products for different projects?

If this is what you are into the category of, this is the guide for you.

We will ensure that you learn basics and keep the checklist at hand before purchasing PTFE Lined Pipes & Fittings or Fluoropolymer Lined Products.

So, let’s get started!

Ø One of the best things you would ever come across to is the Quality of PTFE, PFA, PVDF or any Fluoropolymer Used for Lining

Ø The second thing that is imperatively important to take note of is Base Metal Quality & Finishing

Ø Thus, there’s some the Quality Of Welding & Fabrication

Ø Last, but not the least – Dimensional Accuracy

P.S. Well, are you looking forward to purchasing Lined Reducing Flange Supplier in India? Do you want to get in touch with Diaphragm Valve Supplier & Manufacturer at the same time? If this is what you are considering right now, then get in touch with Ablazelining.com since they also serve their customers with Flush Bottom Valve in Ahmedabad, and across India. Do contact them, today!

Final Thoughts

So, what are your thoughts about the guide which we just discussed?

Did you like the recommendation which we just shared?

We want our readers to comment below and share their thoughts for sure!

In the same regards – Do also share if it has become super easy to get through and purchase quality PTFE Lined Pipes & Fittings in India?

And, on a sweeter note – Thanks for the read, though!

#Lined Reducing Flange supplier in india#tee in Vadodara#Diaphragm Valve supplier and manufacturer#Lined Reducing Flange manufacture in Gujarat#lined reducing flange manufacture in Ahmedabad#Dip Pipe supplier in india#Dip Pipe manufacturer#Flush Bottom Valve#Flush Bottom Valve in india#vadodara#baroda#gujarat#india#manufacture#ball valve supplier in india#deler

0 notes

Link

For Ointment - Cream - Lotion - Paste etc. Manufacturing

With Double Stirrer, Scrapper & Centrally Located High Speed Emulsifier

Special Feature

• Range of models to suit gross volume 60, 100, 140, 200, 350, 600, 1000, 1500 & 2500 Liters for OINTMENT - CREAM - LOTION - PASTE - TOOTH PASTE.

• All contact parts are made out of S.S.304 quality material. (SS316 provided on demand on extra cost)

• Compact design requires comparatively smaller floor space.

• Lowering and lifting movement achieved through motorized drive in 140 & 200 liters model & hydraulic lifting system from 350 liters to 2500 liters size models. (In 60 & 100 liters models product container moving up & down manually. Motorised system can be provided on demand on extra cost, if required.) In all other bigger size models product container remain fixed and mixing drives comes up and down by means of mechanical or hydraulic system.

• Castore wheel mounted product container for the ease of mobility. (This facility available from 60 liters to 350 liters model only.)

• Container with fixed legs above 350 Liters model. Hence no facility of mobility of container.

• A high-speed emulsifier (Homoginizer) will be provided at the center axis, in 140 liters model and above capacity model only. (It can be interchangeable with disperser & necessary assembly provided with m/c)

• In-Line Homoginizer also provided on demand, if required.

• Double stirrer & SS scraper with PTFE blades for better mixing of the material. ( In 140 Liters & above model only )

• Single stirrer with scrapper in 60 & 100 Liters model.

• Planetory motion of the stirrer ( beaters ) enables faster and better mixing of the material at a considerable lesser time.

• As stirrer is a top driven and sealing doesn't comes in contact with product, there isn't any black particle contamination problem.

• Water / steam circulation jacket for mixing bowl, to heat or cool the mix during operation in OINTMENT MIXER only. (Water jacket recommended only in 60 to 350 liters model. Steam heating recommended in 600 litres to onward all models. Jacket also made out of mild steel in Standard Model & SS304 in GMP Model.)

• All non contact parts (general structure) made out of mild steel and claded with SS304 or chrome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model.

• General structure & all non contact parts are made out of Mild Steel & same wil painted in Standard Model.

• Fixed type product container in 600 litres and above capacity models.

• Heater with temperature controller for heating facility. (For 60 / 100 / 200 / 350 litres OINTMENT MIXER only)

• 100 % utilisation of machine can be possible due to facility of change of extra product container.

(In 60 to 350 litres model only)

• Vacuum facility provided on demand for de airation during mixing in Gel product. (For OINTMENT MIXER only)

• Insulation will be provided on jacket of container. (For OINTMENT MIXER only ) as a optional facility.

• Material discharge from bottom. Flush bottom valve provided for material discharge in 350 litres

and above model only. (For OINTMENT MIXER only)

• M/C provided with Light glass, Sight glass , material inlet, air suction valve for vacuum, CIP port facility. (For OINTMENT MIXER only)

• All connection of valve, light glass, sight glass will be triclover ended.

• Sampling port provided in 600 litres & above model.

• Flush bottom type valve in 600 litres & above model.

• All moving parts are enclosed with safety guards.

Optional

• SS316 product contact parts instead of SS304.

• Vacuum system for deairation during mixing. (For gel products)

• Variable speed drive for main agitators motor and emulsifier motor.

• Vacuum Pump Set.

• Flameproof model.

• "PLC" based operating panel for automation.

• Hydraulic lifting system in 60 to 200 litres model, instead of mechanical lifting system.

Application

Ideal for mixing of Pharmaceutical powders, ointments, creams, lotions, pastes, tooth paste, cosmetics, food and confectioneries, rubber and rubber compound, colours and pigments, PVC & plastic material, ceramics, pesticides, insecticides, adhesives, metal powder, resins etc. etc.

0 notes

Text

PTFE Lined Flush Bottom Valve Supplier in Punjab

PTFE Lined Flush Bottom Valve Supplier in Punjab:

Flowline Valve:

Flowline Valve is a manufacturer and supplier of PTFE Lined Flush Bottom Valve in Punjab, India.

Specializing in various PTFE lined valves, the company offers a comprehensive range of products including ball valves, butterfly valves, plug valves, diaphragm valves, check valves, sampling valves, flush bottom tank valves, and…

View On WordPress

#Adampur#Amritsar#Banga Rural#Bassi Pathana#Batala#Bathinda#Doraha#Exporter of PTFE Lined Flush Bottom Valve#Faridkot#Fatehgarh Sahib#Firozpur#Gurdaspur#Hoshiarpur#India#Jalandhar#Kapurthala#Khamanon#Khanna#Ludhiana#Malerkotla#Mansa#Manufactureer of PTFE Lined Flush Bottom Valve#Manufacturer#Nawanshahr#Pathankot#Patiala#Phillaur#PTFE LINED FLUSH BOTTOM VALVE#PTFE Lined Flush Bottom Valve Supplier in Punjab#Rajpura

0 notes

Text

PTFE Lined Flush Bottom Valve Supplier in Hyderabad

PTFE Lined Flush Bottom Valve Supplier in Hyderabad:

Company Overview:

Flowline Valve, a Karnataka, India-based manufacturer and supplier, specializes in the production of PTFE Lined Flush Bottom Valves for diverse industrial applications.

Product Overview:

Dedicated to manufacturing high-quality PTFE Lined Flush Bottom Valves.

Notable attributes include accurate dimensions, robust…

View On WordPress

#Bhongir#Exporter#Hyderabad#India#Jagtial#Jangaon#Kamareddy#Karimnagar#Khammam#Mahbubnagar#Mancherial#Manufacturer#Miryalaguda#Nalgonda#Nizamabad#PTFE LINED FLUSH BOTTOM VALVE#Ramagundam#Siddipet#Supplier#Suryapet#Telangana#Wanaparthy#Warangal

0 notes

Text

PTFE Lined Flush Bottom Valve Supplier in India

PTFE Lined Flush Bottom Valve Supplier in India:

Flowline Valve:Flowline Valve is a Manufacturer and Supplier of PTFE Lined Flush Bottom Valve Supplier in Ahmedabad, Gujarat, India.

PTFE (Polytetrafluoroethylene) lined flush bottom valves are an essential component in industries where the handling of corrosive, viscous, or hazardous fluids is routine. These valves provide a reliable and…

View On WordPress

#Ahmedabad#Anand#Ankleshwar#Bangalore#Chennai#Delhi#Gujarat#Haridwar#India#Jamnagar#Kolkata#Manufacturer#Nagpur#Naroda#PTFE LINED FLUSH BOTTOM VALVE#Rajkot#Supplier#Surat#Vadodara

0 notes

Text

PTFE Lined Flush Bottom Valve Manufacturer in Ahmedabad

PTFE Lined Flush Bottom Valve Manufacturer in Ahmedabad

PTFE Lined Flush Bottom Valve Manufacturer in Ahmedabad:

We have a large selection of PTFE-lined flush bottom valves. We manufacture high-quality items that meet domestic and international requirements. We have our own production plant and a highly experienced and knowledgeable crew.

We manufacture a wide selection of 2pc design ball valves. Manual lever, gear, and actuator operation.

The…

View On WordPress

#PTFE Lined Flush Bottom Valve Manufacturer in Ahmedabad#PTFE Lined Flush Bottom Valve Manufacturer in Asarva#PTFE Lined Flush Bottom Valve Manufacturer in Bakrol#PTFE Lined Flush Bottom Valve Manufacturer in Chandkheda#PTFE Lined Flush Bottom Valve Manufacturer in Chattral#PTFE Lined Flush Bottom Valve Manufacturer in Daskroi#PTFE Lined Flush Bottom Valve Manufacturer in Dhandhuka#PTFE Lined Flush Bottom Valve Manufacturer in Dholka#PTFE Lined Flush Bottom Valve Manufacturer in Kalol#PTFE Lined Flush Bottom Valve Manufacturer in Kathwada#PTFE Lined Flush Bottom Valve Manufacturer in Kerala#PTFE Lined Flush Bottom Valve Manufacturer in Naroda#PTFE Lined Flush Bottom Valve Manufacturer in Odhav#PTFE Lined Flush Bottom Valve Manufacturer in Rakhiyal#PTFE Lined Flush Bottom Valve Manufacturer in Sanand#PTFE Lined Flush Bottom Valve Manufacturer in Singarva#PTFE Lined Flush Bottom Valve Manufacturer in Vani#PTFE Lined Flush Bottom Valve Manufacturer in Vatwa#PTFE Lined Flush Bottom Valve Manufacturer in Viramgam

0 notes

Text

PTFE Lined Flush Bottom Valves Supplier in India

PTFE Lined Flush Bottom Valves Supplier in India:

Flowline Valve:Flowline Valve are Manufacturer and Supplier of PTFE Lined Flush Bottom Valve Supplier in Ahmedabad, Gujarat, India.

PTFE lined flush bottom valves are specialized valves designed with a unique flush-mounted design to ensure complete drainage and minimize dead space inside process vessels. They feature a lining of…

View On WordPress

#Aandhra Pradesh#Ahmedabad#Amreli#Anand#Ankleshwar#Arunachal Pradesh#Assam#Bangalore#Bhachau#Bhalla#Bharuch#Bhavnagar#Bhuj#Bihar#Chennai#Chhatisgarh#Dadra Nagar Haveli#Dahej#Daman#Deesa#Delhi#Gandhinagar#Gujarat#Haridwar#Himmatnagar#Jamnagar#Jharkhand#Junagarh#Kadi#Kalol

2 notes

·

View notes

Text

Supplier of PTFE Lined Sampling Valve in Maharashtra

Flowline Valve:

Flowline Valve is a manufacturer and Supplier of PTFE Lined Sampling Valve in Maharashtra, India.

We specialize in manufacturing various PTFE lined valves, including ball valves, butterfly valves, plug valves, diaphragm valves, check valves, sampling valves, flush bottom tank valves, and globe valves.

We are an ISO 9001:2015 certified company, ensuring the quality and…

View On WordPress

#Ahmednagar#Akola#Amravati#Aurangabad#Bhandara#Bhusawal#Buldhana#Chandrapur#Daulatabad#Dhule#Exporter of PTFE Lined Sampling Valve#India#Jalgaon#Kalyan#Karli#Kolhapur#Mahabaleshwar#Maharashtra#Malegaon#Manufacturer#Manufacturer of PTFE Lined Sampling Valve in Maharashtra#Matheran#Mumbai#Nagpur#Nanded#Nashik#Osmanabad#Pandharpur#Parbhani#PTFE Lined Sampling Valve

0 notes

Text

PTFE Lined Sampling Valve in Maharashtra

Flowline Valve:

Flowline Valve is a manufacturer and supplier of PTFE Lined Sampling Valve in Maharashtra, India.

We specialize in manufacturing various PTFE lined valves, including ball valves, butterfly valves, plug valves, diaphragm valves, check valves, sampling valves, flush bottom tank valves, and globe valves.

We are an ISO 9001:2015 certified company, ensuring the quality and…

View On WordPress

#Ahmednagar#Akola#Amravati#Aurangabad#Bhandara#Bhusawal#Buldhana#Chandrapur#Chemical Processing Plants#Daulatabad#Dhule#Exporter of PTFE Lined Sampling Valve#Food and Beverage Processing#Jalgaon#Kalyan#Karli#Kolhapur#Laboratory and Analytical Testing#Mahabaleshwar#Malegaon#Manufacturer of PTFE Lined Sampling Valve#Matheran#Mumbai#Nagpur#Nanded#Nashik#Osmanabad#Pandharpur#Parbhani#Petrochemical Plants

0 notes

Text

PTFE Lined Flush Bottom Valves

Flowline Valve, based in Ahmedabad, India, specializes in manufacturing and supplying PTFE Lined Flush Bottom Valves for industrial applications.

Flowline Valve offers a comprehensive range of PTFE Lined Flush Bottom Valves, known for their accurate dimensions, robust construction, and corrosion resistance.

These valves are designed for flush tanks, mounted at the tank’s bottom, and are…

View On WordPress

#Badami#Ballari#Belagavi#Bengaluru#Bhadravati#Bidar#Chikkamagaluru#Chitradurga#Davangere#Exporter#Halebid#Hassan#Hubballi-Dharwad#India#Kalaburagi#Karnataka#Kolar#Madikeri#Mandya#Mangaluru#Manufacturer#Mysuru#PTFE Lined Flush Bottom Valves#Raichur#Shivamogga#Shravanabelagola#Shrirangapattana#Supplier#Tumakuru#Vijayapura

0 notes

Text

Supplier of PTFE Lined Butterfly Valve in Jharkhand

Flowline Valve is a Manufacturer, Exporter and Supplier of PTFE Lined Butterfly Valve in Jharkhand.

We are Specialize for PTFE Lined Industrial Valves, Ball Valve, Plug Valve, Globe Valve, Diaphragm Valve, Butterfly Valve, Swing Check Valve, Ball Check Valve, Sampling Valve, Flush Bottom Valve, Pipes & Fittings, Pipes (jacketed/non Jacketed), Elbow (45° / 90°), Equal Tee/unequal Tee, Instrument…

View On WordPress

0 notes

Text

PTFE Lined Flush Bottom Valve Supplier in Karnataka

PTFE Lined Flush Bottom Valve Supplier in Karnataka:

Flowline Valve:Flowline Valve, a manufacturer and supplier based in Karnataka, India, specializes in producing PTFE Lined Flush Bottom Valves for diverse industrial applications.

Product Overview:With extensive market experience, Flowline Valve dedicates itself to manufacturing and supplying a comprehensive range of PTFE Lined Flush Bottom…

View On WordPress

#Badami#Ballari#Belagavi#Bengaluru#Bhadravati#Bidar#Chikkamagaluru#Chitradurga#Davangere#Exporter#Halebid#Hassan#Hubballi-Dharwad#Kalaburagi#Karnataka#Kolar#Madikeri#Mandya#Mangaluru#Manufacturer#Mysuru#PTFE LINED FLUSH BOTTOM VALVE#Raichur#Shivamogga#Shravanabelagola#Shrirangapattana#Tumakuru#Vijayapura

0 notes

Text

PTFE Lined Flush Bottom Valve Supplier in Gujarat

PTFE Lined Flush Bottom Valve Supplier in Gujarat:

Flowline Valve:Flowline Valve are Manufacturer and Supplier of PTFE Lined Flush Bottom Valve Supplier in Ahmedabad, Gujarat, India.

PTFE Lined Flush Bottom Valves efficiently discharge solids-laden or viscous fluids from tanks, reactors, and other vessels. They are particularly useful in applications where complete drainage and product recovery…

View On WordPress

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Dahod#Deesa#Gandhidham#Gandhinagar#Godhra#Gondal#India#Jamnagar#Jetpur#Junagadh#Manufacturer#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#Porbandar#PTFE LINED FLUSH BOTTOM VALVE#Rajkot#Supplier#Surat#Surendranagar

0 notes