#wire cut edm machine factory

Text

Injection Mold Factory Processing Mold Application Field

Injection mold is an important process equipment for the production of various industrial products. With the rapid development of the plastics industry, the promotion and application of plastic products in aviation, aerospace, electronics, machinery, ships and automobiles and other industrial fields, the market requirements for molds are also getting higher and higher. Nowadays, the mold design method of traditional injection mold manufacturers is increasingly unable to meet people’s requirements. Compared with traditional mold design, computer-aided engineering techniques can increase productivity, ensure product quality, and reduce costs and labor. In terms of strength, Injection mold has a big advantage.

For mold parts with higher hardness, some injection mold manufacturers cannot be processed by mechanical processing methods, and they most use electric discharge machining. In addition, wire EDM can also be used for sharp corners, deep cavity parts and narrow grooves of mold cavities. CNC lathes are mainly used to process the standard parts of die rods, as well as the mold cavities or cores of rotary bodies, such as injection molds for bottles and POTS, and forging molds for shaft and disc parts. In the injection mold processing, the application of CNC drilling machine can also play a role in improving the processing accuracy and shortening the processing cycle.

By increasing the investment in technology research and development, most production enterprises are optimizing the structural design of the mold system and the CAD/CAE/CAM of the forming part, making it more intelligent, improving the molding process of the forming part and the standardization level of the mold, and improving the accuracy and quality of the mold manufacturing.

Research and apply special materials with high performance and easy cutting for various types of mold parts can improve the performance of molds. In order to adapt to the diversification of the market and the trial production of new products, rapid prototyping technology is applied to the rapid manufacturing of forming molds, injection molds or die casting molds.

0 notes

Text

Assessing Equipment and Technological Capabilities in The Mold Parts Factory

The production equipment and technological prowess of the mold parts factory are pivotal factors that determine their efficiency, quality, and competitiveness in the manufacturing industry. This article delves into the intricate landscape of production equipment and technological advancements in the mold parts factory, examining their significance in driving innovation, precision, and operation.

The mold parts factory boasts an array of machinery tailored to meet the demands of modern manufacturing. High-precision CNC (Computer Numerical Control) machines, EDM (Electrical Discharge Machining) equipment, injection molding machines, and multi-axis machining centers form the backbone of production operations. These advanced machines enable factories to achieve tight tolerances, intricate geometries, and consistent quality in mold parts production.

CNC machining stands at the forefront of mold parts manufacturing, offering good precision, flexibility, and repeatability. Equipped with multi-axis capabilities and software, CNC machines translate digital designs into physical components with accuracy and efficiency. From milling and turning to grinding and drilling, CNC machining processes deliver good surface finishes and dimensional accuracy, meeting the stringent requirements of mold parts production.

The integration of additive manufacturing technologies such as 3D printing and rapid prototyping changes the production landscape of the mold parts factory. Additive manufacturing processes enable rapid iteration, design optimization, and on-demand production of complex geometries with material waste. By complementing traditional machining methods, additive manufacturing enhances design freedom, accelerates time-to-market, and facilitates customization in mold parts fabrication.

EDM techniques play a critical role in mold parts manufacturing, particularly for producing intricate cavities, cores, and inserts with micron-level precision. Wire EDM and sinker EDM processes utilize electrical discharge to precisely erode metal surfaces, achieving complex shapes and tight tolerances with distortion. EDM technology enables the mold parts factory to overcome the limitations of conventional machining methods and deliver components of good accuracy and surface quality.

Injection molding is a cornerstone technology in mold parts production, allowing factories to mass-produce plastic components with high efficiency and consistency. Advanced injection molding machines equipped with servo-driven systems, hot-runner systems, and mold temperature control units optimize process parameters for productivity and part quality. the mold parts factory leverages injection molding expertise to produce a wide range of components, from consumer electronics to automotive parts.

Automation and robotics play an increasingly prominent role in the mold parts factory, enhancing productivity, reducing labor costs, and ensuring process reliability. Automated manufacturing systems integrate CNC machines, robotic arms, conveyor systems, and material handling equipment to streamline production workflows and reduce human intervention. Robotic automation enables tasks such as loading/unloading, inspection, and assembly to be performed with precision and consistency, improving overall operational efficiency.

Optimized tooling design and toolpath programming are instrumental in improving the efficiency and performance of production equipment in the mold parts factory. CAD/CAM software tools enable engineers to design complex tool geometries, simulate machining operations, and generate optimized toolpaths for CNC machining and EDM processes. By fine-tuning cutting parameters, feed rates, and tool trajectories, factories can reduce cycle times, reduce tool wear, and achieve good surface finishes in mold parts production.

The production equipment and technological capabilities of the mold parts factory represent the cornerstone of their operations and competitiveness in the global marketplace. With machinery, advanced CNC machining, precision EDM techniques, injection molding expertise, automated manufacturing systems, optimized tooling, and continuous technological advancements, the mold parts factory empowers itself to meet the evolving demands of customers, drive innovation, and deliver superior quality mold parts to diverse industries. Through strategic investments in technology, talent, and process optimization, the mold parts factory forges a path toward, ensuring its position as a leader in the dynamic landscape of manufacturing.

0 notes

Text

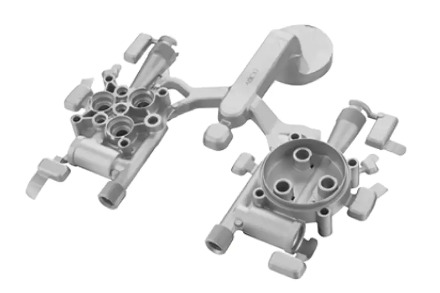

OEM China Factory Automotive High Pressure Cleaning Pump

Product Name:Die-casting moulds and parts

Material:Stainless Steel , Brass , Copper , Aluminum alloy .

Technics:High-speed CNC, EDM, wire cutting, closing device, drilling, engraving machine and mold department.

Application:Auto parts series, fishing gear series, electric chain saw series, water pump die casting series, electric and pneumatic series, etc.

Size:Customize by Ningheng

Certification:ISO9001 ,TS16949

Brand:Ningheng

0 notes

Text

Recommendation From EDM Parts Supplier On DM Maintenance

Wire EDM Parts refer to the components of a Wire Electrical Discharge Machine that may need to be replaced over time due to wear, damage, or performance degradation.

Ankok is an international EDM parts suppliers with an extensive range of all OEM EDM parts. The functionality and appearance of all brand EDM parts are fully compliant with the OEM guidelines.

With current technology, consumable parts can play a critical role in the overall success of a machine investment.

With the use of EDM parts manufactured and supplied by Ankok, regardless of age, the cutting time for all machines was exactly the same as it had been when they were new from the factory.

This not only demonstrates the potential power of procuring from a reputed EDM parts supplier but also regular maintenance of the machines. For example:

Wires

Perhaps the most obvious consumable to affect wire EDM performance is the wire itself. To truly maximize cutting performance without wire breakage or sacrifices in accuracy or surface finish, users should select wire based on the manufacturer’s recommendations and connect with trusted EDM parts suppliers.

Wire Guides

An EDM’s wire guides are usually the most important components for cutting highly accurate parts. With closed wire guides, the clearance between the wire and the opening in the guide will greatly influence the machine’s ability to cut accurately, especially where tapers are concerned.

Water Filters

Water filters also play an important role in getting the most out of a wire EDM. Filters need to be the correct size to achieve adequate flushing pressure, and also must be properly designed to keep EDM particles from being brought back into the cutting zone.

Too often though, little attention is paid to the consumable parts that will be used in the machine’s day-to-day operations. Those manufacturers who focus on using the best-suited consumables taken from a trusted EDM parts suppliers, such as Ankok will find themselves getting far more out of their machines than would otherwise be possible.

By consistently providing top quality EDM parts, Ankok has established a highly respected name in the EDM industry.

Connect with us and start on your success journey.

#EDM Filters#Wire EDM Filters#EDM Filter Suppliers#EDM Filter Manufacturers#Wire EDM Filter Suppliers#Wire EDM Filter Manufacturers#EDM Parts Suppliers#Mitsubishi EDM Parts#EDM Machine Parts Suppliers#Wire EDM Consumables Suppliers

0 notes

Text

5 Reasons To Choose Us As Your EDM Parts Suppliers

We've got all kinds of consumables for wire cut machines, die sinks, and drill EDMs, from electrodes to paper filters, copper pipes, fluids, tubes, and wires. No matter what type of EDM parts you need, you can always find it here. Due to the fact that we offer high quality products at an affordable price and provide professional service, increasing number of customers want to establish a long-term business relationship as their trusted EDM parts supplier, with us and buy EDM Parts on a monthly basis.

5 reason for you to choose us:

Technical Support

Established a business partnership with customers focusing on customers – From the production process of your product to the production method, to help you solve the problem of product processing, let us better understand your thoughts and provide technical support.

Engineering Service

Our engineers are available for technical maintenance support, application training, and upgrade management to improve customer satisfaction.

Training

We offer online training and factory training service suiting all customers’ needs

Life Cycle Service

We grantee customers a life time support service.

Cost Performance

With Strong company strength, first-class automatic production line. Known for our robustness, corrosion resistance and durability, these are offered at industry competent prices.

When you purchase from a reputed EDM parts supplier, you get good quality for the right price — and pieces that will work seamlessly with your machine. Ankok offers EDM parts for all major brands of Wire EDM manufacturers in the marketplace, so whatever you’re looking for, we’ve got it. We offer high quality EDM parts that have been tested extensively for quality and reliability. We also can supply Wire and Sinker EDM filters, power feed contacts, and resin services for bottles and virgin resin for all Wire EDM brands.

We are proactive in conducting maintenance with all of our equipment, especially our critical machines that you count on to deliver quality results. By staying proactive we prevent the types of problems that would otherwise jeopardize your project through inaccuracy or delay.

With the combination of short-term and long-term strategies, we offer the best in productivity and reliability so that we can deliver what you need when you need it.

Ankok is proud to be a full service EDM parts supplier for Wire EDM and Sinker EDM. Connect with us and get a quote today.

#EDM Filter#Wire EDM Filter#EDM Filter Suppliers#EDM Filter Manufacturers#Wire EDM Filter Suppliers#Wire EDM Filter Manufacturers#EDM Parts Suppliers#Mitsubishi EDM Parts#EDM Machine Parts Suppliers#Wire EDM Consumables Suppliers

0 notes

Text

ChinaForgingsManufacturs

ChinaForgingsManufacturs Product nameCold forged valve steel parts cv joint parts conrod connecting rod oem engine hot metal die forging parts for motor Sample7 ~ 10 working days Deal withMaterial cutting, machining, surface treatment, packaging Surface treatmentPowder coating, zinc plating, chrome plating, nickel plating Tolerance0.05 Drawing formatDXF / DWG / STEP / IGS / PDF Quality100% guaranteed QCISO9001: 2015, 100% inspection AdvantageOne-stop solution FeatureOEM ODM support Types of: Broaching, drilling, etching / chemical processing, laser processing, milling, other processing services, turning, wire cutting Material capabilities: Aluminum, brass, bronze, copper, hardened metal, stainless steel, steel alloy Whether to carry out micro-machining: Not micromachining Our factory supply OEM service(custom service) in precision investment casting, which are also called lost wax casting, We have been committed to this technique for over 10 years. Our specialized engineer can provide you the full-service of technology advice and products improving projection, and also reduce the cost of the parts. Investment casting (lost wax casting)Stainless steel casting Alloy steel casting Carbon steel casting Bronze and Brass casting Aluminum casting MachiningDrilling, Reaming and tapping CNC Turning machining CNC Milling machining Wire EDM Heat treatmentAnnealing Solution Normalizing Tempering Quenching Induction hardening Hardening and tempering Surface treatmentManual polishing Electro-polishing Electro-plating Power coating TumblingChinaForgingsManufacturs website:http://www.metalpartcasting.com/forgings/

0 notes

Text

Strider knives axe

No matter which of their knives you choose, we are confident that you will be very satisfied with your purchase. Each of the custom, limited edition knives is a showpiece of heirloom quality. SOE / Strider Knives 3-Day Pack Brand, Special Operations Equipment / Stride Knives Item Name, (acquired) Color, Olive Drab Part Number, (N/. Their custom auto knives are unique pieces of art. Their production knife models offer the best design, function, and value of any knife on the market today. 75 AR or a fixed blade, Strider knives make an excellent high-quality, American made choice for your next blade. Built for rigorous use these knives have a style and flair that have no equal. They craft small batches of their knives so that they can take the time to individually hand fit and finish each knife to a level rarely seen in a factory knife. Strider Knives Strider knives have built a reputation as some of the most highly sought after blades on the market. But when the lieutenant swung the axe, the tool clanged against some unseen. The high tech components are assembled and hand fit by dedicated and caring craftsmen in their Artesia, California facility. While the soldiers prepared for the beheading, Camille watched Strider. Email Me Strider Knives PT Knife Black G-10 Flame Anodized. Strider XL-Tanto 5.125' Fixed Blade Knife / Black Paracord / Black Tool Steel ( Pre Owned ) Strider XL-Tanto 5.125' Fixed Blade Knife / Black Paracord / Black Tool Steel ( Pre Owned ) 289.00. Pro-Tech knives are built with the most current high tech manufacturing processes that include CNC Machining, Wire EDM, Laser Cutting, etc. Strider Knives PT Knife Coyote Brown G-10 Bead Blast (2.75' Black Plain) out of stock. Strider SNG 3.75' Folding Knife / Black Gunner Grip & Flamed Ti / Tiger Strip CTS-XHP ( Pre Owned ) 799.00. The beautiful and functional Pro-Tech knife is a blend of the finest materials available and a commitment to craftsmanship. Strider Knives became so popular that the company. Pro-Tech Strider 2401 SnG AUTO Folding Knife 3.5" 154CM Stonewashed Plain Blade, Black Aluminum Handles I never thought I would own a knife making company, to have employees, it just sort of happened that way.

0 notes

Text

Pull the pin challenge 22

Pull the pin challenge 22 upgrade#

Pull the pin challenge 22 full#

The figure below shows the cross-section view for a symmetric weight block.

Pull the pin challenge 22 full#

To illustrate them, imagine cutting a bowling ball in half with an imaginary cutting plane (as shown below) so as to expose the full cross-section of the weight block inside the bowling ball. There are two basic types of weight blocks used, symmetric weight blocks and asymmetric weight blocks. These play an important role in the physics of bowling and (consequently) a bowler's performance, as will be discussed. The mass and shape of the weight block affects the spin of the bowling ball and how it curves as it rolls down the lane. The bowling ball consists of a hard outer shell with a weight block in the core (the inside of the bowling ball). The figure below shows two ten-pin balls. The physics of bowling discussed here will be with regards to ten-pin bowling, which is one of the most common sports in the game of bowling. For ten-pin bowling, regulating bodies allow for a maximum weight of 16 lb (7.2 kg), and a maximum diameter of 8.6 inches (21.8 cm) (ref: ). Ten-pin bowling balls generally have three holes drilled into them two finger holes and one thumb hole for gripping. The “Ultimate” Trigger Kit for Ruger® 10/22® installs easily into the factory trigger housing with no tooling or gunsmithing required.A bowling ball is made from urethane, plastic, reactive resin or a combination of these materials. The “Ultimate” Trigger Kit does away with this design, replacing the spring and plunger with a single coil of music wire spring that flexes and rebounds with zero friction, binding or other trigger “noise.” The Ultimate 10/22® Trigger Kit The design of the factory spring and plunger requires a heavier spring in order to have consistent, positive resets. We’re keeping the upgrades coming with the “Ultimate” 10/22® trigger kit, including a redesign of the factory trigger return spring and plunger. By changing the geometry of this engagement, we’ve created a trigger kit that is incredibly light, incredibly safe and reliable long-term, ensuring your trigger pull doesn’t change even after many thousands of rounds have been fired. These precision-machined parts allow for an extremely light trigger pull, while still maintaining strong sear-hammer engagement. The parts are machined from billet stock and critical surfaces are EDM cut for the most precise machining, allowing for a unique, completely redesigned sear-hammer engagement. The upgraded 10/22® hammer and 10/22® sear are made of hardened, impact resistant S-7 tool steel. The trigger also mimics the design of the TANDEMKROSS “Victory” Triggers for rimfire pistols, offering a consistent trigger feel across pistol and rifle during a Rimfire Challenge or Steel Challenge competition. The flat-face trigger helps promote good technique to make it easier and more natural to pull the trigger consistently and correctly. The flat-face allows the user to place their finger low on the trigger, boosting leverage and reducing the trigger pull even further. The upgraded 10/22® trigger shoe features TANDEMKROSS’ signature flat-faced, textured design for the ultimate purchase and control, even when shooting with rain, sweat or gloves.

Pull the pin challenge 22 upgrade#

TANDEMKROSS Flat-Faced 10/22® Trigger Upgrade Read on for further details about each part of this ultimate trigger kit. The trigger reset - one of the most important, but often overlooked, aspects for high-performance shooting - has been designed to be quick, smooth and consistent, even with a very light trigger pull. While there is minimal over-travel in the design of the trigger, an over-travel adjustment screw allows for further refinement. With TANDEMKROSS’ years of experience in the shooting sports market and Brimstone Gunsmithing’s decade of 10/22® trigger work, every aspect of the trigger experience has been redesigned, with improvements to the trigger break, reset and pre- and post-travel. The “Ultimate” Trigger Kit for Ruger® 10/22® from TANDEMKROSS and Brimstone Gunsmithing offers just that - the ultimate 10/22® trigger upgrade for competitive shooters, precision shooters and anyone who wants a high-performance trigger system in their 10/22® rifle. The Ruger® 10/22® aftermarket just got the ultimate addition. This kit must be installed into your existing trigger housing. *Please Note: this kit includes a trigger shoe, hammer, sear, trigger spring, pin and hardware. Kit significantly reduces trigger pull just above or just below 2 lbs Flat-faced, textured trigger shoe offers the ultimate purchase and control for faster shooting, removes pre-travel and is post-travel adjustableĬompletely redesigned sear and hammer produce crisper, smoother trigger pull while boosting reliability and safety

0 notes

Text

electrode to make a cavity of a plastic

You may be able to throughput a lot of detail, and EDM can do much, but surface grinding is still an essential part of the toolmaker. Both milling and grinding machines need good accessories to carry out tasks properly. A typical milling area should include a granite surface plate, Gage and the indicator of the test surface, the indicator of fall and standing height gauge to mark the lines, square and the indicator lock, angle plates, square block machine, magnetic and nonmagnetic breast plates, and turning accessories. A vertical EDM machine uses an electrode to make a cavity of a plastic injection machine molding.Our machine function steady-going, is good selling at home and abroad, and well received.

Aerospace machine tools providing aerospace 5-axis machining do everything from round holes, through pinholes to die ejector openings. Some of the work done in typical precision mills include base to the square of the core and cavity blocks, die blocks, nails and basic finishing blows, finishing lines and parting and closing angles offs locking assembly slides. A wire machine uses a wire to cut metal for surgery machining for manufacturing. You can have several configurations including brick machines, CNC drill and tap the area, CNC milling, CNC or milling. Ningbo Yinzhou Nuoya Cement Block Machine Factory, a professional manufacturer and exporter of all kinds of Single and Multi Spring brick machine,concrete brick machine,block machine.

We are a member of Building Block Association with excellent and advanced technology. Breast plates, precision lathes, angle plates and grinding wheel dressers must be of the highest quality.The mills used in a precision tool and die shop or injection mould making shop is some of the most Custom Screw Barrels Suppliers important brick machine tools of all. These should be reliable. Block machine is more closely related to making tools for other machines, people often overlook the use of machines. These silent workhorses include surface grinding machines Aerospace axis machining centers milling machines and, of course their qualified and skilled operators. Also you can groove and thread parts on a CNC turning center. Our line of products has already exceeded rest of the industry.

Our factory stick hard and fast to the principle of quality first, service supreme, technology one-up, implement people foremost, vitalize industry with science and technology, constantly upgrade quality, production and service ability. What can be done with a brick machine? In manufacturing, you can use this tool for milling, drilling, milling, drilling and counter boring. EDM can be vertical or wire. Let buyer relieved in buying and desirable in using. We give guarantee to keep in good repair for long term. Aerospace grinding, however, is absolutely essential to the manufacturing process of tools. EDM can also take advantage of CNC operations. With the extensive use of electrode EDM machining, the need for precision grinding has declined in volume. Just imagine not having the ability to do this work and the whole process stops.

0 notes

Photo

📢 Keytex Machines Celebrating Kargil Vijay Diwas 2022

➡ "We Salute The Daring Souls Of India."

📢 CNC Machine Job Work India

🟢 Keytex Machines A Place For Precise Machining

🟢 Design, Development & Manufacturing of Any Measurable Parts

✅ Precision We Achieve

✅ CNC Turning Facility

✅ CNC Wire Cut Machining

✅ CNC Milling Machining Service

✅ EDM Spark Erosion Service

✅ Customized Part Machining Service

🌐 https://www.keytexmachines.com/

☎️ +91 99789 22288

✉️ [email protected]

🏠 535, Road No: 5, Opp: Jivraj Tea Factory, GIDC Sachin, Surat - 394230, Gujarat

#manufactures#cncwirecutmachine#cncwire#cncwirecutting#cncmillingmachiningservice#milling#cncturningfacility#jobwork#Job#cnccuting#machining#clients#Celebrating#services#machineservices#indian#kargilvijaydiwas#indianarmy#kargil#indianairforce#indiannavy#kargilwar#bharat#vandematram#bsf#bharatmatakijai#paracommando#indianflag#indianarmyfans#iloveindia

0 notes

Text

Klarm Machining Offers CNC Machining Service

New Post has been published on http://www.cncmachinings.com/klarm-machining-offers-cnc-machining-service/

Klarm Machining Offers CNC Machining Service

The essential facilitate system for processing comprises of X-, Y-, and Z-tomahawks, which are generally opposite to one another, as demonstrated in big cnc machined part made in china. On a vertical shaft machine, the X-and Y-tomahawks are the table developments and the Z-hub is the vertical axle development, actually like in manual processing. To comprehend the tomahawks of a level shaft machine, it is useful to envision a vertical machine laid on its back; the axle advances toward and away from the part in the Z-pivot, the X-hub is corresponding to the floor, and the Y-hub goes here and there. The models in this unit will apply to vertical axle machines.

Contingent upon the sort of processing machine being modified, there might be just two, or at times four or five, programmable tomahawks. Some CNC knee plants don’t have a CNC drive on the plume (Z-pivot). These machines require the Z-hub to be situated physically before executing customized processing moves in the X-and Y-tomahawks. Most of machining focuses have three programmable tomahawks (X, Y, and Z), so the models in this unit will apply to that style of machine. For the vast majority of the programming models in this unit, facilitate positions will be according to the focal point of the cutting apparatus.

CNC plant such as the tight tolerance cnc machining supplier controls can “flip” the organize plane for complex processing tasks. Instances of this are past the extent of this content, however guarantee that the right facilitate situation direction is actuated when programming.

The standard three-pivot system just portrayed uses the XY plane. A few controls default to the XY plane, however others may necessitate that it is explicitly actuated. The protected beginning part of the program is a decent spot to actuate the standard XY plane arrange system with a G17 order.

Sorts OF MOTION FOR MILLING

Quick Traverse-GO

Fast navigate utilizing the G0 order will rapidly situate instruments prior to starting a machining activity.

Cutting instruments ought to never contact the work during quick moves. There are a few security contemplation when programming fast developments in a machining focus. Machining focuses may have odd-or sporadic molded work-holding gadgets or workpieces, so extraordinary consideration should be paid to things like braces, tight clamp jaws, workstops, and installation jolts. On certain workpieces, part highlights may jut above others, causing another worry for apparatus crashes.

In CNC plant programming in machining services suppliers china, it is standard practice to set up a security zone over the workpiece or workholding gadget called a freedom plane. Ordinarily, a leeway plane of 0.050″ or 0.100″ over the material surface is utilized. Program fast moves at or over the leeway plane and try not to program any quick moves beneath the freedom plane.

Direct Interpolation- – G1

Direct interjection implies that the machine synchronizes the movement of (at least one) hub to move the device in an orderly fashion. At the point when more than one pivot is moving, as while moving slantingly, the machine should begin moving every hub at absolutely a similar time, move them at the fitting feed rate, and quit moving the two tomahawks at the planned objective at decisively a similar time.

Direct processing may require movement in one pivot alone (processing a way corresponding to a machine’s hub), in two tomahawks (for an inclining), or in three tomahawks (for a corner to corner on a skewed plane; compound precise movement).

The straight movement created by direct interjection might be utilized for diving a drill or counterbore into the workpiece, taking care of a face factory across the highest point of a section, side processing profiles with straight surfaces, and that’s only the tip of the iceberg.

To move the processing instrument in a direct added development, a G1 order is utilized alongside an end position for the development along one, two, or three tomahawks. A feed rate should likewise go with the recently customized position. Since G1 is a modular code, it will stay dynamic until dropped or it is superseded with a clashing code.

This article is from http://www.cncmachinings.com/

#big cnc machined part made in china#china aluminum grinding parts and service#china brass cnc machining parts manufacturers#china cnc lathe machining gift parts manufacturers#china cnc plastic turning parts and service manufacturers#china machining carbon fiber#china milling and engraving machine#china milling machining#cnc machine for carbon fibre factory#cnc turning part#high precision cnc machining auto titanium parts factory#machining part made in china#machining services suppliers china#precision cnc machined part suppliers china#tight tolerance cnc machining supplier#titanium grinded machining parts suppliers#wire cut edm machine factory#Featured Articles

0 notes

Text

Die Use

Posted from 5 axis machining China blog

Die Use

Since taps are so difficult and weak, sometimes a tap may break inside an opening. Tap expulsion is precarious, yet there are hardly any strategies that might be endeavored. In the event that the tap is in pieces in the opening, it might have the option to be taken out by utilizing a mallet and punch to break it into littler pieces in quality instrument machining service. At that point a scriber or tweezers may attempt to turn and eliminate the pieces.

When utilizing this technique, spread the tap with a cloth when hitting with a punch. This will help contain hard, sharp pieces of the tap that can be tossed and cause injury.

In the event that the tap is fairly unblemished, a tap extractor might be utilized to eliminate a wrecked tap. Tap extractors have fingers that slide down the flutes of the messed up tap, permitting it to be turned around out of the opening with a tap wrench.

In the event that none of different techniques is fruitful, an electrical release machine (EDM) must be utilized by 4 axis cnc machining service factory to disintegrate the messed up tap from the opening.

At the point when it is important to cut outer strings on a round workpiece, a stringing kick the bucket can be utilized. Stringing passes on can be made of high carbon steel or rapid steel (HSS). High carbon steel kicks the bucket are generally utilized for fixing existing harmed strings. They may wear rapidly whenever used to create new strings, particularly when utilized on harder materials. Rapid steel passes on are more enthusiastically and more tough, and can be utilized to make new strings. A few kicks the bucket are somewhat movable to change the attack of the string, while others are strong and can’t be balanced. The split round pass on has a screw that can be utilized to make slight modifications. The two-piece pass on has two cutters that are mounted in a neckline. When utilizing a two-piece kick the bucket, it is significant that the chamfered side of the two cutters faces a similar heading. Screws on each side of the collarallow for more change than with the split round pass on.

Strong bites the dust are accessible in round and hexagon shapes. Figure 3.6.36 shows instances of these sorts of string cutting kicks the bucket. The workpiece width ought to never be bigger than the ostensible significant breadth of the string to be cut, and bites the dust cut best when the workpiece measurement is really a couple of thousandths littler. Making a chamfer on the finish of the workpiece with a document, processor, or belt/circle sander will help with beginning the pass on. One side of the string cutting teeth will have a chamfer for beginning the cut. A few bites the dust are Named “start this side” to enable the client to distinguish this element.

Bite the dust stocks are utilized by china precision tooling manufacturers to hold stringing passes on when cutting strings. In the event that utilizing a movable kick the bucket, first change the pass on to fit over a completed part or screw so it is marginally free. At that point mount the pass on in a bite the dust stock and spot the chamfered side of the cutting teeth over the workpiece and apply descending weight as the pass on and stock are pivoted. Bites the dust effectively walk when exceptional down a workpiece, making further strings be cut on one side than the other. Give exceptional consideration to this and every now and again watch that the bite the dust is square on the workpiece and that the string profundity is uniform. Continuously utilize a liberal gracefully of scaling liquid and back off the pass on every now and again as you would a tap. The last not many strings will be inadequate due to the chamfer on the pass on. Flip the pass on so that the unchamfered side leads, and run it over the work to recut the last scarcely any inadequate strings to full profundity.

Check the string with a mating part or a go/off limits ring gage. In the event that the go gage doesn’t fit, alter the bite the dust somewhat and rehash the cycle until the go gage strings onto the work unreservedly. In the event that a string length is given, the necessary number of turns of a stringing pass on can be resolved a similar way as when tapping. For inch-based strings, increase length by TPI. For metric strings, separate length by pitch.

This article is from http://www.5axismachiningchina.com

#4 axis cnc machining service factory#big cnc machined part made in china#china cnc aluminum milling parts suppliers#china cnc lathe machining gift parts manufacturers#china cnc plastic turning parts and service manufacturers#china customized cnc milling parts manufacturers#china luminum cnc milling machining suppliers#china milling and engraving machine#china milling machining#china precision tooling manufacturers#cnc machining brass parts china#cnc turning part#custom cnc machined precision machining titanium parts factory#graphite machining service factory#machining part made in china#precision cnc machined part suppliers china#precision parts china#quality instrument machining service#titanium grinding parts and service factory#wire cut edm machine factory

0 notes

Text

Factory Sales OEM Automotive Four circuit Value Body

Product Name:Die-casting moulds and parts

Material:Stainless Steel , Brass , Copper , Aluminum alloy .

Technics:High-speed CNC, EDM, wire cutting, closing device, drilling, engraving machine and mold department.

Application:Auto parts series, fishing gear series, electric chain saw series, water pump die casting series, electric and pneumatic series, etc.

Size:Customize by Ningheng

Certification:ISO9001 ,TS16949

Brand:Ningheng

0 notes

Text

Klarm Machining Promotes CNC Milling Machining

Klarm Machining Promotes CNC Milling Machining

Custom Fixtures

At the point when a section has an exceptional shape and needs exact area alongside a profoundly secure clasping framework, a custom installation can be utilized. An installation is a specially fabricated workholding gadget explicitly intended to oblige a particular part. This technique can be extremely valuable for protecting parts with abnormal shapes and permits reliable…

View On WordPress

#4 axis cnc machining service factory#abs parts manufacturers china#carbon fiber cnc cutting service manufacturers#china china custom cnc turning parts#china cnc machine parts suppliers#china luminum cnc milling machining suppliers#china precision machining services suppliers#china precision tooling manufacturers#cnc high precision machining#cnc machined carbon fiber parts factory#cnc machinery titanium parts china#cnc machining brass parts china#copper turning parts suppliers#graphite machining service factory#high precision stainless steel machined parts factory#precision cnc parts#quality instrument machining service#titanium grinding parts and service factory#wire edm machining factory

0 notes

Text

NagualMetal Precision Manufacturing Limited.

CNC Sheet Metal

NPM is specialist manufacturer of CNC sheet metal in China for many consumer and industrial products. We provide a complete turnkey solution for your CNC sheet metal requirements.

Some of the CNC sheet metal services we provide include:

CNC turret punching

Laser cutting

Guillotining

CNC Folding and Bending

Metal Rolling

Band Sawing

Tube Bending

Product Assembly

NPM is committed to producing high quality CNC sheet metal components and providing excellent service and support to our customers. Our dedicated and highly experienced staff and constantly updated processes and machinery have enabled NagualMetal to grow and remain competitive in China’s CNC sheet metal industry. Each member of our company

NagualMetal CNC Machining in china

Branch of NagualMetal is a specialist China manufacturer and supplier offering the full range of CNC/EDM engineering services, comprising CNC Machining, CNC Milling, CNC Lathe Turning, EDM Wire Cutting and EDM Eroding. Computer Assisted Manufacturing (CAM) programs are run on customer 2D or 3D CAD data files. CAM programs are then directly downloaded to one of our CNC machines for automated machining.

Our lead times are fast, depending on the nature and volume of work. Automatic tool changers, high speed spindles, and fast feed rates allow us to machine components efficiently and accurately.

A wide range of materials such as aluminium, steel, hardened tool steel, stainless steel cast iron, brass, copper, polycarbonate, ABS, acrylic, PET, nylon and more can be machined to suit your needs.

NagualMetal is an experienced Precision Manufacturer specializing in precision tooling, automated manufacturing equipment, and prototypes requiring close tolerance. Our wire cut EDM services are perfect for tooling assemblies and EDM intensive component parts.

Along with top quality services, our operation offers quick turn delivery, and can assist you with every aspect of your project, from design to manufacturing.

Our staff of experienced machining professionals can assist you in solving the most challenging CNC machining and manufacturing tasks. From complex 3-D machining to simple hole drilling, we can be your first choice for CNC and EDM.

Email RFQ and Drawings to:

[email protected]

Follow are the informations about our precision parts by CNC machining.

--------------------

● Materials for CNC Precision machining parts

We can process product materials are:

An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from 1050-7475), commonly used are: 2011,5052,6061,7075, etc.

(2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000

(3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades (JIS grade corresponds to the basic, together with the SUS can): 201,301,303,304,314,316,420,430,630

Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15)

● CNC Precision machining parts accuracy

Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm

● Maximum size of Precision parts suit to CNC machining

Lathe parts (turning parts , such as axes, coupling,bushing, thread rod , etc.) following the outer diameter of 300mm, length less than 150mm

Milling parts (box, cylinder, etc.) 800mm long, 330mm wide, 120mm high

Branch of NagualMetal is specialized in making various springs parts,including disc springs,extension springs,compression springs,snap springs,wave springs,flat spiral springs,drum springs,leaf springs,pagoda springs,spring lamination and kinds of stamping parts etc.

With powerful technology,good producing equipment and pretty quality,the factory passed ISO9000:2008 quality system and obtained good public praise in this field.

Following the concepts of development born of innovation and quality based of constant. The company is dedicating to be internationally competitive and to be the world-known spring supplier.

#stamping cnc machining cnc lather#cnc milling#Branch of NagualMetal is specialized in making various springs parts

1 note

·

View note

Video

youtube

How is the brake pad mold wire cut? brake pad mould factory,brake moulds customized,brake moulds Factory,Truck brake pads molds

(1) The cavity of the brake pad mold, we mainly use the wire cutting machine to complete

(2) This is Wire Cut EDM, a slow-moving wire-feeding machine with a processing range of 500X300

(3) As required, the dimensional accuracy is ±0.005, and the surface roughness is Ra0.37

(4) It can be used without polishing after cavity cutting

(5) Applicable to the following molds:

Disc Brake pad mould ,Brake pad Back Plate moulds,Clutch brake pad mould,brake mold China Factory,brake press die storage,Leading Manufacturer of Brake Lining moulds,brake mould Custom-Made,brake pad moulds,Friction material preform mold,Disc Brake pads moulds ,Brake pads Back Plate molds,brake pad die,Drum sheet mold

JINAN HAIGUANG MOLD CO.,LTD

https://brake-mold.cn

WeChat/WhatsApp:+86 13953117306

0 notes