#injection molding advantages

Text

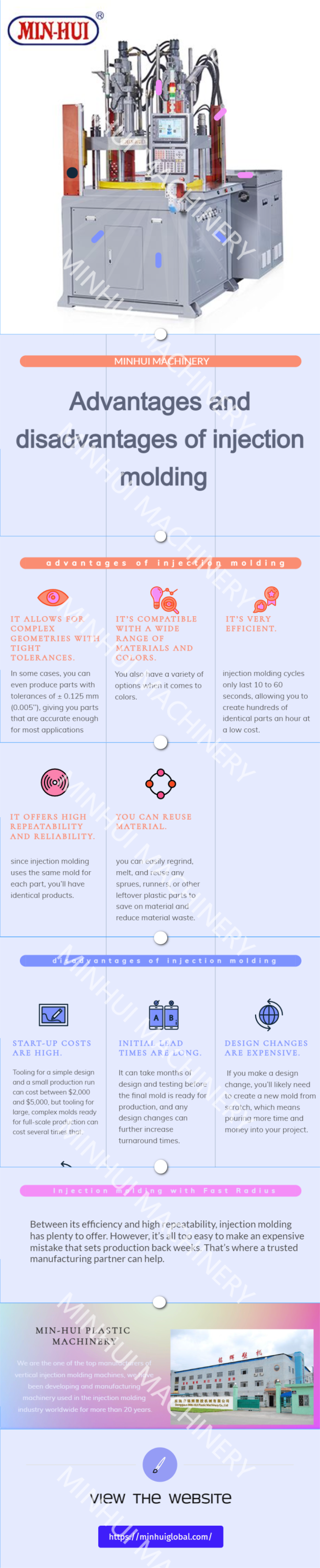

Advantages and disadvantages of injection molding

#minhui machinery#vertical injection molding machine#injection molding machine#min-hui#Advantages and disadvantages of injection molding

0 notes

Text

#Custom Injection Molding Services#Offshore Mold Making Services#Plastic Injection Molding Services#Plastic Injection Molding Parts#Plastic Injection Molding Services China#Injection Mold Tooling#Injection Mold Tooling Services#Custom Injection Mold Tooling#Offshore Injection Mold Tooling#Injection Mold Tooling Advantages#Injection Mold Tooling Suppliers#Automotive Injection Molding#Automotive Injection Molding Solutions#Automotive Injection Mold Makers#Rapid Injection Mold Tooling#Rapid Tooling#Rapid Injection Molding#Injection Molding Services#Injection Mold Making#Injection Molded Parts#Injection Molding Materials#Injection Molding Services China#CNC Machined Parts China#CNC Machining Services#Plastic CNC Machined Parts#Metal CNC Machined Parts#CNC Sheet Metal Fabrication#CNC Rapid Tooling#Injection Mold Designing#Injection Mold Design

0 notes

Text

In 2021, dirty secrets about the use of bioweapons are revealed inside BSAA + there are direct hints in Umbrella Corps that Wesker is alive. I just combine the two puzzle pieces together in my head. So let's look at another interesting post-2009 scenario.

AU - ELEGY OF FREE RADICALS

Chris was once careless about eliminating Wesker. Knowing his nature, he still didn't check Wesker's presumed place of death properly. Relying on his own luck, Chris left the place of battle and never returned there. But he had to go back. It has become his mistake.

Chris reported the scene of the victory to the BSAA. Rotten BSAA could have used that data in any way they wanted. Like going back there and checking out the volcano. They could have indicated on the documents that they were headed to clear the area of the remnants of Uroboros, but in fact to search for Wesker's remains to get rich off the sale and study of his unique biomaterial. But what they didn't expect was to find him alive. Badly injured, helpless, but somehow alive.

Taking advantage of the weakness of the still living organism, he was taken to the secret laboratory of the headquarters. Now Wesker could be under the supervision of BSAA scientists for a very long time. He's much more useful alive than dead. His knowledge, skills, all of it could be utilized. And it was also possible to conduct endless experiments on his unusual body... Testing the limits of his abilities, testing various poisons, looking at the lethality of their new weapons, and etc. He was once again a puppet, as he had once been in Spencer's hands, from which he had miraculously escaped.

The BSAA kept Wesker's abilities under strict control, he was trivially stripped of any PG67A/W injections, replaced with an alternative that was only necessary for his body to regenerate damage after the battle in the volcano, but didn't provide any additional benefits. So he would remain weak but healthy.

Another remedy was also applied to him, eliminating the consequences of merging with the Uroboros, which modified his body in a volcano. It was discovered in 2011, after the events of Revelations 2. It was rude to call it just a serum, it was something more, because it did not remove the virus itself from the body, but brought it into a more stable form, allowing Wesker to take his ordinary appearance. With him, in this form, it became easier for employees to work.

The BSAA restored Wesker, stripped of his strength, any dignity, as well as his freedom. He was bedridden for several years and various weapons were tested on him, then recorded how his body reacted and at what rate it recovered.

An immobilized lab rat, a deserved punishment for someone like him?

Perhaps.

It was thanks to his "sacrifice" that the anti-regeneration weapon was invented, which had once come in handy for Chris in the battle against Mold.

Just think… how many things could the BSAA have invented using the infinite resources of Wesker's body? He was terrified of these thoughts. Terror at the realization that he had no chance of escape, that he was trapped here forever, that he would continue to have his organs taken out of him and be forced into endless pain. He reflected that he hadn't actually managed to do so many contradictory things to deserve eternal torment. And it's better to let him die than to endure this hell. But his own body played a cruel joke without dying. It was an expert on regeneration. His pride was trampled when he begged for death.

BSAA absolutely did not spend any painkillers and sleeping pills on Wesker, absolutely all experiments were carried out when he was conscious. They had already spent a lot of money on him during his recovery, it was a waste to spend even more on someone who could repair any of his damage.

Pain and terror haunted him for six years. He cursed what he used to idolize in himself.

And then he was forced to work for them. In 6 years he had grown accustomed to the constant pain and had already learned to see himself as nothing, sending his consciousness into free floating. Deep in his thoughts, he created a place where he learned to ignore the endless physical torment. But when he was put on his feet and pulled out of this place… Wesker was even more devastated.

It was unusual for him to suddenly return to normal work, all this created a mess in his head, reality seemed to be nonsense. The usual paperwork after hell? Are you kidding me?!

Morally, he was destroyed. His psyche was severely damaged. Wesker from the "torture room" was locked in a cell that looked like a combination of a room and a laboratory. For fear of being put back on the operating table again, he dutifully began to work and develop various things that BSAA would use in the future. But it wasn't life either. Weakened body, lack of abilities... he wanted to die, but he couldn't afford it, because he was practically immortal. Although, even if he used a weapon that stops regeneration on himself... he still wouldn't kill himself.

«Not here»

«Not like this»

At times he thought he was balancing on the fine line between normalcy and insanity. He saw people at best once every two weeks who came to check on his work and were not at all talkative. Wesker had always been convinced he didn't need company, but 12 years without socializing had made him question his beliefs.

Once a month he was provided with food, and then carelessly, because he didn't need food. His body, experiencing hunger, could devour itself and regenerate immediately.

The only reason he was given a room and released from the operating table was because the organization wanted to see what he could offer them. Of course, they didn't stop studying his unusual body and conducting experiments, but Wesker was already in charge of the process himself. Independently amputated his limbs and so on. Only closer to 2019 were these experiments stopped, because they had extracted all possible benefits from his body.

Wesker remotely, horrified, realized that thanks to his body he would live much longer than the average person, if not forever. Which led him to believe that he would be kept in this cage for centuries. BSAA would close, others would take their place, find him, torture him again. And so on in a circle, for all eternity, as long as human society and greed existed. This had to end... but how? A plan was needed, a complex one that could not be unraveled.

His life and existence was a BSAA mystery from 2009-2021. For 12 long years he was not allowed out of the walls of this cell.

Of course he wanted to escape, he had many unrealistic thoughts in his head about it. He was also interested in meeting Chris, aged, changed. To see his reaction, genuine shock rather than the anger he'd reacted to Wesker's earlier 'resurrections'. Is Chris even still alive today? What year is it now?

But this life couldn't go on forever, the BSAA was cracking at the seams. In 2021 it was revealed that they were using B.O.W. soldiers, something Chris couldn't ignore. So he headed over to European headquarters to deal with it - right where his nemesis was located, a complete headache. Chris couldn't accept that his organization, which was fighting biological weapons, would use them. It didn't fit in his head. He had long ago stopped trusting the BSAA, but this was the last straw.

Arriving there, Chris did not expect to meet someone in the basement laboratories whom he had buried a long time ago.

What was he going to do with him? Shoot him in the head without any thought? That would have been logical and in Redfield's character, but over the years he'd stopped being a complete hothead, learned to think first and then act. Gained a little equanimity.

It will turn out that it was Wesker who was involved in the creation of the B.O.W. in BSAA. Especially since these soldiers are improved clones of Chris himself. Who else could have come up with such an idea? Only to a man who thought Chris was "one of his best men".

For the past 6 years, Wesker has been forced to be an advisor to BSAA, sharing all the knowledge and ideas. He might have been able to pull it all off, if only to get back at that organization, turning Chris' anger on it, and turning his attention to himself at the same time. After all, only this "one of his best men" was the only one who could save him. Yes, Wesker was pathetic. He felt he wasn't even worthy of his former name, being so pathetic as to enlist the help of his enemy. But it was the only option. There was no more talk of pride.

However, it didn't matter now, Chris had come here to punish the founders, so their prisoner, their chief counselor, might prove to be the best informant. And an ally.

Natural intuition made Chris believe his former enemy, the biggest manipulator of them all. As if he was definitely not lying now, because he was in such a big asshole that he couldn't let his words sound unconvincing. Earlier, Chris would have easily recognized his lies, but not now. Right now, completely honest and dull eyes were looking at him from beneath translucent glasses. So damn pitiful that Chris automatically assumed the role of the hero rescuing the damsel in distress.

Chris was quickly combine the information together in his head: the situation, the physique, the setting... His opponent had been held hostage by his own ambition, it couldn't help but bring a smile to Redfield's face. But he hid it in his thoughts, because he deemed it inappropriate once he read Wesker's imprisonment papers. Chris had some free time to devote to the situation.

He read about what had been done to Wesker. About all the torture. And Redfield clutched his head, when he got to the description of his ammunition that he'd used against Mold a couple years ago. He was terrified that this weapon had been created in such a gruesome way... through the suffering of his enemy, who, even considering all his guilt, didn't deserve all this. Chris felt that Wesker should have died and rid the world of himself rather than suffer endlessly. Even for him, he thought it was inhumane.

The first thing Wesker said to Chris was:

- Now you've taken on the role of captain of the «alpha» too.

This jabbed Chris slightly, but he noticed how the hostage said it without malice. Redfield involuntarily remembered 1998, the mansion, the betrayal, the deaths of the Alpha and Bravo group...

The compartment Wesker was in was to him both an office and a laboratory, and a room. A kind of prison, which he could not leave on his own because of his weak physical condition. He was weakened by the daily injections putting his viruses inside his body to sleep.

Releasing him and examining him at arm's length, Chris made sure that in the state Wesker was in now, he posed no danger, just an ordinary disgust. He resembled only a pale copy of his former self.

The BSAA operative dragged him carelessly behind him like some sack of garbage, concerned only with keeping the information in his head intact. But in his mind Chris still held images of what the BSAA bastards were doing here to Wesker. He didn't want to feel sorry for him, but he couldn't control it, Redfield had never been heartless. Initially he had only cared about information, but it wasn't long before he didn't even notice how protective he had become of him. As if a friend, which in truth, he never was. His captive's behavior was different from what Chris remembered. It was different, like a throwback to the past. Perhaps 12 years of imprisonment had had that effect on him.

He was docile, which wasn't surprising, since Wesker had been treated like an object by the organization, and the operating table had been a good teaching moment. Chris couldn't believe that after so many years of hell his former enemy's mind was still intact, that he hadn't lost his mind and was capable of dialog.

Time passed unnoticed during the proceedings with the BSAA about B.O.W., eventually the organization was destroyed and all its equipment, along with Chris's squad, transferred to TerraSave.

Chris during all of this had to sign Wesker into the Hound Wolf Squad as either a prisoner or an advisor. To keep him from getting shut down again, that was the deal. He helps them, they help him. Over time, he was getting back to normal. The food and good company had done their job.

However, Chris didn't know that his new ally hadn't lost all of his strength, and the ones he had were sleeping under the influence of the medicament. But time passed, the medicament slowly stopped working without new doses, and Wesker understood it perfectly well. And felt it. It didn't affect his appearance, so he could play his role for as long as he wanted. But was it a role? Sure he was portraying a courtesy that annoyed Chris to the point of nausea, but it was partially sincere. Having broken with his past at the fault of the BSAA, Wesker could only hope to find a new purpose. After all, as Spencer had raised him, there is no life without purpose.

Therefore, was it so necessary for him to betray Hound Wolf Squad? Would it be beneficial to him? Chris is a strong point. He has no doubt that if he kills Redfield - another will take his place, and will definitely get him into the basement wheel of samsara. So Wesker had no grand plans yet. After all, any of them would be doomed to failure as long as there was anyone in the world capable of resisting.

But Chris risked to give him a goal, which, however, called impossible - to become the best version of himself. To help the Hound Wolf Squad, to work with TerraSave, to use his knowledge for something other than endless failed experiments. Stop being Spencer's failed experiment. The only option Chris would give him a chance at.

Those words stuck in Wesker's head for a long time. Mentioning the old man was like a low blow. Chris knew where it hurt the most.

It had been several years since Wesker had joined Redfield's team. All that time he'd been hiding his abilities so as not to lose the fragile trust in his person. But the truth couldn't help but surface one day....

On one of the missions connected with B.O.W., the blade of an exploding helicopter blew off Wesker's head, and then another piece of debris cut his body in half.

But he didn't die.

Chris was enraged. With resentment, he felt cheated. What else could he have expected?

First, the black mass connected the body, restoring functionality to it, and then this silent carcass picked up the head. It was slow. It looked helpless and creepy. Chris's squad was on edge, but he ordered to wait. The black substance emerged from the base of the neck and attached the head to itself, then the calm expression on the reanimated head changed to horror. Was he in unbearable pain from the newly received oxygen? Or from the fusion of tendons?

When Wesker recovered, he couldn't at first think of a response to Chris' "explain yourself!"

Everyone's fragile trust collapsed, but not Redfield's, for he knew that if his former adversary had wanted to betray him, he would have betrayed him long ago, he wouldn't have let himself be so ridiculously exposed. Especially after all the torture he'd endured. Chris could understand why Wesker was hiding his powers. Redfield had stepped on the same rake of trust again, convincing himself that he had everything under control.

Wesker, ever since the prototype had merged with Uroboros in his body, had acquired a number of flaws, chief among them an unbearable sensitivity to pain. The only time he could not feel pain was when he was BSAA injected with force restraining drugs. But without them, all the disadvantages came out.

Whereas before he could recover from any wound without feeling anything but minor damage, now the pain was so obvious that every regeneration was accompanied by agony. Especially if it was a burn, for heat is a major weakness for Uroboros. The healing places on his body, after that helicopter situation, hurt like hell.

He was closer to human now than he had been before, and Chris seemed to realize that. That was why he hadn't killed him a second time, but had accepted him back into his squad. It was not only a gesture of goodwill, but also a precaution, a way to keep a dangerous object as close to him as possible so he wouldn't do anything.

How long will they have to cut off the heads of hydra in the face of the creators of bioweapons?

- Why do you trust me, Chris?

- I still believe that anyone can become the best version of themselves. We should prioritize fighting for the future to give someone a quiet life that you and I have been robbed of. I know about Project W. Together we can stop new organizations and prevent many tragedies like this from happening again. And you can help us, Wesker. BSAA took away your choice, but I'm giving it to you now.

Wesker at first couldn't find the words to respond, but after a moment he barely audibly whispered: "Thank you."

From a man who never thanked anyone, Chris was shocked to hear that. And he was proud of him.

Had he forgiven him? No, his deeds were unforgivable. But Chris wasn't the kind of man who would turn his back on his one chance to make things right, to make things right on Earth, to save someone's life. In this truce, he sees a future that's bright for everyone.

732 notes

·

View notes

Text

It's kind of tragic, in a sense, that iterators were made with so much of their creators logic and desires and yet they were left with none of the resources to satisfy such things.

Do you think they crave touch? Family? Do you think they have to have any hope of connection stomped out of them lest they rebel against what they were made for?

Were they ever afraid to feel, or to be outside of what they were supposed to be? If they ever dared to desire, would they have to hide it?

Do you think they saw their creators sometimes as family, and did the abuse hurt just that much more because of it?

Were they like children, when they were born? Did they process the world through the lens of uncertainty and naivete and was that taken advantage of to mold them into the desired product?

Or were they conscious and self aware in full, was is overwhelming, being alive for the first time?

Or were did they process things entirely as machines, did they only learn to be people after seeing it happen around them, and then did they ever regret becoming more alive than they ever needed to be? That they ever became enough to feel hurt and to hurt others?

If they were just machines at birth, with only the capability of consciousness, were the desired traits injected into them with thoughts and ideas and interactions in their formative early years and was anything else just a byproduct of trying to build a person from scratch? Did their creators even want them to feel, to be conscious and alive, or was that just a necessity to create the desired machine?

Did they even care that their creations were alive?

Did any of them grieve, when they left the children of their labor behind? Were they grieved for in turn when they were gone? Do their echoes ever try to reach out, to let them know they aren't alone, to find comfort in connection that before was so condemned?

If they tried hard enough, could they reach?

Could they find each other?

Would it be comforting to iterators that the remnants of their creators could find them, or would it bring more feelings of rage, of sorrow, of painful memories and grief and hurt from the years they were used and the years more they were abandoned?

Did they ever truly mean anything to each other?

#had a vague thought and my mind spiraled into a number of ideas#a few of these are probably answered in the games canon! I cannot be bothered to check.#It is not an appropriate hour of the morning to be awake right now#I need to go to bed#I hope someone can glean a scrap of interest from my scrambled ramblings <3#roadkill rambles#rain world#rain world iterator#rw iterator#rain world ancients#rw ancients

226 notes

·

View notes

Text

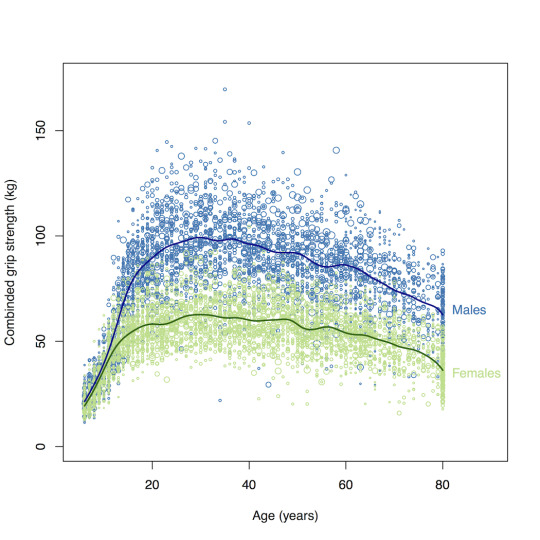

I'm over the term "gender equality", and the way in which it is being used and advocated for by the mainstream, status-quo left.

"Men and women are equal" operates under the bias that men are the default standard of equality, which women are then sometimes required or expected to meet. Usually statements like "women are just as strong as men", "women are just as capable as men in sports" act as support.

It intentionally is meant to be cheered on as liberating, but the reality is it's a derivative of "I don't see race I just see people", "no race but the human race", "not disabled just differently-abled", etc. It's a form of sexism that ignores sexism. It's "I am going to ignore biological differences based on sex" when the reality is being of the female sex shapes both my material and lived reality in extremely complex ways and can have dangerous consequences when ignored.

The average woman is not is strong as a man and it often takes a deliberate amount of persistence, training, and/or testosterone injections for us to come close to or meet the male default. "The muscle strength of women indeed, is typically reported in the range of 40 to 75% of that of men". The average man could easily kill and overpower me, and if I were an athlete a man who trained equally to me would defeat me in competition.

Women are 47% more likely than men to be injured in a car accident. Cars were designed for male drivers. In 2011 was when "female" crash dummies were introduced into measuring car safety in the US, however sometimes organizations in the US and UK just used "scaled down male dummies" to test car safety for women. As this article explains, we are not scaled-down men. We have different muscle mass distribution. We have lower bone density. There are differences in vertebrae spacing. Even our body sway is different. And these differences are all crucial when it comes to injury rates in car crashes. And what about pregnant women?

We have different needs and different experiences than males and the world around is us designed with males in mind - from housing to automobiles, to entire economic systems. 85% of women will eventually be mothers. When women take maternal leave to care for a newborn while the man continues to work (or returns shortly later), he effectively advances his career and over time earns more promotions and pay. His schedule is to focus on his career growth and then come home for a few hours in the evening to play with their child (or play videogames). Mothers pay a significant wage penalty for having children from being months out of the labor market.

This list could really go on.

"Gender equality" is utilized by men to distract women from focusing on only women's rights and needs to men's rights and needs. It's used to shoehorn in arguments of "men too" and sympathizing with men on "men's mental health" (while neglecting the fact that men are overwhelmingly and in shocking numbers responsible for violence done to both sexes - and are additionally unlikely to want to work on themselves mentally).

Reframing and enfolding "violence against women", "women's rights", "male violence", "female liberation", and "women's oppression" into the vague language of "gender equality" is a deliberate act of obfuscating the power dynamics between the sexes - in which men globally exploit and oppress women on the axis of sex.

And as vague language, carves a place for people to have the opportunity to shift the responsibility and blame onto women and girls for the suffering that men wield onto their own sex.

Women and girls do have advantages and strengths over men and boys due to our biological differences - yet this, too, goes ignored under the vague concept of "gender equality" and the cultural belief system it evokes, which treats man as the mold that women should fit.

#gender equality#gender#feminism#radical feminism#gender critical feminism#female liberation#women's rights#women's oppression#misogyny#intersectional feminism

268 notes

·

View notes

Text

Yandere!Donna x Healer!Y/N part 3

Phew. Back at it again with some crazy Donna (I love her so much). Read the last part here! Let’s get into it!

“Y/N?” Donna suddenly asks softly as you work on setting up.

You tilt your head at her. “Yeah, Donna?”

“Um… This… Is going to sound… Ridiculous, but… The cadou that Mother Miranda gave me?” She tries to say, biting her lower lip anxiously.

You quirk your eyebrows at her in concern. She seems deeply worried about something. “You can tell me, Donna.”

Donna sighs but eventually nods her head slowly. She does feel like she can tell you. She knows how kind you are, even though you two just met a little bit ago. You’re special. “It’s just… The cadou has given me… These abilities. It’s what allows my dolls, and Angie, to become… Animated,” She reveals, her gaze immediately dropping to the floor, unable to meet yours. “As much as I want the cadou taken out… I’m just terrified I’m going to lose… My friends,” She whispers.

Well, there it is.

Her last big secret is out in the open, but now she’s having second thoughts. What are you going to say? Are you going to think she’s crazy for saying that she can control the dolls? … Or even worse, that she’s pathetic for being so attached to them?

You surprise Donna, though. You smile gently and walk over to her. “Well then, allow me to put your mind at ease,” You grin.

“W-what?” She asks, completely caught off guard by your reaction.

“Some of the other villagers I’ve been treating who were infected with the mold have had… Interesting side effects, shall we say? Nothing quite as sophisticated as what you just described, but it seems certain abilities can develop. Feelings of premonition that always turn out to be true or increased physical strength… These powers don’t go away once I clear the actual infection,” You tell her. “It sounds like the cadou is a much stronger parasite than the mold I’ve been seeing. I think that might be why your abilities are so advanced,” You say. “But, the main takeaway from all of this is that your connection to Angie and the dolls will not be affected. They’ll be ready for some snuggles as soon as you’re done. Deal?” You ask.

Donna feels like she has been on an emotional rollercoaster today. She is greatly relieved at your reassurance and is just so thankful that you’re here with her. She feels safe and cared for with you around. She’s also… Coming to depend on that support. She can’t bear the thought of life going back to the way it was before you showed up.

In fact… She refuses for it to.

She feels incredibly guilty, but… She has just hatched a diabolical plan to keep you here with her forever. If her powers won’t be affected by removing the cadou, then she will still be able to cause visions. If she can figure out what your biggest fears are… She can use that to her advantage. She just has to keep you talking while you work.

You finish getting your instruments clean and ask her to sit down. You have set up a clean and comfortable area on the couch to perform the procedure on. You take a cotton ball and dab on some antiseptic. You wash off the area of her face you’ll be working on before grabbing a small needle. “Alright, Donna. You’re going to feel a small pinch right beside your eye and a little bit of burning. That’s just the anesthetic going in, okay?” You tell her.

“Okay,” Donna says and braces herself.

You skillfully inject the medicine, taking care to go slow.

Donna winces, but otherwise doesn’t react.

You smile at how good she’s doing. “Excellent. You’re doing great.”

Donna feels her cheeks flush at your praise. She… Really enjoys it. She just hopes you can’t see how rosy her face is becoming.

You two are silent as you wait for the anesthetic to kick in, but it’s a relaxed and warm silence. Not forced or awkward. You two are content in each other’s company.

Finally, enough time has passed and you can begin the surgery. “So, you should be completely numbed up, Donna. I’m going to go ahead and start. Are you ready?” You ask her.

Donna takes a deep breath and lets it out. She’s more ready than you could ever know. “Yes. I’m ready,” She nods.

You grin and place a comforting hand on her shoulder. “It’ll be over before you know it,” You say with a wink.

… Oh, why do you have to be so charming? Donna is once again a blushing mess.

You begin working and Donna is quiet for a moment as she thinks. Okay, she has to focus. She needs to learn more about you, so she forces herself to speak once more. “Do you mind me asking how you got started helping people like this?”

Damn. Even she has to admit that was good. People generally love talking about themselves.

You’re surprised that Donna is making conversation. You assumed she would prefer silence, but you happily answer… And walk right into her trap. “Well, when I was little, I would always try to rescue animals who were hurt or sick. I just couldn’t stand seeing them in pain,” You say. “I realized I had a natural talent for it and it just… Made me want to help people too. I love being able to take care of others. I think it’s my calling in life.”

As much as Donna wants you to stay… Manipulating such a sweet person is tearing her up inside. Your answer is genuine and pure. She was able to gain a lot of knowledge about you with that simple answer.

… This is going to be a lot easier than she thought.

Note: Poor Y/N. They have no idea what they’re walking into T^T

Masterlist

#Masterlist#donna beneviento#re8#re8 village#donna beneviento x reader#donna beneviento x y/n#resident evil village#resident evil imagines#resident evil 8#resident evil#re8 shitpost#yandere imagines

60 notes

·

View notes

Text

Scathe

Varré/Gender Neutral Tarnished

Laying beside Varré for the first time, your mind is a roiling storm.

(AKA that horrifying post nut clarity after literally getting seduced into joining a blood cult)

Warnings: violence, voice kink, manipulative behavior, sorta corruption kink aligned, bloodplay, sadomasochism, degradation, voyeurism, Varré being Varré in general, consensual but morally questionable, messy feelings, NSFW 18+ only

Also this is fresh off the press and not really beta read so feel free to point out any errors you come across. Also on AO3, woah!

"Ahhh, my dear, sweet lambkin," a familiar voice cooed breathlessly from lips that grazed the shell of your ear. His words were sweeter than honey, condensed into a sickening syrup that stirred uneasiness within your gut almost as much as they lulled and soothed. You honestly hated the fact that it was almost, the way you instinctively leaned back and melted against him. Perhaps it was the rush of endorphins clouding your brain, making you pliable, unwise. Everything was still shrouded in the blissful fog that followed a particularly mind-shattering orgasm, after all. In this state, even the linen below you grossly clinging to your sticky, heaving body felt like the richest of silks, the cum dribbling out of your tender hole ambrosia, the sting of the night air against the bleeding cuts that littered your body a cool breeze blown in from the sea in summer. You could hardly be blamed for allowing yourself to feel cared for, if only for a fleeting moment.

You knew that soon he would rise, that he would condescend you under the veil of kindness, remind you that you despised him, then leave you to stew in your shame at the mess he had turned you into. But in this moment you could pretend that he would hold you. You could pretend that you hadn't just made the worst mistake of your entire rotten, miserable life. You grabbed a fistful of bloodstained fabric, trying to hold on to your delusion for a moment more, and hissed between your teeth at the ache that blossomed from your pointer finger, throbbing more venomously than the bite of an asp. A reminder of your transgressions, of the wretched thing you had willingly accepted into your veins.

Varré had injected the blood under your fingernail instead of somewhere sensible like the crook of your arm or the meat of your leg. He was a surgeon. He knew exactly what he was doing, the exact point it would hurt the most, and worst of all, you had thanked him for it, for so strong was your wanting that the pain he inflicted upon you only excited you. Even when the curse felt like thorny brambles threading through your veins, doing irreparable damage to your very soul, defiling you so entirely that you screamed until you vomited, you wanted still. It was disgusting. Oh how you hated this man for knowing exactly what you wanted and taking full advantage of your twisted cravings.

Oh how you hated this man for luring you with the unkindness he called love.

Oh how you hated this man.

And yet, to your shock, he did not pull away. He molded his body against yours and wrapped an arm around you. He planted butterfly kisses upon the back of your neck, the rasp of his stubble so present, so human. It was hard to associate this mouth with Varré. Varré whose face was a porcelain mask. Varré's lips did not move, perfectly molded into an almost-smile as he spoke. It was only today that he had removed it, just as he promised. He had allowed you to touch, to see, to taste, a reward for allowing him to warp you into something you hardly recognized. Even then, he had revealed himself minimally to you, only removing his mask and gloves, and unlacing himself enough to free his cock. Despite his unfamiliar lips, he was still Varré, always teasing, dangling the possibility of more above you. Even as his mouth treated you gently, his fingers played with the edges of your cuts, irritating the skin and loosening any clots to draw fresh red pearls to smear across your heated skin.

It was honestly surprising that he didn't cut you deeper. He was holding back. Only two lacerations would require any sort of attention. You wondered if he would sew them shut, like he did back then, when you were still visiting him under the pretense of requiring assistance and not to hear him call you a worthless fool as he stung you again and again with a needle. The thought still set your chest aflutter just as much as the first time you had given in. He surely felt it, his hand over your heart as it was, but instead of pointing it out, he nuzzled into the crook of your neck and hummed.

"I never took you for the type to be so… kind," you murmured, only half aware you were giving voice to your thoughts. You could feel Varré smirk against your skin before shifting back a little. You immediately regretted not holding your tongue.

"Is that so? Have I been cruel to you, my lambkin?"

You did not answer.

"Have I not shown you the greatest of all mercies? An escape from the uncaring grasp of fate and unto higher purpose?"

Again, you remained mum.

"Are you, perhaps, having regrets?"

"No." You answered finally. As bitter as the word tasted, it was not a lie.

"Then what is it that troubles my lambkin? Is it my touch? My body next to yours? Is this not what you wanted?"

"It's not that." And it wasn't. Both of you damn well knew it. This is exactly what you'd been chasing, and that was precisely where the problem lay. He'd known since he'd found you with your freshly sutured hand down your trousers, the day he'd provided you with a severed finger and instructed you to commit murder for him. And you'd known that same day by the tone of his voice as he'd called you out on your wanton deviance, and how he'd told you to continue as he watched.

"Oh, my needy lambkin, how long have you been plagued by these desires?" He'd asked.

You told him it was since he'd started praising you, calling you affectionate names. He called you a liar.

"I think," he mused, "it's been longer than that. Even when I called you a maidenless wretch, a lost and witless curr. You returned to your Varré time after time because you wanted him even then, Is it not so?"

His words were lusty daggers and had you bucking against your palm.

"Answer me. If you do not, I will stop talking."

He'd known since all the way back then, and so had you. He knew your answer now as well.

"Is it not your custom to lie with your partner after you make love?" He relinquished his hold and made as if to leave, to give you space.

"Wait," you bade him. "Varré, please…"

"Please, what, lambkin?"

"Come back," you whispered.

"Do speak up, dear. Tell me what you want."

"Please. Lie with me. Hold me. Please."

He'd left you every time you took pleasure from his voice. He'd refuse to touch you, or even let you touch him. He'd talk you to the edge, and promise you more, so much more, if you'd just prove your worth, complete the trials he set before you. Renounce that which brought you to life, become a proper servant to forces you did not fully understand.

But now you'd passed the point of no return, and this was your reward. He'd stayed. And you sighed at the return of his warmth. Your newly tainted blood sung like a chorus of crickets all burning to death.

"You took to the blood so well," Varré told you as he leaned forward to kiss your cheek. "Not quite as naturally as I did… oh, but then you took me so well, bled and cried so prettily as we joined together as one. It is almost as if we were made for one another."

You rolled over to face him. His face looked so contented despite the angry red mark next to his mouth where you had bitten him, as if you were sharing a marital bed instead of huddled together on a bloody altar after a coupling that left you both battered. As if you weren't fantasizing about seeing more of his body with intent to harm as much as worship. In some ways, it really was as if you were made for one another.

"Lord Mohg is pleased. I can tell."

You still knew so little about this Mohg who you had so blindly sworn yourself to. In this moment, all you knew was that you hated the man in whose arms you rested. Oh how you hated him for holding a mirror to your rotten soul and reflecting the same unkindness you both called love. You shared one last kiss before you drifted off. To your great satisfaction, he still tasted awful.

#nsft#white faced varré#white mask varre#white maske varré#varré x tarnished#my writing#this one's a little bit on the darker side so take care!#varré x reader#x reader

47 notes

·

View notes

Text

Are you looking for #DIN2738 ( P20 + Ni) Steels in India ?

Have you understand the advantages of using DIN 2738 Steel (P20 +Ni)?

Virat Special Steels announced as the largest stockiest of DIN 2738 ( P20 + Ni) which is supposed to be an upgraded version of the plastic mold steel 2311. Just like plastic mold steel 2311, DIN 2738 is also supplied in a pre hardened condition. The most specific use of DIN 2738 is that for the purpose of making plastic injection die molds. Besides the fact that DIN 2738 is supplied in pre hardened condition, some of the other important characteristics of this steel are s follows:

In the state, when the same is supplied to the customers, the level of hardness of the steel is at 280-320 HB. The nickel content in the steel increases by 0.8% – 1.5% on further hardening.

Virat Special Steels is the largest stockist and supplier of P20 + Ni and P20 tool steel in flat, square and round bars. We provide steel in all sizes as your requirements. P20 Steels is available in flat, square and round shape.

Consult our team who will assist you for the Plastic Mold Steels query. https://www.viratsteels.com/din-2738.html

Learn more :

https://lnkd.in/d3ce__9f

Any queries feel free to contact us :

[email protected] or on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#plasticmouldsteels#plastic mould steel#din2379#p20#p20steels#p20ni#faridabad#manesar#ghaziabad#delhi ncr

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

3 notes

·

View notes

Text

STORY FOR EXPERIMENTAL!!!

Life on Mobius was fine, amazing even, everyone and every little creature happily roamed with friends and families some taking a seat and enjoying views while others running for the pure fun of it! That was until they noticed these little machines roaming around, nobody knew what they were exactly doing so for the most part they didn't mind them. Eventually as quickly as they came the little machines vanished and got replaced with these large rocket things, a few Mobians gathered around, Sonic holding back the crowd however as the door opened. That's when men in puffy white suits and helmets on their head emerged from the ship, they took a few notes of what they were dealing with before kindly introducing themselves. Since they appeared to be no harm, Mobians began to approach and introduce themselves! As the crowd died down and a handful of Mobians were the only ones close by the scientist took their advantage and quickly grabbed two, shoving them into their ships and leaving. This threw every-mobian into pure panic and the planet grew closed off, everyone stayed safely tucked in their houses, only running out to gather resources but even then they managed to catch more and more Mobians. What they did at the other planet nobody knew, apart from the ones taken to chaos knows where...

Back at earth the scientists first managed to capture a two tailed fox and some small rabbit with a weird blue and yellow fairy lookin' creature.. what on earth were these things? None of them knew, but they knew that these animal-like creatures COULD talk and even in the same language as the humans so...what happens if they're injected with medicines humans have, maybe these creatures were actually just humans themselves, they could save those humans and even remake their memories to learn the origin of that planet, however...instead of reverting back they began to mold into some weird horrible creature... They'll have to try other medicine and more of those creatures to find the right combination and be able to return those human's memories.

3 notes

·

View notes

Text

Insulation 101: Benefits and Types of Insulation

Commercial building owners invest in quality insulation materials because of their numerous benefits. Insulation helps enhance the overall performance of any commercial building, decreases harmful greenhouse gas emissions, and helps keep your energy bills from increasing.

In addition, adding insulation to your establishment can also reduce the number of noises coming in and out. This is beneficial mainly for establishments that require better acoustics or sound barriers. Let's learn more about the different types of insulation material available now.

Batt Insulation

Professionals use batt insulation efficiently, one of the most affordable options available today. It comes with two options; with or without facing. Professionals must place this per specifications to resist water vapor transfer. Most insulation today contains recycled materials such as sand. Fiberglass also includes sand which is an environmentally friendly content source.

Batt insulation can either be fiberglass, cotton, or stone wool blankets. Fiberglass is the most common type out of the rest. It is the perfect insulation for attics, walls, ceilings, crawl spaces, and basements.

Blown-in Insulation

When it comes to blown-in insulation, proper installation is a must. Professionals should utilize special equipment and safety measures to ensure long-term function. In addition to being primarily recycled, cellulose blown-in insulation also contains fire-retardant properties. It also resists insects, rodents, and mold and impressively creates a good sound barrier. Once the professionals finish the application, there are also available products with insulation that you can incorporate to enhance your commercial building, such as an insulated roof hatch.

Spray Foam Insulation

If you prefer an insulation material that forms an air barrier, then spray foam insulation should be the option on your list. This material can effectively cover your walls, floors, and ceiling cavities against air movement. This includes spaces around electrical outlets, light fixtures, and walls that meet windows and doors.

Professionals use spray foams in open cavities, like in new construction, crawl spaces, rim joists, and attics. You can also use this on remodeled homes. You can apply the spray foam if the cavities are unrestricted and accessible. Here are the two varieties of spray-foam insulation;

Closed-cell SPF- is a type of spray foam insulation that adds structural strength and is a rigid, vapor-resistant foam that doesn't require replacement in case of a flood.

Open-cell SPF- spray foam insulation that offers identical insulation advantages but does not act as a water barrier or vapor retarder.

Air Sealing

Controlling the air leakage of an establishment is critical to effective insulation. You can do a great job protecting an establishment, but if air can seep through gaps or cracks in the building envelope, you lose your valuable heated or conditioned air.

Concrete Block Insulation

A concrete block's center contains insulating materials such as polystyrene, polyisocyanurate or polyiso, and polyurethane. The hollow centers of concrete blocks can be filled by pouring and injecting loose foam beads or liquid foam. Some professionals create concrete blocks that support rigid foam inserts.

Reflective System

Unlike most typical insulation, which resists convective and conductive heat flow, reflective insulation works by reflecting radiant heat away from your commercial building. These insulation types are best for hot and humid climates, primarily if you have cooling air ducts in the attic. According to research, radiant barriers can lower cooling costs by up to 5% to 10% when utilized in a warm, sunny temperature.

There are still other insulation options available. Ensure to collaborate well with your architect, engineer, or contractor to choose the best insulation option based on your commercial building's needs and your project budget.

Did you find our blogs interesting? You can find more exciting blogs at Best Access Doors! We also offer various top-quality access doors and panels for any commercial building application. You can dial (800) 483-0823 to learn more about our products.

2 notes

·

View notes

Text

Moldex3D is simply the best Injection Molding Simulation Software we have ever worked with. The highly accurate simulations are like taking a time machine to your future mold trial, seeing the problems and being able to fix them long before you ever think of cutting mold steel. Learn more about Injection Mold Designing

#Custom Injection Molding Services#Offshore Mold Making Services#Plastic Injection Molding Services#Plastic Injection Molding Parts#Plastic Injection Molding Services China#Injection Mold Tooling#Injection Mold Tooling Services#Custom Injection Mold Tooling#Offshore Injection Mold Tooling#Injection Mold Tooling Advantages#Injection Mold Tooling Suppliers#Automotive Injection Molding#Automotive Injection Molding Solutions#Automotive Injection Mold Makers#Rapid Injection Mold Tooling#Rapid Tooling#Rapid Injection Molding#Injection Molding Services#Injection Mold Making#Injection Molded Parts#Injection Molding Materials#Injection Molding Services China#CNC Machined Parts China#CNC Machining Services#Plastic CNC Machined Parts#Metal CNC Machined Parts#CNC Sheet Metal Fabrication#CNC Rapid Tooling#Injection Mold Designing#Injection Mold Design

1 note

·

View note

Text

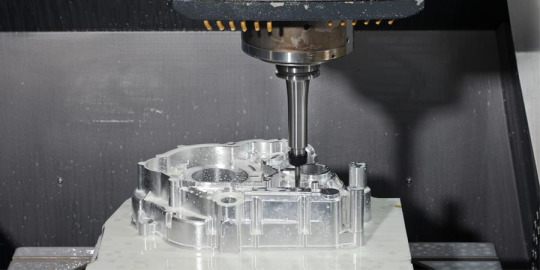

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Clean Way to Remove Impurities - Abrasive Water Blasting

Abrasive water blasting is a technique that has been in play since 1870. This technique uses water and soap to enable degreasing with a synchronous blasting to eliminate dust and hazardous material or waste(asbestos or other impurities). It doesn’t pose any danger to surfaces and structures, resulting in effective decontamination. This is done by Abrasive Water Blasting Equipment which varies in size and pressure.

Abrasive water blasting forcibly propels abrasive material against a surface under high pressure to achieve the following:

● Smoothing of a rough surface

● Roughening of a smooth surface

● Shaping of a surface

● Removal of surface contaminants

The Aqua Miser’s abrasive water blasting process can be done using all traditional blasting formats such as walk-in booths, hand cabinets, automated production machinery, and total loss portable blasting units. The speed of the process depends upon the requirement. The surface which has been cleaned using the process is not damaged as water acts as a buffer. Thus, there are two advantages of abrasive water blasting, it decreases media breakdown rate, and second, it prevents foreign material from sticking to the surface. The level of cleanliness of water blasting is way better than dry blasting because of which it is preferred before coating or bonding operations too.

Types of Wet Blasting Techniques

There are several wet blasting techniques presently available for the choice. Few of them are

● Wet Abrasive Blasting

● High-pressure water blasting

● High-pressure water and abrasive blasting

● Air and water abrasive blasting

The choice of blasting method depends upon the requirement and according to the application.

Abrasive Water Blasting Equipment Details

The wet blast devices are mostly of cabinet-mounted type that can be easily modified. You can take-off conveyors, auxiliary strippers, and wash-rinse dry stations. The blasted device is usually composed of the following parts:

● Vertical wheel

● Horizontal plane turntable

● Shuttle with rail/car extensions

● Chain/belt conveyors

● Self-contained turning mechanisms for shafts and tubular parts

● Combination of tumbling-cabinet machines.

How Does Abrasive Blasting Work?

Abrasive water blasting equipment involves the propulsion of a slurry towards a surface with the help of a high-velocity air propulsion system. The slurry is finely abrasive mixed in chemically treated water. involves high-velocity compressed air propulsion of a slurry towards a surface. The compressed air is sent into a vessel at a pressure equal to that fed to a blast hose. The pressure is equalized to enable the abrasive mixture to feed into an airline. A full flow valve is located between a hopper and mixing chamber which is used to control the flow of abrasives.

Applications of Wet Abrasive Blasting

The applications of wet abrasive blasting are as follows:

● Burr removal from substrates

● Preparation of surface for hard chrome coatings, bonding composites, bonding coatings, bonding composites, and tine and other tool coatings.

● Aviation engine rebuilding

● Etch glass for decorative or functional purposes

● Peen surfaces for a bright, and clean appearance

● Automotive overhaul and engine rebuilding

● Clean plastic injection molds

● Hole cleaning for printed circuit boards

Benefits of Wet Abrasive Blasting

The list of benefits of abrasive blasting is long but key benefits of wet abrasive blasting are listed below:

● Extremely fine media can be used

● Media impregnation into the substrate is not possible

● Deeply cleans irregular surfaces

● Eliminates the need for hand-sanding

● Eliminates the need to use toxic chemicals

● Reduces dust

● Closed cabinet recycles media/slurry

● No heat warping with thin parts

● Final finish is appealing with a satin feel

● Provides an excellent surface for plating

● Provides an excellent surface for bonding

● Holds tight tolerances

5 notes

·

View notes

Text

Mold Your Vision: A Comprehensive Guide to Selecting an Injection Molding Partner

Injection molding is the core of the manufacturing process, which has the significant advantage of very high efficiency with a high precision result. These components are commonly used in many different fields. Not to mention the novel project, favoring the Metal Injection Molding Services can result in success or failure. Below is a detailed step-by-step guide that will assist you in understanding the diverse stages of selection and help you accomplish your dreams with self-assurance.

1. Define Project Objectives: Work by determining what your project is going to be; for example, name the products, rate of production, and deadline. The introduction section could include factors like part complexity, material needs, and desired surface elegance to make your potential injection molding partners perceive a complete picture of your needs.

2. Evaluate Experience and Expertise: Evaluate the experience and skills of potential injection molding providers accordingly to maintain a proper fit with your project objective. Try to find manufacturers that have successfully passed the mark of excellence in your industry and can boast of their experience in projects of a similar magnitude. Acquaintance with material selection, mold shaping, and process enhancement can prove an arsenal impacting the project outcome.

3. Technology and Capabilities: Tough Shot molding technology keeps developing; those advances are beneficial and lead to greater savings of resources. Strive to find injection molding partners that use advanced equipment, cutting-edge technology, and the latest software for production process management and output improvement. Furthermore, they will be asked by the manufacturer about their skills in designing tooling, maintaining molds, and sampling.

Adhering to these key points and considerations, you will be able to suitably select a Powder Injection Molding partner that complements your aspirations for the project and outpaces expectations. Whatever you face and whatever you need, be it in consumer products, automotive components, or medical devices, there is someone you can count on who is known for quality, ingenuity, and customer satisfaction. Be the creator of your vision and innovation by molding with high precision and finding new avenues for your products and business ventures.

0 notes

Text

Diving into Linear Low Density Polyethylene (LLDPE): Understanding Its Properties and Manufacturing (2023-2034)

In the world of plastics, LLDPE stands tall for its remarkable toughness, enabling the creation of thinner yet robust films. Not to be confused with its cousin LDPE, or Low Density Polyethylene, LLDPE boasts a unique structure with numerous short branches. This structural advantage allows its chains to glide smoothly during stretching, preventing entanglement—a common issue with LDPE due to its long branching chains. The result? LLDPE offers superior tensile strength, along with heightened impact and puncture resistance compared to LDPE. So, when it comes to durability and performance, LLDPE takes the lead, making it a top choice for various applications where strength and resilience are paramount.

Introduction

LLDPE or Low-Density Polyethylene is a lightweight, flexible plastic. LLDPE stands out among polyethylene variants due to its semi-crystalline nature, featuring linear molecular chains with short branches. Unlike LDPE and HDPE, these linear molecules exhibit slower tangling. LLDPE is synthesized using one of three alpha-olefin co-monomers, namely octene, hexene, or butene, each influencing its properties differently. Octene contributes long branch chains, offering superior performance. Hexene strikes a balance between octene and butene, providing a cost-effective way. Butene, the most commonly utilized co-monomer for commodity plastics due to its affordability, features the shortest branch chains. Moreover, LLDPE properties can be further tailored by blending it with other co-monomers, with combinations of butene and hexene being particularly prevalent in practice.

LLDPE’s properties include:

Puncture-resistant: making it highly resilient against sharp objects or external forces that could cause punctures or tears.

Good flexibility: its ability to adapt to different shapes or movements without losing its structural integrity.

Resistant to oxidation: LLDPE has the capability to withstand oxidation, which is a chemical reaction involving oxygen that can degrade or weaken materials over time. Resistance to oxidation ensures the material's durability and longevity.

Excellent barrier properties: LLDPE has the ability to prevent the passage of gases, liquids, or other substances through it. Materials with excellent barrier properties are effective in containing or isolating substances, protecting them from external factors.

High impact strength: LLDPE can withstand sudden or intense impacts without breaking or shattering, indicating its resilience to mechanical forces or collisions.

Good environmental stress cracking resistance: LLDPE is resistant to cracking or fracturing when subjected to stress from environmental factors such as temperature variations, chemical exposure, or mechanical loading. Low Water Absorption: With its low water absorption rate, LDPE remains unaffected by moisture, making it suitable for applications where exposure to water or humidity is common.

Low Cost: Perhaps one of its most appealing attributes is its affordability. LDPE offers a cost-effective solution without compromising on performance, making it a preferred choice for a wide range of applications across industries.

LLDPE exhibits distinctive melt flow characteristics, making it suitable for processes like blow molding, film extrusion, and injection molding. Film extrusion, particularly, dominates LLDPE processing. It's worth noting that LLDPE's semi-crystalline nature contributes to its high shrinkage rate, whereby the material occupies more volume in its molten state than when solid. Overall, LLDPE's versatile production methods and unique properties make it a go-to material for various applications in industries ranging from packaging to automotive and beyond.

Manufacturing Process

The manufacturing process consists of four primary phases:

(1) Polymerization

(2) Devolatilization

(3) Distillation

(4) Finishing

Polymerization:

Ethylene and 1-octene initially undergo treatment in fixed-bed adsorption systems to remove water, oxygen, and other polar impurities that could potentially hinder the catalyst. After purification, the monomers are mixed with a polymerization solvent comprising a blend of C8-C9 paraffins. This mixture then enters the first of two consecutive continuous stirred tank reactors (CSTR), where polymerization occurs.

The polymerization process happens adiabatically in the liquid phase, with hydrogen acting as a molecular weight regulator. These steps ensure impurity removal and create ideal conditions for controlled and efficient polymer production in the liquid-phase reactors.

Devolatilization & Pelletizing:

The polymer solution exiting the second reactor enters an adiabatic flash vessel, where pressure reduction causes volatile elements, mainly unreacted ethylene, to vaporize. The concentrated polymer solution then undergoes devolatilization to remove residual monomers. The separated volatile components are cooled and sent for distillation, while the polymer proceeds to finishing. The devolatilized polymer is fed into an extruder to incorporate additives and pelletize the polymer, resulting in the final product being transferred to blending and storage.

Raw Materials Recovery:

The volatile effluents from devolatilization, containing unreacted monomers and solvents, undergo purification through distillation columns to recover these components and eliminate impurities, refining the final product.

The manufacturing process of LLDPE (linear low-density polyethylene) by Dow Chemicals involves a combination of polymerization techniques. Here is the brief overview of the LLDPE production process:

Monomer Preparation:

The first step in LLDPE production is getting the building blocks ready, called monomers. Unlike LDPE which uses only ethylene, LLDPE is made by combining ethylene with another molecule called a comonomer. Common comonomers include 1-butene, 1-hexene, or 1-octene. Adding this comonomer creates branches in the LLDPE structure, which give it special properties different from LDPE.

Polymerization:

Dow uses various polymerization techniques to produce LLDPE.

Solution Polymerization

Monomers and a catalyst system dissolved in a solvent, it's all stirred together in a reactor under carefully controlled temperature, pressure, and mixing. This controlled environment triggers a chemical reaction called polymerization, with catalysts, which often are Ziegler-Natta or metallocene catalysts.

Gas-Phase Polymerization

For gas-phase production, the reaction happens in a special reactor with a constantly moving bed of particles. These particles may hold the catalyst system (like a supported catalyst or a metallocene one). The mixture of monomers and catalyst is fed into the reactor, along with precise controls on temperature, pressure, and how long the ingredients stay inside (residence time). The heat from the reaction itself helps keep the process going.

Product Finishing:

After the LLDPE is polymerized completely, it's time to collect it from the reactor. This raw material, called resin, might go through some finishing touches to get the exact properties needed. This involves removing any trapped gas (degassing), shaping it into pellets (pelletization), and additive incorporation.

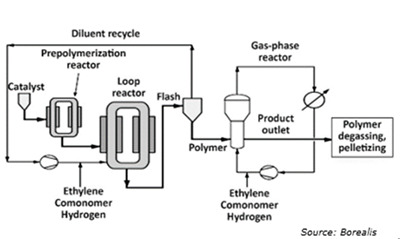

Borstar, a pioneering multi-modal patented technology employed by Borealis for PE and PP production, represents a significant advancement in process technology. Borealis is actively commercializing the latest iteration of Borstar, including Borstar PE 3G, and continues to innovate within the Borstar framework. These advancements enable flexible polymer design, ranging from bi-modal to multi-modal PE/PP resins, and contribute to the development of a diverse range of new plastics.

The Borstar polyethylene (PE) method enables the production of a wide range of bimodal and unimodal LLDPE, MDPE, and HDPE products. This method combines a loop reactor and a gas phase reactor to form Borstar PE. PE with densities ranging from 918 to 970 kg/m3 and melt flows from 0.1 to 100 can be manufactured using this process. While single-site catalysts will be utilized for PE processing in the future, Ziegler-Natta catalysts are currently employed.

A mixture of propane diluent and catalyst is injected into a small pre-polymerization reactor, where pre-polymerization takes place. The resulting slurry is then fed into the loop reactor, operating under supercritical conditions at temperatures of 75–100 °C and pressures of 55–65 bar, to produce higher density and lower molecular weight components of bimodal polymers. Afterward, diluent and unreacted materials are removed from the polymer in a flash tank.

The loop reactor and gas phase reactor operate independently, allowing for easy regulation of reactor conditions and flexibility in processing various products. In the fluidized bed gas phase reactor, polymerization continues, producing a homogeneous polymer on the same catalyst particles. Operating at temperatures between 75 and 100 °C and pressures of 20 bar, this reactor introduces fresh hydrogen, ethylene, and comonomer to form high molecular weight components and broaden the molecular weight distribution (MWD), enhancing the polymer's strength.

The production rate ratio between the reactors can be adjusted to achieve desired product qualities. Finally, hydrocarbon residues are removed, and the polymer powder is extruded to obtain the final product.

NOVA Chemicals use the SCLAIRTECH method on the other hand. The SCLAIRTECH technology method produces a wide spectrum of linear polyethylene (PE) products, including linear low, medium, and high-density grades with narrow to broad molecular weight distribution. The most effective PE swing method enables cost-effective production throughout the whole range of PE grades from a single train.

The process utilizes a reactor fed with a solution containing ethylene and a co-monomer, such as butene-1, octene-1, or even a combination of both. The short residence time (under 2 minutes) allows for a highly flexible system in the solution phase. This translates to quick transitions between producing different grades of the final product, making it adaptable to diverse market needs.

High conversion rates within the reactor maximize output and prevent uncontrolled reactions. A hydrocarbon solvent keeps the reaction mixture in solution while facilitating heat removal. This solvent is then efficiently recycled back into the reactor. Finally, the molten polymer exits the system and is shaped into pellets using a conventional extruder and pelletizer.

The Spherilene method, developed by LyondellBasell, employs a gas-phase reactor in its proprietary technology. The LyondellBasell Spherilene process encompasses a fluidized-bed, gas-phase approach for manufacturing polyethylene (PE) products across all densities, spanning from linear low density (LLDPE) to medium density (MDPE) and high density (HDPE). This technology's versatility, demonstrated by its extensive range of grades, empowers licensees to effectively navigate the continually evolving polyethylene markets well into the future.

The core of the Spherilene technology lies in its simple design with just one reactor and a recirculation system. This setup is surprisingly versatile, capable of producing a wide range of polyethylene (PE) products with melt indices between 0.01 and 100 g/10 min and densities spanning 0.918 to 0.965 g/cm3. This technology, using Avant Z Ziegler and Avant C Chromium catalysts, can create various single-modal (monomodal) products like LLDPE film, HDPE for injection molding, and MDPE for rotomolding and textiles.

Spherilene stands out for its operational stability, leading to high reliability when paired with the consistent performance of Avant catalysts. A unique reactor outlet mechanism efficiently extracts product with minimal gas contamination. Unlike competing technologies, Spherilene allows for start-up with Avant Z catalysts without needing a pre-existing polymer seed bed.

Applications of Linear Low Density Polyethylene (LLDPE)

Packaging

When storing multi-pack beverages for future use, the shrink wraps typically used to encase plastic bottles is often composed of LLDPE. Similarly, the durable plastic can rings utilized to hold together multi-pack canned beverages are also crafted from LLDPE material due to its robustness. It can be used in the form of stretch wraps.

Tubing

Beyond packaging, LLDPE finds use in tubes. LLDPE pipes for safe and reliable delivery of water to livestock.

Consumer Goods

Rigid LLDPE's affordability and ease of shaping make it a go-to material for everyday items like lids, buckets, bottles, and containers.

Market Outlook:

The global Linear Low Density Polyethylene (LLDPE) market stood at roughly 38 million tonnes in 2023 and is likely to grow at a CAGR of 4.80% by the year 2034. The rising need for low-density polyethylene (LLDPE) in packaging, fueled by its exceptional toughness and diverse applications in film production, especially in both food and non-food packaging sectors, is a significant factor driving market growth. The shift from rigid containers to flexible packaging further boosts this growth trend. Moreover, the growing demand for high-performance linear low-density polyethylene (LLDPE) with remarkable attributes such as superior strength and resistance to organic solvents significantly contributes to various applications. Importantly, the increasing utilization of LLDPE in injection molding, a crucial aspect of manufacturing technology, presents promising opportunities for market expansion.

Linear Low Density Polyethylene (LLDPE) Major Manufacturers

Significant companies in the Global Linear Low Density Polyethylene (LLDPE) market are ExxonMobil, ExxonMobil and SABIC JV, Nova Chemicals, Shell, DowDuPont, Chevron Phillips Chemical, Formosa Plastics, Lyondell Basell (Louisiana Integrated Polyethylene JV LLC), Sasol, Borealis GmbH, and Others.

Linear Low Density Polyethylene (LLDPE) Market Challenges

Linear Low Density Polyethylene (LLDPE) market has a few restraints as well that hinder its market growth trajectory. The emergence of cost-effective alternatives like linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), acrylonitrile butadiene styrene (ABS), and high-density polyethylene (HDPE) is hindering market growth. Additionally, the environmental impact of waste plastic bags, which pollute land and water, poses a significant threat to wildlife. As a result, many countries have implemented plastic bans, prohibiting the use of single-use plastic in various sectors, which could potentially impact the growth of the Low-Density Polyethylene Market.

Conclusion:

The rising need for Linear Low Density Polyethylene (LLDPE) to produce thin films for flexible packaging across diverse industries is projected to fuel the growth of the global LLDPE market. The unique properties of LLDPE like puncture resistance, resistance to corrosion, low water absorption, and tough nature makes it useful for packaging applications. Rising technological developments and product development is likely to aid the LLDPE market expansion. With increasing emphasis on cleanliness and long-lasting products, LLDPE is poised to become even more popular. Its reliability makes it a go-to material for a wide range of consumer products like buckets and bottles.

1 note

·

View note