#SupplyChainTech

Text

Mastering Inventory Management System: Strategies with Canary7 WMS

Imagine you’ve finally found the product you’ve been looking for at an online store. You place the order and find out the item is out of stock. This disappointing experience will make you less likely to visit that store again.

For any e-commerce business, every sale is crucial, and you don’t want to miss out on potential customers with a disorganized inventory. Think of your inventory as the backbone of your online store; without it, you won’t be able to maintain your business.

To avoid these hiccups, you must devise a foolproof inventory management strategy. Not sure where to begin? Read along to find helpful tips and tricks for mastering inventory management.

#InventoryManagement#Canary7WMS#WarehouseManagement#SupplyChain#LogisticsSolutions#InventoryControl#BusinessEfficiency#OperationsManagement#InventoryOptimization#SupplyChainTech

0 notes

Text

Manufacturing Supply Chain Analytics Solution

Transform your operations with Manufacturing Supply Chain Analytics Solution - Unlock efficiency and drive growth. Optimize your supply chain today!

#supplychaintech#automotiveindustry#logisticssolutions#automanufacturing#digitaltransformation#supplychainmanagement#automotive#cerestech#autoindustry#supplychain#automobileindustry

0 notes

Text

#TradeComplianceAward#iCustomsWins#AIforTrade#AutomatedCompliance#BoostEfficiency#ReduceErrors#RealTimeData#GlobalTradeSimplified#SupplyChainTech#GetMoving

0 notes

Text

Industrial Buying Made Easier: Embrace AI-Powered eCommerce

Is your industrial procurement stuck in the past? Transform it with AI!

Say goodbye to outdated catalogs and hello to streamlined purchasing with Diginyze.

Dive into the future where industrial buying is not just easier—it's smarter.

Full story here: https://www.diginyze.com/blog/industrial-buying-made-easier-embrace-aipowered-ecommerce/

#FutureOfBuying#AIPoweredProcurement#IndustrialRevolution4_0#eCommerceEvolution#DigitalTransformation#SupplyChainInnovation#IndustrialBuying#IndustrialDistribution#B2BCommerce#ProcurementTech#B2BeCommerce#InventoryManagement#SupplyChain#SmartProcurement#FutureOfProcurement#DigitalProcurement#IndustrialECommerce#SupplyChainTech

0 notes

Text

Power Up Your Supply Chain with Ninjacart supply chain tech stack

Explore the ultimate solution for your supply chain needs with Ninjacart – India's largest tech-driven platform connecting farmers. Our power-packed tech stack covers it all, from end-to-end supply chain management to in-house ERP, warehouse management, logistics, proprietary inventory management, sourcing modules, CRM, and more.

Key Features:

Seamless Integration

End-to-End Supply Chain Modules

In-House ERP

Proprietary Inventory Management

Customer-Centric CRM

Ready to optimize your supply chain? Book an appointment now! Call 8069155666 or visit Ninjacart International. Embrace Ninjacart's tech stack for a scalable, efficient, and seamless supply chain experience!

#Ninjacart#SupplyChainTech#TechStack#Efficiency#ScalableGrowth#ERP#WarehouseManagement#Logistics#InventoryManagement#SourcingModules#CRM#AppointmentBooking#BusinessOptimization#FarmersConnect#SeamlessIntegration#NinjacartInternational

0 notes

Text

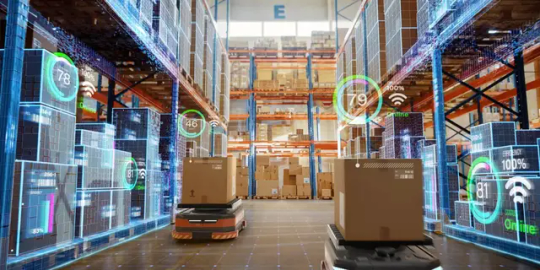

Charting the Growth Path of the Warehouse Robotics Market: Robotic Logistics Revolution

The global warehouse robotics market size is anticipated to reach USD 17.29 billion by 2030, exhibiting a CAGR of 19.6% over the forecast period, according to a new report published by Grand View Research, Inc. The expansion of the e-commerce industry, rising labor costs, and the need for greater efficiency and accuracy in warehouse operations fuel the growth of the market.

The e-commerce sector is witnessing remarkable growth due to technological advancements. Technologies like Virtual Reality (VR), Augmented Reality (AR), blockchain technology, Machine Learning (ML), and Artificial Intelligence (AI) are enhancing the shopping experience. Thus, companies seek new methods to enhance operations and logistics while reducing delivery time and costs.

Warehouse Robotics Market Report Highlights

The cartesian robots are expected to witness a CAGR of approximately 20% in the product segment from 2023 to 2030. The factors such as accuracy, precision, and ability to handle heavy loads is expected to fuel the growth

In terms of function, the transportation segment is anticipated to grow at the fastest CAGR of 20.4% over the forecast period. The growth is attributed to increased demand for sorting, loading, and unloading goods from robots

The 11 kg to 80 kg warehouse robots is likely to witness a CAGR of approximately 20% from 2023 to 2030. The ability to efficiently handle medium and heavy-weight items in manufacturing, healthcare, food, beverages, and other industries is expected to support the growth

The software segment is estimated to experience a CAGR of approximately 21% over the forecast period. The segment is divided into a warehouse management system, a warehouse control system, and a warehouse execution system

The healthcare industry is anticipated to witness the fastest CAGR of approximately 21% in the application segment from 2023 to 2030. The growth is attributed to the continuous developments and increased implementation of robots in the healthcare sector to perform a variety of tasks in healthcare warehouses

For More Details or Sample Copy please visit link @: Warehouse Robotics Market Report

Robots offer a smart, cost-efficient alternative to human labor by automating warehouses catering to the increasing need of the e-commerce sector. The robots help companies to maintain employee safety standards and enhance production quality by performing various tasks such as handling the incoming consignment, picking, packing, slotting, shipping, and asset tracking by saving considerable time and effort.

The COVID-19 pandemic impacted the warehouse robotics industry substantially in terms of the demand for robotics and the supply chain of the robotics industry. However, the need for efficient and contactless order fulfillment and labor shortage due to lockdowns fueled the demand for robots and other automation tools in business operations. The market has shown rising demand and continuously growing as companies invest heavily in research and development activities to improve existing technologies and launch advanced robots.

The initial investment of the robotic set-up into the warehouse is high, creating significant challenges for small and mid-sized companies. Furthermore, implementing robots in warehouse operations is affecting labor jobs. The rising adoption of robots is expected to affect employment and wages, affecting the further growth of the warehouse robotics industry over the forecast period.

#WarehouseRobotics#LogisticsAutomation#RoboticWarehousing#SupplyChainTech#AutomationSolutions#SmartWarehouses#RoboticsInLogistics#Industry40#TechInnovation#EfficientSupplyChain#LogisticsTechnology#RoboticsIntegration#AutomatedStorage#DigitalTransformation#InnovativeLogistics#WarehouseEfficiency#AutonomousWarehousing#RoboticsIndustry#TechInvestment#FutureofLogistics

0 notes

Text

How To Deploy Warehouse Automation System?

Warehouse automation is a solution advised for firms aiming to increase logistics productivity, maximize storage space, and enhance the safety of their personnel, goods, and storage systems. But how exactly does one go about automating a warehouse? What steps should people take? In this blog, let’s discuss the steps to implement warehouse automation.

Rising R&D spending, high labor costs, a shortage of qualified workers, and increasing public awareness of the benefits of the market. Thus, these elements are predicted to boost market growth. In addition, according to a research report by Astute Analytica, the global Warehouse Automation Market is likely to grow at a compound annual growth rate (CAGR) of 15% over the projection period from 2023 to 2031.

Follow This Step-By-Step Guide To Get Started With Warehouse Automation:

Create a committee to oversee the implementation

Create a committee of internal stakeholders with knowledge of current warehouse capabilities, performance, and challenges, as well as an understanding of existing technology gaps; consider bringing in third-party experts who are knowledgeable about supply chain automation and have knowledge of industry and warehouse operations.

Collect essential information

Effective warehouse automation is dependent on data from a person’s existing supply chain and business-critical warehouse operations. Before deploying new automation technology, assess the present data collection method and infrastructure. They should delegate data migration responsibility to qualified IT stakeholders.

Examine inventory controls

Inventory control is crucial to warehouse operations. Determine or refine people inventory control standard operating procedures (SOPs) before using warehouse automation technology. Include standard operating procedures for shipping, purchasing, customer satisfaction, receiving, and inventory loss.

Define the key performance indicators (KPIs) that will be used to assess the effectiveness of automated inventory control procedures and processes. Evaluate the current inventory accounting method (for instance, perpetual or periodic systems) and how automation may affect it.

Set up partnerships with stakeholders

Supply chains can be fairly complicated because they are made up of numerous distinct links. It is beyond a doubt one of the most crucial elements to consider when automating the warehouse because the person must guarantee that the appropriate resources have been engaged.

This entails establishing collaborations with firm stakeholders, who range from funders to technicians, and from their technical assistance team to operations managers. Bringing everyone’s skills and experience together will aid in identifying obstacles, opportunities, and crucial issues at the beginning of the automation process.

Establish a warehouse management system (WMS)

WMS systems include software modules that aid in the control and tracking of inventory, the management of warehouse operations, the reduction of wages associated with manual duties, and the improvement of customer service. A new WMS should aid mobile devices and be compatible with their current enterprise software.

Determine the type of warehouse automation required

Person’s intention to employ automation to cut labor expenses related to back-office warehousing operations and accounting? Or, are they growing their warehouse footprint or opening new locations and believing it’s time to implement advanced physical process automation, like robots and GTP systems? It is critical to identify the type of warehouse automation that corresponds with goals and consumer demand.

Source: How To Deploy Warehouse Automation System?

#Warehouse Automation System#Warehouse Automation Market#Warehouse Automation#WarehouseAutomation#SupplyChainTech#LogisticsSolutions#OperationsManagement#IndustrialEngineering#ManufacturingTech#RoboticsIntegration#BusinessAutomation#TechnologyDeployment#EfficientWarehousing#ProcessOptimization#SmartWarehousing#InventoryManagement#DistributionCenter#AutomatedLogistics

0 notes

Text

Achieve Excellence into Your Supply Chain

Mounting supply chain interruptions are key barriers in acheiving excellence across production and distribution of products on-time. Be prepared to mitigate supply chain disruptions by aligning with good procurement practices.

Enable, Capture & Sustain value through Source to Pay Outsourcing. https://bit.ly/3elV3MF

#supplychainresilience#supplychaindisruption#supplychainmanagement#supplychainoptimization#supplychainvisibility#supplychaintech#DigitalSupplyChain#supplychaintrends#Procurement#Sourcing#Supplychain

0 notes

Text

Retraced Ensures Product Authenticity with...

Oracle Blockchain customer retraced shares their story of authenticating products & fair trade practices for fashion brand Cano Shoes with #blockchain. Watch this short video to hear their story. #blockchaintech #usecases #supplychaintech #supplychainvisibility

Retraced Ensures Product Authenticity with...

Retraced is a German start-up that has launched with the goal of track & trace for fashion. Their mission is to provide the end-consumer with deeper insights into the fairness and sustainability standards of the fashion brands’ supply chains. In order to build brand loyalty & enable consumers to make conscious choices, retraced is using the Oracle Blockchain Platform to verify authenticity and responsible sourcing for CANO shoes' handmade Mexican huaraches. Learn more online at Oracle.com/Blockchain.

Oracle Champions

0 notes

Text

#Sustainability #SupplyChainTech : Stanford researchers reveal limited scope of corporate approaches to social and environmental issues - https://t.co/tHB1DTVgRH https://t.co/8wGTbWazhv

#Sustainability #SupplyChainTech : Stanford researchers reveal limited scope of corporate approaches to social and environmental issues - https://t.co/tHB1DTVgRH pic.twitter.com/8wGTbWazhv

— The Royal Vox Post (@RoyalVoxPost) February 12, 2018

via Twitter https://twitter.com/RoyalVoxPost

February 12, 2018 at 09:27PM

0 notes

Text

Manufacturing Supply Chain Analytics Solution

Transform your operations with Manufacturing Supply Chain Analytics Solution - Unlock efficiency and drive growth. Optimize your supply chain today!

#supplychaintech#automotiveindustry#logisticssolutions#automanufacturing#digitaltransformation#supplychainmanagement#automotive#cerestech#autoindustry#supplychain#automobileindustry

0 notes

Text

iCustoms Receives ICC Digital Trade Award for “Best Port or Logistics Systems

iCustoms Wins Big at International Trade Awards!

We’re thrilled to announce that iCustoms has been awarded the “Best Port or Logistics Systems” award by the International Chamber of Commerce (ICC)! This prestigious recognition highlights our innovative AI-powered solutions that are revolutionizing trade compliance.

Here’s a glimpse of how iCustoms can help you:

Effortlessly automate repetitive tasks like data entry and classification.

Reduce errors and ensure accurate data processing.

Save time and money with streamlined procedures.

Gain valuable insights with real-time data.

Curious how AI can transform your trade compliance?

Head over to our website to learn more and see how iCustoms can help you navigate the complexities of international trade with ease

#TradeComplianceAward#iCustomsWins#AIforTrade#AutomatedCompliance#BoostEfficiency#ReduceErrors#RealTimeData#GlobalTradeSimplified#SupplyChainTech#GetMoving#ai

0 notes

Text

0 notes

Text

Benefits Of IoT In Automotive Supply Chain Management

Unlock the power of IoT in automotive supply chain management! Discover the game-changing benefits of supply chain optimization with IoT technology.

#supplychaintech#automotiveindustry#logisticssolutions#automanufacturing#digitaltransformation#supplychainmanagement#automotive#cerestech#autoindustry#supplychain#automobileindustry

0 notes

Text

How Automotive ERP Solutions Optimize Supply Chain?

Unlock the Power of Automotive ERP Solutions to Supercharge Your Supply Chain Management. Discover How Automotive ERP Solutions Drive Efficiency and Success!

#supplychaintech#automotiveindustry#logisticssolutions#automanufacturing#digitaltransformation#supplychainmanagement#automotive#cerestech#autoindustry#supplychain#automobileindustry

0 notes

Text

Impact Of Technology On Optimizing Automotive Supply Chains

Explore the transformative impact of technology on supply chains within the automotive industry. Learn how innovation optimizes automotive supply chains.

#supplychaintech#automotiveindustry#logisticssolutions#automanufacturing#digitaltransformation#supplychainmanagement#automotive#cerestech#autoindustry#supplychain#automobileindustry

0 notes