Text

youtube

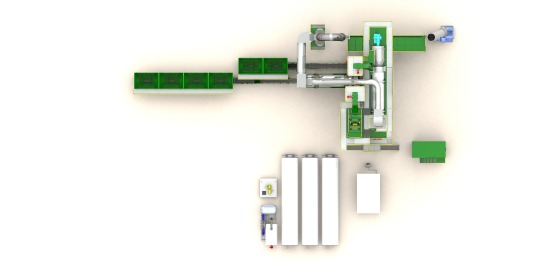

ZAP-S160 Professional Stationary Asphalt Batch Mix Plant Project Starts Production

ZAP-S160 asphalt batch mixing plant combines with various advantages of western models and adopts modular design, which has compact structure, simple assembly and transport. Components of stationary asphalt mix plant adopt international famous brand, keep pace with the international advanced technology, which can guarantee high reliability and security of the equipment in long operating terms.

Besides, the stationary stype asphalt plant machine has strict trial assembly and test every equipment before delivery, so that guarantee stable quality and high standard of our equipment. Our asphalt batching mixing plant equipment also adopts human-computer interface and PLC control system and perfect human-machine exchange function for easy operating with manual, semi-auto, automatic control function; with remote fault detect and maintenance function,those can solve the problem the first time.

Excellent expansibility of ZAP-S160 asphalt batch mixing plant can be realized by adding RAP, wood fiber adding equipment etc, so that it can satisfy more requirements. Low consumption, high efficiency and environment friendly design is the ideal choice of different kinds of road construction asphalt mixing machines.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#concrete#asphalt plant#heavy equipment#asphaltplant#mobile asphalt drum mix plant#construction#asphalt mix plant#stationary asphalt mixing plant#stationary asphalt mixing plants#stationary asphalt plant#asphalt batch mix plant#asphalt batching mixing plant#asphalt batching plant#Youtube

1 note

·

View note

Text

High Efficiency Industrial Bag House Dust Collector for Asphalt Mixing Plant.

- Gravity type primary dust collector collects finer dust and saves consumption.

- The discharge of the secondary dust collector in the baghouse is less than 20mg/Nm3, which is environmentally friendly.

- Using the US Dopont NOMEX filter bags, it is resistant to high temperature and has a long service life. The filter bag can be replaced easily and without special tools.

- Intelligent temperature control system, when the dust temperature is higher than the set value, the cold air valve turns on the cooling automatically to avoid the filter bag being damaged by high temperature.

- Using high-pressure pulse cleaning technology, it is beneficial to reduce bag wear, prolong service life and improve dust removal performance.

-Both stationary and mobile types bag house dust filter are available.

#dust collector#dust filter#dust collection system#bag house dust filter#bag house dust collector#bag house dust collection system#bag house filter#dust collection#dust cover#dust removal#dust remover#asphalt mixing plant#bitumen#road construction#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#asphalt plant#asphalt drum mix plant

1 note

·

View note

Text

ZAP-S120 Asphalt Mixing Plant Project in Kazakhstan.

Date: 2020.08.27----2020.10.24

Location: Aktobe, KZ(Kazakhstan)

Model and capacity: ZAP-S120, 120T/H

Kazakhstan is a landlocked country in Central Asia and the largest landlocked country in the world. It is also a good neighbor of China.

As an important participant in the Belt and Road Initiative, Kazakhstan has been continuously enhancing the construction and upgrading road infrastructure, attracting more tourists and foreign investment to Kazakhstan, and constantly improving the living standards of local residents.

Our customer finally purchased a set 120T/H asphalt mixing plant from our company to meet the increasing project volume, which was the first large-scale asphalt mixing plant in the area.

This set of asphalt mixing plant is composed of 4 cold feed bins system, drying drum, gas burner (German brand gas valve set), cyclone dust removal + bag house dust collector combined dust removal system, new filler silo with reclaimed filler silo, mixing tower, pneumatic system, thermal oil heating system with bitumen storage tank, automatic computer control system and other parts.In order to ensure the stability of the control system, the electrical components are imported from Siemens and other brands.

#asphalt mixing plant#road construction#bitumen#asphalt drum mix plant#asphalt plant#heavy equipment#concrete#asphaltplant#construction#mobile asphalt drum mix plant#stationary asphalt plant#stationary asphalt mixing plants#asphalt mix plant#stationary asphalt mixing plant#asphalt plant machine#asphalt plant equipment#asphalt paving#asphalt repair

1 note

·

View note

Text

8TPH High Quality Asphalt Emulsion Plant, Asphalt Emulsion Equipment, Bitumen Emulsion Plant

Asphalt Emulsion Plant is widely used in various road construction and maintenance projects. The Asphalt Emulsion Equipment developed by our company can produce various types of emulsified bitumen to meet customers' different construction requirements.

We are Professional manufacturer & Exporter of emulsified asphalt equipment solution. Asphalt Emulsions, Bitumen Emulsion Plant, Emulsion Bitumen Plant, Emulsified Asphalt Equipment, Asphalt Emulsion Machine Series Product.

Easy Operation, Successful Project Cases, Competitive Price.

youtube

#asphalt mixing plant#bitumen#asphalt drum mix plant#road construction#asphalt plant#concrete#asphaltplant#heavy equipment#mobile asphalt drum mix plant#asphalt emulsion plant#bitumen emulsion plant#bitumen emulsion#bitumen emulsified equipment#emulsion asphalt#asphalt emulsion#asphalt plants#asphalt emulsified plant#high quality#Youtube

1 note

·

View note

Text

youtube

What's the Main Configurations of LB1500 120tph Professional Stationary Asphalt Mixing Plant?

Main configurations of LB1500 120tph Professional Stationary Asphalt Mix Plant is usually include coal feed system, drying system, the mixing tower assembly, dust filter system, control system and consystem room, bitumen supplying and heating system, etc.

Cold Feed System This system of asphalt mixing plants includes 4 feeding hoppers. Aggregate gathering belt conveyor, middle screen, inclined belt conveyor, frequency control reducer and 2 small vibrating motors.

Drying System It mainly includes T40 drum dryer, MFR-S40 coal burner, one pulverized coal machine, coal supplying hoppers, and Ignition system. The asphalt plant burner can supply enough coal powder for the drum dryer. and it can easily to start the fire by the ignition system. ZOOMELINE coal burner is high efficiency, energy saving, the plant with coal burner can highly reduce the production cost. T40 Drum Dryer is driving by 4x3KW motors, it adopt frication transmission. It makes it can run smoothly and strongly.

The Mixing Tower Assembly ZOOMLINE asphalt mix plant Mixing Tower mainly including the hot aggregate elevator, filler elevator,vibration screen, mixer,weighing system. The Asphalt Mixer adopt 2x15kW motors. Power full enough to reach the rate capacity,even over the rated capacity 60t/h. The weighing system using Mettler Toledo, which can make the weighing more accurate. Cylinder, make sure there is plenty air provided for open the discharging doors.

Dust Filter System It includes primary dust filter(cyclone dust collector)+ water dust filter, draught fan. The model of the asphalt plant water filter is: SMC1200. The Draft fan: 37KW.

5. Control System and Control Room The control room: 4.5m*2.2m*2.5m. the control system adopt SIEMENS PLC. Siemens touch screen, other main electrical elements are SIEMENS Brand.

6. Bitumen Supplying and Heating System This Asphalt Mixing Plant equipped with TWO 30 tons Bitumen Tank. The bitumen tank adopts coal fired direct heating. It is easy for operation. The insulation thickness is: 50mm.

#asphalt mixing plant#bitumen#asphalt drum mix plant#road construction#asphalt plant#concrete#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#configuration#configuración#asphalt plant factory#asphalt plant supplier#road construction machines#road construction equipment#bitumen equipment#asphalt mixing#Youtube

1 note

·

View note

Text

High Capacity ZAP-S240 Stationary Asphalt Mixing Plant, 240tph Asphalt Road Construction Machine

ZAP-S240 Stationary Asphalt Mixing Plant is the product combined with various advantages of western models, modular design, compact structure, simple assembly and transport.

Components of 240tph Asphalt Mix Plant adopt international famous brand, keep pace with the international advanced technology, which can guarantee high reliability and security of the equipment in long operating terms. There are strict trial assembly and test machine of each asphalt plant and road construction equipment before delivery, so we can guarantee stable quality and high standard of the asphalt plant mixer.

Besides, ZOOMLINE Asphalt Hot Mix Plant adopts human-computer interface and PLC control system, perfect human-machine exchange function, reasonable and multiple layout mode, which can change the layout according to different requirement,and also can adapt the actual construction requirement better.

Asphalt plant machine also have other excellent expansibility for satisfied customers requirement, such as can add RAP, wood fiber adding equipment, big and solid installation foundation, low consumption and high efficiency etc.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#asphalt plant machine#asphalt#asphalt mixing plants#bitumen decanter#bitumen melting machine#bitumen melting#bitumen melter#asphalt plant equipment#road construction equipment#road construction machines#recycled hot mix asphalt production plant#mobile hot mix plant#high capacity

1 note

·

View note

Text

What are the environmental impacts of an eco friendly asphalt plant?

Eco-friendly Asphalt Mixing Plant, Environmental-friendly Asphalt Plant,Environment Friendly Asphalt Mix Plant

For the pollution problems from the asphalt mixing plant, we have launched a Full-environmental Asphalt Mixing Plant with the strict environmental protection standards.

Environmental-friendly Asphalt Plant is developed on the basis of LB Series; it retains the advantages of LB Series and attaches great importance on environmental protection and safety. ELB Series asphalt mixing plant is featured by low noise and less pollutant emission, fit for road construction projects in all grades and scales and can be set in urban or near urban area.

From the storage, transportation, heating, mixing and unloading of the asphalt and aggregates, we have achieved environmental protection and effective control. It becomes the pioneer of environmental transformation of asphalt mixing plant because it can be controlled for the producing harmful flue gas, dust and high energy consumption in the production process.

#asphalt mixing plant#bitumen#road construction#asphalt plant#asphalt drum mix plant#concrete#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#eco friendly#environmental#environmental conservation#environmentally friendly#eco friendly asphalt plant#environmentally friendly asphalt plant#Environment Friendly Asphalt Mix Plant#environment pollution#environmental protection#road construction equipment#road repairing

1 note

·

View note

Text

Asphalt Plant Burner Testing at Our Factory Before Shipment.

The burner of the asphalt mixing plant is also called the asphalt equipment burning machine. The burner is an indispensable part of the asphalt mixing plant and an indispensable heating machine in the combustion furnace! We can choose gas, oil, pulverized coal, etc. as fuels for the burners of the asphalt mixing plant.

We customize the production of pulverized coal and fuel oil dual-purpose asphalt mixing plant burners, gas and oil dual-purpose burners, coal, oil and gas multi-use Burner etc. according to customer needs.

#asphalt mixing plant#bitumen#asphalt drum mix plant#road construction#concrete#asphalt plant#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#asphalt burner#asphalt plant burner#coal burner#oil burner#gas burner#asphalt burners#fuel burner#burner supplier#burner price#asphalt burner supplier#asphalt burner manufacturer

1 note

·

View note

Text

youtube

Burner for ZAP-S 120 Asphalt Mixing Plant Working at Thailand

As a kind of mechatronics equipment with high degree of automation, the asphalt mixing burner has a combustion flame heat transfer method for direct contact radiation, short flame shape control but negative pressure design of the combustion chamber.

Advantages of asphalt plant burner include low pressure oil supply, medium atomization, lowA pressure gas, gas ring atomization and low NOx emissions.

Any type of asphalt plant be it continuous (drum type) or batch type machine comes with a burner for heating aggregates. If the aggregates are not heated properly, they cannot bind with bitumen and the end product will be bad. So, heating the aggregates evenly will help produce quality hot mix asphalt. Heated aggregates will play a major role in the success of hot mix asphalt. If the aggregates are hot, they will bind with bitumen.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#asphalt burner#coal burner#oil burner#heating aggregate#aggregate#bitumen decanter#bitumen melting machine#Youtube

1 note

·

View note

Text

Asphalt Mixing Plant Working Site at Thailand.

An asphalt mixing plant is used to mix several aggregates with bitumen to make hot mix paving material for a number of construction industries.The aggregates used can vary depending on the grade and dimensions of asphalt required. Finer aggregates may also be added as well as mineral fillers.

The two main main forms of asphalt mixing plants: continuous mix plants and batch mix plants. Both kinds of plants produce asphalt their difference is found in the process employed to produce said asphalt. Asphalt mixing plant is key equipment for any road construction company.Any asphalt batch mix plant operation has many functions. This makes them a bit complicated compared to the drum types.

Working of any asphalt batching plant is dependent on four main functions:

Drying and heating the aggregates.

Weighing the aggregates, bitumen and binder material.

Mix the bitumen, binder with aggregates.

Discharging the hot mix asphalt.

We can categories the mixing plants as batch mix and drum mix plants. Asphalt Batch plants: These plants produce hot mix asphalt in a series of batches. Drum mix asphalt plant: These plants produce hot mix asphalt in a continuous process. These are usually drum mix plants and counterflow plants.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#thailand#bangkok#cambodia#asia#indonesia#road machinery#road machines#road machine#road construction machines

1 note

·

View note

Text

Installation of 40 cubic metre electrically heated asphalt tank and heating rods in Greece.

The customer is a Greek supplier of road construction equipment. They specialize in providing top-quality asphalt tanks, asphalt plants, spreader trucks, and other related products. Recently, they approved our offer for a 40 cubic meter electrically heated asphalt tank and have finally decided to purchase it.

We take great pride in being selected as their trusted supplier, and we are committed to delivering the highest quality products possible. Our team of experts has worked tirelessly to ensure that our asphalt tank meets all of the customer's specifications and requirements. We look forward to continuing our partnership with this valued customer and providing them with exceptional service and support throughout their project.

#asphalt tanker#asphalt tanks#asphalt tank#asphalt tankers#asphalt storage plants#asphalt storage#asphalt storage tank#bitumen tanker#bitumen tanks#bitumen tank#road construction#asphalt mixing plant#bitumen#heavy equipment#construction#asphaltplant#mobile asphalt drum mix plant#concrete#asphalt plant#asphalt drum mix plant

1 note

·

View note

Text

youtube

How to Do Belt Installing of Batch Asphalt Mixing Plant?

The asphalt plants or asphalt mixing plant is one plant that is used for mixing the dry warm aggregate, padding and asphalt for homogeneous mixture at the required temperature. And it is widely used to the construction of highway, city road and parking lot.

The major components of a batch asphalt mixing plant are the cold- feed system, asphalt cement supply system, aggregate dryer, mixing tower, and emission-control system.

The main activity of an asphaltbatch type mixing plant is that it heats up aggregates and then mixes them with bitumen and other adhesive substances to generate hot mix asphalt. The quantity and nature of the aggregate are dependent on the specific requirements.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#concrete#asphalt plant#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#conveyor belts#conveyorsystem#roller conveyor#screw conveyor#conveyorize#belt conveyor#Youtube

1 note

·

View note

Text

Mobile Asphalt Drum Mix Plant Installed at Our Nigeria Customer Production Site by Henan ZOOMLINE Machinery Co.,Ltd.

Asphalt Plant, also popularly known as asphalt mixing plant or hot mix plant. Mobile drum mix plant also be called mobile asphalt drum mix plant, drum mix asphalt plant, Mobile Automatic hot Mix Plant, portable asphalt mixing plant etc.

Nowadays many road contractors prefer mobile asphalt hot mix plant since they often need to shift it from one road construction site to another. Mobility provides flexibility and allows road contractors to easily and quickly move the hot mix plant from one site to another. To meet this need of our customers, we manufacture range of mobile asphalt plants with different output capacities and also could customize as per customer’s specific requirement.

#asphalt mixing plant#bitumen#asphalt drum mix plant#road construction#concrete#asphalt plant#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#mobile hot mix plant#mobile drum plant#mobile asphalt plant#Nigeria#Asphalt mixture#asphalt production#asphalt mixing plants#asphalt

1 note

·

View note

Text

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum:

Long service life

Energy saving

Low emission

Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

Why Should We Choose Mobile Drum Mix Asphalt Plant ?

One Trailer Mounted Mobile Drum Mix Asphalt Plant Realizes the High Integration of Asphalt Plant.

One transport trailer can realize all the functional requirements of the asphalt mixing station (filling, drying, mixing, storage of finished products, operation), which meets the user's requirements for fast installation, fast transition, and rapid production.

Mobile Asphalt Plant is asphalt mix manufacturing equipment in the form of one or some mobile modules mounted on chassis, so it features fast relocation and rapid reassembly, and pre-production preparation time can be saved greatly.

#asphalt mixing plant#asphalt plant#mobile drum plant#asphalt drum mix plant#mobile asphalt drum mix plant#mobile asphalt plant#drum mix plant#asphaltplant#heavy equipment#concrete#road construction#bitumen#construction#mobile hot mix plant

2 notes

·

View notes

Text

The Burner of An Asphalt Mixing Plant Determines its Success.

youtube

If you are well versed with the machine you will know how important the burner. The asphalt plant burner is the component which determines the success or failure of the product.

The coal and Oil dual purpose burners is a multi-fuel burner, which can use fuel oil alone, or coal alone. It is composed of the main burner, fuel valve group, pulverized coal supply system, and control system. The entire system has a one-key switching centralized control system, and there is no need to replace, add or remove any subsystems when switching the fuel types.

The coal and oil dual purpose burners is a newly designed multi-purpose burner, which is widely used in asphalt mixing plants, drying, boilers and other industries.

Find More Video On:

YouTube: https://www.youtube.com/@ZOOMLINEAsphaltPlants

TikTok: https://www.tiktok.com/@zoomlineasphaltplants

#coal burner#oil burner#gas burner#asphalt burner#fuel burner#asphalt mixing plant#asphalt plant#road construction#road machinery#road machines#heavy machines#heavy machinery#asphaltplant#concrete#bitumen#mobile asphalt drum mix plant#construction#heavy equipment#asphalt drum mix plant#heavy machinery transport#asphalt plant supplier#Youtube

2 notes

·

View notes