#Dip Pipe manufacturer

Text

#Teflon Lined Pipes#Concentric Eccentric Reducers#PTFE Slide Bearings#PTFE Lined Pipes#PTFE Expansion Joints#PTFE Pipes And Fittings#Lined Pipe Fittings#Lined Pipe Manufacturers#Sparger Manufacturer In India#Dip Pipes Suppliers#PTFE Lined Pipe Manufacturer#PTFE Lined Pipe Suppliers#PTFE Lined Pipes and Fittings#PFA molded fittings near me

1 note

·

View note

Text

PTFE Lined Dip Pipe Manufacturer in India

PTFE Lined Dip Pipe Manufacturer in India

We provide a large selection of PTFE lined dip pipes. We manufacture high-quality items that meet domestic and international requirements. We have our own manufacturing facility and a well-experienced and knowledgeable crew.

The minimum liner face (R/F) thickness should be 80 per cent of the liner thickness. The PTFE-lined dip pipes come with a free flange on one end and a fixed flange on the…

View On WordPress

#PTFE Lined Dip Pipe Manufacturer in Ahmedabad#PTFE Lined Dip Pipe Manufacturer in Amritsar#PTFE Lined Dip Pipe Manufacturer in Anand#PTFE Lined Dip Pipe Manufacturer in Banglore#PTFE Lined Dip Pipe Manufacturer in Baroda#PTFE Lined Dip Pipe Manufacturer in Bhavnagar#PTFE Lined Dip Pipe Manufacturer in Bhuj#PTFE Lined Dip Pipe Manufacturer in Chattral#PTFE Lined Dip Pipe Manufacturer in Chennai#PTFE Lined Dip Pipe Manufacturer in Delhi#PTFE Lined Dip Pipe Manufacturer in Faridabad#PTFE Lined Dip Pipe Manufacturer in Gujarat#PTFE Lined Dip Pipe Manufacturer in Haridwar#PTFE Lined Dip Pipe Manufacturer in Hyderabad#PTFE Lined Dip Pipe Manufacturer in India#PTFE Lined Dip Pipe Manufacturer in Kadi#PTFE Lined Dip Pipe Manufacturer in Kalol#PTFE Lined Dip Pipe Manufacturer in Kutch#PTFE Lined Dip Pipe Manufacturer in Mumbai#PTFE Lined Dip Pipe Manufacturer in Nagpur#PTFE Lined Dip Pipe Manufacturer in Nashik#PTFE Lined Dip Pipe Manufacturer in Pune#PTFE Lined Dip Pipe Manufacturer in Surat#PTFE Lined Dip Pipe Manufacturer in Valsad#PTFE Lined Dip Pipe Manufacturer in Vapi

0 notes

Text

[ID: One puffy circle of bread, and three which have been halved to show an internal pocket, on a striped blue and white kitchen towel. End ID]

خبز الكماج / Khubiz al-kmaj (Palestinian flatbread)

Khubiz al-kmaj is a thin flatbread with an internal pocket. It is commonly eaten with breakfast to scoop up dips such as hummus, used to eat stews, served alongside main dishes, and used to make sandwiches and to wrap falafel. "خُبْز," pronounced "khubz" or (in Levantine varieties of Arabic) "khubiz," comes from the root خ ب ز (kh-b-z), which also produces the word "خَبَزَ" "khabaza" (Levantine: "خَبَز" "khabaz"), "to bake."

This bread is eaten across the Levant and in Greece, with slight differences in terminology and style. It is variously called "خُبْز العَرَبِيّ" (khubz al-'arabiyy; Arabian bread), "خُبْز "البَلَدِيّ (khubz al-baladiyy; bread from my country), or (occasionally) "خُبْز البيتة" or "البيتا" (khubz al-bita), a borrowing from "pita." ("Pita" itself is perhaps from Greek "πίτα" "pita," or the modern Hebrew "פיתה.") The bread is referred to as "khubiz al-kmaj" in Palestine, from the Turkic "kömeç" / كُمَجْ ("bread baked in ashes"). The collective term for the bread in general is كماج (kmāj); each individual piece of bread is referred to with the singulative "كماجة" (kmāja).

Today, kmaj is frequently made with white flour; some people add olive oil or milk powder to ensure a very soft dough. Leila el-Haddad writes that a more traditional method omits milk and uses whole white spring wheat, a whiteish wheat grain harvested in late spring and ground without removing the bran.

Since the late 20th century, many Palestinian households have used an electric cooker (طنجرة الكهرباء; ṭanjara al-kahrabā') to cook kmaj, placing one kmaja inside of the chamber and one on top and allowing both to bake at the same time. These aluminum and tin cookers, which were invented in Gaza and became popular there during the first intifada in the late 1980s, are designed to route electricity through a metal pipe or spiral wire on the underside of their lids, heating both the top and the inside of the cooker simultaneously.

The cookers' popularity can be attributed in part to a curfew that Israel imposed on Gazan refugee camps during the intifada, supposedly in an attempt to restrict the movements of resistance fighters. Refugees in the Jabalia camp in the north, for example, unable to afford home stoves, and without the necessary outdoor space to make familial clay ovens, would have to wait in line for hours every day to get bread from shared ovens, risking curfew violations; household electric cookers were far more convenient. The success of local industry and innovation in the form of Gazan-manufactured technology was also symbolically and strategically important during the first intifada, in which Palestinians employed strikes and boycotts (largely organized by women) of Israeli companies and goods as a strategy of resistance to occupation.

An electric cooker is still today considered a very important tool, as it spares families the need to purchase kmaj (the price of which was soaring compared to the cost of flour in the 2010s, and which was often of inferior quality compared to what could be made at home). They are frequently given as wedding or housewarming presents. Lack of access to electricity, though, imposes a limiting condition on the usage of these cookers, as Israel has for over a decade strangled the flow of power to Gaza: Abier Almasri wrote in 2017 that tasks such as cooking and laundry had to be rushed during the four or so hours a day when electricity was available. In this environment, electric cookers are useful in that they can prepare a lot of bread in a short period of time. Fathia Radwan said in 2022 that she would wake up early, after the nightly power outage, to prepare more than 100 loaves of bread at a time for her family of nine.

Today, the taxes that Israel levies on imports of raw materials into Gaza makes the cost of new electric cookers, which sometimes exceeds 120 shekels (37 USD), too expensive for some families to afford. The difficulty and expense of importing materials, and the impossibility of exporting goods to foreign markets with the advent of the 2007 siege, also limit the number of factories in Gaza that are able to manufacture these cooking pots. The aluminum industry, introduced to Gaza in the 1960s and once the basis of a manufacturing and economic renaissance in the region, deteriorated as a result of the siege, as factories were no longer able to export goods to the West Bank and were newly reliant on imports of raw materials from Egypt. Even parts to repair electric cookers are expensive, due to a tax levied on items judged by Israel to have a "dual," i.e. a possible civilian and military, use.

Still, repairman Iyad Faraj estimates that over half the homes in Gaza have and use an electric cooker, as maintaining, repairing, and operating one is cheaper than having a gas pipe installed (at 68 shekels, 20 USD) and purchasing gas. Electric pots thus stand in many homes as both a utilitarian item, and a symbol of Palestinian ingenuity and resistance to Israel's attempts at impoverishment and starvation.

Support Palestinian resistance by contributing to Palestine Action’s bail fund or to Palestine Legal’s defence fund, by attending court or making a sign to support the Elbit Eight, or by buying an e-sim for distribution in Gaza.

Ingredients:

500g (4 cups + 3 Tbsp) white whole wheat (spring) flour

1/2 Tbsp (5g) active dry yeast

1/2 Tbsp (6.25g) vegetarian granulated sugar

1/2 Tbsp (7.25g) kosher salt

About 2 1/4 cups (530mL) room-temperature water, divided

Olive oil

White whole wheat flour is flour that has a white color once ground, despite the fact that it includes both the bran and the germ of the wheatberry. It is milled from white spring wheat (so named because it is harvested in late spring).

You may instead mix white all-purpose flour and brown whole wheat flour in your desired proportion. Keep in mind that whole wheat flour will need more water and more kneading than white flour. If you’re using all white flour, you will need about 1 1/4 cup (300mL) water.

Instructions:

1. Mix flour, yeast, sugar, and salt in a large mixing bowl. Add water gradually until dry ingredients come together into a sticky dough.

2. Knead the dough on the countertop or in a wide, shallow bowl until smooth, about 5 minutes. (If using whole wheat or white whole wheat flour) continue incorporating water into the dough as you knead to maintain a tacky texture.

3. Fold the dough into a ball and return to the bowl, seam-side down. Pat the top of the dough with some olive oil, cover the bowl, and let rise for an hour.

4. Pinch the dough into about 8 balls of equal size (about 110g each). Cover and let rest for 10 minutes.

5. On a lightly floured surface, roll out each ball of dough into a circle about 1/4" (1/2cm) in thickness. Set dough circles on a surface prepared with parchment paper and cover closely with a kitchen towel or plastic wrap. Let rest and ferment for at least 1 and up to 10 hours.

An overnight rest is traditional in Palestine and will create a more complex flavor in the bread (see note below).

6. Remove each circle of dough from its resting place with a metal spatula and roll it out to a 1/4” thickness again. Preheat a baking stone or sheet in the top third of an oven at 500 °F (260 °C), and then cook breads in the oven for three minutes, until large bubbles have begun to form.

7. Flip bread over and cook for another 3 minutes on the other side, until golden brown and puffed up completely.

8. Wrap breads in a kitchen towel or tea towel and allow to steam for a few minutes while the others cook.

Notes

The climate where I live is dry enough that I have discovered a risk of my breads becoming crackers if I leave them out overnight. The dried-out flatbread does puff up in the oven, but the resulting product is not as nice and fluffy as it should be.

Through experimentation, I have found the best method of both preventing drying out and guaranteeing that the flatbreads will puff up during cooking the next day is:

1. Roll out the dough and place dough circles on a lightly oiled surface. Cover them closely with lightly oiled plastic wrap.

2. The next day, fold dough circles back into balls. Place seam-side down and roll out again on a lightly floured surface.

3. Bake as described above.

If you live in a humid environment, the first instructions given in the recipe above should work for you.

422 notes

·

View notes

Text

Best Dab/Wax Pens of 2024 + New User Guide

All dab pens have a similar anatomy- a battery, chamber, and mouthpiece. The main difference is in the coil design. Dab pens can have a "coil-less" bowl where the heat is generated under the bowl and heats the dabs indirectly, or "exposed coils" which have a heating wire wrapped around a center rod and heat up the dabs by direct contact.

The two different coil types cater to the two different groups of dab users- the soft and flavorful vs. the harsh and potent. The first group is looking for a mild experience that highlights every terpene of their delicious solventless rosin, and the second group is looking for high-temp dabbing that provides an experience closer to traditional dabbing with harsh vapor and a strong throat hit.

I fall into the first group more than the second, but regardless, I understand that different users have different preferences, and I will list options for both types of users.

Notes:

Some of these vapes were sent to me for free by the manufacturer for reviews, which I publish on my website- vapeguy.com

Links are affiliate. Thanks for supporting.

Full list of coupons can be found here- https://vapeguy.com/coupon-codes/

"Soft and flavorful."

The Puffco Plus has a built-in ceramic dab tool that can be used to scoop a tiny amount. Screwing the mouthpiece back will position the dab right in the center of the coil so it melts in as soon as you activate the heat. It has three temperature levels, and you can hold it for manual heat or double-click for a ten-minute session. The flavor is good, and this pen is dead simple to use.

The cons of the Plus are-

The chamber is on the small side. Load a tiny amount and be careful not to overfill it.

It uses a 510 charger instead of the more modern and accessible USB-C.

The Puffco Plus retails for $89 from vape-smart.com, and you can use coupon code TVG10 for 10% off.

The Gpen Mirco+ is slightly shorter than the Puffco, has three temp levels, and while it doesn't have a built-in dab tool like the Puffco, it features the much preferred USB-C charger plug.

It also has a microchip that regulates the temperature in the bowl, ensuring the concentrate does not overheat. It has great vapor quality, and at $75, it is a really solid option.

GPen Micro Plus retails for $75 directly from G-Pen and you can use coupon code TVG20 for 20% discount.

"Strong & harsh"

Tronian Gammatron & Utillian 5- Both vapes have a heating wire wrapped around a center red. These get "red hot" very quickly and create a nail-like experience.

The Utillian is thicker and heavier, and it has adjustable airflow and four temperature levels. The Tronian has a built-in wax container and three temperature levels. Both vapes also have a dab tool built into the mouthpiece, but just a heads up, the one of the Utillian 5 is fragile and can break easily. I already broke one. Utillian also sells a compatible water bubbler that sits on top and adds water filtration for more comfortable consumption.

Both vapes are very good options, but I will give a slight edge to the Tronian. They are available from vape-smart.com and you can use coupon code TVG10 for 10% disount.

Hybrid or dual-use vapes

The Ooze Booster has three temp levels and a coil that looks like a spongy stone that soaks up the wax and vaporizes it. The bottom has a 14mm adapter, so it can easily power any existing rig, replacing the old-school nail and torch setup. Read my full review here.

The XMAX Riggo is not a dab pen, but it functions the same way. It has a similar coil and can be used as a dry pipe or used with the included adapter to connect to a bubbler. It has four temp levels and, interestingly enough, can be used with 510 carts as well. Vapor quality is pretty good, considering the $60 price tag. Read my full review here.

The Boundless Terp Pen is a dab straw. Instead of loading dab into the coil, you dip the coil directly into the container. This consumption method means zero wastage and ultimate control over how much vapor you're getting. By moving the coil closer or further away, you have fine control over the experience.

The Boundless also has a built-in wax container, so you can take around a quarter of a graham to go, three temp levels, and a tapered rim that will fit bubblers as well. Read my full review here.

I think that basically covers the available options. Do you have any suggestions? Which vape pens should be added and why?

2 notes

·

View notes

Text

GALVA-PRO GALVANİZ , Türkiye'de kimyasal havuz tankları üreticilerinden birisidir. Ayrıca sıcak daldırma galvaniz tesisleri ve boru yüzey hazırlama tesisleri için tedarikçi firma rolündedir.

Tanklarımız avrupa kaynak normlarına sıkı sıkıya bağlı kalır ve üstün kaliteli tanklar üretir.

GALVA-PRO GALVANİZ Günün her saati teknik destek hizmeti sunmaktadır.

ℹ️

GALVA-PRO GALVANIZ is one of the manufacturers of chemical pool tanks in Turkey. It also acts as a supplier for hot dip galvanizing facilities and pipe surface preparation facilities.

Our tanks adhere strictly to European welding norms and produce premium quality tanks.

GALVA-PRO GALVANIZ provides technical support around the clock.

____________________________________

Firmamız sıcak daldırma galvaniz , yüzey işlem ekipmanlarında Türkiye’de tek elden üreticisi olup

müşterilerimizin özel taleplerine uygun makine tasarımı ve imalatı yapmaktadır.

🇹🇷🇩🇪🇺🇸🇦🇺🇦🇹🇧🇪🇦🇿🇦🇪🇧🇾🇬🇧🇧🇷🇨🇿🇫🇷🇬🇭🇰🇷🇳🇱🇮🇳🇭🇷🇸🇪🇨🇭🇨🇦🇮🇹🇮🇶🇮🇷🇯🇵🇶🇦🇰🇿🇳🇴🇵🇹🇵🇱🇷🇺

Our company is a one-stop manufacturer of hot-dip galvanizing and surface treatment machines in Turkey.

We design and manufacture machines according to the special demands of our customers.

#galvaprogalvaniz#galvanized#galvaniz#galvanizing#turnkeyprojects#turnkeyhotdipgalvanizing#industry#crane#Demir#Çelik#fabrika#galvanização#galvanisieren#hdg#Galvanisierung#machine#makine#çinko#zinc

2 notes

·

View notes

Text

Best Copper Earthing Electrode Manufacturer in India

Veraizen Earthing is a leading copper earthing electrode manufacturer in India. Copper Earthing Electrodes are also made from Hot Dip Galvanized Pipes, with a copper termination and a 20 mm copper inside.Copper Earthing Electrodes Suppliers provides pure copper earthing electrodes in the following sizes: electrogrip 60mm 3 meter, electrogrip 40mm 3 meter, electrogrip 50mm 3 metre, electrogrip 80mm 3 metre, electrogrip 90mm 3 metre, and electrogrip 40mm 2 metre. To assure great quality, these Copper Earthing Electrodes are made using cutting-edge technology and high-grade materials.

The best copper earthing electrode supplier in India is Veraizen Earthing.We have built a solid reputation in both the local and international markets by employing high-quality products like Copper Earthing Electrode and adhering to strong company ethics. We deliver anywhere in the world. Our loyal customers prefer them because of their low cost and long lifespan. We also produce and sell the following items: Earthing Rod, Earth Rod, Solar Earthing, Solar Earth Rod, Copper Bonded Solid Electrode, and Chemical Earthing. We Supply Lightning Arrester Manufacturers in Mumbai and Lightning Arrester Manufacturers in Kolkata.

#Copper Earthing Electrodes manufacturers in india#Copper Earthing Electrodes Supplier in india#Copper Earthing Electrodes Suppliers#Lightning Arrester Manufacturers in Mumbai#Lightning Arrester Manufacturers in Kolkata

0 notes

Text

Understanding Mild Steel's Susceptibility to Corrosion and Protection Methods

Because of its affordability, ease of manufacture, and versatility, mild steel—also known as carbon steel—is used extensively in a variety of sectors. Its composition is mostly composed of carbon and iron. However, its vulnerability to corrosion is one of its major disadvantages. We will examine the varieties of mild steel corrosion, the causes that contribute to it, and practical ways to prevent it in this overview.

Factors Contributing to Corrosion:

Chemical Composition: When mild steel is exposed to oxygen and moisture, its composition—which consists mainly of iron and carbon—makes it susceptible to corrosion. Corrosion is caused by an oxygen-carbon reaction in the steel that results in iron oxide, or rust.

Environmental Factors: Pollution, salt, dampness, and humidity all hasten the corrosion process. More serious corrosion problems arise for industries that are situated near the shore or in places with high air pollution levels.

Microbial Activity: By generating corrosive byproducts or fostering an atmosphere that encourages corrosion, microorganisms like bacteria and fungus can hasten the process of corrosion.

Types of Corrosion:

Uniform Corrosion: This kind of corrosion spreads evenly over the mild steel's surface, causing rust to develop everywhere that is exposed. It frequently happens in settings where oxygen and moisture are continuously present

Pitting Corrosion: This type of corrosion causes tiny pits or craters to appear on the metal surface due to localized damage. It can cause structural flaws and is especially dangerous because it may go undetected until serious harm has been done.

Galvanic corrosion: In the presence of an electrolyte, like saltwater, galvanic corrosion happens when mild steel comes into contact with a dissimilar metal. This initiates an electrochemical reaction that speeds up the galvanic couple's mild steel, which is the less noble metal, from corroding.

Protection Methods:

Surface Coatings: By putting on protective coatings like paint, enamel, or powder coating, mild steel is shielded from the corrosive environment and kept out of direct contact with oxygen and moisture. To find and fix any coating damage, regular inspections and maintenance are required.

Galvanization: Hot-dip galvanizing or electroplating mild steel is two methods used to cover it with a layer of zinc. As a sacrificial anode, zinc corrodes steel beneath it more quickly in order to shield it. Fences, roofing, and structural elements are among the outdoor applications that frequently use galvanized mild steel.

Cathodic Protection: Cathodic protection is the process of joining mild steel to an impressed current system or a sacrificial anode, which is typically magnesium or zinc. This keeps the steel from corroding and maintains its integrity. Storage tanks, marine buildings, and subterranean pipes are common applications for cathodic protection.

Compounding Factors: Copper, nickel, and chromium are examples of alloying elements that can be added to steel to improve its resistance to corrosion. For instance, the chromium in stainless steel creates a passive oxide layer that shields the material from corrosion.

Appropriate Design and Maintenance: You may reduce the danger of corrosion by designing structures to retain less moisture, encouraging drainage, and making sure there is enough ventilation. Additionally essential to preventing and resolving corrosion problems are routine cleaning, maintenance, and inspection.

Conclusion:

Although mild steel has several advantages in terms of cost and adaptability, its caustic nature presents serious difficulties, especially in corrosive situations. To maximize the longevity and performance of mild steel buildings and components, it is imperative to comprehend the variables that contribute to corrosion and to implement effective protective measures. Through appropriate safeguarding measures and adherence to maintenance protocols, industries may reduce the risks associated with corrosion and guarantee the longevity of mild steel assets.

0 notes

Text

Carbon Steel ASTM A105 Flanges Stockists in Mumbai

Shasan Piping Solution stands at the forefront as a prominent provider in the realm of ASTM A105 flanges. These flanges, crafted from forged Carbon Steel ASTM A105 Flanges Manufacturers In India, are engineered to withstand high-temperature environments effectively. Our offerings encompass a diverse range of flange types, each meticulously crafted to meet varying industry

Why Use Carbon Steel ASTM A105?

This material contains carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. These are called Carbon Steel ASTMs because other materials contain less than 1% of the composition. There are different types, including SA105N blind flanges, which are used to close pipelines. The flange also has excellent strength properties. The minimum yield strength of the flange is 250 MPa and the minimum tensile strength is 485 MPa. It is a hard material with a Brinell hardness of 187.

Other Industries in which Carbon Steel ASTM A105 are Used: Sugar Mills & Distilleries, Chemicals, Petrochemicals, Oil & Natural Gas Organizations, , Fertilizers, Cement Industries, Ship Builders, Paper Industries, Pumps, Automation, Paints, Steel Industries, etc.

There are various pressure classes such as class 150, 300, up to 2500, and PN6 to PN64. A105 flanges of class 300 and below do not require heat treatment, but high pressure class can be heat treated. Flanges with a nominal internal diameter greater than 4 inches are heat treated as annealing, normalizing, normalizing and tempering, or normalizing and tempering. ASTM A105 pipe flanges can also be forged. This material is suitable for welding applications. When welding materials, boilers, and pressure vessels, guidelines consistent with ASME standards must be followed. Flanges are both bolted and bolted. ASTM A105 N threaded flanges are useful when welding or screwing methods are not suitable. Threaded flanges can be used on threaded pipes to create connections without welding.

We exports Carbon Steel ASTM A105 for these countries – Asia, North America, western Europe, Singapore,etc..

Specification of Carbon Steel ASTM A105

Specifications: ASTM A182, ASME SA182

Size: 1/2″ to 48″

Standards: ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605.

Pressure Ratings: Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600

Flange Face Type: Flate Face, Raised Face, Ring Type Joint

Coating/Surface Treatment

Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated.

For More Details

CONTACT US: +91 22-6651 8642

EMAIL ID: [email protected]

If any enquiries please contact us our support team will connect you as soon as possible.

0 notes

Text

Firefighting Pipes Manufacturers

Firefighting pipes are a specialized category of steel pipes used primarily in fire protection systems. They are designed to transport water and other extinguishing agents safely and efficiently to necessary points in a building or structure in case of fire. These pipes are subject to stringent manufacturing standards to ensure their reliability, durability, and resistance to heat and pressure.

Overview of Firefighting Pipe Manufacturing

1. Material Selection: Firefighting pipes are typically made from carbon steel or stainless steel, materials known for their high strength and resistance to heat. The choice of material often depends on the specific requirements of the fire protection system and the environment in which they will be installed.

2. Pipe Forming: Steel coils are uncoiled and flattened. The flat steel is then formed into pipe shapes using a process called Electric Resistance Welding (ERW). In this process, the edges of the steel are fused together using electric current and pressure.

3. Seam Welding: For firefighting pipes, the longitudinal seams are continuously welded to ensure watertight connections and to maintain the structural integrity under high pressure during use.

4. Galvanizing: To protect against rust and corrosion, which are critical in fire protection environments, the pipes are often galvanized. This involves dipping the formed pipes into a bath of molten zinc, creating a robust protective layer on the exterior and interior surfaces.

5. Threading and Grooving: Once the pipes are galvanized, they are threaded, grooved, or plain-ended depending on the connection method used in the installation. Threading and grooving are crucial for the secure attachment of fittings and couplings in fire protection systems.

6. Pressure Testing: To ensure that the pipes can withstand the operational pressures of firefighting systems, they undergo hydrostatic pressure tests. This test checks for leaks and verifies the strength and durability of the pipe.

7. Quality Control: Throughout the manufacturing process, quality control measures are strictly enforced. This includes checks on dimensions, material composition, and coating thickness to ensure that all specifications are met.

Applications of Firefighting Pipes

Fire Sprinkler Systems: These are the most common applications of firefighting pipes, used in residential, commercial, and industrial buildings to deliver water to sprinklers in the event of a fire.

Standpipe Systems: Used in large buildings, standpipe systems allow firefighters to connect hoses directly to a water supply, providing a consistent flow of water to combat fires on multiple floors.

Water Supply Lines: Firefighting pipes are also used in the external water supply lines that connect fire protection systems to public water sources.

Specialized Firefighting Systems: In facilities where standard water-based systems are not suitable, such as in chemical plants or data centers, firefighting pipes may carry other extinguishing agents like foam or gases.

Advantages of Firefighting Pipes

High Durability and Strength: Essential for withstanding the high pressures involved in firefighting applications.

Corrosion Resistance: Galvanizing provides protection against corrosion, crucial for maintaining the integrity and longevity of fire protection systems.

Safety and Reliability: Manufactured to meet strict standards, ensuring that they perform reliably in emergency situations.

Leading Firefighting Pipe Manufacturer: Hi-Tech Fire Pipes

Hi-Tech Fire Pipes is a prominent manufacturer known for producing high-quality firefighting pipes that meet or exceed international safety standards. With advanced manufacturing processes and a commitment to quality, Hi-Tech Fire Pipes ensures that its products provide maximum reliability and performance in fire protection systems. Their extensive range of firefighting pipes is designed to cater to various requirements, making them a trusted choice for builders, architects, and safety engineers worldwide.

More Read: Best Firefighting Pipes

0 notes

Text

Basic Working Principle of Diesel Engine Fuel Filter

The fuel filter of diesel engine can filter out the harmful impurities and moisture in the fuel system, protect the normal work of the engine, reduce wear and tear, avoid clogging and improve diesel engine life. Here, we are willing to share the basic working principle of diesel engine fuel filter.

Basic Working Principle of Diesel Fuel Filter

The purpose of any diesel fuel filter is to remove foreign particles as well as water. The use of a suitable filtration system on diesel engines is a must to avoid damage to closely fitted injection pump and injector components. Filter's ability varies between the type and manufacturer. On diesel engines primary and secondary filters are used. The primary filter is capable of removing dirt particles down to 30 microns and the secondary filter between 10 to 12 microns. Secondary filters are available between 3 and 5 microns, which are used in severe service operations. The primary filter is usually located between the tank and the supply pump, the FWS is one type of the primary filters. The secondary filter between the supply pump and the injection pump.

Diesel fuel filter is referred to as full-flow filter, because all the fuel must pass through it before reaching the injection pump. Some filters use internal replaceable element inside a bowl or shell. These are commonly referred to as a shell and element design. Most fuel filters used today are of the spin-on type, which allow for faster change out since the complete filter is a throwaway.

Besides, if the filter is installed on the pressure side of the boost pump it must have sufficient strength to handle pump pressure without bursting or leaking. The filter must be located well away from sources of heat, preferably outside of the engine compartment.

Components

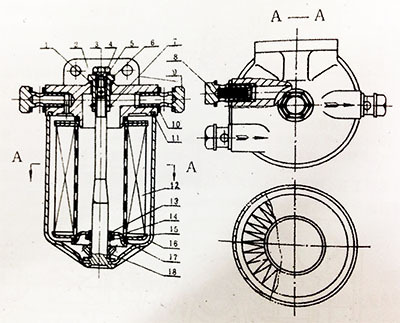

The fuel filter of diesel engine is mainly composed of three parts: filter element, the shell and filter base (As shown in Figure 1). All models are universal except for the overflow valve 8 that has two structures. Choosing C0810A or C0810B filter should be on the basis of different models. For the 12 cylinder V type diesel genset, it should be installed in parallel with each one of C0810A and C0810B.

Figure 1: Fuel filter assembly section

1. Gasket 2. Base of filter 3. Pull rod 4. Bleed screw 5. Gasket 6. Pull-rod nut 7. Jump ring 8. Overflow valve 9. Oil pipe connection 10. Seal ring 11. Sealing washer 12. Filter element 13. Seal ring 14. Tray 15. Spring seat 16. Shell 17. Seal ring 18. Spring

The fuel is sent to the fuel filter mainly by the fuel pump. The impurities in the fuel will be cleared through the paper filter element. And then the fuel can enter the inner cavity of the filter cylinder. Through the collection chamber of the filter sea, it leads to the fuel injection pump. The filter holder is equipped with fuel return fitting and the overflow valve is also installed inside. When the fuel pressure in the fuel filter is more than 78kPa(0.8kgf/C㎡), the excess fuel will return back to the fuel tank from the fuel return fitting. When connecting the low pressure fuel line, you should connect it according to the arrow pointing direction on the socket to avoid connection error. The filter seat and the shell are connected by pull rod, and it is sealed by rubber ring. Due to there is a bleeder plug on the top of filter seat, users can release the screw to clear the air of the fuel filter in use.

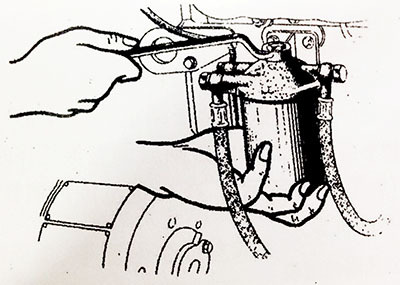

Figure 2: Fuel filter overhauling

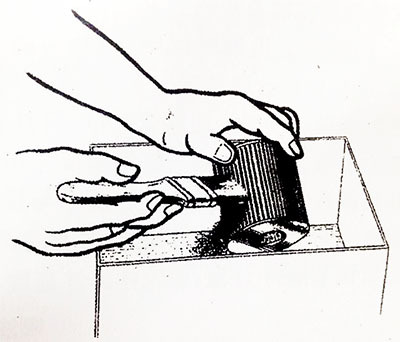

The fuel filter of the diesel engine is fixed on the engine body and bracket with two M8-6H screws. If users find that the fuel supply is not smooth, it is possible that the filter element is pluged. At the moment, you should dump the fuel oil. You can directly loosen the pull rod nut of diesel generator set, remove the shell, and take out the filter cartridge (As shown in Figure 2). After the filter element is dipped into gasoline or diesel oil, you can gently wash the dirt off with brush (As shown in Figure 3). If the filter cartridge is broken or hard to clean, it must be renewed. Then install it as shown in Figure 1 and inject the clean fuel.

Figure 3: Cleaning fuel filter element

The basic working principle of fuel filter for diesel engine mentioned above is share by Jiangsu Starlight Electricity Equipment Co.,Ltd. Hope it is useful for all users. Besides, our company can provide a variety of specifications common from 3KW to 2500KW, automated, four-protection, automatic cut over, low noise and mobile and so on high quality, and the low energy consumption generator set so as to satisfy the customer all electric power demand. We can also satisfy the user different voltage, different frequency request, as well as many units and networking power supply system.

#volvo diesel engine#wuxi diesel generator set#silent diesel generator set#dingbo powe generation#starlight power

0 notes

Text

Welded Flanges Exporters in India

We are broadly known for manufacturing and supplying an extensive variety of high quality of Welded Flanges. These flanges are welded to the end of pipe so that the pipe can be bolted to another pipe with a same flanges. Complying with the characterized parameters of the business, these offered welded flanges hold a few properties, such as,Epoxy Coating, Longer service life, Hot Dip Galvanizing, Resistance against corrosion, Dimensions stability, Compressive strength.SPECIFICATION

Size:

1/2" NB TO 60"NB.

Class:

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS DIN Standard ND-6,10, 16, 25, 40 Etc.

Nickel Alloy Socket Weld Flange:

ASTM / ASME SB 564 / 160 / 472.

UNS 10276 -HASTELLOY C 276 Socket Weld Flange

UNS 2200 -NICKEL 200 Socket Weld Flange

UNS 2201 -NICKEL 201 Socket Weld Flange

UNS 4400 -MONEL 400 Socket Weld Flange

UNS 8020 -ALLOY 20 Socket Weld Flange

UNS 8825 -INCONEL 825 Socket Weld Flange

UNS 6600 -INCONEL 600 Socket Weld Flange

UNS 6601 -INCONEL 601 Socket Weld Flange

UNS 6625 -INCONEL 625 Socket Weld Flange

Copper Alloy Socket Weld Flange:

ASTM / ASME SB 61 / 62 / 151 / 152.

C 70600 (CU -NI- 90/10)/Cupro Nickel Socket Weld Flange

C 71500 (CU -NI- 70/30)/Copper Nickel Socket Weld Flange

UNS NO. C 92200, UNS NO. C 83600, UNS NO. UNS NO C 10100,

C 10200, C 10300, C 10800, C 12000, C 12200

Duplex Steel Socket Weld Flange:

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Stainless Steel Socket Weld Flange/SS SWRF Flange:

ASTM A182 Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Alloy Steel Socket Weld Flange/AS SWRF Flange:

ASTM SA 182 F1/F5/F9/F11/F22/F91

Carbon Steel Socket Weld Flange/CS SWRF Flange:

ASTMA 105 Gr. F42/46/52/56/60/65/70

Low Temperature Carbon Steel Socket Weld Flange/LTCS SWRF Flange:

A350 LF2/A350 LF3, Value Added Services, Hot Dip Galvanizing, Epoxy Coating,, Test Certificate, Mill Test Certificate as per EN 10204 / 3.1Bc

0 notes

Text

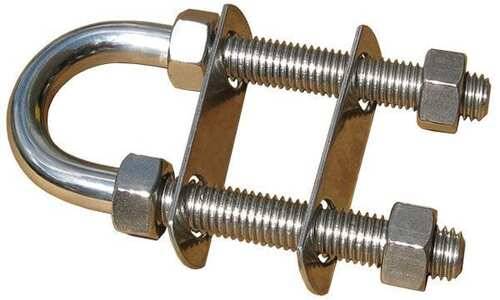

U Bolt Dynamics: Crafting Precision Fasteners for Every Need

In the world of construction, automotive manufacturing, and countless other industries, the unsung heroes are often the smallest components. Among these, U bolts hold a place of critical importance. These U-shaped fasteners are pivotal in their role, offering not just support but also ensuring safety and longevity in various applications. From securing pipelines beneath city streets to holding together the framework of skyscrapers, U bolts are integral to structural integrity and function. In this blog post, we will dive deep into the world of U bolts, exploring their types, manufacturing processes, selection criteria, and how U bolt suppliers play a crucial role in providing high-quality fasteners for every need.

Understanding U Bolts

Understanding U bolts goes beyond recognizing their simple U-shaped design. These essential fasteners play a pivotal role in various industries, offering crucial support and stability. To ensure the right fit and performance, it's vital to source U bolts from reputable U bolt suppliers. These suppliers specialize in providing a wide range of U bolts, tailored to specific needs and applications.

By understanding the nuances of U bolts and partnering with reliable U bolt suppliers, businesses can ensure the structural integrity and safety of their projects. From construction to automotive manufacturing, the importance of high-quality U bolts cannot be overstated, making the choice of supplier a critical decision in any procurement process.

Design Features: U bolts are characterized by their U-shaped design, which allows for easy clamping around cylindrical or square objects.

Material Varieties: These fasteners are available in a range of materials, including stainless steel, carbon steel, and galvanized steel, each offering distinct properties suited to different applications.

Application Specifics: U bolts find application in diverse industries such as construction, automotive, marine, and telecommunications, where they are used for securing various components like pipes, poles, and equipment mounts.

Load Capacity Considerations: Choosing the right U bolt involves assessing factors such as the anticipated load and the material being clamped, ensuring that the bolt can withstand the required forces without failure.

Surface Finish Options: To enhance durability and corrosion resistance, U bolts can be finished with coatings such as zinc plating, epoxy coating, or hot-dip galvanizing, depending on the environmental conditions they will be exposed to.

Thread Specifications: U bolts feature threads on both ends, allowing for easy installation and adjustment. Thread size and pitch must be selected carefully to ensure compatibility with nuts or other fastening components.

Customization Possibilities: Some applications may require U bolts with specific dimensions, angles, or configurations. Customization services offered by suppliers allow for the creation of tailored solutions to meet unique project requirements.

Supplier Expertise: Working with experienced U bolt suppliers ensures access to high-quality products, technical support, and reliable delivery, essential elements in achieving successful project outcomes.

Types of U Bolts

When it comes to securing various components in different industries, U bolts are indispensable. These fasteners come in a variety of types, each designed to suit specific applications and requirements. Understanding the different types of U bolts is essential for selecting the right one for a particular project. Here, we'll delve into some common types of U bolts and how they are used across various industries.

Round Bend U Bolts: As the name suggests, round bend U bolts feature rounded bends on both ends, making them ideal for securing cylindrical objects such as pipes, tubes, or cables. They provide a snug fit around the rounded surface, ensuring stability and preventing slippage. Round bend U bolts are commonly used in plumbing, electrical, and automotive applications.

Square Bend U Bolts: Square bend U bolts are designed for clamping square or rectangular objects securely. Their square-shaped bends provide a tight grip, making them suitable for applications where stability and alignment are crucial. These U bolts are often used in construction, scaffolding, and equipment mounting.

Long Tangent U Bolts: Long tangent U bolts feature extended legs and threads, offering increased clamping force and versatility. They are designed to accommodate thicker materials or multiple components, providing a secure hold even under heavy loads. Long tangent U bolts find application in structural steelwork, bridge construction, and machinery assembly.

Custom U Bolts: In some cases, standard U bolts may not meet the specific requirements of a project. Custom U bolts are tailored to precise specifications, including dimensions, materials, and thread configurations. This customization allows for optimal performance and ensures a perfect fit for unique applications. Custom U bolts are often used in industries such as aerospace, marine, and renewable energy, where standard fasteners may not suffice.

When sourcing U bolts for a project, it's crucial to partner with reliable U bolt suppliers. These suppliers offer a wide range of U bolts in various types, sizes, and materials to meet diverse needs. With their expertise and extensive inventory, U bolt suppliers play a vital role in ensuring that projects are equipped with high-quality fasteners that deliver reliable performance and durability.

Manufacturing Excellence

In the realm of industrial hardware, where precision meets durability, the significance of U bolts cannot be overstated. These unassuming yet essential components serve as the backbone of various applications, from construction to automotive engineering. At the heart of every sturdy structure and reliable machinery lies the reliability of U bolts. In this landscape of manufacturing excellence, the role of U bolt suppliers emerges as pivotal players, ensuring that the foundation of industries remains steadfast.

Manufacturing excellence isn't merely about producing goods; it's a commitment to quality, innovation, and reliability. U bolt suppliers embody this ethos by consistently delivering products that meet and exceed industry standards. Their dedication to precision engineering ensures that each U bolt is crafted with meticulous attention to detail, guaranteeing optimal performance in diverse environments.

One of the hallmarks of manufacturing excellence in the realm of U bolt suppliers is their ability to tailor solutions to meet specific customer needs. Whether it's a bespoke design for a unique application or a large-scale production order, these suppliers exhibit versatility and flexibility in their operations. By leveraging advanced manufacturing techniques and cutting-edge technologies, they empower industries to achieve new heights of efficiency and productivity.

Moreover, manufacturing excellence goes hand in hand with sustainability in today's global landscape. U bolt suppliers recognize their responsibility towards environmental stewardship and adopt eco-friendly practices throughout their operations. From sourcing materials responsibly to optimizing energy consumption, these suppliers strive to minimize their carbon footprint while maximizing value for their customers.

Furthermore, manufacturing excellence isn't confined to the production floor; it extends to every aspect of the supply chain. U bolt suppliers prioritize transparency, reliability, and integrity in their dealings, fostering long-term partnerships built on trust and mutual benefit.

Selection Criteria

When navigating the market for U bolt suppliers, selecting the right partner is crucial for the success of any project or endeavor. Several key criteria should inform this decision-making process to ensure optimal outcomes.

Firstly, expertise and experience play pivotal roles. Assessing a supplier's track record within the industry, including the breadth of their portfolio and the depth of their technical knowledge, provides valuable insights into their capabilities.

Secondly, quality assurance measures are non-negotiable. Look for suppliers who adhere to stringent quality control standards and certifications, ensuring that their U bolts meet or exceed regulatory requirements and industry benchmarks.

Thirdly, responsiveness and communication are vital aspects of a fruitful partnership. Opt for suppliers who prioritize clear and prompt communication channels, fostering transparency and alignment throughout the procurement process.

Additionally, consider factors such as reliability, scalability, and cost-effectiveness when evaluating potential suppliers. A dependable partner with the capacity to scale operations according to your needs, while offering competitive pricing, can significantly enhance project feasibility and success.

Ultimately, the selection of U bolt suppliers should be a well-informed decision, guided by comprehensive assessment against these critical criteria. By prioritizing expertise, quality, communication, reliability, and cost-effectiveness, stakeholders can forge enduring partnerships that drive efficiency, innovation, and success.

Choosing the right U bolt for a specific application requires careful consideration of several factors:

Material: Depending on the environment, a U bolt may need to be made of weather-resistant materials like stainless steel.

Size and Load Capacity: The size and thread design must be suitable for the load it is expected to bear.

Shape: The shape of the U bolt must match the object it is clamping.

Finish: The right finish can greatly extend the lifespan of a U bolt by protecting it against corrosion.

U Bolt Suppliers: Ensuring Quality and Variety

Finding the right U bolt for your project involves more than just understanding the types and manufacturing processes. It requires access to a reliable supplier who can provide high-quality fasteners tailored to your specific needs. U bolt suppliers play a critical role in the ecosystem, ensuring that customers have access to a wide variety of fasteners that meet strict quality standards.

Reputable U bolt suppliers are characterized by their extensive inventory, which includes bolts of different sizes, shapes, and materials. They often offer custom manufacturing services for projects that require unique specifications. Additionally, top suppliers ensure that their products are tested for strength and durability, providing customers with the confidence that their fasteners will perform as expected.

Comprehensive Material Selection: U bolt suppliers meticulously source materials, including high-grade steel and other alloys, to ensure durability and performance across diverse applications.

Advanced Manufacturing Techniques: Leveraging state-of-the-art technologies such as computer-aided design (CAD) and precision machining, suppliers produce U bolts with unparalleled accuracy and consistency.

Rigorous Quality Control Processes: From initial inspection of raw materials to final product testing, suppliers implement stringent quality control measures to maintain the highest standards of quality and reliability.

Customization Capabilities: Recognizing the unique requirements of different industries and applications, U bolt suppliers offer customization options, including varying sizes, coatings, and thread types, to meet specific customer needs.

Diverse Product Range: In addition to traditional U bolts, suppliers often offer a diverse range of related products, such as square U bolts, round U bolts, and specialty configurations, providing customers with comprehensive solutions for their fastening needs.

Read Also: A Journey Through the World of Fastening Systems

The Importance of Quality Control

In the realm of U bolt suppliers, quality control isn't just a checkbox; it's a cornerstone of reliability, safety, and customer satisfaction. These seemingly small components play a significant role in supporting crucial infrastructure across various industries, from construction to transportation. As such, ensuring their quality is paramount.

Quality control measures within U bolt manufacturing encompass a spectrum of processes, from material selection to final inspection. Suppliers must meticulously vet raw materials, utilizing only the highest-grade steel or other suitable materials to withstand the rigors of their intended applications.

Precision engineering is another crucial aspect of quality control. U bolts must adhere to precise dimensional specifications to ensure proper fit and functionality. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enable suppliers to achieve unparalleled accuracy and consistency.

Furthermore, rigorous testing protocols are employed to validate the performance and durability of U bolts. This may include stress testing, corrosion resistance assessments, and fatigue analysis to simulate real-world conditions and ensure long-term reliability.

The importance of quality control extends beyond individual components to the overall reputation and trustworthiness of U bolt suppliers. By prioritizing quality at every stage of the manufacturing process, suppliers demonstrate their commitment to excellence and customer satisfaction, ultimately fostering enduring partnerships and driving industry advancement.

Conclusion

U bolts may be small, but their impact on the safety and integrity of structures and machinery is immense. Understanding the types of U bolts, their manufacturing process, and how to select the right one for your needs is crucial. Equally important is choosing a supplier that can provide high-quality, durable fasteners tailored to your project's requirements.

As industries continue to evolve and new challenges arise, the demand for precision-engineered fasteners like U bolts will only grow. By partnering with reputable U bolt suppliers, businesses can ensure that they are equipped with the best fasteners for the job, contributing to the overall success and longevity of their projects.

In a world where the strength and stability of our constructions, vehicles, and machinery are paramount, U bolts stand out as a critical component. Ensuring that these essential fasteners are of the highest quality and perfectly suited to their intended application is not just a matter of efficiency but of safety and reliability. As we have seen, the dynamics of U bolts encompass a wide range of considerations, from their design and manufacture to the crucial role played by suppliers in delivering precision fasteners for every need. By paying close attention to these aspects, we can continue to build, create, and innovate with confidence, knowing that our smallest components are more than capable of holding together our grandest designs.

Read Also: A Closer Look at Industry-Leading Carriage Bolt Makers

#bolt supplier#manufacturer#business#u bolt manufacturers#U-bolt Suppliers#U-bolt exporters India#U Bolts Manufacturer#U Bolts Manufacturers India

0 notes

Text

Hot-dip galvanizing reigns supreme in safeguarding large, robust metal structures exposed to harsh environments. Its exceptional durability makes it the go-to choice for:

Infrastructure Projects: Bridges, highways, and power transmission towers benefit from hot-dip galvanizing's ability to withstand heavy loads, extreme weather conditions, and constant exposure to salt and de-icing chemicals.

Marine Environments: Piers, docks, and offshore platforms require a robust defense against the corrosive effects of saltwater. Hot-dip galvanizing provides a long-lasting barrier against rust and ensures the structural integrity of these vital installations.

Industrial Applications: From storage tanks containing harsh chemicals to industrial piping systems transporting liquids and gases, hot-dip galvanizing offers superior protection in demanding industrial settings.

Galvanizing Coating : Our hot-dip galvanizing process creates a robust zinc-iron alloy layer on your metal, providing unmatched protection against harsh environments, extreme weather conditions, and industrial wear-and-tear. This long-lasting solution is ideal for structural steel, pipes, railings, and other outdoor metal applications.

Galvanizing Paint : Protexion also offers premium-grade galvanizing paints formulated to replicate the protective properties of galvanization. These paints are perfect for situations where hot-dip galvanizing is not feasible or for adding an additional layer of defense to existing galvanized surfaces. Our galvanizing paints are available in a variety of colors to match your aesthetic requirements.

Galvanizing Paints: A Versatile Solution for Targeted Protection

While not a replacement for hot-dip galvanizing in heavily stressed environments, galvanizing paints offer valuable protection in numerous scenarios:

Building Components: Roofs, gutters, and exterior metal elements on buildings benefit from the protective layer offered by galvanizing paints, especially in areas with moderate weather conditions.

HVAC Systems: The air ducts within a building's HVAC system can be protected from corrosion using galvanizing paints, ensuring efficient airflow and improved indoor air quality.

Machinery and Equipment: Galvanizing paints offer a flexible solution for protecting agricultural equipment, tools, and other metal components used outdoors or in moderately corrosive environments.

Touch-ups and Maintenance: Existing galvanized surfaces can benefit from touch-ups with galvanizing paints to maintain their protective layer and extend their lifespan.

Beyond Applications: Additional Considerations

Remember, the best galvanization method hinges on more than just application. Here are some additional factors to consider:

Maintenance Requirements: Hot-dip galvanized surfaces require minimal maintenance, with occasional inspections recommended. Galvanizing paints may require more frequent touch-ups, especially in areas with high wear and tear.

Environmental Impact: Both methods offer eco-friendly advantages. Hot-dip galvanizing utilizes a closed-loop system, minimizing waste. Modern galvanizing paints are formulated with low VOCs (volatile organic compounds), reducing their environmental footprint.

Standards and Regulations: Hot-dip galvanized coatings adhere to industry standards set by organizations like ASTM International. Paint manufacturers must comply with environmental regulations regarding VOC content.

Contact : +91 9011958800Visit : http://www.protexion.in/cold-galvanizing-coating.php

0 notes

Text

wmass exclusive agent in KSA

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a reputable manufacturer of Carbon Steel Flanges based in India. Our extensive line of flanges encompasses various types and material grades, meticulously engineered to meet diverse requirements. Each flange is precisely crafted with a blend of carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium, tailored to specific material grades as indicated in our Carbon Steel Pipe Flange Price List.

Renowned for their unique dimensions and strengths, our WMASS Carbon Steel Flanges boast a minimum tensile strength ranging from 485MPa to a minimum yield strength of 250MPa. Among our offerings, the Flange ANSI B16.5 Class 150 represents a medium-pressure class within the B16.5 standard. We carefully select materials and pressure classes based on nominal bore sizes and wall thicknesses to ensure optimal performance.

Covering nominal bore sizes from ½ inches to 48 inches and classes such as WMASS Carbon Steel Flanges Rating with varying pressure ratings, our flanges cater to a wide range of applications. Whether it's for permanent or temporary termination of pipe connections, our Carbon Steel Blind Flange is a versatile choice, with permanent connections welded and temporary ones secured with bolts and nuts. Additionally, our CS Lap Joint Flange stands out with its lap joint design, offering added flexibility.

Renowned for their durability and high wear resistance, our carbon steel flanges provide reliable solutions across industries. For detailed information on Carbon Steel Weld Neck Flange Dimensions, pricing, and any further inquiries, please do not hesitate to reach out to us.

Specifications of WMASS Carbon Steel Flanges Companion Flanges:

Sizes: Ranging from 1/2" (15 NB) to 48" (1200NB) DN10~DN5000

API Flanges Standards: ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092

API Flanges Pressure Rating ANSI: Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

API Flanges Pressure Calculation in DIN: 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64

JIS: 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K

UNI: 6Bar 10Bar 16Bar 25Bar 40Bar

EN: 6Bar 10Bar 16Bar 25Bar 40Bar

Coating: Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

Most Common Types of API: Forged / Threaded / Screwed / Plate

Test Certificates: EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc.

Production Technique: Forged, Heat treated, and machined

Connect Type/Flange Face Type: Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove

Special Design: As per your drawing, AS, ANSI, BS, DIN, and JIS, 15 NB (1/2") to 200 NB (8"), Equal and Reducing Configurations

Test: Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector

Equipment: Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine, etc.

Origin: Indian / West Europe / Japan / USA / Korean

Manufacturer of: ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, etc.

API: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

API Flanges Uses & Application: Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals, and acids

Export to: Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc.

Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#Carbon Steel Flanges in UAE#CS Flanges in UAE#Carbon Steel Flanges Stockist in UAE#WMASS Carbon Steel Flanges#WMASS Carbon Steel Flanges UAE#WMASS Carbon Steel Flanges Manufacturers

0 notes

Text

ERW Pipe - Electric Resistance Welded Pipe Manufacturer

Permanent Steel manufacturer of Electric Resistance Welded Pipe and supply worldwide. It is used For ERW Line Pipe, Casing, and Structure Tube. Its surface is Lightly oiled, Hot dip galvanized, and Electro galvanized. It comes with Plastic plugs on both ends, two tags on each bundle, and wrapped in waterproof paper. For more details call us at 86-731-88787784.

0 notes

Text

WHY AM I RUNNING OUT OF HOT WATER?

Running out of hot water halfway through a relaxing shower or bath is both frustrating and inconvenient. If you're facing this problem more frequently, it's time to explore potential causes and solutions. Here's a look at the usual suspects and a reminder that an experienced plumber in Fulham should be a valuable contact at times like these.

Common Causes of Diminished Hot Water Supply

Simultaneous Water Demands: Households with multiple bathrooms or high usage appliances often fall victim to this cause. If several outlets like a shower, a washing machine, and sinks are using hot water simultaneously, the demand may simply be higher than your water heater can meet in real time.

Overwhelmed Tank Size: Your water heater only stores a set amount of hot water. If the demand in your household has drastically changed – a new appliance, frequent guests, or children reaching that 'forever showering' age – the water heater might not be adequate for the job anymore.

Sediment Buildup: Minerals in water supply settle over time, reducing the volume of water heated, leading to quicker depletion. Sediment also acts as an insulator, making your water heater work harder to heat the same amount of water.

Dip Tube Damage: Dip tubes direct cold water to the bottom of your tank for efficient heating. Damaged tubes can disrupt this process, mixing hot and cold water prematurely. This makes hot water run out rapidly.

Thermostat Faults: Your water heater has a thermostat, and a malfunctioning one can significantly impact the water temperature and its duration.

Aging Heating Element: Electric models especially rely on heating elements that can degrade over time. A less efficient element means longer heating times and a more rapid supply depletion.

Troubleshooting Steps To Attempt

Before involving a professional plumber in Fulham, consider a few initial checks:

Usage Patterns: Observe for a day or two whether hot water runs out during peaks. If so, staggered showering or appliance use could be a simple solution.

Drain Sediment: Water heater manufacturers recommend draining a small amount from the tank twice a year to remove build-up. Consult your owner's manual for instructions.

Thermostat Check: A thermostat may have accidentally shifted. Look up the recommended temperature for your model. Remember, scalding water is hazardous, especially for children, so adjustments should be cautious.

When Is it Time to Call a Plumber in Fulham

If your efforts don't yield improvement, a trusted plumber in Fulham should be your next step. These specialists are equipped to:

Diagnose Hidden Culprits: A leaking pipe within your walls or an internal water heater malfunction may not be visually apparent but could dramatically reduce your supply.

Evaluate Your Water Heater: Professional plumbers can accurately gauge whether your unit's life expectancy is a prime factor, or if specific component breakdowns may be to blame.

Recommend Replacements: When a new water heater is the answer, qualified technicians will be knowledgeable about efficient solutions tailored to your household needs.

Additional Concerns with Hot Water Issues

Beyond inconvenience, consider these factors if you have frequent hot water limitations:

Energy Bills: An overtaxed water heater works harder, resulting in potentially higher energy consumption.

Water Damage: Certain hidden causes of reduced hot water supply, like internal leaks, pose a risk for water damage.

Appliance Malfunction: Insufficient hot water supply can trigger malfunctions in washing machines and dishwashers.

Finding the Right Plumbing Support in Fulham

Searching online for "plumber in Fulham" is a straightforward starting point. But, prioritize choosing a company with the following:

Excellent Reputation: Ask around in the Fulham community or seek online reviews about a company's professionalism and problem-solving track record.

Expertise: Verify they have expertise in diagnosing and tackling the most common causes of reduced hot water, and experience with various water heater types.

Transparency: They should provide straightforward estimations and clearly explain diagnoses so informed decisions can be made.

Running out of hot water repeatedly signals an underlying plumbing or water heater issue that's unlikely to magically fix itself. A proactive approach that combines basic troubleshooting and prompt support from a reliable Fulham plumber protects your property and comfort while ensuring an efficient supply of hot water whenever you need it.

0 notes