#small batch cosmetic manufacturing equipment

Text

The Goodness of Nature: Crafting Eco-Friendly Skincare with Small Batch Private Label Manufacturers

In an era where consumers are becoming increasingly conscious of the products they use and their impact on the environment, the skincare industry is witnessing a significant transformation. The demand for eco-friendly cosmetic products and packaging is on the rise, and consumers are seeking skincare solutions that align with their values. Small batch private label skincare manufacturers are at the forefront of this movement, offering sustainable and high-quality products that cater to both consumers and businesses.

Goodness Of Nature, your trusted partner in the skincare industry, stands out as a shining example of how small batch private label skincare manufacturing can deliver exceptional products while prioritizing eco-friendliness. In this article, we will explore the key aspects of Goodness Of Nature's approach, from their commitment to sustainable practices to their role as eco-friendly cosmetic packaging suppliers.

Crafting Beauty in Small Batches

Small batch private label skincare manufacturing is a game-changer for businesses and consumers alike. Goodness Of Nature's commitment to creating products in limited quantities allows for more control over the quality and ingredients used. This results in skincare solutions that are not only effective but also customizable to cater to the unique needs of clients.

Whether you are an established brand looking for private cosmetics line manufacturers or a budding entrepreneur seeking to launch your skincare line, Goodness Of Nature's small batch approach ensures that every product is crafted with precision and care.

Eco-Friendly Cosmetic Packaging Suppliers

Eco-friendly cosmetic packaging is an essential aspect of the skincare industry's sustainable evolution. Goodness Of Nature goes the extra mile by not only producing environmentally conscious skincare products but also offering eco-friendly cosmetic packaging solutions.

These packaging options prioritize recyclability and biodegradability, reducing the environmental footprint of your skincare line. Goodness Of Nature understands that the first step to a greener skincare routine starts with the packaging, making them a valuable resource for those in search of sustainable solutions.

Partnering with Cosmetic Skin Care Manufacturers

When it comes to producing private label skincare products, finding the right cosmetic skin care manufacturers is crucial. Goodness Of Nature's reputation as a reliable and environmentally conscious private cosmetics line manufacturer sets them apart in the industry. They take pride in their ethical sourcing practices and dedication to using natural and organic ingredients whenever possible.

By partnering with Goodness Of Nature, businesses have the opportunity to create their own private label skincare line while maintaining a commitment to eco-friendliness and quality.

The Goodness of Nature Promise

In an industry that's constantly evolving, Goodness Of Nature offers a promise to its partners and customers. They are dedicated to the principles of sustainability, transparency, and quality. Whether you're looking for small batch private label skincare manufacturing, eco-friendly cosmetic packaging suppliers, or cosmetic skin care manufacturers, Goodness Of Nature is your trusted ally in creating products that resonate with your target audience.

Conclusion

The skincare industry is undergoing a transformation, and Goodness Of Nature is at the forefront of this positive change. By prioritizing small batch private label skincare manufacturing, eco-friendly cosmetic packaging solutions, and ethical ingredient sourcing, they stand as a beacon of hope for those who seek sustainable and high-quality skincare products.

In a world where consumers are becoming increasingly eco-conscious, aligning your brand with Goodness Of Nature will not only meet your customers' expectations but also help you contribute to a greener, more sustainable future. Choose the Goodness of Nature and make your skincare products a testament to the beauty of nature.

#cosmetic private label manufacturers#small batch cosmetic manufacturing equipment#organic cosmetic manufacturers private label#private label organic cosmetics manufacturer#private label products skincare#private label cosmetic products#best private label cosmetics manufacturers

0 notes

Text

Toll Blending

Toll Blending: A Strategic Approach to Customized Manufacturing

In today's competitive manufacturing landscape, companies are constantly seeking ways to optimize their production processes while maintaining quality and cost-effectiveness. One approach gaining prominence is toll blending, a strategic method that allows businesses to outsource certain aspects of their manufacturing process to specialized facilities. Toll blending offers numerous advantages, including flexibility, scalability, and access to specialized expertise. In this article, we'll explore the concept of toll blending, its benefits, applications across various industries, and considerations for implementing this approach effectively.

Understanding Toll Blending

Toll blending, also known as contract blending or custom blending, involves outsourcing the mixing, blending, or processing of raw materials to a third-party facility equipped with the necessary infrastructure and expertise. Essentially, a company provides the formulation or recipe, along with the required raw materials, to the toll blender, who then handles the blending process according to the specified parameters. The finished product is then returned to the client for further processing, packaging, and distribution.

Benefits of Toll Blending

Cost-Effectiveness: One of the primary advantages of toll blending is its cost-effectiveness. By outsourcing the blending process, companies can avoid the capital investments associated with purchasing specialized equipment and infrastructure. Instead, they pay a fee based on the volume and complexity of the blending required, allowing for better cost control and budget management.

Flexibility and Scalability: Toll blending offers unparalleled flexibility and scalability, allowing companies to adjust production volumes according to demand fluctuations without committing to fixed overhead costs. Whether it's a small batch or a large-scale production run, toll blenders can accommodate varying requirements, enabling businesses to respond quickly to market changes and customer needs.

Access to Expertise: Toll blending facilities are staffed with experienced professionals who possess in-depth knowledge of blending techniques, formulations, and regulatory requirements. By leveraging the expertise of these specialists, companies can ensure consistent quality, compliance with industry standards, and adherence to safety protocols.

Focus on Core Competencies: Outsourcing blending operations allows companies to focus their resources and attention on their core competencies, such as product development, marketing, and distribution. By delegating non-core activities to external partners, organizations can streamline their operations and allocate resources more effectively, leading to enhanced competitiveness and profitability.

Applications of Toll Blending

Toll blending finds application across a wide range of industries, including:

Chemicals and Petrochemicals: In the chemical and petrochemical sectors, toll blending is commonly used to mix various raw materials and additives to create customized formulations for products such as lubricants, adhesives, and specialty chemicals.

Food and Beverage: In the food and beverage industry, toll blending facilitates the creation of custom blends for ingredients such as spices, flavors, nutritional supplements, and ready-to-mix formulations for processed foods and beverages.

Pharmaceuticals and Cosmetics: Toll blending is instrumental in pharmaceutical and cosmetic manufacturing for producing formulations such as creams, ointments, lotions, and oral solutions, ensuring precise ingredient ratios and consistent quality.

Agriculture and Agrochemicals: In agriculture, toll blending is utilized for mixing fertilizers, pesticides, herbicides, and other agricultural inputs to meet specific crop requirements and application methods.

Considerations for Implementing Toll Blending

While toll blending offers numerous benefits, it's essential for companies to consider certain factors before engaging a toll blender:

Quality Assurance: Selecting a reputable toll blending partner with a proven track record of quality and reliability is paramount. Companies should conduct thorough due diligence, including facility audits, certifications, and reference checks, to ensure compliance with regulatory standards and quality control protocols.

Confidentiality and Intellectual Property: Protecting proprietary formulations and trade secrets is critical when outsourcing blending operations. Establishing confidentiality agreements and safeguards to prevent unauthorized disclosure of sensitive information is essential for safeguarding intellectual property rights.

Logistics and Supply Chain Management: Effective coordination of logistics and supply chain activities is vital to ensure timely delivery of raw materials to the toll blending facility and transportation of finished products back to the client's premises. Clear communication channels and robust inventory management systems are necessary to minimize disruptions and optimize efficiency.

Regulatory Compliance: Compliance with regulatory requirements, such as safety, environmental, and labeling standards, is non-negotiable in industries governed by stringent regulations. Companies must ensure that their toll blending partner adheres to relevant regulations and maintains necessary certifications to mitigate compliance risks.

Toll blending offers companies a strategic approach to customized manufacturing, enabling them to leverage external expertise, optimize costs, and enhance operational flexibility. By outsourcing blending operations to specialized facilities, businesses can focus on their core competencies, respond to market dynamics, and deliver innovative products to meet customer demands. However, successful implementation of toll blending requires careful planning, stringent quality control measures, and effective collaboration with trusted partners. As industries continue to evolve and demand for customized solutions grows, toll blending is poised to play an increasingly vital role in driving innovation and competitiveness across various sectors.

1 note

·

View note

Text

Unlocking the Sweet Potential: The Nutritional Benefits of Third Party Syrup Manufacturing Services

Introduction:

In today's dynamic food industry, meeting the evolving demands of health-conscious consumers while maintaining exceptional taste and quality is paramount. As businesses strive to align with shifting preferences towards natural, nutritious ingredients, the role of third-party syrup manufacturing services emerges as a pivotal solution. These services offer a gateway to enhancing products with wholesome sweetness, crafted from premium ingredients and expertise, ensuring both consumer satisfaction and business success.

The Advantages of Partnering with a Third-Party syrup manufacturing

Partnering with a third-party syrup manufacturing service brings forth a myriad of advantages for businesses navigating the competitive landscape of the food and beverage industry. Firstly, such collaborations offer cost-effective solutions, enabling companies to streamline production processes and allocate resources efficiently. By tapping into the specialized expertise of these manufacturers, businesses can benefit from optimized formulations and production techniques, ensuring consistent quality and flavor profiles across their product lines. Additionally, partnering with reputable third-party syrup manufacturers provides scalability, allowing businesses to adapt to fluctuating market demands and seize growth opportunities without compromising on product integrity. In essence, the advantages of collaborating with third-party syrup manufacturing services extend beyond mere production, empowering businesses to thrive in an ever-evolving market landscape.

Nutritional Benefits of Third Party Syrups:

Natural Ingredients: Discuss the use of natural ingredients in third-party syrups and their benefits for health-conscious consumers.

Reduced Sugar Options: Explore how manufacturers can offer reduced sugar or alternative sweetener options to cater to different dietary needs.

Added Nutrients: Explain how third-party syrups can be fortified with vitamins, minerals, or other beneficial additives to enhance nutritional value.

Customization: Highlight the ability of manufacturers to customize syrup formulations to meet specific nutritional requirements or preferences.

Why Choose Third-Party Syrup Manufacturing Services?

The decision to partner with a third-party syrup manufacturer is not merely a matter of convenience; it's a strategic move that can yield significant benefits. These manufacturers bring expertise honed through years of experience, ensuring that each batch of syrup meets the highest standards of quality and consistency. Moreover, by outsourcing syrup production, businesses can streamline their operations and focus on their core competencies, all while enjoying cost savings and scalability.

Frequently Asked Questions (FAQ) about Third-Party Syrup Manufacturing Services

1. What is a third-party syrup manufacturing service?

Ans. A third-party syrup manufacturing service is a specialized company that produces syrups on behalf of other businesses. These companies have the expertise, equipment, and facilities to create a wide range of syrups, catering to various industries such as food and beverage, pharmaceuticals, and cosmetics.

2.Are third-party syrup manufacturing services suitable for businesses of all sizes?

Ans. Yes, third-party syrup manufacturing services can accommodate businesses of all sizes, from small startups to large corporations. Whether you require small-batch production or bulk manufacturing, reputable manufacturers can tailor their services to meet your specific needs and scale accordingly.

Conclusion:

The nutritional benefits of third-party syrup manufacturing services are undeniable. By harnessing the expertise of these manufacturers, businesses can elevate their products to new heights, offering consumers a deliciously wholesome experience with every bite or sip. As we continue to prioritize wellness and sustainability, the partnership between businesses and third-party syrup manufacturers will undoubtedly play a pivotal role in shaping the future of the food and beverage industry. Embrace the sweet potential that awaits, and embark on a journey towards healthier, more flavorful offerings that delight and nourish in equal measure.

Also read: Revolutionizing Wellness: Third Party Ayurvedic Product Manufacturing Unveiled on Republic Day 2024! , Cosmetics Third-Party Manufacturing Services: Streamlining Excellence

0 notes

Text

The Innovation of Liquid Filling Machines: Revolutionizing Production Processes

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. One innovation that has significantly contributed to streamlining production processes is the liquid filling machine. These machines have revolutionized the way liquids are packaged, offering unparalleled accuracy, speed, and versatility.

Liquid filling machines are utilized across various industries, including pharmaceuticals, cosmetics, food and beverage, and chemicals. They serve a crucial role in ensuring consistent product quality while optimizing production throughput. From filling bottles and containers to pouches and tubes, these machines can handle a wide range of packaging formats with ease.

One of the primary advantages of liquid filling machines is their ability to deliver precise filling volumes. Whether dealing with thin liquids like water or viscous substances such as oils and syrups, these machines can dispense the exact amount required, minimizing product wastage and ensuring uniformity across batches. This precision is especially critical in industries where product consistency is non-negotiable.

Moreover, liquid filling machines enhance operational efficiency by automating the filling process. Manual filling methods are not only labor-intensive but also prone to errors and inconsistencies. By automating this task, manufacturers can significantly increase production output while reducing labor costs and human errors. This automation also allows for continuous operation, leading to higher throughput and shorter lead times.

Another significant benefit of liquid filling machines is their versatility. They can be easily adjusted to accommodate different container sizes, shapes, and types of liquids. Whether filling small vials or large drums, these machines offer flexibility without compromising on accuracy or speed. This adaptability is invaluable for manufacturers who deal with a diverse range of products and packaging requirements.

In addition to improving efficiency and precision, liquid filling machines also contribute to maintaining hygiene standards. Many modern machines are equipped with features such as automatic cleaning and sterilization, ensuring that the filling process meets stringent regulatory requirements for cleanliness and safety.

In conclusion, liquid filling machines represent a significant advancement in manufacturing technology. By combining precision, speed, versatility, and hygiene, these machines have become indispensable assets for businesses looking to optimize their production processes. As industries continue to evolve, the role of liquid filling machines will only become more pronounced, driving further innovation and efficiency in the global manufacturing landscape.

For more info-

ph-61388200090

1 note

·

View note

Text

Third-Party Cosmetics Manufacturing: A Smart Choice For Your Business

The cosmetic industry is undoubtedly one of the fastest-growing sectors in the world, experiencing an impressive annual growth rate of twenty percent. Within this sprawling industry, skincare is divided into five essential categories: body care, skin care, hair care, sun protection, and makeup removal. With cutthroat competition among cosmetic companies, a significant emphasis is placed on marketing and advertising. However, the heart of this industry lies in the manufacturing process, which demands expensive machinery and infrastructure that often exceeds the reach of many budding entrepreneurs and cosmetic brand owners.

Third-party cosmetics manufacturing refers to the outsourcing of the production and manufacturing of cosmetic products to specialized contract manufacturing organizations (CMOs). Elegant Cosmed is a renowned name in the industry, known for its commitment to quality, sustainability, and ethical practices. What Is Private Labeling and How Can It Help Your Business?

If you're a cosmetic brand owner or an aspiring entrepreneur looking to launch your line of cosmetic products, partnering with a trustworthy third-party cosmetic manufacturer like Elegant Cosmed can be pivotal for your company's success. The cosmetics industry's intense competition requires careful consideration of several factors when selecting a manufacturer, as outlined below.

Benefits of Third-Party Cosmetics Manufacturing

Expert Knowledge and Understanding of the Market:

A good manufacturer brings industry-specific expertise on the table. They understand market trends, consumer preferences, and regulatory requirements, ensuring that your products meet the highest standards and resonate with your target audience.

Save Time and Money:

Investing in the machinery and infrastructure required for cosmetic manufacturing can be prohibitively expensive. Partnering with CMOs allows you to bypass these substantial initial costs, allowing you to allocate your resources more efficiently toward marketing, branding, and product development.

Reliable Products and Bulk Quantity:

They have a track record of producing high-quality cosmetic products at scale. They have the infrastructure and capabilities to meet your production needs consistently, whether you require a small batch or mass quantities.

Credibility and Experience:

Established third-party manufacturers bring credibility and years of experience to your brand. Their track record can bolster your brand's reputation, instilling trust in both consumers and retailers.

Quality Criteria & Certifications:

Reputable third-party manufacturers adhere to stringent quality control measures and often possess industry certifications such as Good Manufacturing Practices (GMP) and ISO certifications. These certifications guarantee that your products meet the highest quality standards.

Responsiveness and Communication:

Effective communication is crucial in the cosmetics industry. Reputed CMOs are known for their responsiveness and clear communication, ensuring that your product development process runs smoothly.

Scalability and Adaptability:

As your brand grows, you may need to scale up production or introduce new products. Third-party cosmetics manufacturers are well-equipped to accommodate these changes and adapt to your evolving needs.

Ethical and Sustainable Practices:

Third-party cosmetics manufacturers prioritize ethical and sustainable manufacturing practices, which align with the growing demand for environmentally conscious cosmetics.

Testing and Samples:

CMOs typically offer extensive testing and sample services, allowing you to refine your product formulations and ensure they meet your quality standards before mass production.

Capabilities for Formulation:

Experienced CMOs often have in-house formulation experts who can help you create innovative and effective cosmetic products tailored to your brand's vision. Expert Tips for Selecting a Private Label Cosmetic Manufacturer in India

In conclusion, navigating the competitive landscape of the cosmetics industry requires strategic decisions and resourceful partnerships. Third-party cosmetics manufacturers, such as Elegant Cosmed, emerge as pivotal allies on your journey to success. Beyond the initial cost savings and industry know-how, their commitment to quality and adaptability ensures that your brand not only survives but thrives in a dynamic market.

In the fast-paced world of cosmetics, staying ahead means more than just creating great products; it's about understanding and responding to the ever-evolving needs of consumers. Elegant Cosmed not only handles the intricacies of manufacturing but also empowers you to allocate resources where they matter most—promotion and product innovation. This collaborative approach enables you to focus on what you do best, secure in the knowledge that your manufacturing needs are in expert hands.

Choosing Elegant Cosmed as your cosmeceutical manufacturing partner isn't just a practical business decision: it's a strategic investment in the long-term success of your cosmetic brand. Our state-of-the-art facilities, industry expertise, and unwavering commitment to excellence provide the foundation for your brand's ascent to new heights.

Make the smart move for your cosmetics business—partner with Elegant Cosmed. Contact us today to explore the boundless possibilities that await your brand in the world of cosmetics manufacturing.

0 notes

Text

Make Your Nails Shine with a Premium Gel Products | CKN INTERNATIONAL

CKN International focuses on both international trade events and domestic exhibits. It arranges several exhibitions with the intention of growing its market to a global scale, beginning with beauty shows in China and Japan. They are acquiring competitive items and unique technologies, as well as making plans for new concept products, in order to adjust to the quickly changing nail gel products industry. Particularly, the significant investments made in chemical material development and technology set its products apart from those of other brands. CKN International is a South Korean manufacturer of professional premium nail cosmetics. It manufactures products based on trust and the most recent nail polish technology research. Its products are not ordinary gels, but rather special products with unique color matching, formulation, and chemical development. As a result, they have received a lot of love from customers in a short period of time.

It has also established and is operating an academy to develop technological know-how and provide training, with the goal of improving the professional and making our nails healthy and beautiful. Furthermore, it is making every creative idea that comes from all of its colleagues in an effort to let the world know how nice Korean-made nail gels are.

CKN International’s OEM Process:

It is equipped with the technology and systems needed to secure the ancillary materials. It creates unique shapes, coordinates colors, and produces the finished goods. Additionally, they are the owners of the system that allows them to produce whatever model they create in small or large batches. They also put into practice complete quality control and science at the same time.

CKN International’s ODM Process:

It offers the ideal end-to-end ODM network system service, encompassing planning, developing, manufacturing, and shipping products in addition to investigating market trends and fulfilling customer requests for product development all the way through to the finished product's release.

Want to make your nail more shine with a premium nail cosmetics manufacturer, explore at CKN International.

Click here to contact CKN INTERNATIONAL

View more: Premium Gel Manufacturer Products

0 notes

Text

Boosting Efficiency and Precision with Multi-Fill's High-Speed Counting Machines

In today's fast-paced manufacturing and packaging industries, precision and speed are paramount. Keeping up with consumer demand while maintaining product quality can be a challenging task. Thankfully, innovative solutions are constantly emerging to streamline production processes, and Multi-Fill's range of high-speed counting machines is leading the way.

Whether you are in the pharmaceutical, food, or cosmetic industry, the need for accurate and efficient product counting is universal. Multi-Fill recognizes these needs and has developed a line of cutting-edge machines to cater to diverse requirements, including cellular tray machines, automatic counting machines, and product counting machines.

High-Speed Counting Machines: A Game Changer

One of Multi-Fill's standout offerings is its high-speed counting machines. These machines are designed to count and dispense a wide variety of products quickly and accurately. Whether you are dealing with small pills or larger items like confectionery, Multi-Fill's high-speed counting machines are up to the task.

Here are some key features and benefits of Multi-Fill's high-speed counting machines:

1. Speed and Efficiency

Multi-Fill's high-speed counting machines are engineered for maximum efficiency. They can count and fill a large number of items per minute, significantly reducing production time and labor costs. With these machines, you can meet high-volume demands without compromising on accuracy.

2. Precision and Accuracy

Accuracy is non-negotiable in industries that require precise product counts. Multi-Fill's counting machines use advanced technology to ensure every count is precise, eliminating the risk of overfilling or underfilling products. This precision contributes to consistent product quality and customer satisfaction.

3. Versatility

Multi-Fill's high-speed counting machines are highly versatile and can handle a wide range of product types, shapes, and sizes. Whether you're packaging pharmaceuticals, food products, or cosmetic items, these machines can adapt to your specific needs.

4. User-Friendly Interface

These machines come equipped with user-friendly interfaces, making them easy to operate and set up. This user-friendliness minimizes the learning curve for your staff, allowing you to maximize productivity from day one.

5. Customization

Multi-Fill understands that every business has unique requirements. That's why their high-speed counting machines can be customized to fit your specific needs. Whether you need additional features or adjustments to accommodate special products, Multi-Fill can tailor their machines to your specifications.

Explore Multi-Fill's Range of Counting Machines

In addition to high-speed counting machines, Multi-Fill offers other specialized counting equipment:

1. Cellular Tray Machines

Cellular tray machines are perfect for packaging products in trays or blister packs. Multi-Fill's cellular tray machines are designed to efficiently fill and seal trays, ensuring your products are ready for retail shelves.

2. Automatic Counting Machines

For businesses with high-volume production needs, automatic counting machines are a game-changer. These machines can handle large batches of products with minimal manual intervention, making them a valuable addition to any production line.

3. Product Counting Machines

Product counting machines are versatile tools that can handle various product types. Multi-Fill's product counting machines are designed to streamline the counting and packaging process for a wide range of industries.

Conclusion

In today's competitive market, efficiency and accuracy are key to success. Multi-Fill's high-speed counting machines, cellular tray machines, automatic counting machines, and product counting machines are designed to help businesses stay ahead of the curve. By investing in Multi-Fill's innovative solutions, you can boost production efficiency, improve product quality, and ultimately enhance your bottom line.

To learn more about Multi-Fill's high-speed counting machines and explore their complete range of counting equipment, visit Multi-Fill's website and take the first step toward transforming your production process.

0 notes

Text

Custom Formulation Manufacturers: Crafting Unique Solutions in the Beauty Industry

In the dynamic world of cosmetics and skincare, one size rarely fits all. Customization has emerged as a key trend, with consumers seeking products that cater to their unique needs and preferences. Custom formulation manufacturers play a pivotal role in this beauty revolution, offering brands and individuals the ability to create bespoke skincare and cosmetic products. In this article, we will explore the significance of custom formulation manufacturers in the beauty industry and how they are reshaping the way we approach beauty and self-care.

The demand for personalized beauty products is on the rise, driven by consumers' desire for products that address their specific concerns and preferences. Custom formulation manufacturers are the architects of this personalized beauty landscape. Here are some essential aspects to consider:

Tailored to Your Vision

Custom formulation manufacturers work closely with brands and individuals to bring their beauty product ideas to life. Whether it's a unique skincare serum, a custom lipstick shade, or a specialized haircare formula, these manufacturers have the expertise to create products that align with your vision and brand identity.

Premium Quality Ingredients

Quality is non-negotiable in the beauty industry. Custom formulation manufacturers have access to a wide range of premium-quality ingredients, ensuring that the end product is both effective and safe. They can help you select ingredients that cater to specific skin types, concerns, or desired product characteristics.

Compliance and Regulation

Navigating the complex world of cosmetic regulations can be daunting. Custom formulation manufacturers have a deep understanding of industry regulations and can guide you through the compliance process. This ensures that your products meet all safety and legal requirements.

Small Batch Flexibility

Unlike mass production, custom formulation manufacturers are equipped to produce smaller batches of products. This is especially beneficial for emerging brands or individuals looking to test the market with a new product. It reduces waste and allows for more agile product development.

Innovation and Trends

The beauty industry is ever-evolving, with new ingredients and trends emerging regularly. Custom formulation manufacturers stay up-to-date with the latest innovations, helping you create products that are not only personalized but also aligned with current market trends.

Private Labeling

For those looking to launch their beauty brand without the need for a full-scale manufacturing facility, custom formulation manufacturers often offer private labeling services. This allows you to put your brand name on high-quality products without the hassle of production.

Environmental Consciousness

Many custom formulation manufacturers are adopting eco-friendly practices, using sustainable ingredients and packaging options. This appeals to environmentally conscious consumers and aligns with the growing trend of green beauty.

In conclusion, custom formulation manufacturers are the architects of personalized beauty. They empower brands and individuals to create unique, effective, and safe beauty products tailored to specific needs and preferences. Whether you're a budding entrepreneur with a beauty brand dream or a skincare enthusiast seeking a personalized regimen, custom formulation manufacturers are your partners in achieving beauty excellence.

As the beauty industry continues to evolve, custom formulation manufacturers will remain at the forefront of innovation and personalization. The future of beauty is bespoke, and these manufacturers are the key to unlocking the full potential of customized beauty experiences.

0 notes

Text

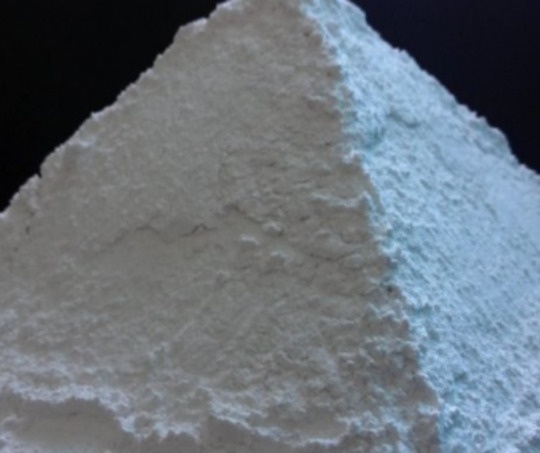

Unveiling the Marvel: Ashirwad Minerals' Exceptional 10 Micron Talc Powder

Introduction

In the world of industrial minerals, precision and quality are paramount. Ashirwad Minerals, a name synonymous with excellence, introduces a game-changing product – the 10 Micron Talc Powder. With a legacy of delivering top-notch minerals, Ashirwad Minerals once again sets the bar high with this exceptional offering. In this blog, we delve into the significance of 10 micron talc powder, its applications, and why Ashirwad Minerals stands as a pioneer in the industry.

Understanding 10 Micron Talc Powder

Talc, a naturally occurring mineral, is known for its softness, low abrasiveness, and its ability to provide unique properties to various products. Micron measurement refers to particle size, and a lower micron value indicates finer particles. The 10 micron talc powder from Ashirwad Minerals boasts an impressively small particle size, which opens the door to a plethora of applications.

Unmatched Smoothness and Opacity

One of the most notable characteristics of the 10 micron talc powder is its unparalleled smoothness. Due to the fine particle size, the talc powder imparts a velvety texture when incorporated into cosmetics, personal care products, and paints. This attribute is highly sought after in industries where texture plays a pivotal role in product acceptance.

Moreover, the 10 micron talc powder enhances opacity. In industries such as plastics, where opacity and color consistency are essential, this talc powder proves to be a valuable additive. The minute particles scatter light more effectively, resulting in improved opacity and a visually appealing final product.

Enhanced Lubrication and Performance

In industrial applications, the 10 micron talc powder demonstrates exceptional lubrication properties. It reduces friction, making it an excellent addition to plastics, rubber, and other materials where smoothness and glide are crucial. This property not only improves the end-product's performance but also extends the lifespan of machinery and equipment that utilize these materials.

Versatile Applications

Ashirwad Minerals' 10 micron talc powder finds its utility across a diverse range of industries. In the cosmetics and personal care sector, it enhances the tactile experience of products like lotions, creams, and powders. Its use in the pharmaceutical industry contributes to the smoothness and flow of tablets during production.

In the world of plastics, this talc powder enhances the processing of polymers and improves the final product's appearance and quality. Its application in paints and coatings leads to improved coverage, texture, and color retention.

Ashirwad Minerals: The Trusted Source

What sets Ashirwad Minerals apart as a premier manufacturer of 10 micron talc powder? It's our commitment to quality and innovation. With years of experience, the company excels in extracting, processing, and refining talc to meet the specific demands of industries. Our rigorous quality control ensures that each batch of talc powder meets the highest standards of purity and performance.

The company's expertise extends beyond just manufacturing. Ashirwad Minerals works closely with clients to understand our unique requirements and offers tailored solutions that align with our needs. This customer-centric approach has earned them a reputation for being a reliable partner in industries that demand nothing but the best.

Conclusion

In the realm of industrial minerals, Ashirwad Minerals stands as a beacon of excellence, and our 10 micron talc powder is a testament to their commitment to innovation and quality. From enhancing the smoothness and opacity of cosmetics to improving the performance of plastics and paints, this talc powder's versatility knows no bounds. With Ashirwad Minerals as the trusted source, industries can unlock the potential of 10 micron talc powder to elevate our products and processes to new heights.

0 notes

Text

Mixing Equipment Supplier in Bangalore

Mixing Equipment Supplier in Bangalore:

Invoit Plast Machinery Pvt. Ltd.:

Invoit Plast Machinery Pvt. Ltd. is a manufacturing company based in Ahmedabad, India, which is home to several large and prominent plastic industries.

There are several types of mixing equipment available for diverse applications. Regularly used mixing equipment includes a high-speed mixer, vertical batch mixer, storage mixer, and budget mixer — comprising the four types.

High-Speed Mixer: Intended to efficiently mix and disperse materials, high-speed mixers find common applications in pharmaceuticals, cosmetics, food processing, and chemicals. These mixers typically run at high rotational speeds to produce vigorous mixing action and ensure proper ingredient blending.

Vertical Batch Mixer: A vertical batch mixer is a versatile mixing equipment used for blending dry powders or granules. It consists of a large vertical vessel featuring a revolving impeller or agitator. The design of the mixer enables effective material mixing by raising and tumbling them while the agitator turns. Vertical batch mixers are common in industries such as agriculture, polymers, construction, and pharmaceuticals.

Storage Mixer: A storage mixer, also known as a holding or reservoir mixer, is a device that stores and mixes huge amounts of liquids or semi-liquid solids. These mixers usually include a big tank or vessel with an agitation mechanism to avoid ingredient separation or settling over time. Industries, including chemical processing, water treatment, and food and beverage production, use storage mixers for various purposes.

Budget Mixer: The term "budget mixer" refers to mixers that are less expensive or tailored to a specific budget range rather than a specific type of mixer. Budget mixers come in a variety of styles, including hand mixers, stand mixers, and compact countertop mixers. While they may have limits when compared to high-end professional mixers, they can nevertheless be useful for a variety of home or small-scale applications.

Keep in mind that choosing the right mixing equipment holds immense importance and relies on the specific demands of your application. This includes factors such as the materials you will mix, the intended results of mixing, your production capacity, and the constraints of your budget. Consultation with a supplier or expert in the industry can assist you in selecting the best mixing equipment for your needs.

We Provide Mixing Equipment Supplier in Bangalore Including Peenya, Doodannakundi, Rajaji Nagar, DDK Industrial Area, Petechannappa, Kamakshipalya, Kiadb, Dobbaspet, Bidadi, Dyavasandra, Jigani, Kumbalgudu, Mahadevpura, Rajaji nagar and kamakshi palya, Attibele Etc.

Read the full article

0 notes

Text

Natural Beauty: Uncovering the Advantages of Specialty Cosmetics Manufacturers

In the fast-paced world of cosmetics, consumers are constantly searching for products that fit their personalities, values, and interests. As the demand for beautiful and ethical products continues to grow, private companies and suppliers have become key players in the industry, offering quality products, technology, and innovation. In this article, we explore the many benefits of working with specialty cosmetics companies and highlight the advantages of working with professionals to create beautiful, unique products that are much more than makeup.

Introduction of private label cosmetics manufacturers

In recent years, the cosmetics industry has experienced a major shift in remaining loyal to private-label cosmetics. Private cosmetics companies benefit from providing many benefits to both established and new businesses. Here are some reasons for suppliers and manufacturers to consider working with a private label:

1. Customized Product Development

One of the key benefits of custom cosmetics development is the ability to create products that align with your brand's vision. Private equity firms understand the importance of personalization, which allows brands to create compelling products that align with their values, their audience, and their business. Whether you're looking to create makeup, skincare, or hair care products, these professionals can help you realize your vision.

2. Affordable

Creating beautiful home decor can be a costly and time-consuming process. Private-label cosmetics manufacturers leverage their expertise and proven supply chains to deliver cost-effective solutions. This means you can bring quality products to market without having to invest significant amounts in factories or equipment.

3. Speed to market

Staying ahead of trends and customer needs is very important in the cosmetics industry. Private sellers and manufacturers benefit greatly from making product improvements and bringing new models to market quickly. This agility gives you a competitive advantage by allowing your target to take advantage of new goodies.

4. Quality assurance

Private-label cosmetics manufacturers often use stringent controls to maintain product consistency and safety. These companies often work with design laboratories and use quality materials to create beautiful, quality products. This commitment to quality assurance is a key selling point for brands looking to create reliable and affordable cosmetic products.

5. Ethical Sourcing

As consumers become more conscious of environmental and ethical issues, private cosmetic companies are striving to meet this need. Many companies pay attention to the importance of ethical ingredients and provide products with an opportunity for responsibility and leadership by implementing good environmental practices throughout the production process.

6. A wide variety of products

Private-label cosmetics manufacturers often have a variety of beauty products, including color cosmetics. Whether you need lipstick, foundation, or any other makeup item, they have you covered. This versatility allows brands to expand their products and meet the different needs of their customers.

Conclusion

Private-label cosmetics manufacturers and others are an important part of the modern cosmetics industry, providing many advantages to meet the ever-changing needs of brands and their customers. By collaborating with these experts, brands can create personalized, affordable, high-quality, and beautiful products. Whether you're looking to create a new cosmetics line or expand your existing products, partnering with specialty cosmetics companies can be the key to success on a cosmetics competition site. Embrace beauty and innovation and let personalized cosmetics take your brand to new heights in the beauty industry.

#organic cosmetic manufacturers private label#small batch cosmetic manufacturing equipment#cosmetic private label manufacturers#private label organic cosmetics manufacturer#best private label cosmetics manufacturers#private label cosmetic products#private label products skincare

0 notes

Text

Touch Free Manufacturing with Robotics for FMCG

The FMCG manufacturing cycle for products including processed food, beverages, dry goods, cosmetics, toiletries, and prepared food needs us to prevent contamination and ensure uniform quality and hygiene. Touch-free manufacturing is ideal to achieve this - while automation using conveyors, silos, and batching is used, robotics also has an important role to play in the process.

Processed Food

Processed food items such as chocolates, biscuits, and different types of bread have turned to robotics to improve efficiency. Handling such items requires specialised robots with food-grade EOATs. Operations such as weighing raw powders and scoring have also benefited from robotics. For pick and place before packing in appropriate packets also the robots need food-grade EOATs to handle these items, and vision systems to identify based on size and shape. These robots also help to pick and place raw produce such as fruits and veggies for sauces and jams, as also in cutting meat slices.

Beverages

Items such as smoothies, coffee, tea, juices, and shakes use programmable robots for mixing the right proportions of fruits, bean grades, or tea grades. Food-grade robots are used for processing raw items. For bottled beverages, vision sensors are used to ensure optimum filling.

Cosmetics

Cosmetics such as eyeliner, nail polish, and face powder need different types of cobots to fill the soft containers optimally. Also, the vast colour palette of nail polish calls for more advanced vision systems to help the cobots distinguish based on colours and sort accordingly. The face powder pack needs to be capped appropriately before being moved to the delivery conveyor.

Many brands have turned to robotics for the research and development of future products. Hair-care products use Collaborative Robots with appropriate grippers to simulate different styles of combing with the associated application pressure.

Toiletries

Many personal grooming products such as shavers, assembled from different parts, are created using different manufacturing lines for each part. For efficient picking and placing of the small components, each robot is accompanied by a vision system. The frequently changing customer requirements call for models to be changed often. The robots used to handle them are programmable so that the same robot can be used for other models with a simple change of program.

Prepared Food

We touch different surfaces, thereby gaining contact with unwanted and hidden bacteria and viruses. For pure food preparation, untouched by hands, cobots are being deployed. Equipped with appropriate End of Arm Tooling (EOATs), the cobots can be programmed for various recipes. With relevant ingredients available at predesignated places within the kitchen, these cobots go about preparing healthier food using the precise amount of ingredients as programmed for the recipe. The use of these robotic kitchens is gaining prevalence today.

Packing and Palletising

Packing and palletising is the most important stage in the supply chain of many FMCG products. Consumers today are overwhelmed by choice in this era of online shopping and these fast-moving products are often dictated by the ever-changing consumer demands resulting in short shelf-life. Robots help in the fast packing and palletising of the finished products leading to shorter goods-to-person times.

Touch-free handling of finished goods for packing is handled by food-grade EOATs fitted on the robots to ensure zero contamination. Palletising is handled by robots ensuring the optimum quantity of goods in each carton. Pick and place is an important task in the packing and palletising process, needing accurate and quick storage and picking from appropriate bins in the warehouse. Robots have transformed the packing and palletising of FMCG in tune with the times.

Common tasks

Over and above the mentioned roles, robots in FMCG perform quality control, when used with vision sensors. These robots are dexterous, capable of soft handling, unlike their counterparts used in other industries. Besides, all these robots are programmable for quick adaptability with different types of goods, as is the norm in the FMCG industry.

MELSS has been providing various industrial automation and robotics solutions to different industry segments, collaborating with major brands such as Doosan Robotics and OnRobot.

Author: https://www.melss.com/

0 notes

Text

Revolutionizing Beauty: How Third-Party Cosmetic Manufacturing Services Are Redefining the Industry

In the ever-evolving landscape of the beauty industry, innovation is key to staying ahead. One such innovation that has been gaining significant traction is third-party cosmetic manufacturing services. This trend is revolutionizing how beauty products are produced, offering brands unparalleled flexibility, efficiency, and quality control. Let's delve deeper into this game-changing phenomenon and explore how it's reshaping the beauty industry as we know it.

Understanding Third-Party Cosmetic Manufacturing Services:

Third-party manufacturers specialize in the formulation, production, and packaging of cosmetic products. These companies have state-of-the-art facilities and a team of experts dedicated to ensuring the highest quality standards. By outsourcing production to third-party manufacturers, brands can focus on their core competencies such as marketing, branding, and distribution, while leaving the manufacturing process in the hands of trusted professionals.

The Benefits of Third-Party Cosmetic Manufacturing

Cost-Effectiveness: Outsourcing production to third-party manufacturers can significantly reduce overhead costs associated with maintaining in-house manufacturing facilities. This includes expenses related to equipment, labor, and facility maintenance.

Flexibility: Third-party manufacturers offer flexibility in production, allowing brands to produce small batch sizes, customize formulations, and quickly adapt to changing market trends. This agility is particularly valuable in a fast-paced industry like cosmetics, where consumer preferences can shift rapidly.

Expertise and Innovation: Partnering with third-party manufacturers provides access to specialized expertise and cutting-edge technology. These manufacturers often invest heavily in research and development, allowing brands to leverage the latest innovations in cosmetic formulation and production.

Scalability: Third-party manufacturers can scale production according to demand fluctuations, ensuring that brands can meet market demands without the risk of overproduction or underutilized capacity. This scalability is especially beneficial for emerging brands looking to grow their presence in the market.

How to Choose the Right Third-Party Manufacturer

Selecting the right third-party manufacturer is crucial for the success of your cosmetic brand. Here are some key factors to consider:

Reputation and Track Record: Research the manufacturer's reputation in the industry and evaluate their track record of delivering high-quality products.

Capabilities and Services: Assess the manufacturer's capabilities and services to ensure they can meet your specific production needs, including formulation expertise, production capacity, and packaging options.

Quality Control Processes: Inquire about the manufacturer's quality control processes and certifications to ensure compliance with regulatory standards and product integrity.

Communication and Collaboration: Establish clear communication channels and foster a collaborative relationship with the manufacturer to facilitate seamless coordination and problem-solving.

FAQ: Third-Party Cosmetic Manufacturing Services

1. What are third-party cosmetic manufacturing services?

Third-party cosmetic manufacturing services involve outsourcing the production of cosmetic products to specialized manufacturers. These manufacturers are equipped with the expertise, facilities, and resources to formulate, produce, and package a wide range of cosmetic products on behalf of cosmetic brands.

2. How can I ensure quality control in third-party manufacturing?

To ensure quality control in third-party manufacturing, establish clear specifications and protocols for raw materials, production processes, and finished products. Conduct regular audits of the manufacturing facilities and practices, and implement testing procedures for product safety, efficacy, and stability throughout the production process.

Embracing Innovation in Beauty Production

In conclusion, third-party cosmetic manufacturing services represent a paradigm shift in the beauty industry, offering brands unparalleled opportunities for growth, efficiency, and innovation. By leveraging the expertise and capabilities of third-party manufacturers, brands can unlock new possibilities and stay ahead of the competition in an increasingly competitive market landscape. Embrace the power of third-party manufacturing and unlock the full potential of your cosmetic brand.

Also read:

#third party manufacturing#ayurvedic third party manufacturing company#third party manufacturing companies

0 notes

Text

Industrial Inkjet Printer Market trend

The industrial inkjet printer market refers to the market for inkjet printers specifically designed for industrial applications. These printers are used in various industries for printing high-quality text, graphics, and barcodes on a wide range of materials, including packaging materials, labels, textiles, ceramics, metals, and more.

Industrial inkjet printers offer several advantages over traditional printing methods, such as flexibility, high-speed printing, variable data printing capabilities, and the ability to print on diverse surfaces. They utilize inkjet technology, which involves the precise deposition of ink droplets onto the printing substrate.

Key factors driving the growth of the industrial inkjet printer market include:

1. Increased Demand for Product Customization: With the rise of e-commerce and changing consumer preferences, there is a growing need for product customization and personalized packaging. Industrial inkjet printers enable on-demand printing of variable data, allowing manufacturers to customize products and packaging with unique codes, serial numbers, barcodes, and even individualized graphics.

2. Advancements in Inkjet Technology: Continuous advancements in inkjet technology have led to improved print quality, faster printing speeds, enhanced durability of printed materials, and expanded compatibility with a wide range of substrates. These technological advancements have made industrial inkjet printers more reliable, efficient, and cost-effective.

3. Regulatory Compliance and Product Traceability: Industries such as food and beverage, pharmaceuticals, and cosmetics have strict regulations regarding product traceability, batch coding, and expiration date labeling. Industrial inkjet printers enable the printing of accurate and readable information, ensuring compliance with regulatory requirements and enhancing product safety.

4. Cost and Time Efficiency: Industrial inkjet printers offer cost and time savings compared to traditional printing methods. They eliminate the need for printing plates or screens, reducing setup costs and allowing for quick job changeovers. Moreover, their high-speed printing capabilities improve production efficiency and reduce downtime.

Talk to analyst :-https://www.alliedmarketresearch.com/connect-to-analyst/5160

5. Growing Packaging Industry: The increasing demand for packaged consumer goods, including food, beverages, cosmetics, and pharmaceuticals, is driving the growth of the packaging industry. Industrial inkjet printers play a crucial role in packaging by providing high-quality printing solutions for product labels, barcodes, expiration dates, and promotional graphics.

Prominent players in the industrial inkjet printer market include Epson, Domino Printing Sciences, Videojet Technologies, Markem-Imaje, and HP Inc., among others. These companies offer a wide range of inkjet printing solutions tailored to meet the specific requirements of different industries.

The industrial inkjet printer market is expected to continue growing as industries across various sectors recognize the benefits of digital printing for customization, efficiency, and compliance with regulations. Technological advancements, such as the development of new ink formulations and increased integration with automation systems, are likely to further drive the market’s growth.

Key players that operate in the market include Kishu Giken Kogyo Co. Ltd., Videojet Technologies, Inc., Pannier Corporation, Engage Technologies Corporation Company, Inkjet, Inc, Keyence Corporation, Zanasi USA, Ricoh, Leibinger Group, and Hitachi Industrial Components & Equipment Group amongst others.

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

Contact Us:

David Correa

5933 NE Win Sivers Drive

#205, Portland, OR 97220

United States

USA/Canada (Toll Free): +1–800–792–5285, +1–503–894–6022

UK: +44–845–528–1300

Hong Kong: +852–301–84916

India (Pune): +91–20–66346060

Fax: +1(855)550–5975

[email protected]

Web: https://www.alliedmarketresearch.com/reports-store/construction-and-manufacturing

0 notes

Text

Third-Party Cosmetics Manufacturing: A Smart Choice For Your Business

The cosmetic industry is undoubtedly one of the fastest-growing sectors in the world, experiencing an impressive annual growth rate of twenty percent. Within this sprawling industry, skincare is divided into five essential categories: body care, skin care, hair care, sun protection, and makeup removal. With cutthroat competition among cosmetic companies, a significant emphasis is placed on marketing and advertising. However, the heart of this industry lies in the manufacturing process, which demands expensive machinery and infrastructure that often exceeds the reach of many budding entrepreneurs and cosmetic brand owners.

Third-party cosmetics manufacturing refers to the outsourcing of the production and manufacturing of cosmetic products to specialized contract manufacturing organizations (CMOs). Elegant Cosmed is a renowned name in the industry, known for its commitment to quality, sustainability, and ethical practices. What Is Private Labeling and How Can It Help Your Business?

If you're a cosmetic brand owner or an aspiring entrepreneur looking to launch your line of cosmetic products, partnering with a trustworthy third-party cosmetic manufacturer like Elegant Cosmed can be pivotal for your company's success. The cosmetics industry's intense competition requires careful consideration of several factors when selecting a manufacturer, as outlined below.

Benefits of Third-Party Cosmetics Manufacturing

Expert Knowledge and Understanding of the Market:

A good manufacturer brings industry-specific expertise on the table. They understand market trends, consumer preferences, and regulatory requirements, ensuring that your products meet the highest standards and resonate with your target audience.

Save Time and Money:

Investing in the machinery and infrastructure required for cosmetic manufacturing can be prohibitively expensive. Partnering with CMOs allows you to bypass these substantial initial costs, allowing you to allocate your resources more efficiently toward marketing, branding, and product development.

Reliable Products and Bulk Quantity:

They have a track record of producing high-quality cosmetic products at scale. They have the infrastructure and capabilities to meet your production needs consistently, whether you require a small batch or mass quantities.

Credibility and Experience:

Established third-party manufacturers bring credibility and years of experience to your brand. Their track record can bolster your brand's reputation, instilling trust in both consumers and retailers.

Quality Criteria & Certifications:

Reputable third-party manufacturers adhere to stringent quality control measures and often possess industry certifications such as Good Manufacturing Practices (GMP) and ISO certifications. These certifications guarantee that your products meet the highest quality standards.

Responsiveness and Communication:

Effective communication is crucial in the cosmetics industry. Reputed CMOs are known for their responsiveness and clear communication, ensuring that your product development process runs smoothly.

Scalability and Adaptability:

As your brand grows, you may need to scale up production or introduce new products. Third-party cosmetics manufacturers are well-equipped to accommodate these changes and adapt to your evolving needs.

Ethical and Sustainable Practices:

Third-party cosmetics manufacturers prioritize ethical and sustainable manufacturing practices, which align with the growing demand for environmentally conscious cosmetics.

Testing and Samples:

CMOs typically offer extensive testing and sample services, allowing you to refine your product formulations and ensure they meet your quality standards before mass production.

Capabilities for Formulation:

Experienced CMOs often have in-house formulation experts who can help you create innovative and effective cosmetic products tailored to your brand's vision. Expert Tips for Selecting a Private Label Cosmetic Manufacturer in India

In conclusion, navigating the competitive landscape of the cosmetics industry requires strategic decisions and resourceful partnerships. Third-party cosmetics manufacturers, such as Elegant Cosmed, emerge as pivotal allies on your journey to success. Beyond the initial cost savings and industry know-how, their commitment to quality and adaptability ensures that your brand not only survives but thrives in a dynamic market.

In the fast-paced world of cosmetics, staying ahead means more than just creating great products; it's about understanding and responding to the ever-evolving needs of consumers. Elegant Cosmed not only handles the intricacies of manufacturing but also empowers you to allocate resources where they matter most—promotion and product innovation. This collaborative approach enables you to focus on what you do best, secure in the knowledge that your manufacturing needs are in expert hands.

Choosing Elegant Cosmed as your cosmeceutical manufacturing partner isn't just a practical business decision: it's a strategic investment in the long-term success of your cosmetic brand. Our state-of-the-art facilities, industry expertise, and unwavering commitment to excellence provide the foundation for your brand's ascent to new heights.

Make the smart move for your cosmetics business—partner with Elegant Cosmed. Contact us today to explore the boundless possibilities that await your brand in the world of cosmetics manufacturing.

0 notes

Text

How Packaging Machinery Can Save Your Business Time and Money

When packaging machinery breaks down it interrupts production – this costs companies time, money and customer satisfaction. This is the main reason it is essential to invest in regular maintenance. Relying on best quality packaging machinery is inevitable.

Human error – overfilling containers, damaging packaging and applying incorrect labels or tightening caps – wastes products and leads to unhappy customers. Automation enables greater consistency in output.

Flow Fillers for Portion-Counted Product Packaging

Using packaging machinery can increase productivity and reduce production costs, while improving hygiene standards. It can also eliminate hand contact with food and medicine to ensure high product quality and safety standards. However, the cost of purchasing and operating this equipment is a significant dynamic that needs to be considered carefully.

Flow fillers are designed for products that are counted by portions, instead of weight. These machines use a hopper that’s set up to scan count candy pieces or tablets and can fill small bottles. They’re best suited for liquids, oils, and thin edible products.

Blister Packing Machines: These machines form a platform in a plastic shell, then add blister board backers that are adhered with glue or by hand to the back of the plastic. Then, the products are placed on the platform and a heated soft plastic layer shapes itself around them to create a sealed blister pack. They’re commonly used for food and pharmaceutical products.

Tablet Fillers for Portion-Counted Product Packaging

Packaging machinery can be utilized to fill a pouch or bottle with products that are counted by portions. These machines include a hopper that scan counts product pieces or tablets before placing them in the bottle, and a filler head that pushes the correct number of items into the bottles accurately. Some examples of such products are heavy sauces, cosmetic creams and thick shampoos.

Another form of packaging equipment is the vertical form fill seal machine, which makes stand-up pouches and plastic bags from a continuous flat film roll and fills them simultaneously with products and seals the filled bags. This type of packaging is capable of handling liquids and solids.

Having representatives from several packaging machinery manufacturers examine existing packaging procedures can help find ways to improve production efficiency and lower costs prior to progression to new equipment. Understanding math included in cost per film utilization will also aid the business to budget properly and exploit packaging materials with efficiency.

Vertical Form Fill Sealing Machine

VFFS machines (also known as vertical baggers) are an effective packaging solution for powdered products. Typically, these machines start with a roll of film that’s pulled by belts to a forming tube that shapes it into the desired pouch size.

Once the bag is formed, a dosing system positioned around the forming tube can fill it with your product. Then, the same sealing jaws that formed the bag form a seal on its top edge, creating a finished and ready-to-ship package.

If you have a need for additional printing, the machine can add date/batch codes and graphics to each completed package. It’s also possible to add a tear notch or euro punch so that the bag can hang on a display for easy retail sales. Depending on how your bags will be used, you can even choose to have the machine add a zipper for added convenience and security. You can find a number of trustworthy packaging machinery companies offering a range of vertical form fill seal machines to fit any type of product and bag.

Liquid Filling Machine

A liquid filling machine pours a fluid into containers that may be bottles, vials, cans, or pouches. Liquid packaging machines may also wash and sterilize containers to remove dust, contaminants, or microbial growth. Some machines have multiple fill heads that increase a machine’s top speed and capacity.

While the exact specifications of liquid filling machinery vary, most systems follow the same general principle. Bottles or jars pass along a conveyor in the machine and are filled before continuing on to the next step of production. The precise technology varies by product and container type, but inline liquid packaging systems are less expensive and more easily upgraded than rotary systems.

Overflow filling machines are especially useful for clear containers because they can produce consistent levels of liquid in each bottle even if the contents of each bottle differ slightly. You must also consider your desired automation level and production capacity when selecting liquid filling machines. Buying from the best supplier will help you get quality and advanced machinery in customized specifications at lucrative costs.

Conclusion

Business means investment. Packaging machines are a major investment to run any business. First choose the right packaging machines for your needs considering the health and well-being of your production line and ensuring that you get the most value out of your investment.

0 notes