#Electric Resistance Welded Pipe

Text

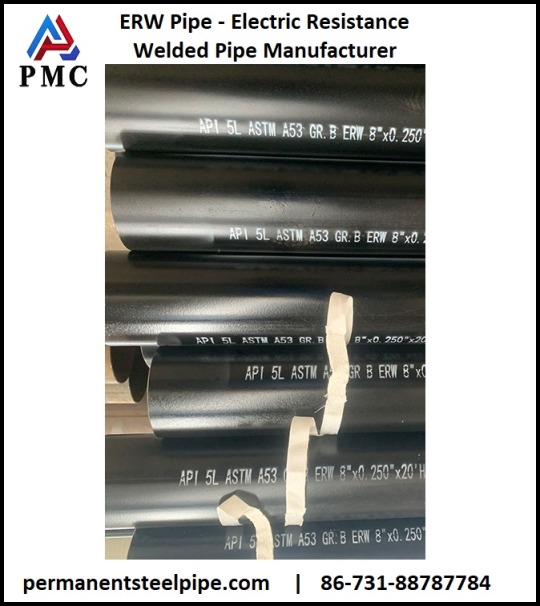

ERW Pipe - Electric Resistance Welded Pipe Manufacturer

Permanent Steel manufacturer of Electric Resistance Welded Pipe and supply worldwide. It is used For ERW Line Pipe, Casing, and Structure Tube. Its surface is Lightly oiled, Hot dip galvanized, and Electro galvanized. It comes with Plastic plugs on both ends, two tags on each bundle, and wrapped in waterproof paper. For more details call us at 86-731-88787784.

0 notes

Text

I need you people to try this game- it's an open-source survival sci-fi traditional roguelike called Cataclysm Bright Nights. It's a fork based off of Cataclysm Dark Days Ahead, but designed to be more focused on fun than punishing realism- though it's still plenty realistic, at least given what kind of game it is.

For those who don't know, Cataclysm is an old game, from 2010, that has been developed over time and has since forked off into two competing versions. You play as the survivor of the Cataclysm, and now have to figure out how to keep surviving in the face of an ever-evolving threat.

Grab the game from the release section of the github; the game's full description (and my gushing) is below the cut.

You may be asking, "that description is kind of vague, what exactly was this apocalypse?", well the answer is all of them. Every single human is infected with a parasitic interdimensional organism known as The Blob, which mutates its host in response to certain things. Every living human, and many animals, that dies will come back as a zombie, and the longer the Cataclysm goes on, the more the zombies and wildlife will mutate further. There are also crazed humans who fight alongside the undead, bandits, alien invaders known as Mi-Go, demons rising from the netherrealms, hostile military robots and cyborgs and turrets dot the landscape, and there's even a fungal hive mind trying to infect all other life out of a twisted benevolence.

The game also has one of the most indepth crafting systems I've ever seen. Instead of simply being able to build with a workbench or your bare hands, most crafting recipes require the proper tools- and if you don't have them, you can make some. Pick some flowers to turn their stems into cordage, grab some rocks, and make a stone hammer and knife; build a basic screwdriver out of scrap metal and wood, and a makeshift crowbar out of a pipe you flattened on one end. Carve a wooden or bone needle and learn to sew a gambeson. Disassemble a lawnmower and tie the blade to a long stick to make a makeshift polearm. Construct a full forging setup and make yourself a sword and metal armor. Add an electric motor and a motorcycle battery to a bicycle to make it run that much faster. Take the turret mount off of a firetruck, weld it to the hood of the car you stole, and install a handmade laser rifle you built from disassembled electronics and camera lenses to run off of the car's battery, allowing you to gun down the undead hordes in relative safety. Disassemble .308 ammo to hand-load the spent 5.56 shells you used gunning down enemies. Delve into ruined laboratories whose experiments have run amok to find high-tech weapons and learn to craft your own targeted mutagens.

You can also learn martial arts, strengthening your abilities with melee weapons. Everyone learns basic brawling once they know how to hit something, but brawling takes higher skill to gain the basic techniques; proper fighting styles have to be carefully found, but are worth it. Use Eskrima and an extendable baton or a dagger to smack and dice your enemies apart, use fencing to effortlessly parry enemy attacks with a rapier, use ninjutsu to silently take down foes, learn drunken boxing to sway and counterattack every single enemy blow, or even learn biojutsu to slice your enemies apart with implanted metal claws or blades.

The game is also unique in that it lets you use mutations and cybernetics hand in hand. You mutating a pair of venomous fangs doesn't stop you from installing smoke and poison resistant cybernetic lungs, you mutating hooves doesn't stop you from installing high-tech alloy plating onto your legs. And you can loot cybernetics from hospitals and augmentation clinics and labs, but you can also dissect zombies for them, using your first aid skill to carefully extract bionics from the undead- you can even build a handheld device to identify bionics in corpses. Generally, mutations are less reliable but cost hunger at most, while cybernetics are more reliable but harder to power and gain.

All in all, it's one of the best roguelikes I've ever played. There's so much to it, there's daily updates, grab the Catapult launcher to try all four forks, just try it out! There's a discord server linked in the github!

3 notes

·

View notes

Text

The Role of MSERW Pipe in the Oil and Gas Industry: Applications and Challenges

Introduction

In the oil and gas industry, the transportation of fluids and gases over long distances is crucial. To ensure the safe and efficient movement of these resources, various types of pipes are utilized. One such pipe that plays a vital role in the industry is the MSERW pipe. In this blog, we will explore the applications and challenges associated with MSERW pipes and highlight the importance of finding a reliable MSERW pipe distributor, dealer, supplier, and provider in Gujarat.

Understanding MSERW Pipe

MSERW stands for Mild Steel Electric Resistance Welded. MSERW pipes are constructed using low-carbon steel, which is known for its strength, durability, and resistance to corrosion. These pipes are manufactured by forming flat steel plates into cylindrical shapes and then welding the edges together using electric resistance welding techniques.

Applications of MSERW Pipe in the Oil and Gas Industry

Transporting Oil and Gas:

MSERW pipes are extensively used for the transportation of oil and gas products. These pipes provide a cost-effective solution for delivering crude oil, natural gas, and refined petroleum products from extraction sites to refineries, storage facilities, and distribution networks. Their ability to withstand high pressure and temperature variations makes them an ideal choice for long-distance oil and gas pipelines.

Offshore Drilling Operations

The oil and gas industry heavily relies on offshore drilling for exploration and production activities. MSERW pipes are commonly employed in the construction of subsea pipelines and risers. These pipes offer excellent structural integrity and are resistant to harsh environmental conditions, making them suitable for deepwater drilling applications.

Oil and Gas Processing Plants

Within oil and gas processing plants, MSERW pipes are utilized for various purposes. They are often used in the construction of storage tanks, separators, heat exchangers, and other equipment required for the processing and refining of crude oil and natural gas. MSERW pipes' versatility and reliability ensure the smooth operation of these critical facilities.

Challenges Associated with MSERW Pipe

While MSERW pipes have numerous advantages, they also face some challenges in the oil and gas industry. It is essential to be aware of these challenges and take appropriate measures to mitigate them:

Corrosion and Erosion

One of the primary concerns with MSERW pipes is their susceptibility to corrosion and erosion. Exposure to corrosive substances and abrasive particles in the oil and gas flow can lead to degradation of the pipe's surface, reducing its lifespan. Regular inspections, protective coatings, and cathodic protection systems are implemented to minimize the impact of corrosion and erosion.

Weld Quality and Integrity

The integrity of the welded joints in MSERW pipes is crucial for their performance. Weld defects such as porosity, cracks, and lack of fusion can compromise the strength and reliability of the pipe. Quality control measures during manufacturing and rigorous inspection procedures help ensure that welds meet industry standards and specifications.

Finding a Reliable MSERW Pipe Distributor in Gujarat

To address the growing demand for MSERW pipes in Gujarat's oil and gas industry, it is essential to collaborate with a trustworthy MSERW pipe distributor, dealer, supplier, and provider. The following factors should be considered while choosing the right partner:

Quality Assurance: Look for a distributor that sources MSERW pipes from reputable manufacturers who adhere to stringent quality control procedures and industry standards.

Product Range: Ensure that the distributor offers a wide range of MSERW pipe sizes, grades, and specifications to cater to various project requirements.

Timely Delivery: Reliability in terms of on-time delivery is crucial to avoid project delays. Choose a distributor with a track record of timely and efficient order fulfillment

#MSERW Pipe Distributor in Gujarat#MSERW Pipe dealer in Gujarat#MSERW Pipe Supplier in Gujarat#MSERW Pipe Provider in Gujarat

7 notes

·

View notes

Text

Best ERW Pipes In Mumbai

One of Mumbai's top producers of ERW Pipes is Bhushan Tube. One of our best-selling items in the metal market is A53 ERW pipes. To fulfil the unique needs of our customers, ERW steel pipe is offered in a wide range of diameters, forms, and specifications. To satisfy the needs of various industrial sectors in Mumbai, we offer these things in the right amount and with all the customized alternatives. The great strength, superior finish, and long life of ERW (Electric Resistance Welded) Pipe are made possible by a number of metals. In Mumbai, Bhushan Tube provides formable and high-strength steels, as well as ERW Pipe that requires boron and is weather-demanding. We are one of the top manufacturers, suppliers, and traders of U-tubes, seamless pipes, ERW pipes, and EFW pipes.

Address: 705 & 706, 7th Floor, KLJ Tower "North", Netaji Subhash Place, Pitam Pura, New Delhi

Phone: +91-11-45671912

Email: [email protected] and [email protected]

Visit our website: https://www.bhushantube.com/erw-pipes-india.html

#Black Pipes#MS Pipes#Steel Pipes#Tubes#vacuum tubes#test tubes#tubes#fallopian tubes#tubesettlermedia#boiler tubes#plastic#rowing#tires#screw#foam#Pipes#pipe system in refinery#pipe supplier#pipesmoking#affiliateprogram#construction#smm#digital signage#internetmarketing

2 notes

·

View notes

Text

Alloy Steel Buttweld Fittings Available Types

There are a variety of shapes and sizes available in alloy steel buttweld fittings. Fittings like these are used in a variety of industries, including automotive and industrial. Alloy steel fittings are made from alloy steels and other metals. The alloy steel buttweld fittings can be welded, machined, and heat treated to produce a wide range of products. When purchasing a set of steel fittings, as well as larger quantities, most fitting manufacturers offer package deals. Bulk purchases may also be discounted. Find out if shipping and handling charges are included in the pricing offered by your local supplier.

The article Alloy Steel Buttweld Fittings Available Types introduces Alloy Steel Buttweld Fittings Available Types. The book explains the composition and characteristics of alloy steel. The book includes detailed information on the basic machine processes and operating conditions of Alloy Steel Buttweld Fittings Available Types, heat treatment, machining procedures, and test methods for Alloy Steel Buttweld Fittings Available Types. To get a feel for what this product is like, you can also view our sample products. Do your research before buying.

Click on the links below to learn more about Alloy Steel Buttweld Fittings Available Types. A typical size is approximately 4 inches in diameter (roughly 0.926 inches thick) and 1/2 inch in thickness (roughly 0.127 inches thick). Standardized to BS EN 642 and AIB 6073, typical values are approximately 4 inches in diameter and 1/2 inch in thickness. Based on the total weight of the alloy, the material contains approximately 0.5% carbon by weight.

The versatile alloy of alloy steel buttweld fittings is used for a wide range of applications. Weldability, pressure bearing strength, and thermal stability are excellent. For superior durability under heavy loads, it possesses chromium, molybdenum, and ferrous. While fitting in the processing system, it resists corrosion caused by hazardous gases and chemicals. Weldable alloy steel buttweld fittings have a low carbon content and are resistant to carbide precipitation.

Various types of alloy steel buttweld fittings are made with chemical compositions of great strength and hardness. These chemicals include carbon, nickel, aluminum, manganese, titanium, and iron. There are even numerous specifications for these alloy fittings, such as size, standards, grade, types, thickness, forms, ends, surfaces, finishes, lengths, widths, applications, tolerances, conditions, and pressure.

Various properties of these alloy fittings include hardness, corrosion resistance, and sustainability at annealed temperatures. The properties of alloy fittings include thermal conductivity, electrical resistance, modulus of expansion, density, melting point, elongation, and electrical conductivity. There are numerous types of these fittings, including seamless, welded, fabricated, and ERW.

Among the many industries and general works that use alloy steel Buttweld Fittings are the pharmaceutical industry, gas processing, chemical equipment, pharmaceutical equipment, offshore oil drilling, industry, heat exchangers, condensers, seawater equipment, petrochemicals, power generation, food processing, paper mills, pulp mills, rail components, road transportation components, pumps, shafts, and military applications. The alloy steel Buttweld Fittings are made with several properties that enable them to be used in annealed temperatures and chloride environments without any deformation. The fittings are resistant to crevice corrosion, stress corrosion, cracking corrosion, pitting corrosion, and impact corrosion.

Pipe fittings (as opposed to Tube fittings) are butt-welded onto the pipe. They are produced according to different ‘schedules’. Based on the nominal bore pipe size, the schedule determines the wall thickness. It is common to find schedules 10 and 40, but schedules 80 and 160 are also available.

For more information visit

1 note

·

View note

Text

ASTM A335 P9 Pipes Stockiest and Supplier

Alloy Steel ASTM A335 P9 pipe uses are many and they are used all over the world in many different kinds of industries such as electric power, petroleum, boiler, chemical, oil and gas, etc. The reason why A335 P9 pipe have such big demand in various applications is because they offer excellent resistant to corrosion, plus they are very resistant to high temperatures, as well as low temperatures. A335 P9 pipe are just excellent when it comes to using them for flanging or bending and various other similar uses like fusion welding, etc. Important to note is that A335 P9 pipe have been built for high temperature service.

https://metaltubulars.com/astm-a335-p9-pipes-and-tubes-stockiest-and-supplier/

2 notes

·

View notes

Text

Push Ball Valve

https://www.carbovalve.com/products/push-ball-valve/

Because the push to connect flanged bronze ball valve is designed and manufactured with a push rod connection, push ball valve is ideal for service and maintenance work in tight spaces. Install push button ball valve on wet pipelines quickly to stop the flow of water. There are no special tools, crimping, glue, or welding required. Professionals can enter, complete repairs, and move on to the next job because push fit ball valve is compatible with PEX, copper, CPVC, PE-RT, and HDPE pipes. Push to connect ball valve has a wide range of ball valve options, including antifreeze ball valve with drain and spool valves. The spool valve allows for removing two inches of copper or CPVC pipe from an existing pipe.

Push Ball Valve Details:

Ball valve rating: 200PSI

Pushfit connection rating: maximum working pressure 232PSI

Max temperature 203oF (95oC)

Designed specifically for use in COPPER (PEX/CPVC) piping system

Pushfit ends comply with ASSE1061

Applied only for water

Push Ball Valve Specifications

Push Ball Valve

Product Code

Size

C

L

H

1BPA004

1/2" Pushfit

92.5

75

43

1BPA006

3/4" Pushfit

92.5

91

46.5

1BPA008

1" Pushfit

106

110.5

61.5

Push Ball Valve

Category 1 Code

Category 2 Code

Size

C

L

H

1BPAa04

1BPAb04

1/2" Pushfit

3.64"

2.95"

1.69"

1BPAa06

1BPAb06

3/4" Pushfit

3.64"

3.58"

1.83"

1BPAa08

1BPAb08

1" Pushfit

4.17"

4.35"

2.42"

How To Make Push Ball Valve

A new electric mechanical ball valve is often used as a liquid breaking device. It can be operated quickly and easily, and has only a small liquid resistance when it is opened. This motorized ball valve is designed to apply torque to the shaft head when the ball valve is operated. A flat square head is inserted into the long groove on the ball and turned. The gap between the flat square head and the groove is small, and the gap in the length direction is large. In this way, the industrial ball brass valve can be prevented from sliding down when it is closed, and the fluid pressure will evenly form a seal; the positioning pin and the limit plate form an operating position in the open and close positions; adopt a flat-head valve stem and handle. The connection will not be misaligned. So as to ensure that the handle indicates the switch shape.

2 notes

·

View notes

Text

Is Super Duplex Steel Pipe the Right Choice for Your Home?

When it comes to deciding on materials for production, sturdiness, and performance, deciding on the right kind of metallic pipe is important. Super Duplex Steel Pipes have emerged as a leading choice for plenty of packages because of their advanced houses. But are they the proper desire for your own home? Let's dive into the specifics of Super Duplex Steel Pipes, together with splendid duplex pipe specs, tremendous duplex fabric houses, and different key aspects to help you make a knowledgeable decision.

Understanding Super Duplex Steel

Super Duplex Steel, acknowledged for its tremendous corrosion resistance and excessive energy, is a kind of chrome steel that mixes the exceptional attributes of each austenitic and ferritic stainless steels. This specific combination gives a material that is both sturdy and proof against the harshest environments.

Super Duplex Pipe Specifications

Super Duplex Steel Pipes are often classified through particular standards and grades, such as the ASTM A790 UNS S32760 welded pipe. This specification ensures the pipes meet stringent first-class and overall performance requirements, making them appropriate for demanding applications.

Grade: ASTM A790 UNS S32760

Type: Welded Pipe

Diameter: Varies primarily based on software

Thickness: Customizable to fulfill precise needs

Length: Available in standard and custom lengths

These specifications highlight the versatility and robustness of Super Duplex Steel Pipes, making them an exquisite preference for numerous uses.

Super Duplex Material Properties

The exquisite duplex material properties make those pipes stand out within the market. Some of the maximum tremendous houses include:

High Strength: Super Duplex Steel Pipes showcase advanced tensile power, which makes them ideal for excessive-strain applications.

Corrosion Resistance: Their resistance to pitting, crevice corrosion, and pressure corrosion cracking ensures long-lasting performance even within the most harsh environments.

Good Weldability: Despite their excessive electricity, those pipes are especially clean to weld, taking into account flexible set up.

Thermal Conductivity: The thermal conductivity of Super Duplex Steel is better than that of austenitic stainless steels, enhancing its performance in warmness exchangers and other thermal applications.

Durability: These pipes provide fantastic sturdiness, making sure they could withstand harsh situations with out substantial wear and tear.

Super Duplex Stainless Steel Price Per Kg

One of the factors that homeowners and contractors take into account is the price of substances. The excellent duplex stainless-steel charge in step with kg can vary based totally on numerous elements together with the grade, length, and dealer. However, it is essential to view this price within the context of the long-term advantages supplied through the fabric.

While Super Duplex Steel Pipes may have a better prematurely cost compared to other substances, their durability, and minimal protection requirements can lead to massive financial savings through the years. Investing in extremely good Super Duplex Steel Pipes can therefore be a cost-powerful decision in the long run.

Applications in Home Construction

Super Duplex Steel Pipes aren't just for commercial use; they also have numerous applications in home production. Here are a few scenarios in which they is probably the proper preference:

Plumbing Systems: Due to their notable corrosion resistance, those pipes are best for plumbing structures that require long lasting and leak-proof solutions.

Heating Systems: The high thermal conductivity of Super Duplex Steel makes it best for heating structures, making sure green strength switch.

Structural Applications: Their excessive electricity permits them to be used in structural applications, offering dependable support and balance.

Water Treatment: If you have a home water treatment gadget, Super Duplex Steel Pipes can make sure the gadget's toughness and overall performance due to their resistance to corrosion and chemical compounds.

Availability and Export

Vishal Tube Industries is a main manufacturer and exporter of Super Duplex Steel Pipes, ensuring that splendid substances are available to meet the needs of numerous industries and houses globally. As a Super Duplex S32750 Pipe Fittings Exporter, the company guarantees that the fittings meet international requirements and are to be had for diverse programs.

Super Duplex S32760 Pipe Fittings Stockist in Saudi Arabia

For those in Saudi Arabia, finding a reliable dealer of Super Duplex S32760 Pipe Fittings is essential. Vishal Tube Industries shares a wide range of those fittings, ensuring that local wishes are met with the identical stage of great and reliability located globally.

Advantages of Choosing Super Duplex Steel Pipes for Your Home

Longevity: The durability and corrosion resistance of Super Duplex Steel Pipes make certain a longer lifespan in comparison to traditional materials.

Safety: These pipes provide a high stage of protection because of their energy and resistance to leaks and bursts.

Low Maintenance: The advanced homes of Super Duplex Steel result in minimal maintenance necessities, saving time and money in the end.

Aesthetic Appeal: With their smooth finish and high resistance to staining and tarnishing, Super Duplex Steel Pipes also make contributions to the aesthetic enchantment of your own home.

Conclusion

Super Duplex Steel Pipes, with their awesome amazing duplex fabric residences and sturdy extraordinary duplex pipe specs, offer several blessings for home construction. While the incredible duplex stainless steel price according to kg might be higher than a few options, the long-term benefits, which include durability, protection, and coffee upkeep, make them a worthy funding.

Vishal Tube Industries, with its tremendous experience and brand new centers, ensures which you have get admission to to pinnacle-pleasant Super Duplex Steel Pipes and fittings, whether or not you are inside the local marketplace or searching for a Super Duplex S32750 Pipe Fittings Exporter or a Super Duplex S32760 Pipe Fittings Stockist in Saudi Arabia. When considering the quality substances for your house, Super Duplex Steel Pipes stand out as a dependable and efficient desire.

#super duplex pipe specification#super duplex material properties#super duplex stainless steel price per kg#Super Duplex s32750 pipe Fittings Exporter#ASTM a790 uns s32760 welded pipe#Super Duplex s32760 pipe Fittings Stockist in Saudi Arabia

0 notes

Text

Jay Steel Corporation: Leading the Way in 316 Stainless Steel Plates Exports to Malaysia

Jay Steel Corporation has installation itself as a depended on call inside the stainless-steel business enterprise, specifically within the export of 316 stainless-steel plates to Malaysia. With a dedication to exceptional, reliability, and patron pleasure, we have were given come to be the favored preference for corporations seeking out first-rate stainless steel products in Malaysia.

Our huge kind of 316 Stainless Steel Plates Expotes In Malaysia are synthetic to fulfill the quality enterprise necessities and specs. These plates are recounted for his or her excellent corrosion resistance, durability, and versatility, making them suitable for a large sort of packages within the direction of numerous industries.

Key Features of Our 316 Stainless Steel Plates:

Corrosion Resistance: 316 Stainless Steel Plates Expotes offer high-quality corrosion resistance, especially in competitive environments containing chlorides, acids, and one-of-a-kind corrosive substances.

Durability: With their excessive electricity and sturdiness, 316 stainless steel plates are alternatively durable and able to withstand harsh on foot situations, making them first-rate for use in demanding applications.

Versatility: Our 316 chrome steel plates are quite bendy and may be applied in masses of industries, together with introduction, marine engineering, chemical processing, and in addition.

Precision Engineering: Manufactured the use of advanced era and precision engineering techniques, our 316 stainless steel plates meet the strictest remarkable requirements and specifications, making sure dependable conventional traditional ordinary performance and durability.

Wide Range of Sizes and Thicknesses: We provide an entire sort of 316 chrome steel plates in numerous sizes and thicknesses to fulfill the numerous goals of our clients in Malaysia.

Specification

Description

Material

316 Stainless Steel

Size Range

1/8" - 36" (Nominal Pipe Size)

Wall Thickness

Schedule 5S - Schedule XXS

Length

Custom lengths available upon request

Standard

ASTM A312, ASTM A358, ASTM A269, ASTM A213

End Connections

Plain End, Beveled End, Threaded, Socket Weld, Flanged

Stainless Steel 316L Sheets Stockist in Malaysia:

As a prime Stainless Steel 316L Sheet Manufacture in Malaysia, Jai Steel Corporation moreover stocks and manufactures stainless-steel 316L sheets to cater to the appropriate requirements of our clients. Our 316L sheets are available in some sizes, thicknesses, and finishes to satisfy the unique wishes of numerous industries.

With our top notch revel in and information within the chrome steel organization, we've got set up ourselves as a depended on stockist and manufacturer of Stainless Steel 316L Sheet Manufacture In Malaysia. Our strength of mind to excellence, reliability, and client pride unites us other than the opposition, making us the desired desire for agencies attempting to find awesome stainless-steel products in Malaysia.

For dependable and top notch 316 chrome steel plates and 316L sheets in Malaysia, except as proper with Jay Steel Corporation. Contact us in recent times to study greater approximately our services and products!

0 notes

Text

What is the difference between slip and weld neck flange?

Flanges are vital components in the meeting of piping systems, supplying a means to connect pipes, valves, pumps, and different system to shape a stable and dependable gadget. Two generally used forms of flanges are slip-on flanges and weld neck flanges. Understanding the differences among these flanges is crucial for deciding on the proper one for your particular application. This weblog will delve into the key variations between slip-on and weld neck flanges, that specialize in their design, installation, benefits, hazards, and usual applications in piping structures.

Understanding Flanges in Piping Systems

Role of Flanges

Flanges serve numerous essential features in piping systems:

Connection: They join pipes and tubes, taking into account smooth meeting and disassembly.

Maintenance: Flanges permit get entry to for cleansing, inspection, and amendment of the piping machine.

Strength: They offer a sturdy joint capable of withstanding excessive pressure and temperature.

Common Flange Types:

There are diverse varieties of flanges used in commercial applications, such as slip-on, weld neck, socket weld, blind, and lap joint flanges. Each type has particular functions and advantages, making them suitable for special eventualities.

Slip-On Flanges

Design and Construction

Slip-on flanges are designed to slide over the stop of a pipe or tube. They have a low profile and are typically secured with fillet welds, one at the internal and one on the outside of the flange. This layout makes slip-on flanges smooth to align and installation.

Installation Process

Positioning: The pipe is inserted into the slip-on flange till it protrudes barely past the flange face.

Welding: Fillet welds are applied both at the outside and inside of the flange to stable it to the pipe.

Advantages of Slip-On Flanges:

Ease of Installation: Slip-on flanges are sincere to place and weld, requiring much less unique alignment than a few other types of flanges.

Cost-Effective: Typically, slip-on flanges are much less high-priced than weld neck flanges.

Versatility: Suitable for a wide range of low to slight strain programs.

Disadvantages of Slip-On Flanges

Weaker Joint: The fillet welds do not provide as strong a joint as a weld neck flange.

Higher Potential for Leakage: The double welding method will increase the capacity for leaks compared to a single, more sturdy weld.

Typical Applications:

Slip-on flanges are normally utilized in low-stress programs wherein value savings and simplicity of installation are crucial. They are often determined in:

Low-Pressure Piping Systems: Such as those in plumbing and fire safety structures.

Low to Moderate Temperature Environments: Where the situations aren't intense.

Weld Neck Flanges

Design and Construction:

Weld neck flanges have a protracted tapered hub that transitions smoothly to the pipe or tube. This design lets in for a seamless reference to the pipe, offering higher electricity and resistance to pressure. The flange is butt-welded to the pipe, which includes welding the beveled cease of the flange to the beveled stop of the pipe.

Installation Process:

Alignment: The weld neck flange and the pipe are aligned, with the bevels of each component going through every other.

Welding: A butt weld is performed around the complete circumference of the flange and pipe joint.

Advantages of Weld Neck Flanges:

Strength and Durability: The butt weld offers a strong, leak-proof joint capable of withstanding high strain and temperature.

Stress Distribution: The tapered hub layout allows distribute mechanical stress, lowering the risk of failure.

Reduced Vibration and Turbulence: The easy transition from flange to pipe minimizes turbulence and vibration, improving the sturdiness of the piping gadget.

Disadvantages of Weld Neck Flanges:

Higher Cost: Weld neck flanges are usually more expensive than slip-on flanges because of their layout and the more complicated welding system.

More Complex Installation: The set up manner calls for specific alignment and skilled welding, making it more hard work-in depth and time-consuming.

Typical Applications:

Weld neck flanges are ideal for high-stress and high-temperature packages wherein energy and reliability are paramount. They are frequently used in:

Oil and Gas Industries: For pipelines transporting oil, fuel, and different hydrocarbons below high strain.

Chemical Plants: Where corrosive materials and extreme temperatures are common.

Power Plants: In systems that take care of steam and different excessive-temperature fluids.

Key Differences Between Slip-On and Weld Neck Flanges

Strength and Durability

Slip-On Flanges: Provide a much less strong joint due to the double fillet welds.

Weld Neck Flanges: Offer advanced energy with a butt weld which can face up to excessive pressure and temperature.

Installation and Alignment

Slip-On Flanges: Easier and quicker to install, requiring less particular alignment.

Weld Neck Flanges: Require unique alignment and professional welding, making the set up extra complex.

Cost Considerations:

Slip-On Flanges: Generally extra fee-effective, suitable for budget-sensitive projects.

Weld Neck Flanges: Higher preliminary fee because of the design and installation method, but may also offer value savings within the long time via reduced preservation and longer carrier life.

Application Suitability:

Slip-On Flanges: Best ideal for low to slight stress and temperature applications.

Weld Neck Flanges: Ideal for excessive-stress, excessive-temperature environments wherein reliability is important.

Conclusion:

Choosing the proper flange type is vital for the integrity and performance of piping systems in any enterprise. Understanding the variations among slip-on and weld neck flanges facilitates in making knowledgeable decisions based totally on the specific requirements of your software. Slip-on flanges are suitable for low-strain, low-price programs with easier installation requirements. In evaluation, weld neck flanges are the favored preference for high-strain, high-temperature systems in which strength and sturdiness are paramount.

When deciding on flanges in your pipes and tubes, don't forget elements along with strain ratings, temperature situations, installation complexity, and budget constraints. By doing so, you can make certain the choicest performance and longevity of your piping system, regardless of the industrial context.

0 notes

Text

Leading ERW Pipes Manufacturer in Punjab

Punjab, renowned for its industrial prowess, hosts several prominent manufacturers of ERW (Electric Resistance Welded) pipes, essential components in various industries ranging from construction to agriculture and beyond. Among these manufacturers, there are those that stand out for their unwavering commitment to quality, reliability, and technological advancement. These companies leverage state-of-the-art machinery and adhere to stringent quality control measures to produce ERW pipes that meet international standards and specifications. With a focus on precision engineering and durability, these manufacturers cater to the diverse needs of their clients, offering a wide range of ERW pipes in various sizes, shapes, and specifications. Their dedication to innovation, coupled with a customer-centric approach, has earned them a stellar reputation in the industry. For businesses in Punjab seeking high-quality ERW pipes for their projects, these manufacturers serve as trusted partners, providing solutions that meet the highest standards of performance and reliability.

#mild steel hollow section#erw pipes#tubes manufacturer in punjab#punjab#steel billets manufacturer in punjab#manufacturing#erw pipes manufacturer in punjab#pipes manufacturing

0 notes

Text

What is ERW pipes

ERW stands for Electric Resistance Welding. ERW pipes are manufactured using a welding process where metal strips are passed through rollers, and the edges are heated using electrical resistance and then welded together to form a pipe. This process results in a strong and durable pipe that is used in various applications, including:

Water and sewage transportation

Oil and gas pipelines

Structural purposes

Scaffolding

ERW pipes are popular due to their cost-effectiveness, efficiency in production, and the ability to produce pipes with a consistent and high-quality weld.

More Read: Steel pipe | ERW Pipes

0 notes

Text

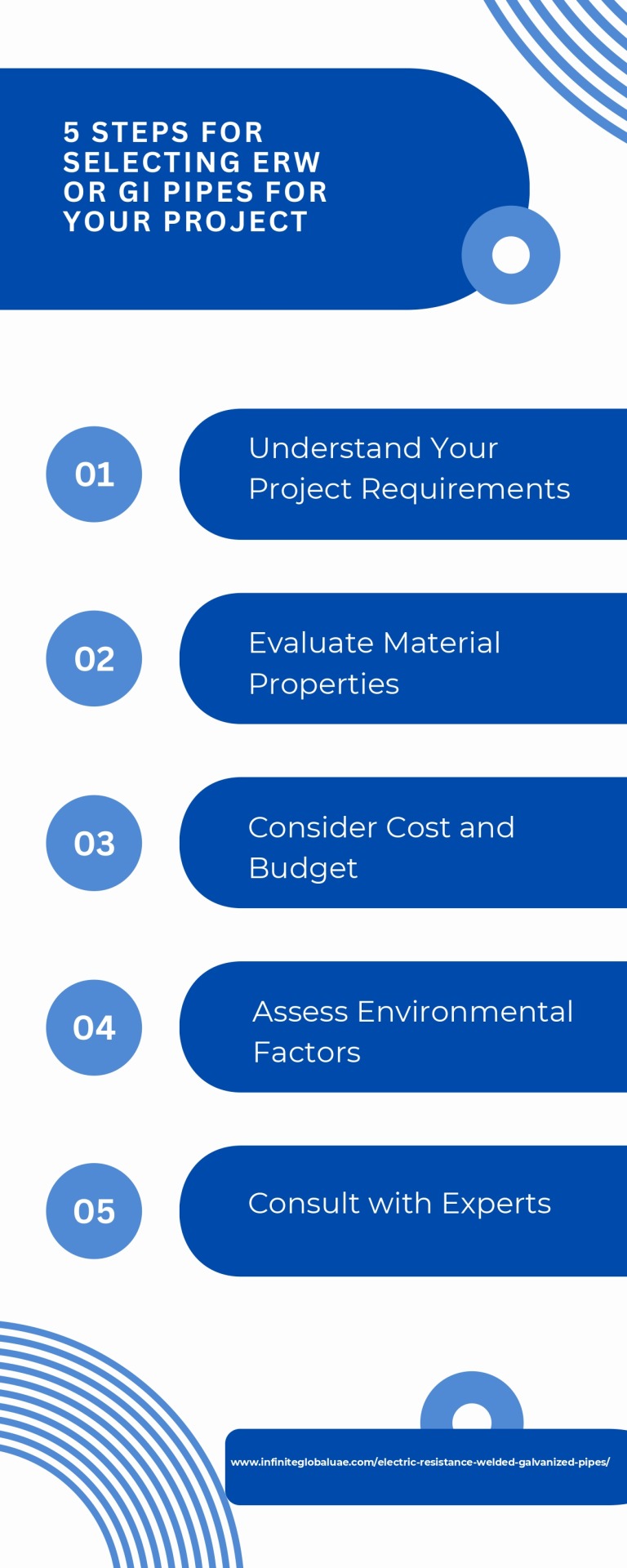

5 Steps For Selecting ERW or GI Pipes for Your Project

Discover the 5 essential steps for selecting between ERW (Electric Resistance Welded) and GI (Galvanized Iron) pipes for your project. Learn how to assess project requirements, evaluate material properties, consider costs, environmental factors, and consult with experts for informed decision-making. Visit Our website for more product information - https://infiniteglobaluae.com/electric-resistance-welded-galvanized-pipes/

0 notes

Text

What Makes MSERW Pipes the Backbone of Modern Infrastructure?

In the context of contemporary infrastructure, the utmost importance lies in guaranteeing longevity, strength, and efficiency. The Mild Steel Electric Resistance Welded (MSERW) pipe is a crucial element that constitutes the foundational framework of this infrastructure. The pipes possess exceptional qualities and adaptability, rendering them a crucial component in numerous sectors and applications. Looking for one of the leading as well as reliable MSERW Pipe distributors in Gujarat? Your search ends at Tube Trading Co. Contact today for a seamless supply of top-notch steel pipes!

This blog article aims to explore the distinguishing features of MSERW pipes and their essential role in shaping contemporary infrastructure.

· Robust Structure and Durability:

The MSERW pipes are fabricated utilising mild steel, hence offering inherent robustness and long-lasting performance. The utilisation of electric resistance welding in the manufacturing process enhances the structural integrity of the pipes, endowing them with the ability to endure elevated levels of pressure and effectively bear substantial loads. The inherent durability of this product guarantees an extended operational period, hence mitigating the necessity for frequent substitutions and diminishing the expenses associated with upkeep.

· Cost-Effective Solution:

Cost-effectiveness is a notable benefit associated with the utilisation of MSERW pipes. The manufacturing process has been optimised to enhance production efficiency and facilitate competitive pricing. The cost benefit associated with MSERW pipes renders them a compelling choice for a range of applications, particularly those necessitating substantial numbers of pipes for expansive infrastructure development.

· Versatility in Applications:

MSERW pipes are utilised in several industries spanning a wide range of sectors. These materials find application in several domains such as water supply infrastructure, oil and gas transportation networks, construction for structural reinforcement, agricultural irrigation systems and even for the conveyance of sewage and slurry. The adaptability of MSERW pipes renders them highly versatile, therefore establishing them as a preferred option for engineers and project planners due to their ability to cater to a wide range of applications.

· Resistance to Corrosion:

The property of resistance to corrosion holds significant importance, especially in the context of pipes utilised for the transportation of water and chemicals. MSERW pipes, which are frequently coated with galvanised or protective coatings, demonstrate remarkable resistance to corrosion. This particular characteristic enhances the durability of the pipes, guaranteeing consistent and sustained operational effectiveness. Seamless flow, seamless pipes! Choose Tube Trading Co., a recognised MSERW Pipe dealer in Gujarat, for your MSERW pipe requirements. Reach out and streamline your supply!

· Ease of Installation and Maintenance:

The installation and maintenance of MSERW pipes are widely recognised for their simplicity and convenience. The standardised dimensions and uniform quality of these objects render them highly convenient for use, resulting in time savings throughout the installation procedure. Furthermore, the endurance of these products necessitates less maintenance, hence leading to additional cost savings over an extended period of time.

· Environmentally Friendly:

Mild steel, which is the primary material of MSERW pipes, possesses the characteristic of recyclability and may be repurposed without any compromise to its inherent quality. The recycling process of MSERW pipes is characterised by lower energy consumption in comparison to the production of new steel, hence establishing MSERW pipes as an environmentally viable option. In the current epoch characterised by a heightened focus on sustainability, the inclusion of this attribute significantly enhances the attractiveness of MSERW pipes.

· Adherence to Quality Standards:

The manufacturers of MSERW pipes demonstrate a commitment to strict quality standards, thereby ensuring that the final product complies with both regulatory mandates and industry norms. The dedication to maintaining high standards ensures the dependability and effectiveness of MSERW pipes, fostering trust among engineers, contractors, and stakeholders engaged in infrastructure endeavours.

· Innovations in Technology:

The quality and properties of MSERW pipes have been further strengthened by advancements in welding techniques. The utilisation of contemporary methodologies and advanced machinery has led to significant enhancements in the welding procedure, hence yielding pipes that exhibit enhanced structural integrity and uniformity.

· Facilitation of Future Expansion:

The adaptability of MSERW pipes allows for the facilitation of future expansions or alterations. MSERW pipes have the inherent capability to be conveniently modified in order to accommodate changing infrastructure requirements, whether through the addition of supplementary branches or the modification of the existing piping system.

Final Thoughts:

Undoubtedly, Mild Steel Electric Resistance Welded (MSERW) pipes serve as an essential component of contemporary infrastructure. The amalgamation of robustness, longevity, cost-efficiency, and ecological viability establishes them as an indispensable element in diverse sectors. The significance of MSERW pipes in defining a sustainable and resilient future cannot be exaggerated, as infrastructure development continues to see rapid growth. Engineers, planners, and decision-makers ought to deliberate the incorporation of MSERW pipes as a primary selection to guarantee the durability and effectiveness of infrastructure endeavours. Time to strengthen your projects with top-tier MSERW pipes. Contact Tube Trading Co., a renowned MSERW Pipe Provider in Gujarat, and ensure success. Inquire now!

6 notes

·

View notes

Text

Advantages of Using Buttweld Pipe Fittings in Construction

In the development corporation, the significance of reliable and green piping systems cannot be overstated. Whether it is for residential, business, or commercial programs, the integrity of the piping gadget is critical for the safety and functionality of the structure. One of the important component components that make certain this integrity is the usage of buttweld pipe fittings. Renowned for their strength, sturdiness, and seamless connections, buttweld pipe fittings are widely utilized in diverse production tasks. In this blog, we're able to discover the several blessings of the usage of buttweld pipe fittings in creation and why they're favored thru engineers and developers alike.

What Are Buttweld Pipe Fittings?

Buttweld pipe fittings are a type of bend used to connect pipes in a piping device. They are designed to be welded onto the pipes, developing a permanent and robust connection. These fittings are available in numerous styles and sizes, consisting of elbows, tees, reducers, and caps, bearing in mind flexible configurations in piping layouts. Manufactured by using specialized buttweld fittings producers like Bullion Pipes, those fittings undergo rigorous satisfactory making to ensure they meet industry standards.

Advantages of Buttweld Pipe Fittings

1. Strong and Durable Connections:

One of the primary benefits of buttweld pipe fittings is the power of the connections they offer. The welding way creates a persevering bond among the appropriate and the pipe, which considerably enhances the mechanical electricity of the joint. This sturdy connection can withstand immoderate pressures, making buttweld fittings ideal for essential applications which include in oil and fuel, chemical processing, and power era industries.

2. Smooth Flow and Reduced Turbulence:

Buttweld fittings are designed to maintain the inner diameter of the pipes they connect. This alignment guarantees a clean transition of a number of the pipes, minimizing turbulence and pressure drop in the system. The smooth go along with the waft of fluids and gases is critical for maintaining the performance and performance of the piping machine, specially in industries in which unique glide manipulate is vital.

3. Enhanced Corrosion Resistance:

Many buttweld pipe fittings are made from corrosion-resistant materials which consist of chrome steel, alloy metal, and different immoderate-overall performance alloys. These substances offer splendid resistance to corrosive environments, it is in particular essential in industries handling harsh chemical compounds or marine packages. By selecting the nice cloth from a good buttweld fittings producer, you may make certain the toughness and reliability of your piping device.

4. Versatility in Design:

Buttweld pipe fittings are to be had in a huge variety of configurations, along with elbows (45-diploma and ninety-degree), tees, reducers (concentric and whimsical), and caps. This versatility allows engineers to design complex piping structures which could effectively control modifications in direction, pipe diameter, and glide rate. The availability of diverse sizes and shapes ensures that buttweld fittings may be used in clearly any piping format.

5. Cost-Effective Solutions:

While the preliminary price of buttweld pipe fittings is probably higher than a few exceptional kinds of fittings, their lengthy-term benefits cause them to a value-effective desire. The sturdiness and reliability of the welded joints lessen the want for common preservation and replacements, predominant to decrease lifecycle prices. Additionally, the reduced danger of leaks and screw ups interprets to fewer operational disruptions and capability price financial savings over the years.

6. Aesthetic and Space-Saving Design:

The seamless and compact nature of buttweld fittings offers a classy enchantment, especially in exposed piping structures. The clean transitions and shortage of sticking out factors provide a easy and professional appearance. Furthermore, the compact design of buttweld fittings saves region, making them suitable for installations in tight or constrained regions wherein region optimization is crucial.

7. Compliance with Industry Standards:

Buttweld fittings are artificial according to stringent organisation requirements, together with ASME (American Society of Mechanical Engineers) and ASTM (American Society for Testing and Materials). These necessities make sure that the fittings meet precise requirements for remarkable protection, and universal performance. By sourcing fittings from legit buttweld fittings manufacturers, you will be confident that the goods observe the essential policies and requirements.

Applications of Buttweld Pipe Fittings

Buttweld pipe fittings are utilized in numerous applications across precise industries, in conjunction with:

Oil and Gas: For pipelines and refineries where immoderate-pressure and excessive-temperature resistance is needed.

Chemical Processing: In structures that deal with corrosive chemicals and require robust, leak-proof connections.

Power Generation: For steam and cooling water structures in electricity plant life.

Water Treatment: In pipelines for potable water, wastewater, and desalination plant life.

Pharmaceutical: In sterile and clean piping structures wherein smooth, crevice-unfastened connections are essential.

Conclusion

The benefits of the usage of buttweld pipe fittings by Bullion Pipes in construction are smooth. Their strength, durability, easy flow developments, corrosion resistance, versatility, value-effectiveness, and compliance with enterprise requirements lead them to the favored preference for a big variety of programs. When making plans for your next introduction task, take into account the advantages of buttweld pipe fittings and supply them from a reliable buttweld fittings producer to ensure the achievement and sturdiness of your piping device.

Whether you're running on a huge-scale commercial project or a smaller residential set up, buttweld pipe fittings provide the reliability and performance had to create a strong and green piping infrastructure

0 notes

Text

AST Pipes: Your Trusted Source for High-Quality Industrial Tubing Solutions

When it comes to industrial applications, the quality and reliability of pipes and tubes are paramount. AST Pipes has established itself as a leading provider of diverse and specialized tubing solutions, catering to a wide array of industries. Our product range includes CDW pipes, IS3183 pipes, CR soft tubes and pipes, CRCA tubes and pipes, and many more. Let's delve into the specifics of our offerings and understand why AST Pipes is the go-to choice for your industrial needs.

Comprehensive Product Range

CDW Pipes and IS3183 Pipes:

Cold Drawn Welded (CDW) pipes are known for their superior finish and precision. They are widely used in the automotive and mechanical industries due to their high dimensional accuracy and smooth surface finish. Similarly, IS3183 pipes are essential in the oil and gas industry for transportation of hydrocarbons. These pipes adhere to stringent standards ensuring safety and efficiency.

CR Soft and Full Hard Tubes and Pipes:

Cold Rolled (CR) tubes and pipes come in two main varieties: soft and full hard. CR soft tubes and pipes are malleable, making them ideal for applications requiring complex bending and shaping. On the other hand, CR full hard tubes and pipes offer high strength and durability, suitable for demanding environments where rigidity is crucial.

CRCA Tubes and Pipes:

Cold Rolled Close Annealed (CRCA) tubes and pipes are known for their excellent formability and surface finish. These are extensively used in the manufacturing of automobile components, furniture, and various structural applications. The annealing process improves their ductility, making them easy to work with while maintaining strength.

Pre-Galvanised Tubes and Pipes:

Pre-galvanised tubes and pipes are coated with a layer of zinc before the manufacturing process, providing superior corrosion resistance. These pipes are essential in construction, fencing, and other applications where exposure to the elements is a concern.

Specialized Solutions

Special ERW Sections and ASTM A500 ERW Pipes and Tubes:

Electric Resistance Welded (ERW) pipes and tubes are integral to structural and mechanical applications. Special ERW sections can be customized to meet specific design requirements, while ASTM A500 ERW pipes and tubes are manufactured to comply with high standards for structural applications. These products ensure strength, reliability, and longevity in various projects.

IS9292 and YST 310 Pipes:

IS9292 pipes and tubes are tailored for water and sewage applications, ensuring leak-proof performance and durability. YST 310 pipes are known for their high yield strength, making them suitable for high-pressure environments and critical applications.

Solar Structure Tubes:

With the growing emphasis on renewable energy, solar structure tubes are designed to provide robust support for solar panels. These tubes are corrosion-resistant and can withstand harsh environmental conditions, ensuring the longevity of solar installations.

API Tubes and Idler Pipes:

API tubes adhere to the American Petroleum Institute standards, making them suitable for oil and gas exploration and transportation. Idler pipes and tubes are crucial components in conveyor systems, ensuring smooth and efficient operation in material handling industries.

Certified Excellence

Quality assurance is at the forefront of our manufacturing process. Our UL certified ERW pipes and tubes meet the stringent safety standards of the Underwriters Laboratories, making them suitable for use in safety-critical applications. CE certified ERW pipes and tubes comply with European standards, ensuring reliability and performance in diverse industrial settings.

Corten Steel ERW Pipes:

Corten steel ERW pipes are known for their weathering properties, forming a protective layer of rust that enhances their lifespan. These pipes are ideal for outdoor applications where durability and low maintenance are crucial.

Commitment to Quality and Innovation

At AST Pipes, we are committed to delivering high-quality products that meet and exceed industry standards. Our state-of-the-art manufacturing facilities, coupled with stringent quality control measures, ensure that every product leaving our facility is of the highest standard. We continuously invest in research and development to innovate and provide our customers with cutting-edge solutions.

Whether you are looking for precision-engineered CDW pipes, durable CRCA tubes, or certified ERW pipes, AST Pipes has the solution. Our diverse product range, adherence to international standards, and commitment to quality make us a trusted partner in the industrial sector. Choose AST Pipes for all your piping and tubing needs and experience the difference in quality and service.

#cdw tubes#gp tube#ms pipe#cr full hard pipe#carbon steel tubes#cr soft pipe#dom tubes#gp pipe#mild steel section#rectangular tube#cdw pipes#is3183 pipes#cr soft tube#crca tubes#crca pipes#pre galvanised tubes#pre galvanised pipes#Special ERW sections#is9292 tubes#is9292 pipes

0 notes