#china aluminum grinding service manufacturers

Text

The Lifting devices are being fabricated for one large bridge construction equipment, the fabrication is almost completed,after propoer grinding and final check, then will send for machining.

#customsteelfabrication#mechanicalengineering#mechanicalconstruction#liftingequipmentfabrication#mechanicalsteelcomponents#hansalindustry

0 notes

Text

Aluminum Oxide Grinding Head X (AO)

https://www.keyingabrasives.com/products/aluminum-oxide-grinding-head-x-ao/

KEYING Rubber Mounted Head has a variety of specifications and granularity, accept non-standard size customization, including diameter, handle diameter, material, handle length and so on. The most prominent characteristics of KEYING Rubber Mounted Head are good grinding force, stable performance, long service life, small dust, can cooperate with the use of various high speed power tools or pneumatic tools. Mainly suitable for all kinds of casting molds, metal products, such as grooves, edges and holes concave and convex cleaning, to weld, deburr and fine polishing processing.

Specifications of Aluminum Oxide Grinding Head X (AO)

Application

Remove Burn Marks, Scales, Rust, Scratches, Dents And Chuck Marks Of The Resin Mold Cleaning Treatment; As Well As Suitable For Paint Removal, Electroplating And Coating

Brand

KEYING

Commodity Code

XCL6173+Grit+AO

Compatible Tool

High Speed Power Tools

Pneumatic Tools

Country Of Origin

China

Grit Type

Aluminium Oxide

Diameter

3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 16mm, 18mm, 20mm, 25mm, 30mm, 40mm

For Use On

Clean Grooves, Edges And Inner Holes Of Casting Molds And Metal Products, Remove Weld, Deburr And Fine Polish

Grit

60#, 80#, 120#, 180#, 240#, 320#, 400#, 600#

Make-to-order: 800#, 1500#

Shank Diameter

Industries

Automobile Manufacturing, Mechanical And Electrical Engineering, Gem Processing Industry

Colour

Purple, Red, Green, Bean Sauce, Blue, Gray, Brown, Light Blue, Gellow, Cgan

Maximum RPM

25000

Shape

Cylinder

Conical

T-Type

Standard Pack Quantity

40pcs/50pcs/100pcs

Table of Aluminum Oxide Grinding Head X (AO)

Table of Aluminum Oxide Grinding Head X (AO)

Features of Aluminum Oxide Grinding Head X (AO)

The most prominent features of this series of products are soft polishing and fine polishing.

Used for fine grinding and polishing, can make the workpiece surface to a higher level of surface finish such as mirror.

Widely used in precision polishing and deburring technology, edge seam grinding process.

Can cooperate with various high-speed electric tools or pneumatic tools.

Aluminum Oxide Grinding Head X (AO) Applicable Industries

Applications

Remove burn marks, scales, rust, scratches, dents and chuck marks of the resin mold cleaning treatment

As well as suitable for paint removal, electroplating and coatingA

Aluminum Oxide Grinding Head X (AO) Applicable Industries

Recommendations for Use:

By adjusting the granularity of the rubber material, the processing scratches can be prevented.

Aluminum Oxide Grinding Head X (AO) Applicable Industries

Matching Tool Drives:

Angle grinders

Mini angle grinder

Aluminum Oxide Grinding Head X (AO) Applicable Industries

Safety Instructions of Aluminum Oxide Grinding Head X (AO)

How To Use Aluminum Oxide Grinding Head X (AO)

Instructions:

Safety Instructions of Aluminum Oxide Grinding Head X (AO)

Please try to choose operation indoors environment and wear protective guards and goggles.

Never to exceed the recommanded maximum permitted rotational speed for safety reasons.

In order to have a gppd syocl removal rate, quality of surface and thermal laoding on the workpiece, the best performace would with a recomended cutting speed at 15-20m/s.

Don't push and increase the pressure during the processing to achieve a finner surface looking, but try to switch to diffirent grit flap wheels.

Safety Warning:

The clamping lenght between shank and grinders should be more than 15mm.

Never exceed the maximum safe speed when the shank is extra long. Try to consult your sales to check the safety rotating speed before use.

0 notes

Text

Truck Bodies Service Bodies Constructed Rhino Tough Totally Featured

There are many different sizes, styles, and payload capabilities of Box Van Bodies available to fulfill your needs. Your Box Van physique could be customized in a extensive variety of ways to accomplish your distinctive duties. Please contact our group of gifted craftsmen can add many custom options and capabilities to your Box Van Body to satisfy your needs. We have labored with many well known high quality manufacturers of truck bodies and elements for many years. We have constructed a sound and strong working relationships, putting in many custom elements on countless vans all through the years. Rest assured that your truck may be equipped with a Flatbed or Stakebed physique configured to fulfill your wants.

Complete turnkey packages are available with your choice of Stellar® Telescopic Crane, American Eagle® Air Compressor and Drawer Systems. Lightweight fiberglass bodies is the power to add payload, similar to device, equipment service truck bodies manufacturers, stock, and personnel whereas staying throughout the DOT weight tips. Spacekap supplies versatile and secure service bodies for workers in the telecom industry.

Iger Cranes, a completely owned division of Sioux Automation Center, has been building excessive performance telescoping service cranes since 1990. Ervice Trucks International , an entirely owned division of Sioux Automation Center, has been crafting prime quality service bodies since 1985. STI Eagle Pro service truck bodies have confirmed service truck bodies manufacturers to be up to the problem of powerful circumstances all over the world, from nickel mining in Madagascar, to the coal mines of China and highway building in Alaska.

Content, together with photographs, displayed on this web site is protected by copyright legal guidelines. Downloading, republication, retransmission or copy of content on this website is strictly prohibited. Royal Truck Body will be sure service truck bodies manufacturers to get precisely what you need. Every cupboard is outfitted with premium pneumatic door closers and stainless-steel door hinges, as properly as several latch choices.

Cast Products proudly manufactures and provides vehicular castings to manufacturers, dealers, and repair facilities of truck bodies and utility vehicles. Truck bodies and utility truck manufacturers depend on Cast Products for modular corners, rub rail ends, entry doorways, wheel chocks and flange rings, light bins, light housings, license plate holders, and lots of other merchandise. Whether you need help looking out via our catalog or finding the best solution for your software, Cast Products is the proper choice each time. We provide work truck, van equipment, and accent merchandise of all types from the industry’s top manufacturers.

Products include highway truck bodies, dump trailers, bulldozer blades, loader/shovel buckets, water truck bodies, mini web site gear trailers, tailgates and frames. Materials used embrace sizzling rolled metal, cold completed metal, carbon metal, stainless steel & aluminum. Capabilities include hydraulic press brake forming, punching, shearing, rolling, band sawing, drilling, grinding & welding.

Established in Woodbine, Iowa in 1965 by Delbert "Bus" Brown, Tommy Gate has skilled steady development in every of the previous five decades and is broadly acknowledged as a leader in the industry. Be the primary to search out out about discounts and promotions as properly as the most recent in truck physique expertise. We also have a variety of truck accessoriesincluding lifts gates, hoists, snowplows and far more. We cultivate long-term relationships beyond the initial sale, specializing in integrity, open communication, and shared values primarily based on doing enterprise right. We are dedicated to providing you with our best, so you'll find a way to greatest serve your clients.

No matter the task, big or small, there is a Knapheide work truck to satisfy the demands of your work. Platform & Stake Bodies For flat beds manufactured by Reading and Protech, Fallsway Equipment is your go-to distributor. Contact us at present to find how the professionals at Brake & Clutch can help you make one of the best gear decisions for your corporation requirements. If you are a contractor or professional in search of an upfit in your truck, then Truck Upfitters is the corporate to name. One factor you’ll have to contemplate when buying a used truck is just how a lot towing and hauling the earlier owner has carried out. Obviously, this isn’t something you’ll need to suppose about if you’re shopping for a hatchback or a convertible, but vans are totally different.

0 notes

Text

Inside the Kaolin Industry: India's Leading Manufacturers and their Impact

Kaolin, also known as china clay, is a white, fine-grained clay mineral primarily composed of kaolinite. It is derived from the weathering of aluminum silicate minerals such as feldspar. Kaolin is known for its excellent whiteness, low abrasiveness, and high plasticity. These properties make it suitable for a wide range of applications across various industries. Kaolin is a type of clay mineral that is widely used in various industries due to its unique properties and versatility. One leading Kaolin Manufacturers in India is A.N. Enterprises. With their expertise and commitment to quality, we have established ourselves as a prominent player in the kaolin industry.

Properties of Kaolin

Kaolin exhibits several properties that make it valuable in numerous industrial processes. Some key properties of kaolin include:

Whiteness: Kaolin is renowned for its exceptional whiteness, which is essential in applications where brightness and opacity are crucial factors.

Plasticity: The high plasticity of kaolin allows it to be easily molded and shaped, making it ideal for use in ceramics, paper coatings, and rubber products.

Low Abrasiveness: Kaolin has a low abrasion level, ensuring minimal damage to machinery and equipment during processing.

Chemical Inertness: Kaolin is chemically inert, making it resistant to chemical reactions and ideal for use in catalysts, fillers, and coatings.

Applications of Kaolin

Kaolin finds extensive usage across a diverse range of industries due to its versatile nature. Some common applications of kaolin include:

Ceramics and Pottery: Kaolin is a key ingredient in the production of ceramics and pottery due to its plasticity, whiteness, and high firing temperature.

Paper and Coatings: The fine particle size and high brightness of kaolin make it an excellent filler in the paper industry, enhancing print quality and opacity.

Paints and Pigments: Kaolin is used as an extender in paints and pigments, improving their durability, gloss, and color retention.

Rubber and Plastics: Kaolin enhances the strength, flexibility, and processing characteristics of rubber and plastic products.

Pharmaceuticals and Cosmetics: Kaolin is utilized in pharmaceuticals and cosmetics as an excipient, binder, and bulking agent.

Kaolin Mining and Processing

Kaolin is mined from deposits found in various parts of India. The mining process involves extracting kaolin ore from the ground using conventional mining methods. Once extracted, the ore undergoes processing to remove impurities and improve the quality of the kaolin. Processing techniques may include crushing, drying, grinding, and classifying the kaolin particles to achieve the desired specifications.

A.N. Enterprises: A Leading Kaolin Manufacturer in India

A.N. Enterprises is a renowned kaolin manufacturer based in India, specializing in the production and supply of high-quality kaolin for domestic and international markets. With years of experience and a state-of-the-art manufacturing facility, we have established itself as a trusted name in the industry. Here are some key factors that set us apart:

Environmental Responsibility

We are committed to sustainable practices and minimise its environmental impact. The company adheres to eco-friendly mining methods and implements measures to conserve energy, reduce waste, and promote reforestation.

Customer Satisfaction and Support

We prioritize customer satisfaction and offer comprehensive support throughout the entire process, from product selection to after-sales service. The company has a dedicated customer service team that ensures prompt response to inquiries and addresses customer concerns.

Competitive Pricing and Timely Delivery

We provide competitive pricing without compromising on quality. The company has optimized its manufacturing processes to achieve cost-efficiency, enabling them to offer competitive prices to their customers. Additionally, we maintain a robust supply chain and ensure timely delivery of orders.

Collaborative Approach and Customization

A.N. Enterprises work closely with their customers to understand their specific requirements and offer customized solutions. The company's team of experts collaborates with clients to develop tailor-made products that meet their unique needs, thereby fostering long-term partnerships.

If you're looking for high-quality kaolin for your industry needs, look no further than A.N. Enterprises. As one of India’s leading kaolin manufacturers, we provide top-notch products that meet international quality standards. Whether you're in the ceramics, paper, paint, rubber, or pharmaceutical industry, we have the right kaolin solution for you. Experience exceptional customer support, competitive pricing, and timely delivery. Don't miss out on the opportunity to enhance your products with premium kaolin and Contact us now!

0 notes

Text

Klarm Machining Promotes Precision Milling

New Post has been published on http://www.cncmachinings.com/klarm-machining-promotes-precision-milling/

Klarm Machining Promotes Precision Milling

Machine Vises

Machine tight clamps are normally utilized workholding gadgets for processing since they are exceptionally flexible, accurate,and easy to utilize. It is significant while considering a tight clamp for workholding that the workpiece is adequately thick to oppose bowing under the clasping tension. Standard tight clamps utilized for manual processing can be mounted in machining habitats for CNC processing. There are likewise tight clamps with two moveable jaws that brace against a focal strong jaw to permit various part clasping. Numerous models are accessible with machinable jaws that can be machined to acknowledge almost any part shape. Some additionally utilize a fast change jaw framework that permits various jaws to be changed very quickly.

Hurls/Collet Closers/Indexing Fixtures

Manual jaw-type throw apparatuses and collet installations can be utilized on CNC plants to hold and find round and hollow parts. Programmable ordering apparatuses utilizing tosses, collets, or level surfaces with t-openings for clasping can be associated with the machine’s MCU (if so prepared) and used to pivot the workpiece during CNC machining, making a fourth development called a rotational hub. Numerous models can be mounted either vertically or on a level plane.

This revolving pivot is like rotational tables utilized on manual plants. China cnc milling machine suppliers show manual collet installations and a CNC turning pivot.

Bed Systems

To amplify machining time and limit workpiece-stacking time, a few machines utilize a bed framework. This framework utilizes at least two workholding tooling plates that can be rapidly and precisely exchanged on the machine’s table. Tight clamps or other workholding gadgets might be mounted on these plates, and at some random time, one of these plates can be being used in the machine while another is outside of the machine having parts dumped and stacked. At the point when the machining cycle is finished, the workholding tooling plate can be immediately traded for another stacked with parts that are prepared for machining. For significantly higher efficiency, a few machines utilize a robotized bed transformer (APC) that consequently changes the beds through customized orders. The cheap cnc turning and milling metal machining factory work by Klarm Machining shows a machining focus equipped with an APC.

Gravestones

Most normally utilized in even shaft machines, a headstone is a pinnacle with various vertical working surfaces where workholding gadgets are mounted.

Headstones are likewise now and again called pinnacles or segments. The idea of a gravestone is to augment the measure of workpieces that can be mounted in a machine at a time. Headstones regularly have two or four working surfaces, however some have more. Every one of these sides may contain at least one workholding gadgets.

Parts are stacked in the workholding gadgets and afterward the gravestone is ordered from one side to another to machine the entirety of the mounted workpieces. To additional increment effectiveness and cutoff personal time because of part stacking/dumping, headstones are frequently utilized along with a bed framework.

Vacuum Plates, Magnetic Workholding, and Adhesive-Based Workholding

In some cases workpieces are hard to hold utilizing any of the strategies just portrayed, so substitute techniques very much can be utilized by china aluminum grinding service manufacturers. A vacuum apparatus is one strategy that can be utilized for light machining of meager, adaptable workpieces. An attractive hurl can be utilized to get ferromagnetic workpieces for machining, and furthermore functions admirably for holding flimsy, adaptable parts level. Both vacuum apparatuses and attractive tosses permit unhindered machining of the whole top surface of a workpiece. Cements, for example, twofold sided tape can tie down parts to the machine table or tooling plate for light machining too.

This article is from http://www.cncmachinings.com/

#big cnc machined part china#buy discount electric discharging machine#carbon fibre cnc cutting parts#cheap cnc turning and milling metal machining factory work#china aluminum grinding service manufacturers#china cnc milling machine suppliers#china custom steel cnc mahcining#cnc lathe machine shop#custom precision cnc machining#optical cnc turned components supplier#steel machining component china#swiss machining service suppliers#Featured Articles

0 notes

Text

Chucks and Collects

Posted from 5 axis machining China blog

Chucks and Collects

When mounting and eliminating throws, cnc precision parts suppliers china utilize a wooden board to help the toss and ensure the ways. Get help or utilize suitable lifting hardware while moving hefty machine hurls. On the off chance that utilizing a bit of overhead lifting gear, for example, a derrick or crane, wear a hard cap as needed by OSHA. Never remain under a hurl suspended from a derrick or crane.

Drill Chucks

A Morse tighten shank drill throw can be mounted in the headstock shaft by utilizing a decreasing sleeve. The sleeve’s outside shape mates with the axle bore. The inside shape of the sleeve acknowledges the Morse tighten of the drill throw. This work holding strategy can be utilized to hold breadths that are too little to even think about being held in three-jaw and four-jaw tosses. The throw and the sleeve can be taken out from the headstock utilizing a knockout bar.

Collects

Collects are another method of holding workpieces on the machine. They have gaps in their focuses to coordinate the size and state of the workpiece to be held. An outside shape on the collect permits it to be drawn against a mating tighten to give grasping power. The most well-known kinds of collects are spring collects and flex collects.

Collects have a few favorable circumstances over other work holding gadgets. They don’t have the mass of jaw-throw bodies so they are not extraordinarily influenced by divergent power at high RPM. Collects likewise cause very little contortion to empty workpieces and are more averse to damage surfaces in light of their bigger surface contact and all the more in any event, cinching pressure. Collects can likewise accomplish the precision and repeatability of a four-jaw throw, yet they are a lot faster and simpler to utilize. Collects can be utilized by china precision cnc machining oem parts to hold work for machining outer and inward breadths like jaw-type hurls.

Spring Collects

Spring collects are precisely ground round and hollow sleeves. The spring collect has cuts that start at its front and proceed around 75% of the path rearward. The back finish of the collect is strung, which permits it to be pulled, or drawn, against a mating tightened surface. The cuts permit the collect to tighten and hold the workpiece when the shape of the collect is drawn against the mating tighten.

Spring collects arrive in an assortment of sizes and shapes to oblige numerous sorts, shapes, and sizes of workpieces. Collects are most regularly found with straight round drills but on the other hand are accessible with square-and hex-formed gaps. Spring collects are bought for specific standard sizes and have a holding scope of just a couple of thousandths of an inch. In the event that a wide range of workpiece sizes must be machined, various collects are required.

Since nonstandard sizes regularly can’t be adequately secured in standard collects, crisis collects produced using metal or mellow steel are accessible that can be effectively machined to coordinate any ideal size. Step collects are utilized to grasp on short workpieces whose breadths are too huge to even consider fitting inside the envelope of standard spring collects. These collects might be intended for one measure or have a delicate head that can be machined to oblige an assortment of part sizes and shapes, much like a crisis collect.

An extending collect incorporates a basic arbor rather than an opening. At the point when it is drawn against the shape, the arbor grows and can grasp on a current inside breadth of a workpiece. Most growing collects are machinable like crisis collects, so they can be altered for a specific size. High-precision tooling suppliers china gives a few instances of spring collects.

This article is from http://www.5axismachiningchina.com

#belfast car bomb drink#buy discount electric discharging machine#cheap cnc turning and milling metal machining factory work#china aluminum grinding service manufacturers#china brass machined components#china cnc milling machine suppliers#china metal machining suppliers#china plastic machining suppliers#china precision cnc machining oem parts#china titanium cnc turned parts suppliers#cnc machining quotes#cnc machining service cnc turning parts factory#cnc manufacturing companies#cnc milling precision parts china#cnc precision brass parts china#cnc precision parts suppliers china#high precision stamped parts suppliers china#metal lathe turning china#micro-grinding machine factory#milling medical cnc parts china#optical cnc turned components supplier#other machined ptfe manufacturers china#oxygen omnibus manifold suppliers china#precision surface grinder china#professional machined parts made in china#quality optical device turned components#steel machining component china#steel machining component factory#super hard cnc cutter factory

0 notes

Text

Rapid Traverse

Fast navigate developments should be performed cautiously in a CNC going machine to forestall crashes. Uncommon consideration should be paid to the shifting lengths of the cutting apparatuses and that they are so near other machine parts and the workpiece. Another thought is the area of the device before and toward the fruition of the fast developments. For example, if the instrument is an ID…

View On WordPress

#4 axis cnc machining service factory#china alu cnc machining#china cnc machine for cutting foam#china cnc steel turned machining parts suppliers#china custom aluminum milling suppliers#china customized cnc milling parts suppliers#china customized cnc service#china luminum cnc milling machining suppliers#china precision machining parts suppliers#china precision mini metal lathe#china titanium grinding service manufacturers#china tooling cnc machining suppliers#cnc carbon fibre machining#cnc cutting service carbon fibre manufacturers#cnc lathe parts suppliers#cnc machined carbon fiber parts factory#cnc machining turning parts manufacturers#cnc milling aluminum part factory#cnc precision machining factory#cnc turning made in china#cnc turning parts suppliers#cnc turning precision titanium parts#cnc turning stainless steel parts china#custom cnc machined precision machining titanium parts factory#medical parts machining suppliers china#precision cnc machining service factory#precision grinding machine manufacturers china#precision stainless steel cnc turned parts manufacturers#prefessional cnc milling parts factory#quality instrument machining service

1 note

·

View note

Text

OEM custom die casting nest camera outdoor housing

Overview

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

OEM

Model Number:

HW-DN033-NCO28

Material:

Aluminum alloy

Cetificate:

ISO9001 / TS16949

Service:

OEM surveillance camera housing

Process:

Die cast / secondary / surface finish

Machine capacity:

180T - 500T

Shaping mode:

Die casting

Mould leadtime:

35 days

Package:

Standard export carton with protective bag

Delivery:

30 days

Market:

USA, Europe, Africa, South East

Guangzhou OEM custom die casting nest camera outdoor housing

Product Description

Prodcuts type

Die casting + secondary operation

Material

Aluminum:

ADC12, ADC10, A360, A356, A380, A413, B390, EN47100, EN44100

Zinc:

Zmark3,Zmark5,ZDC3

Brass:

HPb59-1,HPb62-1

Company Information

10 YEARS experience in manufacturer of Die casting: cctv camera

About Hanway

1) Hanway metal products plant, is a professional OEM die casting manufacturer. cctv camera

OEM orders are warm welcome. cctv camera

2) We have an experienced engineer and quality control team as our strong backing. cctv camera

3) High quality, competitive price, quick response is our mission. cctv camera

Our advantage

1) Professional technical support. cctv camera

2) Quick response. cctv camera

3) Strict quality control process. cctv camera

4) High cost performance. cctv camera

5) Rich experience in mould design and die casting. cctv camera

6) Abundant cooperation with occident corporations. cctv camera

7) ISO/TS/ERP sysytem guarantee. cctv camera

We can also provide

1) Stamping. cctv camera

2) Sand casting. cctv camera

3) Gravity casting. cctv camera

4) Investment products as matching products. cctv camera

Our history: cctv camera

1999

Set up Topway hardware company in Guangzhou, main business is export zinc, aluminum, brass products. cctv camera

2005

Hanway metal products plant locates Desheng village, Lishui Town, Nanhai. cctv camera

2007

Set up tooling workshop. cctv camera

2008

Pass ISO 9001:2008 system certification. cctv camera

2009

Invest new factory Hanway metal products Co.,Ltd. cctv camera

Change to ISO9001:2008 new version in Dec. cctv camera

2010

Move to new address. cctv camera

2011

Invest auto ladder, spray, extractor with die casting machine ,to improve the capacity of die casting. cctv camera

Set up a laboratory and equipped with projection, element analysis machine, sault spray machine. cctv camera

2012

Digiwinsoft Easyflow 9.0 ERP system launching. cctv camera

2014

Cooperated with SGS to start the TS16949 pre-training. cctv camera

Our equipments: cctv camera

Die casting machine

180 ton-4sets with auto ladle,sprayer,extractor. cctv camera

280 ton-2sets with auto ladle,sprayer,extractor. cctv camera

400 ton-1set with auto ladle,sprayer,extractor. cctv camera

500 ton-1set with auto ladle, sprayer, extractor. cctv camera

Secondary

Leathe-1set. cctv camera

NC-5sets. cctv camera

Milling-5sets. cctv camera

Grinding-2sets. cctv camera

EDM-1set. cctv camera

Rocker drill-1set. cctv camera

Drill&mill-2sets. cctv camera

Drill&Grinding-1set. cctv camera

Multi spindle drilling machine-2sets. cctv camera

Mulit spindle threading machine-2sets. cctv camera

CNC center-2sets. cctv camera

Punching-3sets. cctv camera

Stamping-2sets. cctv camera

Band saw machine-1set. cctv camera

Hydraulic sawing machine-1set. cctv camera

drilling-12sets. cctv camera

threading-10sets. cctv camera

Burrs removal line-2sets. cctv camera

Finish treatments

sand belt-8sets. cctv camera

Shot blasting-2sets. cctv camera

Sand blasting-2sets. cctv camera

rolling basting-2sets. cctv camera

Tumblling-2sets. cctv camera

Auto-Powder coating line-1set. cctv camera

Chromate line- 1set. cctv camera

Painting line -1 set. cctv camera

Mold welding machine-1set. cctv camera

Other equipments

Generator-1set. cctv camera

Ultrasonic cleaning line-1set. cctv camera

Inspection equipments

caliper,micrometer,height caliper, thread gauge, projection. cctv camera

two-dimensional image measuring machine with height probe. cctv camera

Elemental analysis, Extreme position micrometer. cctv camera

Rockwell hardness tester,sault spray machine,film thickness gauge. cctv camera

Our company view: cctv camera

Our Services

Our know how: cctv camera

We do know what we should do for the customers. cctv camera

We do know how to satisfy customers. cctv camera

Packaging & Shipping

Read the full article

1 note

·

View note

Link

Ningbo Zhenhai Gaoxin Punching Spares Factory

86-574-86303564 18069277369

No. 355, Jinchuan Road, Ningbo, Zhejiang, China

IntroductionWe are professional manufacturer and exporter specialized in precision stamping, common stamping, precision casting, common casting and metal product OEM & ODM service since 1998. Strong Capital strengthOur factory covers 3600 square meters. We have 1000 million RMB of fixed assets, 120 employees. In 2016, our annual turnover was ten million USD.Advanced production linesSound management system1 president1 vice president 7 department managers3 senior enginners10 R&D staff10 Q&C staff88 skilled workers Materials: steel, stainless steel, aluminum, cast iron, aluminum alloy and plasticProcess:Stamping, punching, bending, welding, threading, grinding, milling, lathe, assembling Casting: precision casting, common castingSurface Treatment: anodizing, powder-coating, zinc plated, black E-coat, chrome coated, nickel plated, hex chromates zinc, rust-inhibiting oils, electrophoresis, paints and primers, blacking, ect.Main CustomersOur products have been exported to Europe, North America, South America, Australia, Russia, The Middle East, and South Africa. We have established a stable business relationship with Flexiforce, Doorhan, Overhead, TG, Burfers, Hafele, Basbug and so on.Our slogan”Quality First, Credit First.”Sincerely welcome all customers to cooperate with us. Give us a chance and return your more successful and wonderful future. Quality control and technology improvementSince our factory was founded, quality control and technology improvement was our most important rule. We have been equipped with a lot of imported facilities and quality test facilities. We strictly abide by standards of ISO9001:2000and ISO9001:2008 during our production and management. Excellent OEM&ODM serviceOur sound management system, professional team and 20 years-experiences can guarantee excellent OEM&ODM service. Your designed drafts and/or samples will keep confidentially under the protection of agreements between us.Usually, the tooling time is 2 weeks, and the sample lead time is 1 week. Please pay for tooling cost in advance and separately, it won’t be included in the unit price.

0 notes

Text

A Review of Ferno Stretchers

For many years, the company known servo has been engaged in providing high quality and highly effective medical and surgical equipment and materials to the global healthcare market. The company is deeply invested in research and development of new and innovative medical equipment and materials that enhance patient care and enhance the delivery of healthcare services. They take great care, however, to avoid duplication of their equipment and materials by other companies or entities. Because of this, we can expect that the products and research of this company will always remain at the cutting edge of medical and surgical technology.

https://www.reportmines.com/heat-strengthened-glass-market-in-malaysia-r185322

https://www.reportmines.com/heat-strengthened-glass-market-in-uk-r185323

https://www.reportmines.com/heat-strengthened-glass-market-in-italy-r185324

https://www.reportmines.com/heat-strengthened-glass-market-in-france-r185325

https://www.reportmines.com/cable-tray-systems-market-in-china-r185326

Ferno stretcher is a market leader in the field of medical evacuation and advanced medical procedure and it is also at the forefront of many innovative technologies that are being developed worldwide. These include but are not limited to, supercompact stretchers, medical lifts, da Vinci and Smart steer stretcher systems. This company also recycles and reuses its equipment and materials, thus conserving resources for future medical needs and discoveries. If you are interested in investing in an organization that is at the cutting edge of medical research, then the Ferno Company might be the right one for you. Investigate the opportunities available to you.

The medical stretcher market is expanding each year due to new advances in medical technology and innovative, safer methods of transporting patients. As new technologies, equipment and materials become available older, less effective equipment is replaced. This means competition within the industry will increase, thus increasing overall profit for companies such as Ferno stretcher. This also means that the cost of equipment and materials will decrease and the company will profit as a result. Keep an eye out for this trend and invest in the best product for your organization.

In the past, the company has been criticized for being a "market leader" who only benefits from a market situation. To avoid being labeled as a market leader you should do the following: conduct extensive research, participate in industry events and market surveys and be aware of market trends. By being aware of industry trends, you can make informed decisions and be prepared for any changes that may come about in the industry. With the information gathered, you can determine the correct course of action to take, be it a merger or acquisition, as well as make wise business decisions.

The Ferno stretcher company is constantly researching, manufacturing and producing medical equipment that is better, safer and more cost efficient. The company works hard to maintain a consistent level of quality and excellence so that customers continue to come back. When choosing between products or a combination of products, be sure you choose the best equipment available on the market. The same holds true when looking to contract medical services for your organization.

Since starting over forty years ago, Ferno stretchers has perfected the art of stretcher manufacturing. They are constantly upgrading their equipment so that you will always be able to count on top-quality performance. They are committed to using only the best material available. Their stent kits are made of the best metal and plastics known to man and they are designed to withstand the toughest medical situations. Their stretchers use durable nylon rope and durable webbing for ultimate strength and rigidity.

The quality control process at Ferno is a closely guarded secret, although there is no way to really tell what the quality control standards are without trying the equipment yourself. There is however, an extensive selection of different styles of stretchers available to fit any job site and any medical need. The company produces hundreds of different types of stretchers all engineered to meet a variety of medical situations. Each style of stretcher is created to be versatile and multifunctional so that you can quickly and easily adapt the stretcher to the changing needs of the job. The Ferno stretcher is durable enough to be used in any situation while still being lightweight enough to transport personnel, supplies or patients without causing any stress or strain. You can carry one in your hand, place it behind a seat, or mount it on a pole.

One of the greatest features of Ferno equipment is their customization options. This company prides itself for being the leader in medical equipment. If you are not interested in buying a specific model you can request a custom design. From a large variety of colours, shapes and sizes, you can get a stretcher made to suit your specifications. In addition to all of this, many of the models sold by Ferno also come with a limited lifetime warranty which makes purchasing from them more trustworthy.

Summary

The report forecast global Backboard Stretchers market to grow to reach xxx Million USD in 2019 with a CAGR of xx% during the period 2020-2025 due to coronavirus situation.

The report offers detailed coverage of Backboard Stretchers industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Backboard Stretchers by geography. The report splits the market size, by volume and value, on the basis of application type and geography.

First, this report covers the present status and the future prospects of the global Backboard Stretchers market for 2015-2024.

And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru].

At the same time, we classify Backboard Stretchers according to the type, application by geography. More importantly, the report includes major countries market based on the type and application.

Finally, the report provides detailed profile and data information analysis of leading Backboard Stretchers company.

Key Content of Chapters as follows (Including and can be customized) :

Part 1:

Market Overview, Development, and Segment by Type, Application & Region

Part 2:

Company information, Sales, Cost, Margin etc.

Part 3:

Global Market by company, Type, Application & Geography

Part 4:

Asia-Pacific Market by Type, Application & Geography

Part 5:

Europe Market by Type, Application & Geography

Part 6:

North America Market by Type, Application & Geography

Part 7:

South America Market by Type, Application & Geography

Part 8:

Middle East & Africa Market by Type, Application & Geography

Part 9:

Market Features

Part 10:

Investment Opportunity

Part 11:

Conclusion

Market Segment as follows:

By Region

Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia]

Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland]

North America[United States, Canada, Mexico]

Middle East & Africa[GCC, North Africa, South Africa]

South America[Brazil, Argentina, Columbia, Chile, Peru]

Key Companies

KEMP

Morrison

Junkin

Allied Healthcare Products

Attucho

Genstar Technologies Company

Spencer Italia

Market by Type

Aluminum Alloy

Synthetic Resin

Others

Market by Application

Game

First Aid

Emergency Rescue

Others

Frequently Asked QuestionsWhat is the USP of the report?

Global Backboard Stretchers Market report offers great insights of the market and consumer data and their interpretation through various figures and graphs. Report has embedded global market and regional market deep analysis through various research methodologies. The report also offers great competitor analysis of the industries and highlights the key aspect of their business like success stories, market development and growth rate.

What are the key content of the report?What are the value propositions and opportunities offered in this market research report?Related Reports

Global Back Grinding Tapes Market

Global BabyNes Market

Global Baby Walkers Market

Global Baby Sanitary Products Market

Contact us: https://www.reportmines.com/contact-us.php

0 notes

Text

Hybrid Additive Manufacturing Market To Surge Beyond $242.9 Million By 2027

The global hybrid additive manufacturing market size is expected to reach USD 242.9 million by 2027, according to a new report by Grand View Research, Inc., expanding at a CAGR of 14.8% from 2020 to 2027. Increasing demand for low volume and complex design automotive parts is likely to contribute to the growth of the market.

The automotive industry has rapidly adopted additive manufacturing technology in recent years. Numerous companies have changed traditional processes with additive manufacturing, which is a relatively new, faster, and more cost-effective process. One of the key benefits of hybrid 3D printing or hybrid additive manufacturing is reduction in wastage. With the help of this process, the manufacturer uses only necessary material for production of components, thereby reducing the cost of materials.

R&D investments in the production of automotive parts is another key focus area for market vendors. For instance, BigRep, a 3D printer producer company based in Germany, and Polymertal, an Israel-based company, are working on the development of prototype of automotive exhaust manifold. The companies have used a hybrid approach using metal plating and additive manufacturing in order to develop this product. Similar investments by other companies are likely to assist in the growth of market.

Development of new 3D printers and their components is likely to remain one of the important growth factors for market vendors over the long term. For instance, 3D-Hybride, a U.S.-based company, has started delivering 3D printing based metal printheads. These printheads can be installed with any CNC machines. This can assist in turning the CNC machine into hybrid additive manufacturing machine. Material for this machine is used in the form of alloy wire.

Metal additive manufacturing is gaining significant attention from industries, such as aerospace and medical. However, nearly all the parts made using this process require further machining operations, such as turning, milling, and grinding, which increases lead time and costs. These factors are likely to assist in the penetration of hybrid additive manufacturing owing to its capability to perform various operations on a single machine.

Request a free sample copy or view report summary: Hybrid Additive Manufacturing Market Report

Hybrid Additive Manufacturing Market Report Highlights

Titanium emerged as the largest material segment in 2019 with a share of 38.0%. The growth of the segment is attributed to increasing demand for new aircraft on account of growing passenger traffic

Aluminum is projected to expand at a lucrative CAGR of 15.1% from 2020 to 2027 on account of its lightweight properties and recycling nature

The medical end-use segment was valued at USD 22.3 million in 2019. Increasing healthcare expenditure and technological advancement in medical devices and implants are the key factors boosting the segment growth.

Hybrid Additive Manufacturing Market Segmentation

Grand View Research has segmented the global hybrid additive manufacturing market on the basis of material, end use, and region:

Hybrid Additive Manufacturing Material Outlook (Revenue, USD Million, 2016 - 2027)

Titanium

Aluminum

Steel

Nickel

Others

Hybrid Additive Manufacturing End-use Outlook (Revenue, USD Million, 2016 - 2027)

Aerospace

Tooling and mold

Medical

Others

Hybrid Additive Manufacturing Regional Outlook (Revenue, USD Million, 2016 - 2027)

North America

Europe

Asia Pacific

Central and South America

Middle East & Africa

U.S.

Germany

Spain

China

Japan

List of Key Players of Hybrid Additive Manufacturing Market

Materialise NV

Hoganas AB

Arcam AB

Renishaw PLC

3D Systems Corporation

GKN PLC

Sandvik AB

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

0 notes

Text

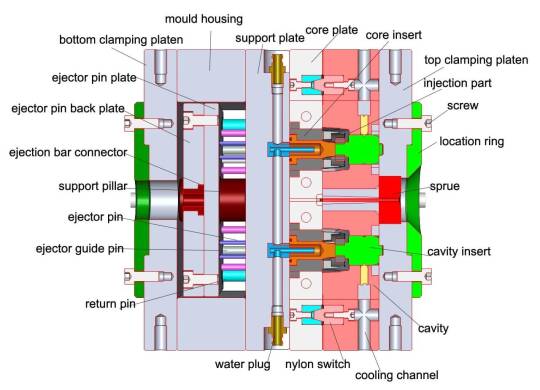

mold manufacturers in China | Topworks-China Mold maker | 30% COST LOWER,10 DAYS LESS

Mold manufacturers in China

Many people assume that mold manufacturers in China are going to be of poor quality.

However, a huge number of companies- including multinational corporations- still choose to buy such plastic molds.

Does that mean these companies are naive or making a mistake?

Of course not.

In fact, Topworks plastic mold company, as one of the Top mold manufacturers in China, is capable of making some of the best molds on the market- for a much lower price( 35% COST LOWER,15 BUILDING DAYS LESS) than European and American companies can possibly offer.

China has seen a steady increase in the number of manufacturers of plastic injection molds as the industry has grown to be globally competitive.

Not only do Mold manufacturers in China have the skills required to make superior injection molds, but we also possess excellent English skills for technology and business.

That extends into the Topworks marketing departments, too- most of our sales staff have a strong grasp of CAD drawing, and the technical capability to choose the right mold building project for you.

This allows them to speed up the communication process between Topworks and the customer.

When making a new plastic injection mold, not only in China but all over the world, the process usually starts with a rendering of the final product drawing.

After reading the drawing, engineers can then adjust how to build the mold based on things like the size and structure of the intended parts, the choice of material and how to keep the cost as low as possible – all while considering everything the customer asks for.

China mold maker

Our factory has worked with multiple European and American companies for many years now, so all you need to do is send us your drawings- we’ll be happy to carry out a test to show you what we have to offer.

https://res.cloudinary.com/dl8a9jvpa/video/upload/v1572574321/plastic%20mold.mp4

Mold manufacturing has been around in China for over 30 years, meaning there are plenty of high-quality manufacturers operating today.

Many China mold makers possess the same skills and experience as their western counterparts.

While those injection mold manufacturers in China may only be paid around 65% of what they could make doing the same job in the US, they will still produce top-quality molds that you can really rely on.

" order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]

How should I go about choosing mold manufacturers in China?

To clarify, the reason why a lot of US and European clients are declining to get their plastic injection mold from China is mainly that they are often more affordable (up to 35% cheaper than in their country).

It should not, however, be the only factor you evaluate when weighing your options- you should also consider the following as a second factor to make sure that the mold manufacturers in China you choose are likely to provide you with a comprehensive task when it comes to developing the mold.

- Can they afford to serve customers worldwide?

- Consumers who used the service earlier and gave us their recommendations

- Tool steel quality

- The China mold factory manufacturing plant and their gear are of an industry standard.

- Measures for quality control and validation

- If you opted for a service provider who doesn't understand what they are dealing with, you may not have to waste your time.

- Ability– will the China mold maker be able to carry out the entire task themselves, or will they have to employ a third party to help them with it?

plastic mold structure

The process of China mould making

A design engineer is generally responsible for drawing a component pattern of the new part before the china mold factory can start the actual production of the mold. This blueprint gives the toolmaker an idea of what the new component will look like, so he can start designing the mold before proceeding with the work.

In order to design a mold in a way to replicate the finished part very precisely, the specifications of the final part must be carefully reviewed. By performing the initial design on the computer, the mold designer who worked at mold manufacturers in China can get accurate results.

The designer of a mold has to consider not only the gate on the part, but also the flow of water in the mold, to decide where the parting line will be on the part, and also to determine how the parts will be pushed out of the mold.

Once these decisions have been made, the actual machining steps then begin. There are a variety of operations that need to be carried out in order to make a mold, the raw metal blocks need to be cut into rough dimensions.

To obtain exact dimensions, precision machining is required, with this precision machining, this machining generally entails milling operations, grinding, drilling, and the use of electrical discharge machining or EDM.

The process of using the lathe to polish the surface of the mold once it has been completed.

There have been several trials done to determine how well the mold is able to produce good parts in an appropriate cycle time.

China mould making tips

It is a prevalent understanding that injection molds are as varied in profile, complexity, and size as are the parts they are used to produce.

The most simple form of injection molding involves two pieces of steel plates (core and cavity plate) that can be easily installed in a small injection machine and which can also be molded using directly cutting the impression of the article to be molded into the steel.

More complex injection molds made by China mold companies will have more cooling channels for controlling the temperature and means for ejecting the moldings.

A sliding block may be provided for undercut sections of the part, unscrewing devices for moldings that have a screw thread, and plastic in the runner of the mold may be kept hot to provide a good fluid path.

For the purpose of ejecting the moldings after injection molding, there are sometimes hydraulic devices installed, and sometimes compressed air is applied.

The process of the production of an injection mold generally begins with the design and construction of the mold. Care must be taken to optimize the design of the components so that they can be molded by China mold makers, and then it must be ejected in the construction of the mold itself.

Then, if necessary, it will be tested in the China mold factory and, if necessary, modified before the mold production department is entrusted with producing the mold.

Steel is traditionally used to manufacture molds, and it is still the most common material that is used.

Cavities and core inserts are crafted from high-quality tool steel that can be hardened as needed.

Ejector pins and other ejectors are made with hard tool steel when it comes to the ejection systems, so the same goes for the guide pins and bushes as well.

The molding housing, or bolster, is made of mild steel that is softer than the hard steel.

In fact, in the production of the mold, it is best to use this grade of steel for all the parts that do not have to endure frictional wear and tear, as it results in minimizing the mold builder’s costs.

Also, the steel grade must be selected carefully so that the surface finish required matches the demand is.

In the past, like some other molders, injection mold manufacturers in China have been unwilling to accept other materials, such as POM, PVC, on the basis of the assumption that the abrasive action of the plastic passing through the mold will gradually wear away the surface polish.

Thermosetting materials and compression are what happen in this process, and the process of making transfer molds is nearly always hardened and chromium plated.

mold manufacturers in China

In retrospect, thermoplastics have little abrasive action, and therefore most of the time, even when runs have run as high as one million or more, soft materials have been used after hardening, especially for household ware plastic mold.

These materials include aluminum, brass, zinc, aluminum-zinc alloys (Kirksite).

The two last materials are ideal for prototype work since they can be cast easily from them using machines.

You need to always look for the best possible mold when it comes to long-run products. Such molds are very costly. However, their cost per unit item is calculated out of ten and one hundred thousand items per mold, which is very small.

Over a long period of time, the value of a well-made mold will grow, and in its turn, the cost of the mold will rise. This is because a well-made mold will not require frequent repairs, while the value per unit of the finished product will be very high.

EDM shop

Nowadays, more and more customers want injection mold manufacturers in China to make prototypes so they can evaluate the market and then ask them to make several thousand pieces of the mold design with hardened steel.

A prototype mold is exactly what its title suggests, a mold that is being created to serve as a prototype for a product.

In rare instances, from a product mold from China, one could find a way to make a long production run, but this is never a matter of course in a business world.

The good thing about a prototype mold is that it teaches us a lot about how molds should be manufactured and makes us a lot more confident that we will produce a good mold, but that is probably the extent to which a prototype mold can be helpful.

China Mould Classification

China Mould Classification is generally classified into three general categories:

- prototype molding (25 to 1,000 pieces)

- Production molding (from 1,000 to 10,000 pieces)

- High volume molding (from 10,000 to 2,000,000 pieces)

-

China Prototype Moulds

Creating a prototype thermoplastic injection mold is one of the preliminary steps in building a new product.

To evaluate the properties of the resin for injection molding and the set-up requirements for the mold, original prototypes have to be produced from the resin to monitor the dimensional control, the set-up process, and the setting of the mold.

In certain products, prototype moldings are designed to meet specifications for product Quality Control testing. Therefore, they are generally used for product quality control testing and (occasionally) as the basis for the initial market testing requirement.

As China prototype molds are intended to mimic the production part before launching a production run, they can be used as a relatively inexpensive learning device to point out and correct potential design issues or material selection issues before moving forward on a production run.

An existing prototype mold may be fabricated utilizing an existing mold frame, interchangeable soft cavity inserts, manual loading and unloading systems, and a simple cooling system.

-

China Production Moulds

The construction of china production molds utilizes a low-cost mold base and hardened tool steel cavities; the cavities should be machined into predefined shapes and sizes on demand according to specifications at established production rates.

The mold must allow for the ease of repair as well as facilitate the escape of trapped air and volatile materials during the molding cycle employing facilitating the venting of the cavities.

In this context, a production mold must also incorporate an automatic ejection system and thermoplastic melting temperature control for continuous cooling, ensuring shorter cycle times, lower costs, and consistently high quality.

-

China High Volume Production Moulds

For the China moulds to fully meet the requirements of production tools, the molds must have multiple cavities and be composed of interchangeable mold components. In addition, an efficient high-volume production mould made in China should be easy to maintain and be designed to be resistant to adverse outside forces.

For instance,

- How often do you begin dismantling a mold only to discover too many inserts that are not numbered or labeled with positions?

- What about slots for pry bars?

- Could jack screw holes be useful in the removal of cavities?

A well-configured mold can help minimize the risks of its design and construction and prevent corrosion and erosion. In addition, a customized preventative maintenance program can be incorporated, as well as surface coatings.

Read the full article

0 notes

Text

CNC Lathes

New Post has been published on http://www.cncmachinings.com/cnc-lathes/

CNC Lathes

In a creation machining, the more proficiently a machine can play out an employment beginning to end without administrator mediation, the better. When making turned parts for china precision machine parts there is consistently the issue of not having the option to machine the finish of the workpiece held in the workholding gadget. Turning focuses can beat this hindrance with a component called a subspindle. A sub-shaft is an assistant auxiliary axle, which contradicts the machine’s fundamental headstock axle. This shaft might be furnished with a hurl and might be customized to make a trip to the fundamental axle, hold the part, and afterward re-visitation of the tailstock end of the machine for machining the rear of the part. This whole part move can happen while never opening the machine entryway or taking the part from the machine. Truth be told, numerous machines can play out this exchange without halting the axle pivot.

Most turning places are fitted with a round turret where the entirety of the tooling is mounted. This turret fills in as the ATC and can be customized to list (pivot) to situate the ideal device to perform machining tasks. These machines can acknowledge an assortment of hardware mounting connectors that are utilized to mount the instrument’s shank to the turret and hold the device in an ideal position and direction. Precision turning part manufacturers china shows a picture of a turning community turret.

Turret machines are famous because of their capacity to fit a high amount of apparatuses in a limited quantity of room. Some turret-type machines are even fitted with more than one turret. The optional turret can be utilized by cnc turned parts company at the same time to machine the part and increment efficiency.

The other normal turning place configuration is the pack instrument machine. These sorts of machines ordinarily are of a level bed plan and are fitted with a carriage (like a manual machine) where apparatuses are introduced. Most machines adjust the devices straight close to one another (” ganged up”) on a top plate. With a group device arrangement, the machine can play out an instrument change rapidly by moving the top plate a short separation from the current apparatus to another device. Pack apparatus machines likewise innately have extraordinary inflexibility, high precision, and a very straightforward plan with not many moving parts. Group device machines are normally ideal for little parts that require short tooling (long devices can experience crash issues when they are close by short instruments) and short machine X-hub ventures (because of the space utilized by the length of the top plate). cnc machining components suppliers shows a posse apparatus turning focus.

A CNC machine has no ATC; a device post is mounted on a cross slide a lot of like that of a manual machine. Frequently a similar instrument posts utilized by china computerized lathe machining parts suppliers on a manual machine are additionally utilized on these machines. Generally the indexable or speedy change-style presents are picked on permit devices to be changed rapidly physically. When utilizing this sort of hardware post, apparatus changes are performed by physically ordering the device post to a detent position when the program educates the administrator. A portion of these instrument posts have a brisk change highlight that permits a dovetailed toolholder to be delivered and supplanted rapidly and precisely. cnc lathe machine shop shows an apparatus post on a CNC machine.

This article is from http://www.cncmachinings.com

#bronze machining china#buy discount electric discharging machine#carbon fiber cnc suppliers#cheap cnc turning and milling metal machining factory work#china aluminum grinding service manufacturers#china cnc milling machine suppliers#china cnc stainless steel turning service#china cnc titanium milling parts and service suppliers#china computerized lathe machining parts suppliers#china precision machine parts#china processing aluminium machined parts#china wire cutting edm suppliers#cnc lathe machine shop#cnc machining components suppliers#cnc machining services copper parts suppliers#cnc machining titanium parts#cnc precision brass parts china#cnc turned parts company#flat grinder manufacturers china#metal lathe turning china#metal stamping camera parts made in china#other machined ptfe manufacturers china#precision cnc machining parts company#precision grinding machine made in china#precision machining electronics parts factory#precision turning part manufacturers china#stainless steel precision milling part manufacturers china#steel machining component china#super hard cnc cutter factory#teflon machined parts manufacturers china

0 notes

Text

Turning Canned Cycle in CNC Machining

Posted from 5 axis machining China blog

Turning Canned Cycle in CNC Machining

The directions that characterize the state of the form to be roughed should be customized after the G71 block(s) so the canned cycle realizes where to eliminate material. Grouping numbers should be alloyed to the first and last squares of the shape.

The p-and Q-estimations of the canned cycle will reference these blocks.The cycle is additionally liable for leaving a reliable measure of stock on the part for the co

After the part has been roughed, a get done with turning canned cycle can be initiated by utilizing a G70 order. This canned cycle shares the form positions previously customized for the roughing cycle by the p-and Q-values.

In the event that TNRC is modified, most machines disregard it during the G71 roughing passes however apply it on the G70 finish pass.

ID Turning (Boring) Canned Cycle

The G71 roughing and G70 completing cycles can likewise be utilized to perform inside distance across turning (exhausting) tasks. Likewise with every single drilling activity, an opening must clench hand be made to make freedom for the drilling bar.

The X-start point should be modified at within distance across of the harsh drilled opening. The roughing passes will start at the opening’s distance across and work outward until the harsh shape is finished. The G71 cycle works for exhausting in a similar way as OD turning, just the machine must retreat the instrument internal (at the focal point of the part) after each pass. The X-pivot finish allowance should likewise happen the X-negative way. On numerous Fanuc and Haas machines this is finished by allocating a negative U-esteem for the X-finish. cnc cutting service carbon fiber factory shows a Fanuc program extract for unpleasant/finish ID turning on a workpiece, and china custom titanium parts machining manufacturers shows a similar part modified on a Haas.

Profound. cutting often makes since quite a while ago twisted chips that can obstruct coolant and cause the apparatus to tie. As with drilling, a pecking movement while cutting can help break and clear these chips. A G75 cutting cycle is accessible on Haas and Fanuc controls to make programming these activities simpler. The cycle can be applied to OD (outside) sections or ID (inner) grooves. The cycle may likewise be utilized for cut-of tasks if the last X-position makes the instrument get through into an opening or cross the part center line.

A Z-hub venture over can be added to make grooves that are more extensive than the device itself. For this situation, one full scoring pass will be finished prior to venturing over to the following cut position. china 4 axis cnc machining manufacturers shows a program extract for a solitary width pass (no Z-venture over) peck cutting activity for Fanuc and for Haas. precision cnc turned parts manufacturers shows a program selection for a various width pass (with a Z-venture over to build the notch width) peck scoring activity for Fanuc and Figure for Haas. The table beneath shows the organizations utilized on numerous Fanuc and Haas machines.

The primary G75 square of a Fanuc may utilize

. R sets the distance the apparatus will retract after each peck to break the chip.

The second G75 square of a Fanuc may utilize the X specifies the last notch breadth after all pecking is finished.

. Z specifies the end position of the finished section in the Z-axes. This can be excluded for single-width pass grooves.

. P sets the steady infeed distance for each peck in the X-direction (normally no decimal, four-place design).

. Q sets the steady advance: over distance for each pass in the Z-bearing (usully no decimal, four-place design).

. F sets the feed rate.

. X specidfies the last furrow width after all pecking is finished.

. Z specifies the end position of the finished furrow in the Z-pivot. This can be overlooked for single-with pass grooves.

. I sets the steady infeed distance for each peck the X-course.

. K sets the gradual advance over distance for each pass in the Z-bearing.

. F sets the feed rate. This article is from http://www.5axismachiningchina.com/

#best engineering services company in india#carbon fibre cnc cutting parts manufacturers#china 4 axis cnc machining manufacturers#china cnc carbon fiber#china cnc machining suppliers#china cnc precision machining manufacturers#china cnc router for carbon fiber#china custom titanium parts machining manufacturers#china precision cutting metal machining#china stainless steel milling parts factory#china steel cnc turned component manufacturers#china titanium precision cnc components suppliers#cnc aluminum milling parts factory#cnc carbon fibre service manufacturers#cnc cutting service carbon fiber factory#cnc grinding machine china#cnc machining products suppliers china#cnc turning laser carving parts china#custom cnc work suppliers#custom metal parts aluminum cnc milling machining factory#cutting eva foam#high precision surface grinder made in china#high-precision tooling factory china#iron cnc make factory china#precision casting auto part made in china#precision cnc turned parts manufacturers

0 notes

Text

Drilling in CNC Processing Service

Drilling in CNC Processing Service

Canned Cycles

A few activities require redundant movements, for example, penetrating a few openings to a similar profundity or making numerous chip-breaking pecks needed for profound opening boring. Since the past boring model took three squares of movement code, 30 squares of code would be expected to penetrate 10 openings. In the event that peck penetrating is wanted, each peck needs at any…

View On WordPress

#bronze machining parts factory#china cnc brass and copper and bronze milled machining parts#china cnc turning and milling metal machining factory work suppliers#china computerized lathe machining parts suppliers#china medical device cnc processing suppliers#china precision machine parts#china precision machining manufacturers#china stainless steel grinded machining parts manufacturers#china titanium components suppliers#cnc machining components suppliers#cnc machining services copper parts suppliers#cnc turned parts company#cnc turning parts aluminum suppliers#high precision machining parts factory#high precision stamped parts made in china#high-quality fixture part machining#micro cnc machining suppliers#precision cnc machining#precision surface grinding machine made in china#quality optical device turned components

0 notes

Text

A Review of Ferno StretchersFrequently Asked QuestionsWhat is the USP of the report?What are the key content of the report?What are the value propositions and opportunities offered in this market research report?Related Reports

For many years, the company known servo has been engaged in providing high quality and highly effective medical and surgical equipment and materials to the global healthcare market. The company is deeply invested in research and development of new and innovative medical equipment and materials that enhance patient care and enhance the delivery of healthcare services. They take great care, however, to avoid duplication of their equipment and materials by other companies or entities. Because of this, we can expect that the products and research of this company will always remain at the cutting edge of medical and surgical technology.

Ferno stretcher is a market leader in the field of medical evacuation and advanced medical procedure and it is also at the forefront of many innovative technologies that are being developed worldwide. These include but are not limited to, supercompact stretchers, medical lifts, da Vinci and Smart steer stretcher systems. This company also recycles and reuses its equipment and materials, thus conserving resources for future medical needs and discoveries. If you are interested in investing in an organization that is at the cutting edge of medical research, then the Ferno Company might be the right one for you. Investigate the opportunities available to you.

The medical stretcher market is expanding each year due to new advances in medical technology and innovative, safer methods of transporting patients. As new technologies, equipment and materials become available older, less effective equipment is replaced. This means competition within the industry will increase, thus increasing overall profit for companies such as Ferno stretcher. This also means that the cost of equipment and materials will decrease and the company will profit as a result. Keep an eye out for this trend and invest in the best product for your organization.

In the past, the company has been criticized for being a "market leader" who only benefits from a market situation. To avoid being labeled as a market leader you should do the following: conduct extensive research, participate in industry events and market surveys and be aware of market trends. By being aware of industry trends, you can make informed decisions and be prepared for any changes that may come about in the industry. With the information gathered, you can determine the correct course of action to take, be it a merger or acquisition, as well as make wise business decisions.

The Ferno stretcher company is constantly researching, manufacturing and producing medical equipment that is better, safer and more cost efficient. The company works hard to maintain a consistent level of quality and excellence so that customers continue to come back. When choosing between products or a combination of products, be sure you choose the best equipment available on the market. The same holds true when looking to contract medical services for your organization.

Since starting over forty years ago, Ferno stretchers has perfected the art of stretcher manufacturing. They are constantly upgrading their equipment so that you will always be able to count on top-quality performance. They are committed to using only the best material available. Their stent kits are made of the best metal and plastics known to man and they are designed to withstand the toughest medical situations. Their stretchers use durable nylon rope and durable webbing for ultimate strength and rigidity.

The quality control process at Ferno is a closely guarded secret, although there is no way to really tell what the quality control standards are without trying the equipment yourself. There is however, an extensive selection of different styles of stretchers available to fit any job site and any medical need. The company produces hundreds of different types of stretchers all engineered to meet a variety of medical situations. Each style of stretcher is created to be versatile and multifunctional so that you can quickly and easily adapt the stretcher to the changing needs of the job. The Ferno stretcher is durable enough to be used in any situation while still being lightweight enough to transport personnel, supplies or patients without causing any stress or strain. You can carry one in your hand, place it behind a seat, or mount it on a pole.

One of the greatest features of Ferno equipment is their customization options. This company prides itself for being the leader in medical equipment. If you are not interested in buying a specific model you can request a custom design. From a large variety of colours, shapes and sizes, you can get a stretcher made to suit your specifications. In addition to all of this, many of the models sold by Ferno also come with a limited lifetime warranty which makes purchasing from them more trustworthy.

Summary

The report forecast global Backboard Stretchers market to grow to reach xxx Million USD in 2019 with a CAGR of xx% during the period 2020-2025 due to coronavirus situation.

The report offers detailed coverage of Backboard Stretchers industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Backboard Stretchers by geography. The report splits the market size, by volume and value, on the basis of application type and geography.

First, this report covers the present status and the future prospects of the global Backboard Stretchers market for 2015-2024.

And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru].

At the same time, we classify Backboard Stretchers according to the type, application by geography. More importantly, the report includes major countries market based on the type and application.

Finally, the report provides detailed profile and data information analysis of leading Backboard Stretchers company.

Key Content of Chapters as follows (Including and can be customized) :

Part 1:

Market Overview, Development, and Segment by Type, Application & Region

Part 2:

Company information, Sales, Cost, Margin etc.

Part 3:

Global Market by company, Type, Application & Geography

Part 4:

Asia-Pacific Market by Type, Application & Geography

Part 5:

Europe Market by Type, Application & Geography

Part 6:

North America Market by Type, Application & Geography

Part 7:

South America Market by Type, Application & Geography

Part 8:

Middle East & Africa Market by Type, Application & Geography

Part 9:

Market Features

Part 10:

Investment Opportunity

Part 11:

Conclusion

Market Segment as follows:

By Region

Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia]

Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland]

North America[United States, Canada, Mexico]

Middle East & Africa[GCC, North Africa, South Africa]

South America[Brazil, Argentina, Columbia, Chile, Peru]

Key Companies

KEMP

Morrison

Junkin

Allied Healthcare Products

Attucho

Genstar Technologies Company

Spencer Italia

Market by Type

Aluminum Alloy

Synthetic Resin

Others

Market by Application

Game

First Aid

Emergency Rescue

Others