#Packaging Machinery

Link

#market research future#bagging machine market#bagging machine#packaging machinery#bagging machines market

0 notes

Video

youtube

Automatic Used Imported Packaging Machinery for Sale at IndiaBizzness

#youtube#Automatic Used Imported Packaging Machinery for Sale#Packaging Machinery#Buy Used Packaging Machinery#Second Hand Imported Packaging Machinery

0 notes

Text

Discover the future of packaging with Prasanna Packaging, your trusted partner for Packaging Machinery. Our commitment to excellence and innovation ensures that your packaging processes are efficient, reliable, and tailored to meet your unique needs. explore our comprehensive range of packaging solutions, featuring advanced machinery designed to optimize production, enhance product protection, and streamline your operations.

Visit website: https://prasannapackaging.com/

0 notes

Text

Sigma CapSeal Induction Sealers

Welcome to the cutting-edge world of Sigma CapSeal Induction Sealers, where innovation meets precision in the realm of packaging solutions. As a global leader, we bring you state-of-the-art technology that transforms your packaging processes. Discover the seamless fusion of efficiency, reliability, and quality, as we redefine the standards of induction sealing. Dive into our blog for insights into the future of packaging technology with Sigma CapSeal.

0 notes

Link

RIDAT: Leading UK Manufacturer of Thermoforming Equipment

RIDAT is a leading UK manufacturer of thermoforming equipment with over 70 models and 60+ years of experience. We offer a wide range of thermoforming machines, including blister packaging and skin pack machinery. Our machines are known for their durability, reliability, and performance. We have a global customer base and our machines are operating in over 65 countries around the world.

#Thermoforming Equipment#Blister Packaging#Vacuum Forming#Pressure Forming#Packaging Machinery#Manufacturing#Packaging Solutions#Industrial Equipment#Automated Packaging#Sustainable Packaging#Product Packaging#Plastics Industry

0 notes

Text

Chocolate Packing Machine Maintenance: A Key to Efficiency Gains

In the world of chocolate production, packaging plays a crucial role in ensuring product quality, attractiveness, and shelf life. As the demand for chocolates continues to rise, manufacturers are constantly seeking ways to streamline their packaging processes. One key solution to achieve higher efficiency is the use of a state-of-the-art Chocolate Packaging Machine. In this blog, we will explore the benefits of integrating a Chocolate Packaging Machine into your production line and how it can help you optimize your packaging processes.

Efficiency and Productivity:

Manual packaging can be time-consuming and prone to human error. A Chocolate Packaging Machine automates the packaging process, increasing overall efficiency and productivity. These machines are designed to handle a high volume of chocolates, ensuring consistent and accurate packaging. By eliminating the need for manual labor, manufacturers can significantly increase their output while maintaining a consistent level of quality.

Versatility and Customization:

Chocolate Packaging Machines offer a variety of packaging options, allowing manufacturers to customize their products according to different sizes, shapes, and branding requirements. Whether it's wrapping individual chocolate bars, creating assortments, or packaging gift sets, these machines can be programmed to meet various packaging needs. This versatility not only ensures efficient packaging but also enhances the overall aesthetic appeal of the final product.

Sealing and Protection:

One of the main functions of a Chocolate Packaging Machine is to provide a secure seal for each chocolate. This ensures the integrity of the product, prevents contamination, and extends its shelf life. These machines utilize advanced sealing technologies, such as heat sealing or ultrasonic sealing, to create airtight packaging that keeps the chocolates fresh and safe from external elements.

Consistency and Quality Control:

Consistency is vital in the chocolate industry, where even the slightest variation can impact the taste and texture of the final product. Chocolate Packaging Machines are designed to provide precise and consistent packaging, ensuring uniformity in the presentation of each chocolate. This not only enhances the visual appeal but also reflects the commitment to quality that consumers expect from your brand.

Ammar Machinery, a leader in the chocolate packaging industry, offers a range of cutting-edge Chocolate Packaging Machines to streamline your packaging processes. With their years of experience and expertise, Ammar Machinery has developed machines that meet international standards, combining efficiency, precision, and innovation. Their machines are not only designed for high performance but also come with a five-year warranty, providing peace of mind to manufacturers. By partnering with Ammar Machinery, you can elevate your packaging processes and take your brand to new heights of success.

Conclusion:

Streamlining chocolate packaging processes is essential for higher efficiency and productivity. By incorporating a Chocolate Packaging Machine into your production line, you can achieve consistent, customizable, and high-quality packaging for your chocolates. Ammar Machinery offers state-of-the-art machines that are designed to optimize packaging operations and deliver exceptional results. Embrace the future of chocolate packaging and boost your brand's success by investing in a Chocolate Packaging Machine from Ammar Machinery.

#chocolate packaging machine#chocolate machinery#packaging machinery#machinery manufacturer#chocolate wrapping machines on sale#wrapping machine

1 note

·

View note

Text

The Role of Packaging Machinery and Filling Machines

In today's fast-paced and highly competitive manufacturing industry, efficiency and precision are paramount. Title: "Efficiency and Precision: The Role of Packaging Machinery and Filling Machines"

In today's fast-paced and highly competitive manufacturing industry, efficiency and precision are paramount. Packaging machinery and filling machines play a crucial role in meeting these demands, ensuring that products are not only delivered to customers in top condition but also with reduced production costs. These machines have revolutionized the way businesses package their goods, whether in the food and beverage, pharmaceutical, cosmetics, or other industries.

Packaging machinery encompasses a wide range of equipment designed to streamline the packaging process. This includes filling machines, capping machines, labeling machines, and more. Filling machines, in particular, are at the heart of many industries. They precisely dispense liquids, powders, granules, and other substances into containers, eliminating human errors and variations in filling quantities. This not only reduces product wastage but also ensures that customers receive consistent and accurate quantities of the product.

One of the key benefits of packaging machinery and filling machines is speed. These machines are engineered for high production rates, helping businesses meet the demands of a rapidly growing market. Moreover, they operate continuously, significantly increasing the efficiency of the packaging process. This translates to cost savings, as fewer resources are needed to produce and package the same quantity of goods.

Quality control is another critical aspect that packaging machinery and filling machines bring to the table. They ensure that products are sealed, labeled, and packaged correctly, reducing the risk of contamination and damage. This is particularly crucial in industries like pharmaceuticals and food, where product integrity is paramount.

Additionally, these machines are highly adaptable. They can be configured to handle various container sizes and shapes, accommodating the diverse needs of different products and industries. This versatility is a significant advantage for manufacturers looking to diversify their product lines or adapt to changing market demands.

In conclusion, packaging machinery and filling machines are the unsung heroes of modern manufacturing. They enhance efficiency, precision, and product quality while contributing to cost savings. Their adaptability and speed make them indispensable tools for industries striving to stay competitive and meet customer demands in today's fast-paced world.

Original source: https://proquipx1.gumroad.com/p/the-role-of-packaging-machinery-and-filling-machines

0 notes

Text

AUTOMATION IN DIWALI PACKAGING

कैसे करें दिवाली पैकेजिंग में ऑटोमेशन का उपयोग: समय और लेबर की बचत का तरीका"

"Harnessing Automation in Diwali Packaging: A Way to Save Time and Labor"

1. Diwali Packing for Automatic Machines

2. Saving Time

3. Labor Efficiency:

4. Smart Pack Diwali Packaging Machines

5. Improved Design and Branding Control:

6. Business Expansion Opportunities:

7. Ensuring Safety and Hygiene:

8. Reduced Environmental Impact:

9. Quality Control:

10. Financial Benefits:

Explain the benefits of automation in Diwali packaging processes for industries, including cost and time savings

Diwali, one of India's most celebrated festivals, is a time when people exchange gifts and share sweets with their loved ones. It's a time when the packaging industry experiences a flow in demand, but it also poses a significant challenge as it requires both time and labor-intensive efforts.

In this article, we will explore the advantages of incorporating automation into the Diwali packaging processes, highlighting how it can lead to substantial cost and time savings.

1. Diwali Packing for Automatic Machines:

One of the most efficient ways to streamline Diwali packaging is by utilizing automatic packaging machines. These machines, often referred to as "Diwali packing machines" or "Diwali sweet packing machines," are designed to package items such as sweets, gifts, and other Diwali essentials with speed and precision. Once set up, these machines can work autonomously, packaging a large volume of items quickly, thus saving both time and labor.

2. Saving Time:

Automation in Diwali packaging translates into significant time savings. When done manually, packaging each item requires careful counting and packaging, which can take hours. Automated machines can accomplish the same task in a matter of minutes, enabling you to prepare more packages in less time.

**3. Labor Efficiency:**

Utilizing Diwali packaging machines can lead to substantial labor savings. Manual packaging processes often require a large workforce to meet the high demand during the festive season. Automation reduces the need for human intervention, thus minimizing labor costs.

**4. Smart Pack Diwali Packaging Machines:**

Some advanced machines now fall under the category of "smart packaging machines." These machines incorporate sensors and IoT (Internet of Things) technology to enhance their functionality. By using data, you can manage your production process efficiently and make better use of your resources, ultimately aiding your packaging process in meeting its requirements more effectively.

**5. Improved Design and Branding Control:**

Automation allows for better control over the design and branding of your packaging. These machines can consistently produce packages with a professional and attractive appearance. This not only saves time but also ensures that your products are presented in the best possible way to attract customers.

**6. Business Expansion Opportunities:**

By automating your Diwali packaging process, you free up resources that can be redirected toward expanding your business. You can focus on aspects like distribution and marketing because the packaging workload is significantly reduced due to automation.

**7. Ensuring Safety and Hygiene:**

Safety and hygiene are of utmost importance during Diwali packaging, especially when handling food items like sweets. Automated machines can ensure high levels of hygiene and safety in the packaging process, instilling trust in your customers and maintaining the quality of your products.

Read More

#packaging machines sealing machines#packaging industry#packaging machinery#packaging machines#packaging#sealing machines

0 notes

Text

5 Types of Food Packaging Equipment

Food packaging equipment executes unit operations that preserve food materials at a high level of safety, quality and taste. The most effective type food packaging equipment abides by strict governmental standards and specifications.

Common examples of this machinery include Form, Fill and Seal machines, sleeve systems, closing machines and vacuum chambers. The functionality and cost of this equipment varies by model.

Fillers and Depositors

Our fillers and depositors are designed to accurately dose a specific amount of liquid, cream or powder into packaging containers. Depending on the type of product, they can accommodate low- to high-viscosity compounds and operate as standalone units or integrate with other machines in your production line.

Using a servo-drive, the Unifiller multi-piston depositor can help you package a variety of entrée items including soups, sauces, salsas, dips and dressings into bags, cups or trays. It features a 16-gallon removable hopper for easy sanitation, an adjustable nozzle bridge for 4-8 across portioning and a diving and fixed nozzle option.

Sleeve systems are great for automating sleeving operations that are normally manual and time-consuming. They can help reduce waste and increase productivity. Capping machines are popular in soda and bottled-water factories and help close a bottle's air-tight cap. These machines are often used in conjunction with accumulation machinery and conveyors. Krones offers a range of food packaging equipment under the portfolio segments of digitalisation, process technology, bottling and packaging lines and intralogistics.

Vacuum Chambers

Vacuum chambers are large containment vessels that create a low-pressure environment. They can be designed to mimic specific environmental and atmospheric conditions, such as high altitudes. These chambers can be used to test and perform applications for manufacturing operations.

The food industry uses vacuum chambers to speed up the cooling and drying processes for products. This helps preserve a product’s cellular integrity, color, taste and appearance.

Another common use for a vacuum chamber is the creation of crystalline materials. In this process, a saturated solution of liquids is mixed and agitated so that structural solid crystal deposits will form. This is done because crystalline materials are much more stable than liquids, even in extreme temperatures and pressures.

A vacuum chamber can be fitted with a number of valves and gauges to monitor and control the process. Some vacuum chambers use a manual control system, while others require an automated controller that can make adjustments to the process.

Sleeve Systems

A sleeve system allows for an easier and faster process of labeling bottles or containers. Rather than using pre-printed labels, these sleeves are printed on film and then seamed to the bottle or container. The sleeve can then be heated with steam or electricity to fit the bottle or container perfectly.

Once on the container, a tamper evident band is added. This helps protect the product while ensuring that it is safe for consumption by consumers. Additionally, the sleeve can include full color branding and unique shaped containers to differentiate the brand from competition.

The sleeve may also be fabricated on-site, rather than being shipped to the user as a finished unit. The sleeve may be formed to an elongated generally cylindrical shape, with a tab 22 that is provided axially along one or more of the long side edges of sleeve parts 21. The axially-terminating ends of the tab 22 may be chamfered, angled, or otherwise modified as desired.

Labeling Machines

Labelling machines are used to attach labels or decorations to packaging containers. This can be either to promote a brand, communicate product details or offer tamper evidence. The machine can use wet glue or pressure sensitive (self-adhesive) labels and comes in a variety of configurations.

Usually the container or item is conveyed to the label distribution area by a conveyor belt. The labels are then positioned and fixed to the items using a roller system that ensures proper spacing between products. This is especially important for products that are round-shaped, like bottles.

Another type of labeling machine is the hot melt machine, which applies thin stripes of molten adhesive to a paper label and wraps it around a product, such as a soup or paint can. Activated by a foot or hand switch, this machine is incredibly fast and offers high-quality labeling results. This type of machine is ideal for labelling large-volume containers. SaintyCo labeling machines come in different options and designs.

You can also read the types of food packaging machines here.

0 notes

Text

Revolutionizing the Packaging Industry: A Look at the Latest Machinery in Kenya

The packaging industry has come a long way, and with the advent of technology, it has experienced a paradigm shift that has revolutionized the way products are packaged. In Kenya, the packaging industry is no exception, with the latest machinery making a significant impact. These machines have transformed the way packaging is done, increasing efficiency, speed, and accuracy while reducing…

View On WordPress

0 notes

Text

Elevate Your Business with Verified Lead - IndiaBizzness

IndiaBizzness: Elevate your business with India's premier online B2B platform. Connect, showcase, and expand your reach effortlessly. Explore a myriad of opportunities for growth and success with IndiaBizzness.

#Business#IndiaBizzness#B2B Site#Second Hand Machinery#Used Machinery Sale#Packaging Machinery#Plastic Processing Machinery#Printing Machinery#Businesses for Sale#Industrial Plants For Sale

0 notes

Photo

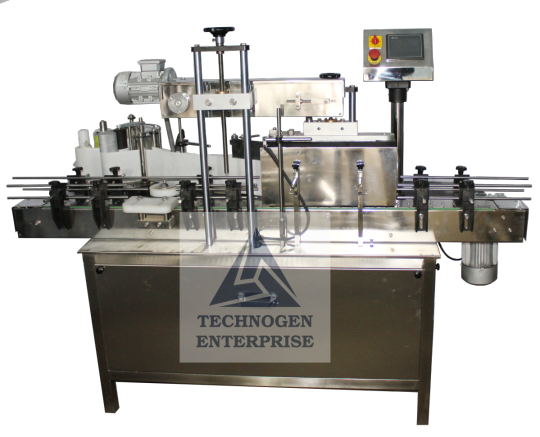

Offering Best Quality Packaging Machine | Hubs Engineering

We are a top quality packaging machine in Singapore. Our best packaging machines are suitable for your needs. You can choose from any of available packaging machines to meet your needs and wishes. For more information, you can visit our website or call us +65 8298 5012.

0 notes

Text

Induction Cap Sealing – An Efficacious Solution for Pharmaceuticals

Pharmaceutical products are formulated in various dosage forms – solids (powders, tablets, capsules), liquids (solutions, syrups, suspensions, emulsions), semi-solids (creams, ointments, lotions), etc. based on therapeutic use and route of administration.

The packaging of the product is designed to retain the potency and efficacy of the drug throughout its shelf life. The general rule is that the drug should retain 90% or more of its potency at the expiration date. Exposure to unwanted contaminants can affect the potency and efficacy of the drug and also accelerate the rate of deterioration.

Sigma CapSeal, a pioneer in induction cap sealing, has partnered with various Pharma companies to improve the packaging and deliver efficacious products to consumers. Read More

#pharmaceutical#induction sealing machine#induction sealers#packaging machinery#packaging#automation#technology

0 notes

Link

Blister Packaging Machine: An Easy Guide to Buying Blister Packaging Machines (2023)

Learn everything you need to know about buying a blister packaging machine, from the different types available to the factors to consider when making a purchase.

#packaging solutions#packaging machinery#sustainable packaging#packaging solution#blister packaging machines#packaging equipment#product packaging#versatile packaging#packaging machine buying guide#blister packaging machine buying guide

0 notes