#bitumen decanter

Text

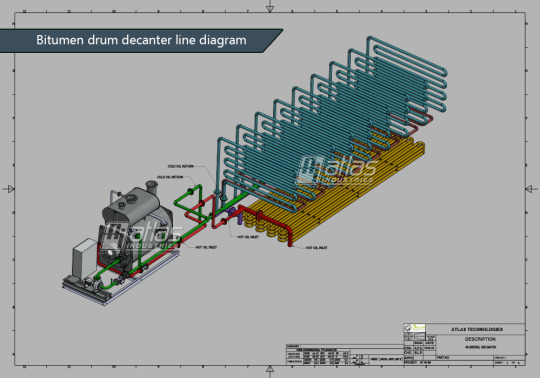

Drummed bitumen decanter - Atlas Technologies

The drummed bitumen decanting system featured here can give production of 3.5-4 tons per hour we have bigger models also that can go up to 10 tons per hour.

0 notes

Text

High Capacity ZAP-S240 Stationary Asphalt Mixing Plant, 240tph Asphalt Road Construction Machine

ZAP-S240 Stationary Asphalt Mixing Plant is the product combined with various advantages of western models, modular design, compact structure, simple assembly and transport.

Components of 240tph Asphalt Mix Plant adopt international famous brand, keep pace with the international advanced technology, which can guarantee high reliability and security of the equipment in long operating terms. There are strict trial assembly and test machine of each asphalt plant and road construction equipment before delivery, so we can guarantee stable quality and high standard of the asphalt plant mixer.

Besides, ZOOMLINE Asphalt Hot Mix Plant adopts human-computer interface and PLC control system, perfect human-machine exchange function, reasonable and multiple layout mode, which can change the layout according to different requirement,and also can adapt the actual construction requirement better.

Asphalt plant machine also have other excellent expansibility for satisfied customers requirement, such as can add RAP, wood fiber adding equipment, big and solid installation foundation, low consumption and high efficiency etc.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#asphalt plant machine#asphalt#asphalt mixing plants#bitumen decanter#bitumen melting machine#bitumen melting#bitumen melter#asphalt plant equipment#road construction equipment#road construction machines#recycled hot mix asphalt production plant#mobile hot mix plant#high capacity

1 note

·

View note

Link

Reliable and efficient design of Atlas bitumen drum decanters are ideal for melting bitumen at sites where bitumen is not available in liquid form or where bitumen is only available in the form of drums. These machines are developed keeping in mind the practical aspects of melting asphalt at construction site with less or no facility and also for places which are very remote. It will help you get tension free as far as melting, storage and reheating of bitumen packed in drums is considered.

#Drummed asphalt Melter#bitumen pressure distributors#BitumenDecantingmachineprice#bitumen#bitumen decanter#asphalt melting equipment

1 note

·

View note

Text

Asphalt Bitumen decanting machine - Atlas Equipments

Bitumen decanting machine is easy to use and economical. Asphalt melting equipment manufacturers of decanters in capacities up to 11 tph. For sale Bitumen drum melting unit with lowest price.visit our website:https://www.atlasequipments.com/bitumen-decanting-machine/

0 notes

Text

Bitumen drum decanter working principle - Asphalt Industries melting unit

Bitumen drum decanter

A bitumen drum decanter, also known as an asphalt drum melter or a bitumen melting unit, is a piece of equipment used in the asphalt industry to melt bitumen from drums into liquid form for use in various asphalt applications.

The working principle of a bitumen drum decanter involves heating the bitumen drums in a chamber using hot air. The machine has a heating chamber that is enclosed to maintain the heat and prevent heat loss. The chamber is usually lined with heat-resistant materials to protect the equipment and provide insulation.

To operate the machine, the bitumen drums are loaded into the heating chamber, and the chamber is sealed. The heating system is then activated, and hot air is circulated throughout the heating chamber. The hot air heats the bitumen drums, causing the bitumen to melt and become a liquid.

youtube

The liquid bitumen is then transferred via a pipeline or hose to a storage tank or a mixing plant for further processing. The bitumen drum decanter can also be fitted with a temperature gauge and a control system to regulate the heating process and ensure that the bitumen is melted to the desired temperature.

The Asphalt Industries melting unit is a bitumen drum decanter that is designed to melt bitumen from drums quickly and efficiently. It is a portable unit that can be easily transported to different job sites, making it ideal for use in remote locations or areas where there is limited access to infrastructure.

The key features of the Asphalt Industries melting unit

One of the key features of the Asphalt Industries melting unit is its heating system. The unit uses a direct-fired heating system that is powered by diesel or gas, which allows for fast and efficient heating of the bitumen drums. The heating system is equipped with a temperature gauge and a control system that allows for precise temperature control, ensuring that the bitumen is melted to the desired temperature.

The melting unit is also designed to be easy to use. It has a user-friendly control panel that allows operators to monitor and control the heating process. The unit is also equipped with safety features such as automatic shut-off valves and pressure relief valves, which help to ensure safe and reliable operation.

Additionally, the Asphalt Industries melting unit is designed to be durable and reliable. It is built with high-quality materials and components that are designed to withstand harsh operating conditions and to provide long-lasting performance. It is also easy to maintain, with components that can be easily accessed and replaced when necessary.

Overall, the Asphalt Industries melting unit is a high-quality bitumen drum decanter that is designed to meet the needs of the asphalt industry. Its efficient heating system, user-friendly controls, and durable construction make it a reliable and effective solution for melting bitumen from drums.

0 notes

Text

What is a bitumen emulsion plant and why you really need it?

if you are seeking bitumen emulsion for waterproofing, asphalt road surfacing as well as road building, you need a proper bitumen emulsion plant and use it to produce bitumen emulsion at any given time without looking to others for the breath. It’s really a good choice if you are engaged in road construction and maintenance.

Have no idea what bitumen emulsion is? there's a passage in Wikipedia that makes it very clear. View https://en.wikipedia.org/wiki/Asphalt#Asphalt_emulsion to learn about it.

This is a bitumen emulsion plant. It looks not complicated, though it’s widely used in road construction projects and road maintenance projects.

In short, the bitumen emulsion plant is the ideal equipment for bitumen emulsion production. It has an integrated structure, quite easy for transportation and relocation. Here is an image showing the structure below.

What are the main features of bitumen emulsion plant?

According to the different process flow of the bitumen emulsion equipment, it can be divided into two types: batch bitumen emulsion plant and continuous bitumen emulsion plant.

Batch bitumen emulsion plant is characterized by the blending of emulsifier and water. The emulsifier soap liquid is prepared in a container in advance, and then it is pumped into an emulsification machine. After the emulsifier, the aqueous solution is used up, another tank of emulsifier soap liquid is about to be produced.

The continuous operation type is characterized in that water, emulsifier and other additives (acid, calcium chloride) are respectively fed into the emulsification machine by a metering pump, and the mixing of the emulsifier aqueous solution is completed in the pipeline. This type of bitumen emulsion plant can realize continuous operation with large flow rate; it has the advantages of small tank volume, large output and high degree of automation.

There are many features that I can’t explain in detail here. Click the link https://www.lyroad.com/bitumen-emulsion-plant.html if you would like to learn more about it.

1 note

·

View note

Video

youtube

Bitumen Decanting Machine Manufacturer and Suppliers – Atlas Technologies Pvt. Ltd.

For heating bitumen decanting machine is a very safe option. It is preferred by road contractors and also by bitumen sellers around the world. This equipment will take in drums full of solid material. Heat inside the chamber is responsible for melting the asphalt that comes in drums. Drummed decanters are very safe as heating process is indirect by circulation of hot thermic oil inside the pipelines that run inside the chamber.

#bitumen sprayer#Bitumen Pressure Distributor#bitumen pressure distributors#bitumen sprayers#decanting machine#bitumen decanting machine#bitumen decanter#Bitumen decanting machine price#manufacturer#atlasequipments

0 notes

Link

Bitumen drum decanter is a machine for safe and reliable melting of bitumen. It can safely extract bitumen from the barrels or bags by a melting method. The process of working of bitumen drum decanter is safe because it uses heat generated by the hot oil for the melting process. The bitumen which is melt is stored and then transferred to asphalt tanks for use. They can also be pumped into a bitumen sprayer for spraying on the roads.

#Bitumen Drum Decanter#bitumen melting machine#bitumen sprayer#bitumen decanting machine#decanting machine

0 notes

Text

Sensitive Info About Decanter Only the Experts Know About

Decanters are occasionally better referred to as glass coffee pots or carafes. A decanter is a kind of vessel that is used for holding decantation results. A Port decanter is a significant wine accessory if you would like to decant your Port wine. If you've got an antique decanter at home, you ought to be mighty proud as not lots of people own a really distinctive vintage piece of glassware. When you would like to authenticate your antique decanter, you have to take age in consideration. Engraved crystal decanters and glasses are likely to be perfect gifts for any event.

If you are fortunate enough to have a decanter that's shaped such that it is possible to find a kitchen sponge into, be sure it's clean. Wine decanters are offered in an array of shapes, designs and are even available in various colors with colored glass making a strong comeback in the plan scene. Next you might want to consider about a wine decanter. Wine decanters could include a stoppered lid. They may have a stoppered lid. Style Wine decanters arrive in a number of designs.

Wine decanter is made from many materials as glass, crystal, mud and several different materials. The wine decanter is one of the finest on the market. Style Wine decanters arrive in a collection of designs.

There are several expensive and lovely decanters readily available, but wine may also be satisfactorily decanted into any carafe or perhaps a massive wine glass. You might have heard people tell you which you can allow the wine breathe'' by taking away the cork an hour or two before serving. Thus, let's get started and I want to show you a number of steps on how best to taste wine. Decanting wine may also remove sediment which may be at the base of the vintage.

Even people who don't have large collections of wine in their homes continue to be interested in decanting wine for a few reasons. Decanting wine is an excellent procedure to boost the flavor. It is a type of liquid that often must be decanted in order to remove excess sediment. It is a kind of liquid that often must be decanted to be able to get rid of extra sediment. It is a sort of liquid that often must be decanted so as to eliminate extra sediment. Moreover, in general it's much better to make an effort to pair wines with foods with a similar quantity of flavor intensity. Marsala wine is found in several kinds that are classified in accordance with the sweetness and age.

Decanter is provided in various shapes and prices it's dependent on us which one we choose and which is excellent for all of us. A decanter is a sort of vessel which is used for holding decantation success. A decanter is a type of vessel that's used for holding decantation consequences. Whiskey decanters may prove to be truly timeless gifts and will endure for a long time. Best for a marriage gift for that distinctive few, a whiskey decanter established is a great gift idea. Furthermore as a consequence of conventional Irish design the whiskey decanter gives a remarkable drinking experience. You're able to get the Skull Shaped Whiskey Decanter on Amazon, where it is possible to view precise photographs and extra product details.

What you are interested in getting the decanter for should effect the price that you're prepared to pay. Wine decanters are offered in different affordable rates. Furthermore, some wine decanters include an integrated rod that aids the decanting process. It's critical to be well informed, since there are quite a lot of kinds of wine decanters readily available in the marketplace. The wine decanter is one of the greatest on the market. The le chateau wine decanter is one of the finest in the organization.

Decanters are utilized to preserve all kinds of alcohol that has sediments. Alternatively it's possible to pre-chill your wine decanter and fill it using a white wine which will be consumed fairly quickly. Wine decanters may include a stoppered lid. They have really develop into a means to express your own personal style. They have really become a way to express your personal style. Most wine decanters have an extremely upright and tall form and are made from glass so the practice of decanting may be observed.

Brandy decanter is made to be temporary show vessels which also help in aerating spirits which were bottled up and will need to breathe before being imbibed! Bitumen decanter is nowadays an ideal solution which makes sense when you would like to get liquid bitumen since it is often impossible to find liquid bitumen at construction sites and in addition it becomes difficult that you regularly get it. Clearly, a decanter could also be used simply for aesthetic aspects. Wine decanters are offered in many various shapes and sizes and in most price ranges. To summarize, if you want to acquire a wonderful red wine decanter you ought to take into consideration the features mentioned previously.

1 note

·

View note

Text

youtube

Burner for ZAP-S 120 Asphalt Mixing Plant Working at Thailand

As a kind of mechatronics equipment with high degree of automation, the asphalt mixing burner has a combustion flame heat transfer method for direct contact radiation, short flame shape control but negative pressure design of the combustion chamber.

Advantages of asphalt plant burner include low pressure oil supply, medium atomization, lowA pressure gas, gas ring atomization and low NOx emissions.

Any type of asphalt plant be it continuous (drum type) or batch type machine comes with a burner for heating aggregates. If the aggregates are not heated properly, they cannot bind with bitumen and the end product will be bad. So, heating the aggregates evenly will help produce quality hot mix asphalt. Heated aggregates will play a major role in the success of hot mix asphalt. If the aggregates are hot, they will bind with bitumen.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#asphalt burner#coal burner#oil burner#heating aggregate#aggregate#bitumen decanter#bitumen melting machine#Youtube

1 note

·

View note

Video

youtube

Bitumen Drum Decanter Manufacturer and Exporter – Atlas Technologies

The drummed bitumen decanting system featured here can give production of 3.5-4 tons per hour we have bigger models also that can go up to 10 tons per hour. Atlas offers containerized bitumen drum decanter that can melt 27 barrels at a time. Heating of the bitumen barrels in the bitumen decanter is done by continuous circulation of thermic oil inside the heating chamber.

#bitumen drum decanters#asphalt drum decanting equipment#bitumen decanter#construction equipment#civil construction#road construction machinery#construction machinery

0 notes

Text

Drummed decanting machine manufacturer - Atlas Equipments

7 tph decanter near Pali. Atlas is drummed decanting machine manufacturer. Click to see photos. Safe, economical and reliable way to melt bitumen.

0 notes

Text

The leading manufacturer of drummed bitumen decanting equipment is based

By providing Drummed Bitumen Decanting Machine, we have carved out a niche for ourselves in this industry. Our supplied decanting machine is well-respected in the industry for its dependability and high quality.

0 notes

Text

How Does a Bitumen Drum Decanter Work ?

Bitumen drum decanter is a machine for safe and reliable melting of bitumen. The process of working of bitumen drum decanter is safe because it uses heat generated by the hot oil for the melting process. The applications and value that a drum decanter gives is immense. Added to that, our design of it being reliable, safe and economic operation makes it ideal and very easy choice for those sites where bitumen is available only in the form of barrels. Bitumen Decanter Working (process):.

The process of melting of bitumen is simple. Bitumen drum decanter working can be categorized into a total of three steps, which includes:. - Feeding of the barrels. - Heating process. - Pumping out of bitumen. In the first step, the barrels have to be fed into the machine by use of the hydraulically operated arms. The second process which is heating process consists of the heating of bitumen in the barrels by continuous flow of heat transfer oil in the pipelines. This heat transfer oil continuously flows from the pipelines surrounding the barrels to ensure fast heating of the bitumen. As the bitumen is heated, it will start melting and start falling in the chamber below due to gravity. From here it will be transferred to the storage tank by use of bitumen transfer pump. Key Components of Bitumen Drum Decanter,. All Tech manufacturer and Exporters of asphalt batch mix plant.

Key components of bitumen decanter include a heating/ melting chamber, barrel feeding hydraulic arms, hydraulic power pack, thermic oil heater, pipelines for thermic oil transfer and bitumen pumping system. All these components can be easily connected to each other easily at the site. Some of the main components are highlighted as below:. - Melting chamber: It consists of a thermally insulated room with a network of pipelines designed to transfer the thermic oil for heating process. The melting chamber is divided into two parts.

Image:-

Asphalt Batch mix plant

-

All Tech Group

The upper part will hold the barrels for heating, and the lower part will temporarily store bitumen till the time it is pumped out. - Hydraulics: The role of all the hydraulically operated arms in this machine is very important. They have to be of adequate capacity to push the bitumen barrels with good pressure. A hydraulic power pack has the hydraulic levers for individual hydraulic feeding gate control. - Thermic oil heater: This is the key component of the bitumen drum decanter. Atlas provides a three pass system for maximum fuel efficiency. It consists of a burner which will heat the oil flowing from the coils. - Pipelines for heat transfer: In the bitumen drum decanter, there is a series of pipelines that run from near each of the barrel feeding system.

These pipelines are very close to where the barrels stand during the melting process. Pipelines start from the thermic heating system where the burner is located and runs through the melting chamber back into the thermic heating system to complete the flow of thermic oil. - Bitumen pumping system: Bitumen pumping system is very important. It consists of a bitumen gear drive pump and a motor attached to it. Once bitumen is melt it will be transferred through this pumping system into another tank.

Installation Process For Bitumen Decanter. Proper installation of the bitumen decanter is key to long life of the equipment. There are many points that have to be taken care when installation of the machine is due. - For installation, we need to select the best available location which is slightly elevated. This is to avoid water seepage. - It is advisable to prepare a closed shade with some ventilation and place this machine inside a shade. - If construction of a shade is not possible, some barriers can be placed opposite to the entry and exit points of the barrels so that it blocks the free flow of the wind. This will help in minimizing heat loss. - Foundation drawing supplied should be strictly followed. - Before the trial run make sure all the components like cylinders, valves, burner, etc are working properly.

Image:-

Batch mix plant suppliers

-

All Tech Group

All the pipelines can also be checked and any extra materials, insects, etc can be removed prior to operation. - We want to ensure that no foreign particle enters the bitumen pump and damages the same, so having clean pipelines and storage chamber is a must. - Proper hygiene and safety standards have to be followed at the site at all times. Bitumen drumdecanter is a machine for safe and reliable melting of bitumen. It can safely extract bitumen from the barrels or bags by a melting method.

The process of working of bitumen drum decanter is safe because it uses heat generated by the hot oil for the melting process. - Pipelines for heat transfer: In the bitumen drum decanter, there is a series of pipelines that run from near each of the barrel feeding system. - Bitumen pumping system: Bitumen pumping system is very important.

0 notes

Video

youtube

Bitumen Drum Decanting Machine Manufacturer and Exporter – Atlas

Bitumen drum decanter short video. This decanting machine is available in 4 different models with smallest model being 4 tph and biggest capacity being 10 tph. Atlas is quality construction equipment manufacturer. This drum decanter is suitable for fast melting of bitumen barrels in a safe manner. The efficiency of this machine is the key factor that it is preferred by customers worldwide.

0 notes

Link

The bitumen drum decanter working principle revolves around the idea of safely melting the bitumen. Once the bitumen is in liquid form the machine will extract/transfer it to the storage or transfer tanks. Asphalt melting units by Atlas are available in capacities ranging from 4 tons, 6 tons, 8 tons and 10 tons. Bitumen filled in the barrel or bags can be melted by this decanting machine.

0 notes