#polyurethane resin flooring

Text

#prime resin flooring#resin flooring#resin flooring installers#epoxy resin flooring#polyurethane resin flooring#resin flooring company

0 notes

Text

Pro Resin Flooring

The decision to purchase pro resin flooring can be a difficult one, but the rewards are well worth it. This type of flooring is versatile and resistant to damage, cleans easily with soap and water or a simple vinegar solution, gives your space a refreshed and clean appearance. If you are going to invest in pro resin flooring, you are going to want to hire a professional installation company like us. Here are 5 things that you will get from us as we install your new flooring:

1) Estimate comparisons

Our Pro Resin Flooring installation company offers free, no obligation estimates for all of our products. This means you can review every available option, including price, color and style. You're also welcome to purchase your product from us online and pick it up at a local retailer.

2) Professional installation

One of the most important things in choosing a flooring company is the installation process. You want a team that provides quality service, and with our Pro Resin Flooring installation company you can be sure of that. All of our employees are courteous and professional, not to mention they have extensive training on all types of flooring materials.

3. Installation is fast, reliable and professional

You can trust in our installation team that they will make sure your flooring installation is done right. They will be able to work with your schedule while they install while making sure that all areas are covered. We are there to help you with the whole process from start to finish so you can relax and enjoy the day of your new flooring installation!

4. Your satisfaction is our number one priority

We are committed to providing you with the highest quality pro resin flooring products and professional installation services. You will have a team of professionals dedicated to your concerns, ensuring that your investment goes smoothly. You can trust that You can trust in us to be there for you through the whole process from picking out the perfect style and color to helping you long after you install your new floors.

#resin flooring#epoxy resin flooring#polyurethane resin flooring#resin flooring company#resin flooring installers

1 note

·

View note

Text

25/3.2024 (3) - love this floor

0 notes

Text

Unleash the Potential of Your Floors with IC PRECIFLOOR!

Engineered for durability and performance, IC PRECIFLOOR offers unmatched strength and resilience for all your flooring needs. With its high-strength formulation and easy application, achieve flawless results every time. Elevate your spaces with IC PRECIFLOOR and experience the difference! To know more about floor repairs mortars in India and high strength flooring mortars visit: https://capaindia.in/product/ic-precifloor/

#top building materials companies in india#tile adhesives for vitrified tiles#top tile adhesive brands in india#best tile adhesive in india#block jointing mortar manufacturers in india#high strength flooring mortars#tile adhesive companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#floor repairs mortars in india#best waterproofing mineral mortars in india#tile adhesive brands in india#tile and stone adhesive#cement based tile adhesive#affordable waterproofing solutions#aliphatic polyurethane waterproofing coating#epoxy resin adhesives manufacturers#epoxy grouts in india#epoxy adhesive manufacturers

0 notes

Text

Lazercote Ltd

When selecting a flooring type for newly built or renovated flooring, you would surely look for a flooring solution that is durable, long-lasting, and easy to clean. You want something that will withstand heavy foot traffic and resist chemicals and moisture. You also want a floor that is easy to maintain and won't require frequent repairs. With that, you can always consider the resin flooring solutions offered by Lazercote—a leading provider of resin flooring solutions for commercial properties in the West Midlands and throughout the UK. Having been in the business for over 35 years, we are confident that we provide high-quality, cost-effective, and durable industrial resin flooring solutions for all our clients. We also work closely with leading manufacturers to ensure that we only use up-to-date technologies, so our clients receive the best possible service. If you are interested in learning more about our services or would like a free quote, don't hesitate to get in touch with us today at 01299 556943 or [email protected]. We will be more than happy to answer any questions and help you choose the right resin flooring for your commercial property.

#resin flooring#industrial resin flooring#resin floor coatings uk#epoxy resin flooring#polyurethane coatings

1 note

·

View note

Text

Wood Coatings Market: Trends & Opportunities 2024-2032

According to Triton Market Research, the Global Wood Coatings Market report is sectioned by Resin Type (Polyurethane, Nitrocellulose, Acrylic, Other Resin Types), Technology (Water-Borne, Powder Coatings, UV-cured, Solvent-Borne), Application (Furniture and Fixture, Cabinet, Doors and Window, Flooring, Deck), and Regional Outlook (Middle East and Africa, Europe, Asia-Pacific, North America, Latin America).

The report highlights the Market Summary, Industry Outlook, Porter’s Five Forces Analysis, Market Maturity Analysis, Supply Chain Analysis, Regulatory Framework, Key Buying Impact Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology and scope, Global Market Size, Forecasts & Analysis (2024-2032).

Based on Triton’s research report, the global market for wood coatings is set to advance in value at a CAGR of 4.02% during the forecast period 2024-2032.

Wood coating serves a dual purpose: safeguarding and enhancing wood or wood-based structures. By shielding wooden surfaces, it bolsters their durability and utility. Simultaneously, it elevates their aesthetic appeal, contributing to effective product promotion.

Factors such as personalized solutions for flooring and furniture, the emergence of smart coating technology, and improved coating performance via nanotechnology, creates lucrative opportunities for the wood coatings market globally. Smart coatings offer an array of functionalities, such as self-healing, anti-fouling, and antimicrobial properties, enhancing the durability and performance of wood surfaces. This extends the lifespan of wood products and reduces maintenance costs. Moreover, smart coatings contribute to sustainability efforts by minimizing the need for frequent reapplications and replacements, thus reducing waste. With increasing environmental concerns and a growing emphasis on eco-friendly solutions, the adoption of smart coatings is set to escalate, driving market growth and innovation.

However, fluctuating raw material costs and competition from composite materials limit the overall development of the wood coatings market worldwide.

The Asia-Pacific region is set for the fastest growth in the coming years. One key driver is the region’s growing construction and furniture industries, particularly in countries like China, India, and Vietnam, where urbanization and rising disposable incomes have fueled demand for high-quality wood products. Additionally, there is a growing awareness and emphasis on environmental sustainability, leading to an increasing preference for eco-friendly coatings with low volatile organic compound (VOC) content. Moreover, technological advancements in coatings formulations, such as the development of water-based and UV-curable coatings, are gaining traction due to their superior performance and reduced environmental impact.

The renowned companies in the wood coatings market are Nippon Paint Holdings Co Ltd, Diamond Paints, PPG Industries Inc, Asian Paints, RPM International Inc, The Sherwin-Williams Company, BASF SE, Akzo Nobel NV, Axalta Coating Systems LLC, and Kansai Helios.

With evolving consumer preferences and stringent environmental regulations, barriers to entry remain significant, deterring potential newcomers. Established players continually innovate to maintain market share, investing in research and development to offer eco-friendly and high-performance coatings. Intense rivalry among existing competitors fuels pricing pressures and product differentiation strategies, compelling companies to enhance quality and expand distribution networks. Amidst these challenges, strategic alliances and mergers are common, reshaping the competitive landscape and fostering consolidation.

0 notes

Text

How Synthetic Resin Adhesives Are Revolutionizing the Construction Industry

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

0 notes

Text

Resin Flooring in Dubai provides seamless and versatile flooring options suitable for various environments, from industrial to residential settings. Our epoxy and polyurethane resin floors offer durability, chemical resistance, and customizable designs, meeting the diverse needs of our clients.

0 notes

Text

#prime resin flooring#resin flooring#resin flooring installers#epoxy resin flooring#polyurethane resin flooring#resin flooring company

0 notes

Text

Enhance Durability and Aesthetics: Exploring Epoxy Grouting in Melbourne Services

Epoxy grouting in Melbourne involves the use of epoxy resin-based grout, which is a two-part system consisting of a resin and a hardener and hence is much popular. Because of its versatility, concrete has been the cornerstone of the construction industry. Businesses that specialise in concrete services may provide a variety of services, from commercial concrete grinding to concrete repair. The top companies in this industry can serve a broad spectrum of customers, from commercial to residential, and have the greatest instruments available to do the task securely and successfully. Concrete occasionally cracks with time, necessitating concrete repair.

Polyurethane crack repair technique is commonly used in construction and civil engineering projects to restore the integrity and durability of concrete surfaces. In addition to providing concrete services, the best companies in this industry also provide other services including trip hazard elimination and protective coatings, giving consumers a one-stop shop for all their needs. A firm that has undergone an ISO 9001 audit is the one to choose if you need concrete services.

A Look at the Services Offered by Companies That Focus on Concrete Services

Repairing Floor Joints: Joints can get cracked and damaged as a result of wear and strain over time. This is particularly true in industrial buildings like warehouses where a lot of things are moved about using forklifts, etc. If joint damage is ignored for an extended period of time, it may become hard to reseal the joint, necessitating the expenditure of more funds.

Concrete Floor Resurfacing: This easy yet efficient method rejuvenates an old or damaged concrete floor by adding a thin layer of new material over the current surface to increase its longevity and give it a new look. This method may be used to generate a broad range of finishes and even level damaged surfaces, which reduces the possibility of people tripping and falling.

Concrete Grinding: To guarantee that all surface imperfections are eliminated, a variety of instruments, primarily abrasive ones, are used in this procedure. It's similar to giving concrete floors a makeover, and the paint or epoxy floor covering may even be removed.

Removal of Trip Hazards: Ramps and stairs provide a significant risk of tripping in commercial and educational settings. In order to prevent falls, this service ensures that ramps and stairs are in compliance, even surfaces are created, and luminance strips are installed.

Businesses and industries need to be cautious when it comes to their concrete surfaces and seek expert guidance when needed. Obtain an estimate as quickly as possible from the top companies providing concrete and related services if you need them.

Source

0 notes

Text

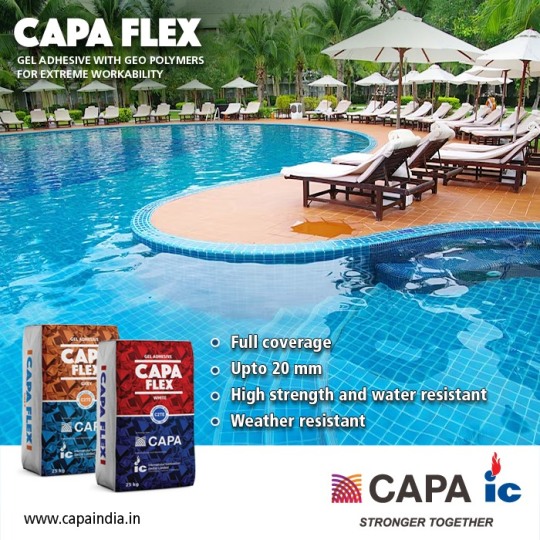

Revolutionize your tiling endeavors with CAPA FLEX, the pinnacle of gel adhesive excellence!

Proudly crafted by leading tile adhesive manufacturers in India, CAPA FLEX is designed to exceed your expectations. With its C2TE classification, this gel adhesive offers unparalleled workability and security, thanks to its unique blend of modified resins and rheological agents. From vitrified to natural stone tiles, CAPA FLEX ensures exceptional adhesion to both surfaces, making it the perfect choice for any tiling endeavor. Elevate your tiling game with CAPA FLEX today!

To know more about tile gel adhesive manufacturers and natural tile stone adhesive in India visit: https://capaindia.in/product/capa-flex/

#top building materials companies in india#tile adhesive companies in india#top tile adhesive brands in india#tile adhesive manufacturers#best tile adhesive in india#high strength flooring mortars#tile adhesives for vitrified tiles#tile adhesives for fixing natural stones#block jointing mortar manufacturers in india#floor repairs mortars in india#epoxy resin adhesives manufacturers#epoxy adhesives manufacturers#tile powder premium grouting solutions#industrial grouts manufacturers in india#building materials manufacturers in india#ready mix plaster manufacturers in india#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating

0 notes

Text

Ultra Rapid 2 Component Polyurethane Resin

FOAMJET T

High viscosity ultra rapid setting two-component polyurethane resin to be injected for consolidating and waterproofing structural elements subject to high pressure water ingress.

Use Foamjet T to waterproof cracked concrete and masonry structures such as tunnels, shafts, dams, canals, bulkheads, flooring or beds subject to strong water ingress. Foamjet T is a two-component halogen-free resin that must be used with special machinery that is able to measure and mix Part A with Part B in a 1:1 ratio by volume.

Thanks to its high fluidity, Foamjet T can penetrate through fissures of even several hundred microns and seal the cracks even if they are subject to water infiltrations.

Once set, Foamjet T becomes perfectly watertight and ensures an effective consolidation of the treated structure.

0 notes

Text

Resin Flooring

Resin flooring epitomizes contemporary style and practicality, offering a seamless, glossy surface that enhances any space. Comprising a mixture of epoxy or polyurethane resins, it provides a durable, low-maintenance solution suitable for diverse environments. Resin flooring is available in a spectrum of colors and finishes, allowing for creative customization. Its resistance to stains, chemicals, and wear makes it an excellent choice for both residential and commercial spaces, marrying aesthetic appeal with resilience for a sleek and enduring flooring solution.

For More Information Visit Our Website https://www.terrazzoflooringdubai.com/resin-flooring/

Or Contact Us On +97156 600 9626

Email: [email protected]

0 notes

Text

Enhancing Protection and Longevity with Durable Polyurethane Coatings

In the realm of protective coatings, durable polyurethane coatings stand out as versatile solutions for safeguarding surfaces against wear, weathering, and environmental damage. Offering a range of benefits, from exceptional durability and flexibility to resistance against chemicals and UV radiation, durable polyurethane coatings are widely used in various industries and applications. In this article, we explore the advantages, applications, and key features of durable polyurethane coatings, highlighting their role in enhancing protection and longevity for a wide range of substrates.

Understanding Durable Polyurethane Coatings

Durable polyurethane coatings are formulated using polyurethane resins, a versatile class of polymers known for their strength, flexibility, and chemical resistance. These coatings are designed to provide a protective barrier over surfaces, offering superior durability and performance in diverse environmental conditions. Durable polyurethane coatings adhere seamlessly to substrates, creating a resilient shield that withstands abrasion, impact, moisture, and UV exposure. If you want to know more about Advanced Polyurethane Roofing Technology please visit our website.

Key Features of Durable Polyurethane Coatings:

Exceptional Durability: Durable polyurethane coatings are renowned for their exceptional durability and long-lasting performance. The robust nature of polyurethane resins enables these coatings to withstand heavy traffic, mechanical stress, and environmental factors without deteriorating or losing their protective properties.

Flexibility and Elasticity: One of the key features of durable polyurethane coatings is their flexibility and elasticity. These coatings can stretch and bend without cracking or peeling, adapting to the natural movements and fluctuations of the substrate. This flexibility allows for greater resistance against thermal expansion, substrate movement, and impact damage.

Chemical Resistance: Durable polyurethane coatings exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. This chemical resistance makes them suitable for applications in industrial settings, where exposure to corrosive substances is common. Durable polyurethane coatings help protect surfaces from chemical attack and degradation, preserving their integrity and appearance.

UV Stability: UV stability is another important feature of durable polyurethane coatings. These coatings contain UV inhibitors and stabilizers that help protect surfaces from the damaging effects of sunlight and UV radiation. By preventing UV-induced degradation, durable polyurethane coatings maintain their color, gloss, and performance over time, even in outdoor applications.

Weather Resistance: Durable polyurethane coatings offer excellent weather resistance, making them suitable for both indoor and outdoor applications. These coatings withstand exposure to rain, snow, humidity, and temperature fluctuations without compromising their protective properties. Durable polyurethane coatings help prevent moisture intrusion, corrosion, and deterioration, prolonging the lifespan of substrates.

Applications of Durable Polyurethane Coatings:

Industrial Flooring: Durable polyurethane coatings are commonly used for industrial flooring applications due to their durability, chemical resistance, and abrasion resistance. These coatings provide a seamless and protective finish that withstands heavy foot traffic, equipment movement, and chemical spills in manufacturing facilities, warehouses, and production areas.

Concrete Protection: Durable polyurethane coatings are applied to concrete surfaces to enhance their durability and longevity. These coatings protect concrete floors, walls, and structures from moisture penetration, chemical exposure, and surface abrasion, extending the lifespan of the concrete and reducing maintenance costs.

Metal Protection: Durable polyurethane coatings are used to protect metal surfaces from corrosion, rust, and weathering. These coatings form a protective barrier that prevents moisture and oxygen from reaching the metal substrate, inhibiting the formation of rust and extending the lifespan of metal components, structures, and equipment.

Wood Finishes: Durable polyurethane coatings are applied as wood finishes to enhance the durability and appearance of wood surfaces. These coatings provide a protective seal that resists scratches, stains, and water damage, preserving the natural beauty of the wood and increasing its resistance to wear and tear.

Architectural Coatings: Durable polyurethane coatings are used as architectural coatings to protect building exteriors, facades, and structural elements. These coatings offer weather resistance, UV stability, and long-term durability, maintaining the aesthetic appeal and structural integrity of buildings in various climatic conditions.

Conclusion

Durable polyurethane coatings offer a comprehensive solution for protecting surfaces against wear, weathering, and environmental damage. With their exceptional durability, flexibility, and chemical resistance, these coatings provide long-lasting protection and performance in a wide range of applications. Whether it's industrial flooring, concrete protection, metal finishing, wood coatings, or architectural applications, durable polyurethane coatings offer unmatched reliability and versatility. Invest in durable polyurethane coatings to enhance protection and longevity for your surfaces, ensuring optimal performance and durability for years to come.

youtube

1 note

·

View note

Text

Caster Central

When it comes to outfitting your equipment with mobility, selecting the right caster wheels is critical to ensuring performance, efficiency, and safety. At Caster Wheels Central, we understand that integrating smooth-rolling and durable caster wheels is central to an array of industries. In this guide, we’ll walk you through key aspects to look for when you're ready to buy caster wheels and mention some of the trusted brands we carry.

Consider the Load Capacity: Before purchasing your casters, it's important to consider the weight they need to support. Different caster wheel models are designed for varying load capacities, it’s essential that you choose a product that can handle your requirements without failure.

Evaluate the Floor Conditions: The condition of flooring where casters will be used largely impacts their wear and performance. For environments with debris or irregular surfaces, choosing caster wheels designed for more rugged terrain might be necessary.

Determine Wheel Material: Caster wheels come in various materials such as rubber, polyurethane, phenolic resin, and even steel. Each material offers unique benefits; for example, rubber provides quiet operation while steel may offer greater durability under high weight loads.

Contact us

Caster Central

42 Winter Street, Pembroke, MA, 02359, US

Phone: 800-445-4082

Company Email: [email protected]

1 note

·

View note

Text

Examples of polymers and their uses

Their are many important examples of polymers such as Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Polyethylene Terephthalate (PET), Polyurethane (PU), Polyamide (nylon), epoxy resins, Polyethylene glycol (PEG), and Polyisoprene

Polyethylene (PE):

HDPE is commonly used in packaging materials such as bottles, containers, and plastic bags due to its strength and chemical resistance. LDPE is used in flexible packaging, plastic films, and coatings.

Polypropylene (PP):

PP is used in a variety of applications including packaging, textiles, automotive components, medical devices, and household goods due to its high strength, chemical resistance, and heat resistance.

Polyvinyl Chloride (PVC):

PVC is widely used in construction for pipes, window frames, flooring, and siding. It is also used in medical devices, packaging, electrical cables, and automotive parts due to its durability, versatility, and fire resistance.

Read more:

#polymers#materials science#science#engineering#materials#materials science and engineering#plastics

0 notes