#Temperature Control

Text

For all your industrial heating needs, trust our expertise as a leading manufacturer of mica band heaters and thermocouple accessories. As specialists in heating solutions, we deliver top-quality products designed to meet the highest standards of performance and reliability. Whether you require efficient mica band heaters or precise thermocouple accessories, our comprehensive range ensures we have the perfect solution for your application. Count on us to provide innovative and reliable heating solutions to optimize your processes and maximize productivity.

#Heating Solutions#Industrial Technology#Mica Band Heaters#Thermocouple Accessories#Manufacturing#Temperature Control#Efficient Heating#Sustainable Technology#Productivity#Quality Control

0 notes

Text

Portable autoclave

A portable autoclave is a compact and versatile sterilization device used in various settings such as laboratories, clinics, field research stations, and even in homes for sterilizing medical instruments, laboratory equipment, glassware, and other items.

0 notes

Text

In serving cold drinks, having a reliable commercial beverage refrigeration system is not just an option; it’s essential. This decision doesn’t merely impact the quality of your beverages but also affects your overall customer satisfaction and operational efficiency. The dilemma between upgrading your current system or opting for a repair is a common predicament many businesses face.

0 notes

Text

Dive Deep into the World of Foam Packaging Inserts- Types, Benefits, and Uses

In the world of e-commerce and shipping, safeguarding your products during their journey to the customer is paramount. Foam packaging inserts have emerged as a popular and versatile solution for businesses seeking reliable product protection. But what exactly are foam inserts, and how can Custom Box Inserts Enhance Your Packaging and Brand?

Understanding Foam Packaging Inserts

Foam packaging inserts are precisely cut pieces of foam, typically polystyrene or polyurethane, that are strategically placed within personalized product boxes to secure and cushion your products. They come in a variety of shapes, sizes, and densities to accommodate a wide range of products, from delicate electronics to heavy machinery.

The Advantages of Foam Inserts

Enhanced Protection: Foam's shock-absorbing properties effectively shield your products from bumps, vibrations, and impacts that can occur during shipping. This minimizes the risk of damage and ensures your products reach their destination in pristine condition.

Lightweight Marvels: Foam inserts are incredibly lightweight, which can significantly reduce your overall shipping costs. This is a major benefit, especially for businesses that ship large volumes of products.

Insulation Powerhouse: Certain types of foam offer thermal insulation properties, making them ideal for products that require temperature control during transportation. This is particularly crucial for items sensitive to heat or cold, such as pharmaceuticals or food products.

Customizable Comfort: Foam inserts can be custom-designed to perfectly cradle your specific products. This snug fit prevents them from shifting around within the box, further minimizing the risk of damage.

Eco-Conscious Considerations: While some boxes with foam inserts materials may have environmental drawbacks, advancements have been made in recent years. Biodegradable and recyclable foam options are becoming increasingly available, allowing businesses to prioritize both product protection and environmental responsibility.

Unveiling the Applications of Foam Inserts

Foam inserts offer a broad spectrum of applications across various industries. Here are a few examples:

Electronics: Foam inserts are widely used to safeguard delicate electronic components like circuit boards, computer parts, and mobile devices.

Fragile Items: For businesses shipping glassware, artwork, or other fragile items, foam inserts provide essential cushioning and prevent breakage.

Medical Supplies: The temperature-sensitive nature of medical supplies necessitates reliable insulation. Foam inserts can ensure these products maintain proper temperatures during transport.

Luxury Goods: For high-end products like jewelry or cosmetics, foam inserts add a touch of elegance and sophistication to the unboxing experience.

Choosing the Right Foam Insert

With the diverse range of foam insert options available, selecting right form insert ,the most suitable type for your needs is crucial. Here are some key factors to consider:

Product Requirements: The size, weight, and fragility of your product will determine the necessary insert thickness and density.

Budget Constraints: Foam inserts come in various price points. Consider the cost-effectiveness factor while ensuring adequate protection for your products.

Environmental Impact: If eco-friendliness is a priority for your brand, explore biodegradable or recyclable foam options.

By understanding the types, benefits, and applications of foam packaging inserts, you can make informed decisions to elevate your packaging strategy. Foam inserts not only safeguard your products but also enhance the overall customer experience by ensuring their safe arrival.

#product protection#shipping supplies#packaging materials#e-commerce packaging#custom packaging solutions#unboxing experience#fragile items#temperature control#eco-friendly packaging

0 notes

Text

Chef WK, lead charcuterie specialist in Alberta Canada

Table of contents

1. Control Program Requirements for Fermented Meat Products

2. Facility and Equipment Requirements

3. Starter Culture

4. Chemical Acidification

5. Water Activity Critical Limits

6. Time and Temperature for Fermented Products

7. Fermentation Done at a Constant Temperature

8. Examples of Degree-hours at constant room temperatures

9. Fermentation Done at Different Temperatures

10. Fermentation done at Different temperatures

11. What happens if fermentation fails to hit critical limit?

12. E. coli and Salmonella Control in Fermented Sausages

13. Options for E. coli validation

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

Control Program Requirements for Fermented Meat Products

The producer must have a program in place to assess the incoming product. This program should outline specifications for the incoming ingredients. This may include criteria including receiving temperature, farm/ supplier, lot code or packed on date, species/cut etc.

2. Facility and Equipment Requirements

Equipment used in the fermentation process must be included in the operator's prerequisite control programs. These must include the following elements:

Temperature in the fermentation, drying and smoking chambers must be uniform and controlled to prevent any fluctuation that could impact on the safety of the final product.

Fermentation, drying and smoking chambers must be equipped with a shatter resistant indicating thermometer, (or equivalent), with graduations of 1°C or less. If mercury thermometers are used, their mercury columns must be free from separations. All thermometers must be located such that they can be easily read.

Fermentation and smoking chambers must be equipped with a recording thermometer for determining degree-hours calculations in a reliable manner. Recording thermometers are also preferable in drying and aging rooms but, in these rooms, it may be sufficient to read and record the temperatures 2 times a day.

Drying and aging rooms must be equipped with humidity recorders in order to prevent uncontrolled fluctuations of the relative humidity. The only alternative to an automatic humidity recorder in these rooms would be for the company to manually monitor and record ambient humidity twice a day (morning and afternoon) every day with a properly calibrated portable humidity recorder.

For routine monitoring, accurate measurement electronic pH meters (± 0.05 units) should be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument as well as recommended sample preparation and testing be followed.

When the aw of a product is a critical limit set out in the HACCP plan for a meat product, accurate measurement devices must be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument be followed.

3. Starter Culture

The operator must use a CFIA approved starter culture. This includes Freeze-dried commercially available culture as well as back-slopping (use of previously successful fermented meat used to inoculate a new batch). When performing back-slopping, the operator must have a control program in place to prevent the transmission of pathogens from when using the inoculum from a previous batch to initiate the fermentation process of a new batch. These must include:

The storage temperature must be maintained at 4°C or less and a pH of 5.3 or less.

Samples for microbiological analysis must be taken to ensure that the process is in line with the specifications.

The frequency of sampling is to be adjusted according to compliance to specifications.

Any batch of inoculum which has a pH greater than 5.3 must be analysed to detect at least Staphylococcus aureus. Only upon satisfactory results will this inoculum be permitted for use in back slopping.

This can be an expensive and a time exhaustive process and is generally avoided due to food safety concerns. AHS does not allow back-slopping.

[Chef WK was in communication with the U of A to get his method, a starter mix, studied.]

4. Chemical Acidification

If product is chemically acidified by addition of citric acid, glucono-delta-lactone or another chemical agent approved for this purpose, controls must be in place and records kept to ensure that a pH of 5.3 or lower is achieved by the end of the fermentation process. These acids are encapsulated in different coatings that melt at specific temperatures, which then release the powdered acids into the meat batter and directly chemically acidulate the protein.

Summer sausage is a very common chemically acidified product. The flavor profile tends to be monotone and lacking depth.

5. Water Activity Critical Limits

The aw may be reduced by adding solutes (salt, sugar) or removing moisture.

Approximate minimum levels of aw (if considered alone) for the growth of:

molds: 0.61 to 0.96

yeasts: 0.62 to 0.90

bacteria: 0.86 to 0.97

Clostridium botulinum: 0.95 to 0.97

Clostridium perfringens: 0.95

Enterobacteriaceae: 0.94 to 0.97

Pseudomonas fluorescens: 0.97

Salmonella: 0.92 - 0.95

Staphylococcus aureus: 0.86

parasites: Trichinella spiralis will survive at an aw of 0.93 but is destroyed at an aw of 0.85 or less.

The above levels are based on the absence of other inhibitory effects such as nitrite, competitive growth, sub-optimum temperatures, etc., which may be present in meat products. In normal conditions, Staphylococcus aureus enterotoxins are not produced below aw 0.86, although in vacuum packed products this is unlikely below aw 0.89.

6. Time and Temperature for Fermented Products

Certain strains of the bacteria Staphylococcus aureus are capable of producing a highly heat stable toxin that causes illness in humans. Above a critical temperature of 15.6°C, Staphylococcus aureus multiplication and toxin production can take place. Once a pH of 5.3 is reached, Staphylococcus aureus multiplication and toxin production are stopped.

Degree-hours are the product of time as measured in hours at a particular temperature multiplied by the "degrees" measured in excess of 15.6°C (the critical temperature for growth of Staphylococcus aureus). Degree-hours are calculated for each temperature used in the process. The limitation of the number of degree-hours depends upon the highest temperature in the fermentation process prior to the time that a pH of 5.3 or less is attained.

The operator is encouraged to measure temperatures at the surface of the product. Where this is not possible, the operator should utilize fermentation room temperatures. The degree hour calculations are based on fermentation room temperatures. Temperature and humidity should be uniform throughout the fermentation room.

A process can be judged as acceptable provided the product consistently reaches a pH of 5.3 using:

fewer than 665 degree-hours when the highest fermentation temperature is less than 33°C;

fewer than 555 degree-hours when the highest fermentation temperature is between 33° and 37°C; and

fewer than 500 degree-hours when the highest fermentation temperature is greater than 37°C.

This means that as the temperature increases, the amount of time that you have available to reach 5.3 or under is shorter. The warmer the temperature, the sharper the log growth phase of bacteria, which equates to more overshoot in lactic acid production, faster.

8. Examples of Degree-hours at constant room temperatures

Example 1:

Fermentation room temperature is a constant 26°C. It takes 55 hours for the pH to reach 5.3.

Degrees above 15.6°C: 26°C - 15.6°C = 10.4°C

Hours to reach pH of 5.3: 55

Degree-hours calculation: (10.4°C) x (55) = 572 degree-hours

The corresponding degree-hours limit (less than 33°C) is 665 degree-hours.

Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

Example 2:

Fermentation room temperature is a constant 35°C. It takes 40 hours for the pH to reach 5.3.

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C

Hours to reach pH of 5.3: 40

Degree-hours calculation: (19.4°C) x (40) = 776 degree-hours

The corresponding degree-hours limit (between 33 and 37°C) is 555 degree-hours.

Conclusion: Example 2 does not meet the guideline because its degree-hours exceed the limit

9. Fermentation Done at Different Temperatures

When the fermentation takes place at various temperatures, each temperature step in the process is analyzed for the number of degree-hours it contributes. The degree-hours limit for the entire fermentation process is based on the highest temperature reached during fermentation.

Example 1:

It takes 35 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for second 10 hours and 35°C for the final 15 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C

Hours to reach pH of 5.3: 15

Degree-hours calculation: (19.4°C) x (15) = 291 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 291 = 519

The highest temperature reached = 35°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

10. Fermentation done at Different temperatures

Example 2:

It takes 38 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for the second 10 hours and 37°C for the final 18 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 37°C - 15.6°C = 21.4°C

Hours to reach pH of 5.3: 18

Degree-hours calculation: (21.4°C) x (18) = 385.2 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 385.2 = 613.2

The highest temperature reached = 37°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)

Conclusion: Example 2 does not meet the guidelines because its degree-hours exceed the limit.

11. What happens if fermentation fails to hit critical limit?

What happens if the batch takes longer than degree-hours allows? For restaurant level production, it's always safer to discard the product. The toxin that Staph. Aureus produces is heat stable and cannot be cooked to deactivate. In large facilities that produce substantial batches, the operator must notify the CFIA of each case where degree-hours limits have been exceeded. Such lots must be held and samples of product submitted for microbiological laboratory examination after the drying period has been completed. Analyses should be done for Staphylococcus aureus and its enterotoxin, and for principal pathogens, such as E. coli O157:H7, Salmonella, and Clostridium botulinum and Listeria monocytogenes.

If the bacteriological evaluation proves that there are fewer than 104 Staphylococcus aureus per gram and that no enterotoxin or other pathogens are detected, then the product may be sold provided that it is labelled as requiring refrigeration.

In the case of a Staphylococcus aureus level higher than 104 per gram with no enterotoxin present the product may be used in the production of a cooked product but only if the heating process achieves full lethality applicable to the meat product.

In the case where Staphylococcus aureus enterotoxin is detected in the product the product must be destroyed.

12. E. coli and Salmonella Control in Fermented Sausages

Business' that manufacture fermented sausages are required to control for verotoxinogenic E. coli including E. coli O157:H7 and Salmonella when they make this type of product. This includes:

establishments which use beef as an ingredient in a dry or semi-dry fermented meat sausage;

establishments which store or handle uncooked beef on site;

Establishments which do not use beef and do not obtain meat ingredients from establishments which handle beef are not currently required to use one of the five options for the control of E. coli O157:H7 in dry/semi-dry fermented sausages.

Any processed RTE product containing beef or processed in a facility that also processed beef, must be subjected to a heat treatment step to control E. coli O157:H7. Heating to an internal temperature of 71°C for 15 seconds or other treatment to achieve a 5D reduction is necessary. This is a CFIA requirement and is not negotiable.

Uncooked air dried products produced as RTE, must meet shelf stable requirements as detailed for Fermented-Dry products.

13. Options for E. coli validation

Without lab testing, the two main methods of validation are with heat treating by either low temp and a long duration, or various hotter processing temperatures for a shorter timeframe.

A challenge study to validate a process can take 1 year and over $100,000!

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

The aw and pH values are critical in the control of pathogens as well as to ensure shelf-stability in all semi-dry and dry fermented meat products. Each batch must be tested for aw and/or pH in order to verify that the critical limits are met.

Although aw measurement is mandatory only for shelf stable products, it is strongly recommended that the producer determine the aw values achieved for each product type they manufacture and for each product. Once this has been established, frequent regular checks should be made to ensure consistency. In the U.S., they rely on moisture to protein ratio and have set targets. This lab-tested value is a direct correlation of the % water to % meat protein and not aw. This gives more consistency to common names. For example, to legally call a product "jerky" it must have a MPR of 0.75:1 or lower.

Remember your ABCs:

Always be compliant.

-AND-

Documentation or it didn't happen.

(tags)

Charcuterie,Fermented Meat,Food Safety,Starter Culture,Chemical Acidification,Water Activity,Fermentation Process,Degree-Hours Method,Foodborne Pathogens,Meat Processing Guidelines,Chef WK Alberta Canada,Food Industry Standards,pH Critical Limits,Thermal Processing,Food Preservation,Food Microbiology,Sausage Fermentation,Charcuterie Expertise,Fermented Meats ,Food Safety Standards,Food Processing Guidelines,Starter Cultures,Chemical Acidification,Water Activity (a_w),Critical Limits,Degree-Hours Method,Foodborne Pathogens,Meat Processing Equipment,Processing Facility Requirements,Hazard Analysis and Critical Control Points (HACCP),Food Preservation Techniques,Temperature Control,Pathogen Reduction,Food Industry Compliance,Documentation Practices,Heat Treatment,pH Control,Food Stability,Consistency in Production,Microbial Testing,Real-time Monitoring,Process Validation,Regulatory Requirements,Verotoxigenic E. coli,Lethality Standards,Product Labelling,Spoilage Prevention,Enterotoxin Detection,Shelf-Stable Products,Moisture to Protein Ratio (MPR)

#Charcuterie#Fermented Meat#Food Safety#Starter Culture#Chemical Acidification#Water Activity#Fermentation Process#Degree-Hours#Meat Processing Guidelines#Thermal Processing#Food Preservation#Food Microbiology#Sausage Fermentation#Starter Cultures#Critical Limits#Meat Processing#Food Preservation Techniques#Temperature Control#Pathogen Reduction#Food Industry#Heat Treatment#pH Control#Food Stability#Microbial Testing#Real-time Monitoring#Process Validation#Spoilage Prevention#Enterotoxin Detection#Shelf-Stable Products#Moisture to Protein Ratio (MPR)

1 note

·

View note

Text

Smart Thermostat For Energy Efficiency At Your Home

Smart Thermostat For Energy Efficiency At Your Home - #homeimprovementreferral #Energy - https://www.homeimprovementreferral.com/smart-thermostat-for-energy-efficiency-at-your-home-2024-03/

#Adaptability#Cost Reduction#energy efficiency#Energy Savings#smart home#Smart Home Features#Smart Thermostat#Temperature Control#Thermostat

0 notes

Text

Bath time should be a relaxing ritual for seniors, promoting personal hygiene and overall well-being. Hence, as experts in personal care in Pennsylvania, we at Attentive Home Care highlight how ensuring a comfortable bath experience for seniors involves thoughtful considerations and practical solutions.

0 notes

Text

Skin is a breathing blanket of our bodies..

What skills or lessons have you learned recently?

My body is reacting on temperature changes… even a tiny amount..

I reflected it to our human body, adapting environment is always our body work. If the temperature/living environment changes dramatically within even few minutes, it can cause problems..

View On WordPress

#dailyprompt#dailyprompt-2154#human adaptability#human is millions of years adaption result according to Mother Earth climate change#life#temperature control

0 notes

Text

How to Maintain a Heller Upright Freezer for Maximum Efficiency and Longevity

#Information#Kitchen#Cleaning#Defrosting#Freezer#Heller Upright Freezer#Routine Maintenance#Temperature Control

0 notes

Text

Some Basic Structures of Fast Blue Impeller Paddle Wheel Aerator

Fast Blue Impeller Paddle Wheel Aerator utilizes a straightforward yet highly effective mechanism to enhance water quality and oxygen levels within aquaculture systems. The aerator is equipped with an impeller, driven by an electric motor, that rotates within the water. The impeller blades create a vigorous water movement, resulting in several critical effects:

Oxygenation: The primary objective of the Fast Blue Impeller Paddle Wheel Aerator is to elevate the dissolved oxygen levels in the water. As the impeller blades agitate and disperse water, they facilitate increased oxygen exchange between the air and the aquatic organisms. Adequate oxygen levels are paramount for the respiration and overall health of fish and other aquatic species.

Temperature Control: Continuous water circulation helps maintain a consistent temperature throughout the aquaculture environment, preventing the formation of harmful temperature gradients that could endanger aquatic life.

Nutrient Dispersal: The aerator ensures that essential nutrients and feed are evenly distributed throughout the pond, promoting uniform growth and minimizing resource wastage.

0 notes

Text

Triac thyristor circuits, Power thyristor applications, Temperature control

T435 Series 600 Vdrm 4 A Snubberless Triac AC Switch Surface Mount - TO-252

0 notes

Text

TIAC circuit, Silicon controlled rectifier, Temperature control, Light control

Snubberless Triac AC Switch Surface Mount - TO-252

0 notes

Text

Mini Spray Dryer

A mini spray dryer is a laboratory-scale instrument used for the rapid drying of liquid samples into powder form through atomization and evaporation. Equipped with air inlet filter to ensure the purity of the sample.

0 notes

Text

The commercial sector is undergoing a profound transformation in its approach to refrigeration in the rapidly evolving landscape of environmental consciousness and sustainable business practices. Among the innovative technologies gaining prominence is the use of carbon dioxide (CO2) as a refrigerant. This blog explores the benefits and applications of eco-friendly CO2 refrigeration for commercial use, shedding light on its potential to revolutionize the way businesses approach cooling and refrigeration.

0 notes

Photo

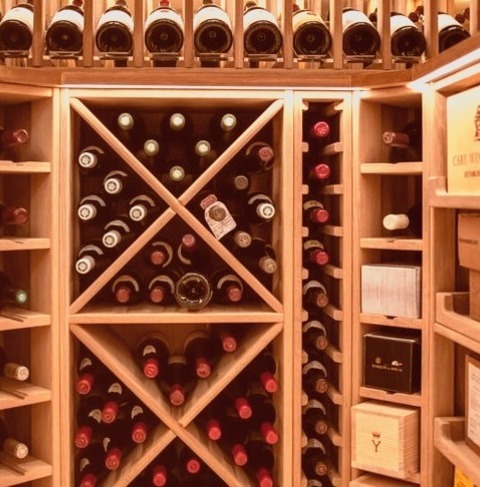

Medium Kent

Mid-sized farmhouse wine cellar photo with storage racks

0 notes

Text

How does one monitor and control fermentation temperature for optimal results?

Fermentation is a crucial part of the beer brewing process that transforms wort into beer. During fermentation, yeast consumes the sugars in the wort and produces alcohol and carbon dioxide. The temperature at which fermentation occurs can have a significant impact on the flavor and aroma of the finished beer. In this article, we will discuss how to monitor and control fermentation temperature…

View On WordPress

#attenuation#beer styles#brewing#Consistency#equipment#experimentation#fermentation#fermentation chamber#fermentation temperature#homebrewing#insulation#off-flavors#optimal results#temperature adjustment#temperature control#temperature monitoring#yeast strain

0 notes