#monel

Text

#IYKYK #405LexingtonAvenue #Manhattan #Eagle #Monel

112 notes

·

View notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Run Mon-El!! 🏃🏻

#dc#dccomics#dc comics#cw supergirl#cwsupergirl#supergirl#karadanvers#karazorel#kara#lenaluthor#lena_luthor#lena#alexdanvers#alex#monel#karaxlena#lenaxkara#kara and lena#lena and kara#karlena#supercorp#supercorpau#supercorpfree#supercorpendgame#supercorp endgame#supercorpsupremacy#supercorp supremacy

11 notes

·

View notes

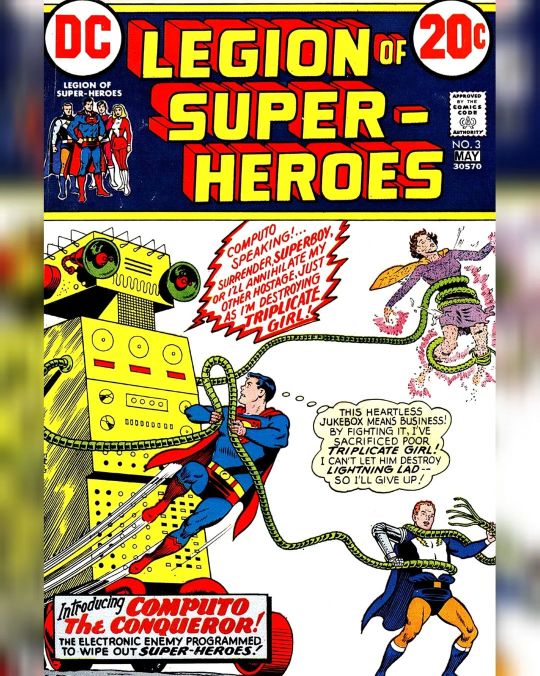

Photo

Legion of Super-Heroes vol 1 3 (1973) . Computo, the Conqueror . Written by Jerry Siegel Penciled by Curt Swan Inked by George Klein Lettered by Milt Snapinn Edited by Jeff Rovin . Brainiac-5 created a computer that wanted to rule the world... . See more relevant content here: #marvelman901curtswan #marvelman901legionofsuperheroes #marvelman901brainiac5 #marvelman901superboy . #legionofsuperheroes #curtswan #superboy #brainiac5 #monel #robot https://www.instagram.com/p/CpBTPGtsxc7/?igshid=NGJjMDIxMWI=

#marvelman901curtswan#marvelman901legionofsuperheroes#marvelman901brainiac5#marvelman901superboy#legionofsuperheroes#curtswan#superboy#brainiac5#monel#robot

2 notes

·

View notes

Text

Call & WhatsApp:- +91 83690 74984

Mail:- [email protected]

Website:- https://anankafasteners.com/

#bolt#studbolt#hex#nut#hexnut#stud#ss316#ss304#monel#nickel#inconel#hastelloy#manufacturer#supplier#fasteners#ananka#anankafasteners#uk#usa#uae#mumbai#gujarat#chennai#delhi#russia#italy#france

2 notes

·

View notes

Text

High-Quality Monel Fasteners Manufacturer and Supplier - Fasteners LLP

Fasteners LLP offers a wide range of high-quality Monel fasteners for various industrial applications. Our Monel fasteners are made from premium-grade materials and are known for their strength, corrosion resistance, and durability. Contact us for all your Monel fastener needs.

0 notes

Text

Exploring the Diversity of Nickel Alloys: A Guide by Apex Metal India

Nickel alloys are the unsung heroes of the materials world, offering a unique blend of strength, corrosion resistance, and versatility. At Apex Metal India, we take pride in being a Leading Importer, Supplier, and Stockist of these diverse nickel alloys, sourced from reputable European mills with valid certificates. In this guide, we'll delve into the different types of nickel alloys and their unique characteristics, shedding light on how they empower various industries.

1. Inconel Alloys - Inconel alloys are the high-temperature champions. They offer superb resistance to extreme temperatures and corrosion, making them indispensable in aerospace and gas turbine components. Apex Metal India provides various grades, including Inconel 600 and Inconel 718,and many more ensuring top-notch quality for your projects.

2. Hastelloy Alloys- Hastelloy alloys are renowned for their exceptional corrosion resistance, especially in highly aggressive chemical environments. Industries such as chemical processing and oil and gas rely on Hastelloy alloys like Hastelloy C4, C-276, etc for their critical applications.

3. Incoloy Alloys- Incoloy alloys are valued for their unique combination of strength and corrosion resistance. They find use in diverse applications, ranging from marine environments to nuclear reactors. Apex Metal India offers a range of Incoloy alloys, ensuring that you have access to materials tailored to your specific requirements.

4. Monel Alloys- Monel alloys are celebrated for their exceptional corrosion resistance, making them ideal for applications in marine and acidic environments. One of the most widely used grades is Monel 400, but Apex Metal India goes further by providing options like Monel K-500 and Monel R405, ensuring you have the right Monel alloy for your specific needs.

5. Nickel-Copper Alloys Nickel-copper alloys offer a balanced blend of strength and corrosion resistance, making them highly suitable for applications in chemical processing and marine industries. Apex Metal India provides Nickel-Copper alloys like Alloy 825 and Alloy 925, ensuring that you have access to materials that can withstand the toughest challenges.

Your Partner for Nickel Alloys

With our extensive range of nickel alloys, you gain the power to choose the perfect material tailored to your specific needs. Whether you're soaring in the Aerospace Industry, working in corrosive Chemical Environments, or Power and Energy Generation, Apex Metal India is here to provide you with the finest nickel alloys available.

Reach out today and unlock the potential of nickel alloys for your projects. Contact us now for expert guidance and top-notch materials!

0 notes

Text

https://bullionpipe.com/our-product/hastelloy-products/hastelloy-buttweld-fittings/hastelloy-c22-b2-buttweld-fittings-exporters/

Hastelloy B2 Buttweld Fittings - Bullion Pipe

Bullion pipe is the Manufacturer, Exporter & Suppliers of Hastelloy B2 Buttweld Fittings & Hastelloy C22 Buttweld Fittings, Hastelloy Buttweld Fittings in India. Hastelloy ASTM B366 Seamless Buttweld Fittings, Hastelloy Buttweld Fittings, Hastelloy Alloy Elbow these are types of Hastelloy B2 Buttweld Fittings. For more information visit the website today !!

0 notes

Text

Incorporating Monel pipe fittings into your project is a smart decision due to their superior resistance to corrosion, tolerance to high temperatures, and exceptional durability. However, before making any final decisions, it's vital to understand their properties, manufacturing standards, and applications fully.

0 notes

Text

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering

#DrugFreeSociety#metalgasket

Metallic Gaskets are used for sealing higher temperature and pressure applications, where non-asbestos materials will fail. Typical applications are for heat exchangers, compressors, condensers, pumps, and valves.

Metal gaskets are manufactured from a material such as Soft iron, Low Carbon steel, Stainless Steel, Monel, and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets

here are 3 main classifications of gasket: metallic, semi-metallic and non-metallic.

Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...

Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.

Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces, particularly metal surfaces, have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.

A gasket is a seal that is manufactured to fit between two or more surfaces, such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.

Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel, Copper, Cast Steel, Monel, Inconel, Brass, Bronze, 17-4, among many others. They also can be combined with various rubber products.

Gaskets are normally made from a flat material, a sheet such as paper, rubber, silicone, metal, cork, felt, neoprene, nitrile rubber, fiberglass, polytetrafluoroethylene (otherwise known as PTFE or Teflon) or a plastic polymer (such as polychlorotrifluoroethylene).

A combination of cork and rubber, for example neoprene or nitrile, yields a gasket resistant to solvents, oils, and fuels. Some of the materials used in the formulations and grades include: Cork & Neoprene Blend. Cork & Viton Blend.

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#DrugFreeSociety#metalgasket#Metallic Gaskets are used for sealing higher temperature and pressure applications#where non-asbestos materials will fail. Typical applications are for heat exchangers#compressors#condensers#pumps#and valves.#Metal gaskets are manufactured from a material such as Soft iron#Low Carbon steel#Stainless Steel#Monel#and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets#here are 3 main classifications of gasket: metallic#semi-metallic and non-metallic.#Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...#Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.#Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces#particularly metal surfaces#have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.#A gasket is a seal that is manufactured to fit between two or more surfaces#such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.#Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel#Copper

0 notes

Text

What is the ASTM grade of Monel 400?

In the realm of metallic materials, Monel 400 holds a distinct position as a nickel-copper alloy with exceptional corrosion resistance and high strength. Therefore, understanding the ASTM grade of Monel 400 is very important for its application in various industries, especially those involving harsh environmental conditions.

What is the ASTM grade of Monel 400?

Monel 400, also known by its UNS number N04400, is a nickel-copper alloy primarily composed of approximately 63% to 70% nickel and 28% to 34% copper, with minor additions of iron, sulfur, carbon, silicon, and manganese. This composition gives it remarkable resistance to corrosion in a wide range of environments, including seawater, hydrogen fluoride, fluorine, sulfuric acid, and alkaline media.

The ASTM grade of Monel 400 is specified in several ASTM standards, including ASTM B127, ASTM B163, ASTM B164, and ASTM B165. These standards define the chemical composition, mechanical properties, and other characteristics of the alloy, ensuring its consistent performance across different applications.

The chemical composition specified in these ASTM standards ensures that Monel 400 maintains its corrosion resistance and mechanical properties. The high nickel content, in particular, confers immunity to chloride-induced stress corrosion cracking, a common failure mode in many other alloys. Additionally, the alloy’s ductility and toughness allow it to be easily formed and processed into various shapes and sizes.

Mechanically, Monel 400 exhibits high strength and toughness over a broad temperature range. Its yield strength and tensile strength, as defined by the ASTM standards, are sufficient to withstand significant loads and stresses in demanding applications. Furthermore, its ductility enables it to absorb deformation without fracturing, enhancing its reliability and durability.

Physically, Monel 400 has a density of approximately 8.80 grams per cubic centimeter and a melting range of 1300-1350 degrees Celsius. Its thermal conductivity and specific heat capacity are also within the range specified by the ASTM standards, ensuring consistent thermal performance.

The processing characteristics of Monel 400 are also addressed in the ASTM standards. It can be easily processed using traditional machining operations, making it suitable for a wide range of manufacturing processes. Its soft nature allows for hot forming into almost any shape, while cold working is typically performed on annealed material to optimize its mechanical properties.

Conclusion

In conclusion, the ASTM grade of Monel 400 is defined by a set of standards that ensure its consistent chemical composition, mechanical properties, and processing characteristics. These standards are the foundation for its widespread use in various industries, where its corrosion resistance and high strength are paramount.

Thank you for reading our article and we hope it can help you to have a better understanding of the ASTM grade of Monel 400. If you are looking for Monel Alloy suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel Alloy products from Shanghai China, Huaxiao Alloy offers customers high-quality Monel alloy products such as Monel 400 and Monel K500 at a very competitive price.

0 notes

Text

Custom Automatic Rivet Service China

With the increase of stamping parts, the requirement of stamping production efficiency is higher and higher. With the continuous development of die and stamping technology, many secondary processing processes originally carried out outside the stamping die are gradually introduced into the die, such as in-die tapping, in-die riveting, and so on. Orienson has accumulated certain experience in in-die riveting technology. Through sorting and feeding by vibrating plate, automatic riveting can be realized in the mold, which can shorten the production cycle, improve productivity and reduce cost.

What Is Automatic Riveting Process?

01

In-die Riveting

In-die riveting is a continuous working process in which the parts are automatically riveted while the hardware with an assembly hole is stamped and formed by a vibrating plate and automatic feeder. Of course, we can complete it with an automatic riveting machine. Here is the process.

02

Process

(a) Clamp the workpiece

(b) Drill holes according to nailhead shape requirements

(c) Feed rivets

(d) Press riveting, the workpiece floats upward, forming nail head and pier head at the same time, and the workpiece is reset to the riveting plane after riveting

(e) Mill off the excess section of the countersunk head

(f) Loosen the clamp and prepare the next rivet for riveting

Benefits Of Automatic Riveting

1. Compared with the traditional connection completely relying on the welding process, the automatic riveting parts not only have good aesthetic results but also have higher strength and better consistency in the stress of the structure.

2. Directly cancel the secondary processing of riveting process, save manpower as well as shorten the process to only complete in the production workshop of stamping plant.

3. Greatly improved the production efficiency and reduced the cost.

Features Of Automatic Riveting

Using automatic riveting technology can assembly efficiency.

Reduce costs, improve working conditions, to ensure assembly quality.

The riveting process is stable without shaking.

The surface of the riveting parts is smooth and beautiful.

The riveting pressure, feed speed and riveting quantity can be adjusted to ensure the best effect.

0 notes

Text

Vareta e eletrodo Monel/Inconel, possível realizar processos de solda específicos com muita eficiência. Modelos a Pronta entrega.

0 notes

Text

Call & WhatsApp:- +91 83690 74984

Mail:- [email protected]

Website:- https://anankafasteners.com/

#bolt#studbolt#hex#nut#hexnut#stud#ss316#ss304#monel#nickel#inconel#hastelloy#manufacturer#supplier#fasteners#ananka#anankafasteners#uk#usa#uae#mumbai#gujarat#chennai#delhi#russia#italy#france

0 notes

Text

Monel Fasteners & Nut Bolts Manufacturer, Supplier in India.

Best quality Monel Fasteners, Nuts bolts, screws, washers are manufactured by Fasteners Fixtures We supply Monel fasteners all over India across the globe.

For More Information Visit Our Website :

0 notes

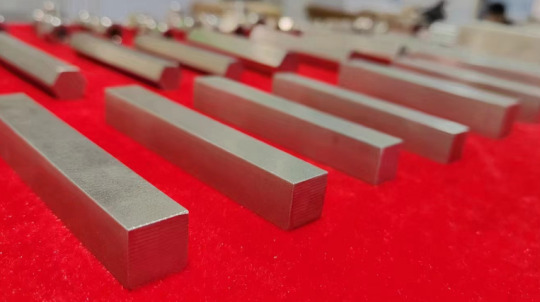

Photo

MONEL 400/K500 FORGING RING, CIRCLES, PIPES #monel #monel400 #monelk500 #alloy400 #alloyk500 ##monelflanges #forging #forgedcircle #nickelalloys #rings #circle #monelplates #manufacturers #exporters #stockists #jainexmetalindustries #mechanicalseal #mechanicalseals #pumpseal (at India Mumbai) https://www.instagram.com/p/ClV1UzXNO2j/?igshid=NGJjMDIxMWI=

#monel#monel400#monelk500#alloy400#alloyk500#monelflanges#forging#forgedcircle#nickelalloys#rings#circle#monelplates#manufacturers#exporters#stockists#jainexmetalindustries#mechanicalseal#mechanicalseals#pumpseal

0 notes