#precision cnc machining service factory

Text

Electronic Metal Fabrication

Electronic Industry Sheet Metal Parts

Sheet metal fabrication pays an important role in electronic industry. From big parts like metal cabinet, chassis, housing, brackets to small parts like terminal, USB connectors, contact chip etc, we can see sheet metal parts everywhere. The consumer electronics industry has witnessed tremendous growth in recent years and precision sheet metal fabrication has provided a guarantee for the updating and replacement of electronic industry products.

Consumers are now pursuing smaller, thinner, and lower energy consuming electronic devices, which can be achieved through precision sheet metal production. Our factory uses advanced materials, machines, and processes to manufacture micro electronic products and also big electronic parts shell, which not only ensure the firmness, accuracy, and precision of the products, but also enhance the aesthetics of electronic products through powder coating, anodizing, electroplating, and other surface treatment.

Electronic Metal Parts Manufacturing Capabilities

At Shanghai Yixing Technology, we have complete range of equipment like flat laser cutting machine, 3D laser cutting machine, hydraulic press, deep drawing machine, punching machine, shearing machine, CNC bending and welding machines to combine all the sheet metal fabrications like metal bending, metal stamping, progressive die stamping, welding and also surface treatment for one stop sourcing.

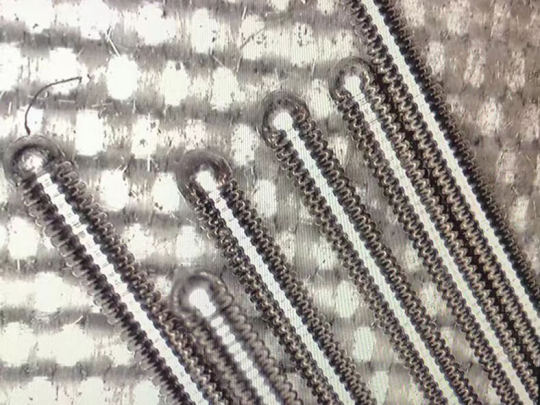

Some electronic components can be very small in size but complex in structure. Our facility has been very professional in progressive die stamping for these small components. Progressive die stamping is ideal for big volume production and at the same time ensures cost effective and great accuracy.

How Yixing Technology Produce Electronic Metal Parts

First of all, we select the correct material grade based on the drawing materials. We will strictly control the inspection of incoming materials and material storage. We will require the mill factory to provide raw material certificates and ask a third party to test the chemical composition of the materials. Our own inspectors will conduct visual inspection (mainly looking for surface defects, scratches and rust), thickness and size inspection of raw materials.

We will then evaluate the production process based on the design of the customer's drawings, which is generally divided into the following steps:

1. Cutting

We can use laser cutting, plasma cutting, flame cutting and water cutting, etc. for blanking. Cutting is usually the first step in sheet metal production.

2. Punching

According to the design requirements, punch holes in the cut metal plate to facilitate subsequent bending and forming.

3. Bending and forming

Bending and forming the punched metal plate, we usually use equipment such as bending machines and stamping machines.

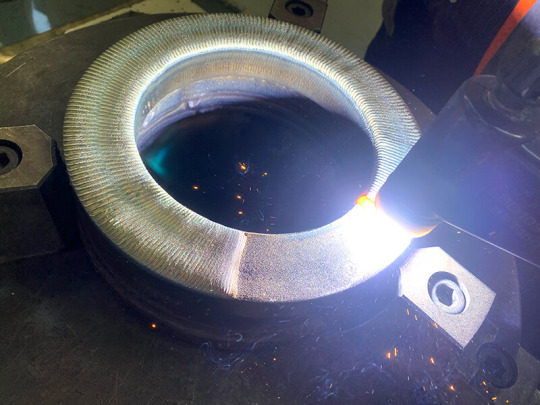

4. Welding

For sheet metal parts that need to be joined together, welding is most common assembly method. Commonly used welding methods include argon arc welding, laser welding, etc.

5. Surface treatmen

The surface of sheet metal parts needs to be treated to enhance its corrosion resistance, wear resistance and aesthetics, such as powder coating, chrome plating, anodization, electroplating and other treatments.

0 notes

Text

youtube

High quality machining grinding parts with rich factory experience

We make turning cnc machining parts, cnc oem machining parts, 3d printing precision cnc spare turning, cnc machining lathe parts, high precision cnc machining accessories, machining services custom cnc machining, machining center cnc 5 axis, custom cnc machining service, cnc machining motorcycle accessories etc .

-------------------------------------------------------------

https://cncmtf.com

0 notes

Text

What You Need To Know About The Different Types Of CNC Milling Machines?

In factories and workshops, getting things done quickly and accurately is really important. CNC milling machines are like the superheroes of technology because they're super precise and can adapt to different tasks. Let's explore the different kinds of machines that are helping industries come up with cool new stuff, making CNC milling easier to understand.

1. Vertical Mills:

- An easily accessible workpiece from above is made possible by the vertical axis used on vertical milling machines. Flat surfaces, slots, and pockets are frequently created using them. For tasks like mould production and prototyping, where accessibility and precision are important, vertical mills are perfect.

2. Horizontal Mills:

- Horizontal milling machines have a spindle aligned horizontally, in contrast to vertical mills. These configurations are ideal for heavy-duty machining activities and batch production because they allow the cutting of numerous sides of a workpiece without requiring repositioning. Manufacturing sectors including aerospace, automotive, and marine are strongholds for horizontal mills.

3. Multi-Axis Mills:

- Advanced features of multi-axis milling machines include simultaneous movement along several axes. These devices have unmatched accuracy and productivity when it comes to carrying out intricate machining tasks. Multi-axis mills are essential in sectors like jewellery manufacture, medical, and aerospace because they can create complex geometries and shapes by adding extra axes of movement, such as rotational or tilting axes.

4. CNC Router Mills:

- To cut and shape wood, plastic, and other non-metallic materials, specialised milling machines known as CNC router mills are used. Signage, cabinetry, and woodworking businesses will find them perfect because of their big work envelopes and high-speed spindles. For small-scale producers, artists, and hobbyists, CNC router mills are great.

5. Benchtop Mills:

- Benchtop milling machines are compact and portable, making them ideal for small workshops, educational institutions, and prototype laboratories. Despite their diminutive size, these machines provide precision and adaptability that rival bigger industrial mills. Benchtop mills are popular among amateurs, DIY enthusiasts, and students learning the principles of machining.

CNC milling machines are available in a wide range of designs that satisfy a variety of industrial requirements, from vertical mills to multi-axis machining centres. Understanding the strengths and capabilities of each kind enables producers to pick the best machine for their individual applications, enabling innovation and efficiency in the ever-changing world of contemporary production.

Why choose HLH Rapid?

HLH Rapid is a remarkable team that combines the best of the West and East. It was founded by Vader Yu from China and Director James Murphy from the United Kingdom, both of whom have extensive industry expertise.

We help companies globally by promptly producing high-quality prototypes and parts. Our skills as well as expertise promote innovation, making it easier for businesses to develop new products swiftly.

We are pleased to provide a wide range of services, including rapid injection moulding, CNC machining, and numerous 3D printing technologies (such as SLA, SLS, and SLM), all in one stop.

To know more about cnc milling services, talk to our experts today by sending an email at [email protected] or visit our website: www./hlhrapid.com

0 notes

Video

youtube

China factory CNC machining service OEM precision complex machined parts...

0 notes

Text

The Importance of a CNC Machine Shop

The Importance of a CNC Machine Shop

A CNC machine shop is a great choice for businesses and individuals who need to produce precision parts or prototypes. If you're in the process of designing a new product and are unsure of how to produce it, outsourcing the process can be a good option. CNC machines allow for much more accurate and efficient production than manual machining methods.

Precision machining

CNC machine shops, like Bates Machine and Mfg in Farmersville, TX, are a valuable resource for companies seeking precision machining services. Whether a company needs a single component or a complex component made of many parts, they can provide quality CNC machining services. With the help of these shops, businesses can reduce the cost of production and achieve higher productivity. Moreover, these machining companies also offer emergency machining services.

Precision CNC machining is a high-volume process that can produce a wide range of parts with a high degree of accuracy and tolerance. Its flexibility allows it to handle a variety of materials and plastics. This flexibility makes it a perfect choice for many industries.

Drill presses

Drill presses are a crucial part of any CNC machine shop. These high-tech machines feature a vertical spindle, a chuck, a clamp, and a feed lever that controls the depth and speed of the drill bit. They also allow users to add lubricant and coolant to ensure smooth drilling. Drill presses are also more accurate and provide greater power than handheld drills.

Drill presses are also useful for punching holes. When a mill is not equipped with a quill, a drill press is needed for this second operation. In addition to drilling, drill presses can also tap.

Milling machines

Milling machines in CNC machine shops are often used to manufacture small parts. They can be used to mill gears and gear teeth or to form flat surfaces. These machines use different kinds of cutting tools depending on the task that they are used for. Typically, milling machines produce parts that are within a tolerance of 5 mm. One millimeter is equal to 1/24500 inch. Modern CNC machine shops have quality control teams that make it a point to maintain this tolerance. This saves time and resources and benefits the customer.

Milling machines were first used as production machines. Whitney's machine, for example, was the first milling machine, but it did not allow the knee to move vertically. It assumed that the part design had been previously set on the milling machine, so the vertical position was not necessary for each successive part. Early milling machines were primarily designed as production machines and did not require precise vertical positioning.

Optical inspection

Optical inspection in CNC machine shops uses different metrology tools to determine the overall quality and accuracy of a component. Typically, a surface plate is used for vertical measurements. These plates must be calibrated and maintain their shape. Granite is a popular choice for these surfaces. Optical inspection tools can be installed directly on a CNC machine or in a test room.

Optical inspection tools are generally affordable and easy to use. They can also be used in the shop floor and should be integrated into the workflow of machine operators. The equipment should include go/no-go gages and appropriate work instructions. The data from these measurements should be recorded digitally.

Maintenance schedules

A maintenance schedule for CNC machine shops is a critical part of ensuring the continued uptime and output efficiencies of a machine shop. In addition, it can improve profits by preventing unexpected breakdowns. Unplanned downtime can cost a factory anywhere from five to twenty percent of its total productivity. Unfortunately, six out of seven shops continue to run their machines to failure despite the potential benefits.

Maintenance schedules for CNC machine shops should be aligned with the use of the equipment. If maintenance is planned at the right intervals, it will not disrupt production. By incorporating a worker check system, the schedule can be based on availability and usage patterns to reduce costs and unnecessary downtime.

Read the full article

0 notes

Text

youtube

Metal steel precision investment casting parts with factory price

We are specialize in cnc aluminum investment casting parts, presicion die casting parts, cnc machining parts, stainless steel cnc machining casting parts, cnc turning parts, plastic injection molding parts, 3D printing parts etc.

We also can provide the customized service as per customer's product requirement, oem aluminum cast cnc die casting part, vacuum investment sand die casting parts, vacuum investment sand die casting parts, die casting aluminum housing for led light, 316 investment die casting etc.

----------------------------------------

https://mxymachining.com

0 notes

Text

Gasket Sheet Material

The PTFE envelopes are open onto the outer or inner diameter, or encase the whole insert, depending on what is required. Lathed envelopes could be produced with an inside diameter 2 to four mm thicker to provide greater diffusion sealing. PTFE envelope gaskets are notably helpful with aggressive chemical substances within the chemical industry, because of their excessive resistance strength. PTFE can be physiologically innocent, and so can be used within the food and pharmaceutical sectors.

A special production course of ensures equal tensile power in all directions. This makes gaskets minimize from TEADIT ® 24 SH probably the greatest, most versatile and most dependable gasket materials on the market. Cold move and creep have been eliminated, gasket parameters have been drastically improved, whereas all the superb physical properties of PTFE have been absolutely retained. Advantages - material does not get wider underneath compression - easy to cut or punch -...

The consistency and precision of Gore manufacturing processes give GORE GR Sheet Gasketing a way more uniform distribution of mass than other ePTFE sheets. Chemically-inert GORE GR Sheet Gasketing seals durably, whether in strong alkali-, acid- or solvent-based course of methods. It resists all media (pH 0-14) except for molten/dissolved alkali metals and elemental fluorine.

MultiFlon® ECO is the cost-effective way to produce high-quality seals from one hundred pc pure, multidirectionally expanded PTFE. PTFE is a soft, low friction fluoropolymer with excellent chemical resistance and weathering resistance. Often used as a seal for steam and hot valves, taylor ring gaskets are minimize from quite so much of sheet metals and formed into corrugated concentric rings. Sichem® S11 is a premium re-structured PTFE gasket sheet with wonderful physical properties made of 100 percent PTFE and silica fillers.

Expanded Virgin PTFE are in style for use on delicate, worn or broken flanges as a result of increased compressibility over the usual virgin grade. Many different grades with extra fillers may be provided including; bronze, carbon, glass, 316l stainless-steel and metallic detectable. For extra information on every grade, please see the hyperlinks within the table below. PTFE envelope gaskets include a stable gasket insert and a PTFE envelope. Only high-quality, non-porous PTFE is used for the envelope, in order to guard the insert against chemical attack.

ptfe gaskets

This course of is more labor intensive and slower in manufacturing than regular PTFE sheets, but the uniform tensile power reduces chilly move or creep relaxation. Sichem® S33 is a real re-structured PTFE gasket sheet made from virgin PTFE and Barium Sulfate fillers, which limits each creep and cold flow in service and at temperature. The distinction is within the methodology of manufacture, the fillers used, and the brand. We do supply Gylon® from Garlock, but we choose to offer another option. Gasket Resources Inc. supplies well timed and correct factory fabricated reduce gaskets, welded gaskets, and sheet merchandise available for a selection of industries.

The largest down aspect to utilizing clicker presses is tooling should be made to produce a gasket, the second is the tolerance. Just as CNC lathes revolutionized the machining business, laser cutters, flash cutters and water jet are all pc controled methods of chopping a gasket with out the need for tooling or dies. A laser cuts PTFE and EPTFE like butter with an in depth tolerance clean minimize.

INERTEX® INERMET Insertable Gaskets are made with a corrugated metallic insert. The typical sheet thickness is 1/16″ (1mm also available,) and the typical metallic used is 24 gauge 316L chrome steel. The ASTM F36 test technique covers determination of the short-time compressibility and restoration at room temperature of sheet-gasket supplies. It isn't intended as a take a look at for compressibility beneath prolonged stress software, usually referred to as "creep." In a chemical aggressive environment, the place air pollution of the medium just isn't allowed, it is sophisticated to apply a regular gasket.

1 note

·

View note

Text

CNC assembly technology: revolutionizing the manufacturing field and opening up broad application prospects

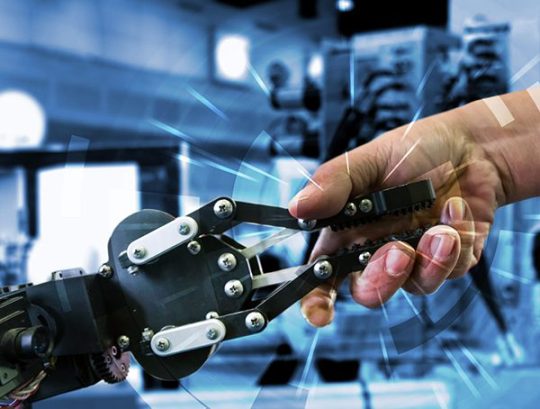

In today's era of rapid technological advancement, precise and efficient production methods have become the core competitiveness of the manufacturing industry. Among them, CNC machine tool (CNC) assembly technology, with its advantages of high precision and high degree of automation, is gradually reshaping the manufacturing landscape and showing great application prospects.

I. The cornerstone of intelligent manufacturing

CNC assembly technology is a deep integration of computer numerical control technology and precision mechanical assembly technology. It can assemble various complex parts accurately and efficiently through preset programs. Its core value is to directly transform design data into actual products, greatly reducing human intervention and significantly improving production efficiency and product quality. As an important part of intelligent manufacturing, CNC assembly technology plays an irreplaceable role in realizing the digital, networked, and intelligent transformation of the manufacturing industry, laying a solid foundation for building smart factories and promoting the Industry 4.0 process.

II. Wide range of industry applications

1. Automobile manufacturing: There are many types of auto parts, complex structures, and extremely high precision requirements. CNC assembly technology can accurately control every assembly link to ensure close cooperation between parts, effectively improving the overall performance and service life of the car. At the same time, its efficient automation features help shorten the production cycle and respond to the rapidly changing needs of the market.

2. Aerospace: The manufacturing of aerospace equipment has almost stringent requirements for accuracy and stability. CNC assembly technology, with its ultra-high positioning accuracy and repetitive positioning accuracy, can complete the assembly of complex components at the micron level, greatly improving the reliability and safety of products such as spacecraft and aircraft.

3. Electronic and electrical appliances: As electronic products develop towards thinner, lighter and miniaturized products, the demand for refined assembly of internal components has become increasingly prominent. CNC assembly technology can accurately control tiny components and achieve refined and batch assembly operations, effectively promoting product innovation in consumer electronics, communication equipment, medical equipment and other fields.

Other fields: From precision instruments and mold manufacturing to energy equipment and heavy machinery, the application of CNC assembly technology covers almost all industries that require precision assembly operations, providing a strong force for improving product quality, reducing costs, and enhancing market competitiveness. technical support.

In today's era of rapid technological advancement, precise and efficient production methods have become the core competitiveness of the manufacturing industry. Among them, CNC machine tool (CNC) assembly technology, with its advantages of high precision and high degree of automation, is gradually reshaping the manufacturing landscape and showing great application prospects.

III. Future development trends

With the development of cutting-edge technologies such as the Internet of Things, big data, and artificial intelligence, the application prospects of CNC assembly technology will be even broader:

1. Intelligent optimization: By integrating sensors and data analysis systems, CNC assembly equipment can monitor working status in real time, self-diagnose faults, predict maintenance needs, and further improve equipment utilization and production efficiency.

2. Cloud manufacturing: With the help of cloud computing platforms, CNC assembly technology is expected to realize functions such as remote monitoring, remote programming, and resource sharing, break geographical restrictions, and promote innovation in manufacturing service models.

3. Additive manufacturing integration: The deep integration of CNC assembly technology and 3D printing and other additive manufacturing technologies will give birth to a new hybrid manufacturing model, which can not only achieve precision assembly of complex structures, but also carry out personalized and customized production. Meet the diversified needs of the market.

To sum up, CNC assembly technology, with its significant technical advantages and wide range of application fields, has become a key force in promoting the upgrading and transformation of the manufacturing industry. Facing the future, with the continuous advancement and innovative application of science and technology, CNC assembly technology will surely open up broader application prospects and inject strong impetus into the prosperity and development of the global manufacturing industry.

0 notes

Text

Medical Sheet Metal Fabrication

In the modern medical industry, sheet metal products are an indispensable part. Medical device sheet metal product processing is an important manufacturing process that can provide high-quality medical equipment and appliances for hospitals and medical institutions, and provide better healthcare services for patients.

The application of medical device sheet metal processing is very wide, mainly involving medical equipment, medical devices, medical appliances and other fields. Sheet metal processing technology can manufacture medical devices of various shapes and sizes, such as operating tables, surgical lamps, surgical instrument racks, etc. These devices can help doctors perform surgeries and treatments more effectively. Medical sheet metal products can also be used to manufacture medical equipment, such as stretchers, wheelchairs, beds, etc. These tools can provide a more comfortable nursing environment and help patients recover.

Medical Metal Parts Manufacturing Capabilities

The advantage of medical sheet metal product processing is its precision and reliability. As an experienced sheet metal factory in China, we follow the strict quality control system, use well trained engineers and workers, use state of the art equipment to ensure our sheet metal parts have the best precision and accuracy.

We have decades of experience in manufacturing sheet metal parts for medical industry. Because of its complexity in design and aesthetics in appearance, medical device has high requirements on factories, and almost all processes will be involved, such as laser cutting, CNC bending, precision stamping, deep drawing, welding, surface treatment, etc. We already have a deep understanding of medical devices and can meet our customers' quality requirements.

How Yixing Technology Produce Medical Metal Parts

How to make medical device can be mainly divided into below four parts:

Part 1: Cutting Materials

Laser cutting is one of the most common cutting methods in sheet metal processing. Firstly, according to the size specifications of the finished sheet metal parts, stainless steel and other sheets are laser cut into the required dimensions for backup. This process is collectively referred to as cutting.

Part 2: Bending

Bending is the process of CNC bending the finished material according to the size specifications of the sheet metal workpiece. It will be prepared for the next step of sheet metal welding. Take patient transfer device as example, the main parts are square tubes. We use press brake or pipe bending machine to do the precise bending.

Part 3: Welding

Welding can be divided into two methods: manual welding or robot automatic welding. It is a process of welding finished materials based on the cut, bent or formed sheet metal parts. It is combining two or more types of the same or different types of sheets. Shanghai Yixing Technology can do TIG and MIG welding. Material selection and welding quality is the most important because it will influence the load bearing capacity and whether the machine can do straight line rolling. We pay attention on every detail.

Part 4: Surface Treatment

There are many surface treatment we can do such as sandblasting, anodization, polishing, powder coating, electrophoretic paint, hot-dip galvanizing, electroplating or others. For the patient transfer device, the main surface treatment is powder coating. The minimum coating thickness is more than 60um and we do 100 grid test and salt spray test to check the adhesion and corrosion resistance.

Patient transfer device is a complicated design and more process will be involved which is not listed above like riveting, threading, printing, heat treatment, assembly with motors and other plastic parts and hammock.

0 notes

Text

youtube

Laser cutting/milling/turning wooden cnc machining wood parts

We are cnc machining factory, and we make wood cnc service machining, wood cnc machining service, custom design wooden machinery machining wood cnc, 5 axis wood machining cnc, cnc machining center wood parts etc.

We also can provide the customization services as per customer's drawing or sample, turning milling cnc machining aluminum, cnc machining service custom precision, precision stainless steel cnc machining.

-------------------------------------

https://cncmtf.com

0 notes

Text

Bending processing machine wholesale (what brand of Jiangsu CNC bus is good)

The scope of work (bending, punching, cutting) is used for multiple uses. This is a professional design of a combination of multiple functions. Perfect considerations avoid manpower waste, that is, the provincial working hours, which meets the process of consistent operations, so that the staff can handle it, produce high -efficiency and high -quality perfect works.

Narut crusher: REC-MM36, REC-MM26, CWC-243D150S-DSC, IS-MM20L, IS-MM20, IS-CP13, SJM-24, HPN200RA-DSC, HPN200A-DSC Bare Wholesale

What direction will the bus manufacturer develop in the future? What technology and materials can be added on the basis of itself. Now let's take a closer look at the bus manufacturer!

So the linear motor attracted the attention of people. It directly produced linear movements, simple structure, small motion inertia, high system rigidity, good response characteristics, and can achieve precise positioning in high -speed conditions. Several times of the bar, the working itinerary can be infinitely long, less maintenance and long life. These advantages make it an ideal component for modern machine tools.

When the busbar machine wholesale checks, first check the electrical components from the question of the mechanical parts. Only after the mechanical part is determined that the mechanical part is not faulty, then the electrical view is performed. First look at the special parts from the maintenance of more components. The problems caused by the quality of the accessories or the installation questions usually account for 50%of the more common faults.

Jinan CNC Equipment Co., Ltd. is the main bus processing machine, CNC bus machining machine, transfer parent line processing machine, homeline, bus bending machine, multi -functional bus processing machine, multi -site bus processor, hydraulic bending machine, copper volume Machining machines, copper row bending machines, parent row processing machines, etc. The products are enterprises that integrate the development, production, and selling series of parent line machine equipment. The majority of customers come to the factory to call (1596311292 for consultation.

Now there are a lot of parent-line machine plants, and the prices are also different. The difference is about 200-2000 yuan, mainly because the craftsmanship is different, and the parts configuration in it is also different. So the price is different. Bending processing machine wholesale

The bending unit adopts a closed overall frame structure to make it more uniform when processing flat bending and pressing flowers, greatly improving the duplicate positioning accuracy during mass production, and extending the service life.

0 notes

Text

The Impact of Digitalization on Valve Manufacturing

Valve manufacturing, like many industries, is undergoing a transformative shift with the advent of digitalization. The integration of digital technologies into manufacturing processes has revolutionized the way valves are designed, produced, and monitored. Valve Directory List, a trusted resource for professionals in the valve industry, offers insights into the profound impact that digitalization is having on valve manufacturing.

Design and Engineering Advancements:

Digitalization has enabled valve manufacturers to streamline the design and engineering process significantly. Advanced computer-aided design (CAD) software allows for precise modeling and simulation of valve components, leading to improved efficiency and reduced time-to-market. Valve Directory List provides access to information on the latest design tools and technologies, empowering manufacturers to create innovative and customized valve solutions.

Enhanced Manufacturing Processes:

The adoption of digital technologies such as computer numerical control (CNC) machining, 3D printing, and robotics has transformed traditional manufacturing processes in the valve industry. These technologies enable manufacturers to achieve higher levels of precision, consistency, and efficiency in valve production. Valve Directory List offers a glimpse into the latest advancements in manufacturing techniques, helping manufacturers stay competitive in the digital age.

IoT and Smart Valve Technologies:

Perhaps one of the most significant impacts of digitalization on valve manufacturing is the rise of Internet of Things (IoT) and smart valve technologies. Smart valves are equipped with sensors and actuators that collect real-time data on factors such as pressure, temperature, and flow rates. Valve Directory List showcases the latest developments in smart valve technologies, highlighting their role in predictive maintenance, remote monitoring, and improved operational efficiency.

Data-Driven Decision-Making:

With the abundance of data generated by smart valves and IoT devices, manufacturers have access to valuable insights into valve performance and system behavior. This data-driven approach allows for proactive maintenance scheduling, predictive analytics, and optimized process control. Valve Directory List serves as a platform for manufacturers to explore the potential of data analytics in improving valve reliability and performance.

Remote Monitoring and Maintenance:

Digitalization has enabled remote monitoring and diagnostics of valves, reducing the need for on-site inspections and manual interventions. Valve Directory List provides information on remote monitoring solutions and services offered by industry-leading providers. Manufacturers can leverage these technologies to enhance asset management, minimize downtime, and improve overall system reliability.

Integration with Industry 4.0:

Valve manufacturing is aligning with the principles of Industry 4.0, where interconnected systems, automation, and data exchange drive smart factories. Valve Directory List showcases how manufacturers are integrating digital technologies into their production lines to create intelligent, adaptive manufacturing environments.

In conclusion, the impact of digitalization on valve manufacturing is profound and multifaceted. From design and engineering advancements to the rise of smart valve technologies and data-driven decision-making, digitalization is reshaping the industry landscape. Valve Directory List serves as a valuable resource for professionals seeking to understand and embrace these digital innovations, ensuring that the valve manufacturing sector remains at the forefront of technological advancement.

1 note

·

View note

Text

Deewi Automation-Pioneering the Future of Manufacturing with Cutting-Edge Solutions

Since its establishment in 2009, Deewi Automation has quickly become a beacon of innovation in the field of integrated automation equipment. As a pioneer in our field, we are committed to pushing global manufacturing to new heights of efficiency and intelligence. Our product lines, including cutting-edge weld overlay machines, plasma cladding, laser cladding machines, automated weld overlays, micro-plasma welding, thermal spray systems, and custom CNC machines, are engineered to meet our customers' evolving needs. Whether you are looking for a stand-alone unit or a complete integrated system, Deewi has everything you need.

At the heart of Deewi is a bold and transformative vision - to lead breakthroughs in automation technology and elevate manufacturing to unprecedented levels of efficiency and intelligence. Our commitment to continued technological innovation is more than a business strategy; it is our commitment to the future. By cultivating a culture of creativity and precision, we strive to be at the forefront of the automation revolution, delivering solutions that are not only innovative but also reliable and cost-effective.

In a highly competitive market, Deewi's distinction is not only our advanced technology products, but also our unwavering commitment to innovation, precision, reliability, and our core values of putting customers first. These guiding principles shape every aspect of our operations, ensuring that we always provide the highest quality products and services to our valued customers. It is this dedication to excellence that has made Deewi Automation a trusted name in the automation industry.

The cornerstone of Deewi's success is our outstanding team of engineers. With 7 industry-leading professionals, including senior experts with more than 20 years of experience, our team of engineers represents the pinnacle of expertise covering the fields of welding and CNC machining. Their deep knowledge and innovative approach enable us to deliver complex technical solutions to the specific challenges faced by our customers in multiple industries including valves, petroleum, medical, aerospace, and electronics.

We know that excellent products come from strict quality control. Therefore, Deewi has implemented a strict three-step quality inspection (QC) process, from the incoming inspection of raw materials, monitoring of each link in the production process, to the factory testing of the final product, every step is strictly controlled. This meticulous attention ensures that our equipment not only meets industry standards but also delivers unrivaled performance and durability.

Furthermore, we believe that excellent after-sales service is an integral part of our products. Therefore, we are committed to providing lifetime support for our products, and our customer service team is always ready to respond to provide fast, professional technical support and maintenance services. Whether you have installation issues, operational questions or need technical advice, Deewi will work with you to ensure your equipment runs smoothly and extends its service life.

Choosing Deewi Automation means choosing a partner with a top-notch engineering team, strict quality control system, and lifelong after-sales service commitment. We are here not only to manufacture industry-leading automation equipment but also to support and promote your business success.

1 note

·

View note

Text

Boosting Industrial Efficiency: The Importance of Metal Fabrication in Melbourne

Metal fabrication in Melbourne is crucial for productivity and profitability whether one is in charge of a manufacturing plant, a construction site, or a fleet of heavy machinery. This is something that machining companies are aware of and can handle. If machines' parts are not maintained, they have a reputation for wearing out rapidly, which can lead to costly running expenses from frequent breakdowns. As soon as there are minor flaws, it's crucial to schedule skilled professionals for repairs in order to avoid any failures and to protect the individuals using the device.

An Overview of a Few Important Machining Services

CNC Machining Services: It is a precision machining in Melbourne service and CNC machines are now required for a variety of activities, including laser cutting, turret punching, and tube bending. This type of work should only be assigned to knowledgeable CNC specialists. Leading specialists offer cutting services, CNC turret punching, CNC laser cutting, and other services.

Workshop Services and Capabilities: Top machining service providers provide a wide range of workshop services and capabilities, such as CNC lathes, presses, line boring, heavy equipment, and CNC milling.

Welding Services: To weld different metal pieces, welding is necessary in all industrial buildings, including mills, factories, refineries, and other structures. The top businesses provide a variety of welding services, including TIG, ARC, and aluminium welding.

Plant Design Engineering Services: It is crucial to give careful thought to the industrial facility's design and worker safety. Working with expert businesses can help complete plumbing, structural design, electrical work, procurement, and other associated essential tasks as swiftly and simply as possible.

Install & Commission: Leading engineering service suppliers are also competent in the installation and commissioning of systems in many industries. Among the industries are sand mining, quarrying systems, and paper machine modifications.

Experts are necessary when providing the best solution for industrial issues, such as repairing crusher swing jaws or grinding large-diameter bores. Get the best pricing on solutions to a variety of industrial problems by speaking with reliable machining service suppliers.

Source

0 notes

Text

youtube

Factory custom made cnc laser cutting machining service

We are specialize in cnc laser cutting precision metal machining parts, cnc machining acrylic laser cutting service, stainless steel cnc machining casting parts, cnc turning parts, die casting parts, plastic injection molding parts, 3D printing parts etc.

We also can provide the customized service as per customer's product requirement, demand aluminium cnc machining customization parts, micro machining turned milled brass cnc, machining service plastic cnc peek milling parts etc.

Looking forward to your feedback~

https://mxymachining.com

0 notes

Text

Motion Control Companies - ABB (Switzerland) and FANUC Corporation (Japan) are the Key Players

The motion control market is estimated to be worth USD 16.5 billion in 2024 and is projected to reach USD 21.6 billion by 2029 at a CAGR of 5.5% during the forecast period. The global Motion Control Market is primarily propelled by the increasing demand for automation across industries, aiming for enhanced efficiency and precision in manufacturing processes. Technological advancements in motion control systems, offering improved performance and reliability, contribute significantly to market growth.

Major Motion Control companies include:

ABB (Switzerland),

FANUC Corporation (Japan),

Siemens (Germany),

Yaskawa Electric Corporation (Japan), and

Mitsubishi Electric Corporation (Japan).

Major players in the Motion Control market are strategically implementing initiatives to establish a robust global presence. These efforts often involve a combination of mergers and acquisitions, strategic partnerships, and geographic expansions. Key players are actively seeking to broaden their market reach by acquiring companies with complementary technologies or a strong regional presence. Additionally, partnerships with local distributors and system integrators enable these players to enhance their market penetration and provide customized solutions tailored to specific regional needs.

ABB is a Swiss multinational corporation, a technology leader in terms of electrification, industrial automation, motion, and robotics and discrete automation. ABB offers a range of autonomous mobile robot products that are designed to operate in industrial and logistics settings, improving efficiency and safety. ABB’s products and services are used by a wide range of industries, including utilities, transportation, manufacturing, and infrastructure. The company operates through four business segments, namely, Electrification, Motion, Process Automation, and Robotics & Discrete Automation.

FANUC Corporation is a leading global manufacturer and supplier of factory automation solutions and industrial robots. The company has become a pioneer in the field of computer numerical control (CNC) systems, producing cutting-edge technologies that empower industries with precision, efficiency, and productivity. FANUC CORPORATION's diverse range of products includes industrial robots, CNC systems, machine tools, and factory automation solutions, catering to various sectors such as automotive, electronics, aerospace, and more. FANUC CORPORATION operates its business through four divisions, namely, Factory Automation (FA), Robot, Robomachine, and Service. FANUC manufactures products such as servo motors, servo amplifiers, lasers, robot machines, field systems, and robots. The company operates its business through four segments—Field Automation (FA), Robot, Robomachine, and Service.

Mitsubishi Electric Corporation manufactures a range of control and power electronics products based on automation technologies. The company is well-known for its air conditioning products, home appliances, automotive equipment, rail transportation systems, satellites, digital signage, semiconductors, and electronics. It provides industrial automation solutions in Asia, with its origin in Japan. The company operates through six business segments, namely, Energy and Electric Systems, Industrial Automation Systems, Home Appliances, Information and Communication Systems, Electronic Devices, and Others (Procurement, Logistic, Real Estate, Advertising, Finance, and Other Services).

Siemens is a global powerhouse in the fields of electrification, automation, and digitalization. The company has evolved into a diversified conglomerate with a significant impact on various industries worldwide. Siemens operates across numerous sectors, including energy, healthcare, industry, and infrastructure, delivering cutting-edge solutions that address complex challenges and drive sustainable progress. It operates through six business segments, namely, Digital Industries, Smart Infrastructure, Mobility, Siemens Healthineers, Siemens Financial Services, and Portfolio Companies.

Yaskawa Electric Corporation is one of the leading manufacturers in the fields of drive technology, industrial automation, and robotics in Japan. The company is operating its business through three segments, namely Motion Control, Robotics, and System Engineering. Yaskawa has been ensuring to provide cutting-edge technologies in its products and services. Yaskawa Electric Corporation is a company involved in the manufacturing, sales, installation, and maintenance of control systems and industrial products.

0 notes