#asphalt drum mix plant

Text

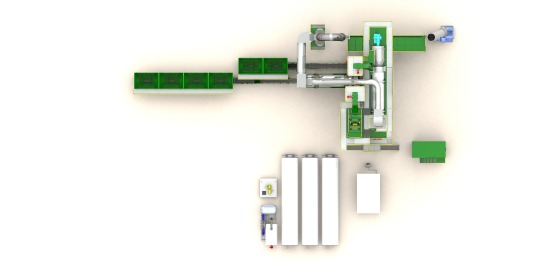

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Photo

Counter flow Asphalt Plant Manufacturer and Exporter – Atlas Technologies

Proven design of Atlas Counter flow drum mixers have helped customers achieve better quality of hot mix. The simple design of this equipment has helped customers achieve optimum fuel efficiency. It is also possible to use bag filter with the machine. We are looking to export counter flow asphalt plant to Europe and countries like Bangladesh and Sri Lanka.

#counter flow asphalt plant#Counter flow asphalt mixer#counterflow asphalt plant#asphalt drum mix plant#Drum Mix Plant#asphalt drum mix#construction equipment

4 notes

·

View notes

Text

60-90 TPH Hot Mix Plant

60-90 tph hot mix plant is a kind of equipment used to produce asphalt mixture, which is widely used in road construction, maintenance and repair works. The main function of 60-90 tph hot mix asphalt plant equipment is to mix aggregate, asphalt and other additives in a certain proportion and produce asphalt mixture that meets the requirements of the project by heating and mixing. Haomei Machinery offer 60-90 ton per hour hot mix asphalt plant in the model of LB1000, whose production capacity is 80 ton per hour, and the mixer rated capacity is 1000L.

Here are some key features and considerations about 60-90 tph hot mix plant:

Production capacity:

60-90 tons per hour asphalt hot mix plant has a high production capacity and is suitable for small and medium-sized projects. Depending on the model and configuration, the actual capacity may vary.

Equipment Configuration:

Asphalt hot mix plant usually consists of aggregate conveying system, asphalt supply system, mixing system, control system and other parts. These systems need to work together to ensure the uniformity and stability of the asphalt mixture.

Environmental performance:

With the improvement of environmental awareness, hot mix asphalt plant pays more and more attention to environmental performance in the design and production process. For example, low emission burners, effective dust removal devices and noise control technologies are used to minimize the impact on the environment.

Degree of automation:

Modern asphalt hot mix plant usually has a high degree of automation, which can realize the functions of automatic batching, automatic control and automatic inspection to improve the production efficiency and product quality.

When choosing 60-90 tph hot mix plant, you need to consider the following factors:

Project demand:

According to the scale, duration and quality requirements of the project, choose the right model and configuration of asphalt hot mix plant.

Site conditions:

Asphalt hot mix plant needs to occupy a certain site space, so you need to consider factors such as the size, shape and infrastructure of the site.

Investment budget:

The price of asphalt hot mix plant varies according to the model, configuration and brand, so you need to make a reasonable choice according to the investment budget.

After-sales service:

Choose manufacturers or suppliers with good after-sales service and technical support to ensure the normal operation and timely maintenance of the equipment.

In short, 60-90 tph hot mix plant is an important road construction equipment, choosing the right equipment is important to ensure the quality and progress of the project.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/60-90-tph-hot-mix-plant.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

Asphalt Plant 60-90 tph - Morocco

Atlas 60-90 tph semi mobile plant installed in Morocco. The feeding unit, drying and mixing drum are fully mobile. The bitumen tank is stationary.

0 notes

Text

Stationary Asphalt Plant - Atlas Industries

Atlas for sale high quality of asphalt drum mix plant. We are manufacturer of stationary asphalt plants. Available 40 tph to 120 tph capacity of drum mixer.

0 notes

Text

5 Questions You Must Ask a Construction Equipment Manufacturer

Are you wondering what kind of questions to ask your construction equipment manufacturer? If yes, here is a complete guide to help you ask the right questions to your asphalt drum mix plant manufacturer. Read the article to learn more.

#asphalt drum mix plant#asphalt drum-mix plant manufacturer#construction machine manufacturer#asphalt mix plant#construction equipment manufacturers

0 notes

Text

C&D Waste Wet Line Processing Plant| Get Lastest Price | C&D Waste | Wet Line Processing Plant - Picson Equipment Pvt. Ltd

Manufacture & Supplier of C&D Waste Recycling Plant | Bucket Classifier | Asphalt Drum Mix Plant | PICS INTERNATIONAL is the world's number one C&D processing equipment manufacturer & supplier for sand and aggregates, mining, C&D waste recycling and industrial sands.

#Manufacture & Supplier of C&D Waste Recycling Plant#Bucket Classifier#Asphalt Drum Mix Plant#Waste Management Services#Solid Waste#Construction Waste#Waste Disposal Management Company#Recycling#Services#Environmentally Sustainable Waste Management

0 notes

Text

Reasons to buy Atlas asphalt drum mix plant - Atlas Industries

Many advantages and features have made Atlas asphalt drum mix plant the first choice of customers. Read about the many reasons to buy one.

0 notes

Text

Air Classification Plant in Karnataka

We are a Manufacturer, Exporter, and Supplier and provide Air Classification Plant in Karnataka.

Proc Tech Machineries India Pvt. Ltd. is an ISO 9001:2015 certified company in Ahmedabad, Gujarat,

India.

Proc Tech Machineries India Pvt. Ltd. specializes in the manufacturing, exporting, and supplying of a diverse range of products.

Our offerings include Industrial Rotary Dryers, Air Classification Plants, Chilly Processing Plants, Asphalt Drum Mix Plants, RMC Plants, Turmeric Processing Plants, Waste Type Pyrolysis Plants, Jaggery Plants, Coriander Processing Plants, and more.

We provide a comprehensive selection of products, including air classification plants, ss air classifiers, air classifier systems, MS air classifiers, air classifiers, and air classifier machines.

Our air classifiers are utilized across industries to separate various particles in dry powder. With a wide range of applications, products, and fineness ranges, our classification systems are highly versatile.

As a leading Air Classifier Manufacturer in India, our state-of-the-art products are recognized globally for their quality and performance.

Serving both domestic and international markets, we have earned the trust of our customers with our superior industrial offerings and services.

In our classifier, the feed material enters with the main airflow, offering a cost-effective process option when integrated into a system with direct pneumatic feed.

Users can smoothly adjust the classifying wheel speed using a frequency converter, enabling easy particle size adjustments even during operation.

Proc Tech Machineries India Pvt. Ltd. Is Provides Air Classification Plant in Karnataka and including location like Bengaluru, Mangaluru, Kalaburagi, Udupi, Tumakuru, Vijayapura, Hosapete, Belagavi,

Kalaburagi, Koppal, Uttara Kannada, Chitradurga, Hassan.

For further details, please feel free to contact us.

https://proctechindia.com/2024/04/30/air-classification-plant-in-karnataka/

0 notes

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum:

Long service life

Energy saving

Low emission

Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Video

youtube

Asphalt Drum Mix Plant Manufacturer and Exporter – Atlas Technologies

Atlas asphalt drum mix plant in all aspects including superior build quality and performance. Drum Mixing Plants are available from 40 tph to 120 tph. The units are modular and build to last. Burner unit is fuel efficient and designed for optimal performance. It is also available in mobile version. We are looking to export of Drum Asphalt Plant in Sri Lanka, Uganda, Ethiopia and South Africa.

#AsphaltDrumMixplantprice#asphalt drum mix plant#Drum Mix Plant#Portable Asphalt Drum Mix Plant#Asphalt Drum Mix Plant Manufacturers

0 notes

Text

Understanding Asphalt Mixing Plant Prices: Factors Influencing Costs

Asphalt mixing plants play a crucial role in the construction industry, providing the necessary asphalt mix for roads, highways, and various infrastructure projects. When considering the purchase of an asphalt mixing plant, understanding the factors influencing prices is essential. From project requirements to equipment specifications, several factors contribute to the variability in asphalt mixing plant prices. In this article, we delve into the key considerations that impact the cost of asphalt mixing plants.

Capacity and Output

The capacity of an asphalt mixing plant, measured in tons per hour (TPH), significantly affects the asphalt mixing plant price. Plants with higher capacities are generally more expensive due to their ability to produce larger volumes of asphalt mix in a shorter time frame. The size of your project and anticipated asphalt demand will dictate the required capacity of the plant. It's crucial to assess your project requirements accurately to invest in a plant with an appropriate capacity to meet your needs efficiently.

Plant Type and Configuration

Asphalt mixing plants come in various types and configurations, each catering to specific project requirements and operational preferences. Drum mix plants and batch mix plants are the two primary types available, with each offering distinct advantages in terms of production efficiency and flexibility. Additionally, the configuration of the plant, including the number of bins, storage silos, and auxiliary equipment such as dust collectors and asphalt tanks, influences the overall price. Customizable features and optional add-ons may also impact the cost of the plant.

Technology and Innovation

Advancements in technology and innovative features incorporated into asphalt mixing plants can contribute to higher prices. Modern plants equipped with state-of-the-art control systems, advanced automation, and energy-efficient components may command a premium due to their enhanced performance, reliability, and sustainability. While the initial investment may be higher for technologically advanced plants, they often offer long-term cost savings through improved efficiency and reduced operational expenses.

Quality and Durability

The quality of materials and components used in the construction of asphalt mixing plants directly impacts their price. High-quality materials, such as robust steel structures, corrosion-resistant coatings, and durable mechanical components, contribute to the longevity and reliability of the plant. While plants constructed with premium materials may entail higher upfront costs, they offer greater durability and require fewer repairs and replacements over their operational lifespan, resulting in lower overall ownership of mobile asphalt mixing plant price.

Manufacturer Reputation and Support

The reputation of the manufacturer and the level of after-sales support provided can influence the price of asphalt mixing plants. Established manufacturers with a track record of delivering quality products and comprehensive customer service may command higher prices due to the perceived value and reliability they offer. Investing in a plant from a reputable manufacturer ensures access to technical expertise, spare parts availability, and ongoing support, enhancing the overall value proposition of the plant.

Geographic Location and Regulations

Local market conditions, geographic location, and regulatory requirements can also impact asphalt mixing plant prices. Factors such as transportation costs, import/export tariffs, taxes, and environmental regulations may vary from region to region, affecting the final cost of the plant. Additionally, compliance with local emissions standards and environmental regulations may necessitate the incorporation of specific features or technologies, which can influence the price accordingly.

Conclusion

Asphalt mixing plant prices vary based on a multitude of factors, including capacity, plant type, technology, quality, manufacturer reputation, and regulatory considerations. By understanding these factors and assessing your project requirements carefully, you can make informed decisions when selecting an asphalt mixing plant that offers the best balance of performance, reliability, and value for your investment. Prioritize quality, efficiency, and long-term sustainability to ensure the success of your asphalt production operations. Contact aimix machinery for more details.

0 notes

Text

Coninfra Machinery: Your Premier Asphalt Drum Mix Plant Manufacturer in Ahmedabad

Coninfra Machinery, situated in the bustling city of Ahmedabad, stands tall as the leading asphalt drum mix plant manufacturer in the region. With an unwavering commitment to innovation and quality, we have earned a stellar reputation in the construction machinery industry. Our state-of-the-art manufacturing facility is equipped with cutting-edge technology and a skilled workforce that ensures the production of top-notch asphalt drum mix plants.

At Coninfra Machinery, we take pride in delivering solutions that meet the evolving needs of the construction sector. Our range of asphalt drum mix plants is designed for efficiency, reliability, and environmental sustainability. We prioritize customer satisfaction and offer comprehensive support throughout the product lifecycle. Whether you are embarking on a new project or upgrading your existing infrastructure, Coninfra Machinery is your trusted partner for asphalt drum mix plants in Ahmedabad and beyond.

For More details, Kindly contact us at 90999 41311 this Number and visit our site:https://www.coninfra.in/

0 notes

Text

Asphalt Mixing Plant With 50 Tons Hot Mix Silo - Atlas

View photos of installed asphalt mixing plant with 50 tons hot mix silo in Nigeria. Atlas Technologies exporter of asphalt drum mix plant at the best price.

0 notes

Text

Sustainability in Construction: The Role of Equipment Manufacturers

Discover how equipment manufacturers play a vital role in achieving sustainability in construction. Learn about the benefits of sustainable equipment and its impact on the environment and your bottom line. Read more on our blog.

#best asphalt drum mix plant manufacturer#construction equipment experts#construction equipment manufacturer#construction equipment manufacturer in India#construction equipment manufacturers#construction equipment manufacturing#sustainable construction products

0 notes