#Automotive Plastics

Text

The Growing Role of Automotive Plastics in Vehicle Design and Manufacturing

Automotive plastics are materials used for the construction of parts and components in automobiles, including the body, interior, and powertrain. These plastics are designed to be lightweight, durable, and cost-effective. Common types of automotive plastics include polypropylene, polyurethane, ABS, and polycarbonate. Automotive plastics are used in many areas of the vehicle, including interior…

View On WordPress

#automotive bioplastic market#automotive injection#automotive injection molding#automotive injection molding companies#automotive plastic additives market#automotive plastic injection molding companies#automotive plastic manufacturers#Automotive Plastics#Automotive Plastics Industry#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Market for Passenger Cars#automotive plastics market industry share#automotive plastics market industry size#automotive plastics suppliers#COVID 19 impact on Automotive Plastics Market#global automotive plastics market#injection molding in automotive industry#plastic car#plastic car part#plastics for electric vehicle market#polypropylene in cars#use of plastic in automobile

0 notes

Text

The global automotive plastics market for passenger cars size is projected to grow from USD 21.1 billion in 2021 and is projected to reach USD 30.8 billion by 2026, at a CAGR of 7.9%. The demand for automotive plastics is mainly driven by the increase in passenger car production and the increasing utilization of automotive plastics in vehicle designs. Plastics offer a maximum weight reduction for automobiles, which in turn reduces carbon emissions. These could be the major reasons propelling the market.

The shift towards the use of bioplastics in vehicle production, the use of anti-microbial plastics and additives, the use of composites and PMMA, and the growing trend of vehicle electrification have increased the demand for automotive plastics across the globe. The development of 3D printing technology is expected to act as a new opportunity for the automotive plastics market for passenger cars to grow. However, the high cost of capital and infrastructure for re-engineering plastics is expected to hinder market growth during the forecasted period.

The under-bonnet is the fastest-growing application segment of the automotive plastics market for passenger cars during the forecast period. Automotive plastics used in the manufacturing of under-bonnet components of passenger cars include Polypropylene, PBT, polyamide, and other engineered plastics. The use of plastics in under-bonnet applications provides high durability, high-temperature resistance, strength, and rigidity to automobiles. The under-bonnet segment includes components such as the battery, onboard chargers, connectors, cables, electric motor, anti-lock braking system, hoses, hydraulic booster unit, load-sensing valve, master cylinder, metering valve, fuel delivery modules, intake manifolds, brackets, duck work, accumulator pistons pressure differential valve, proportioning valve, and thermal management system which require plastics in their manufacturing.

Polyamide is the fastest-growing product type segment of the automotive plastics market for passenger cars during the forecast period, owing to its enhanced properties, such as impact strength and superior surface finish. Commonly used grades are PA 6 and PA 66. It has various properties such as high stiffness, strength, dimensional stability, high temperature and abrasion resistance, and low friction characteristics, along with chemical, flame, abrasion, creep, and fatigue resistance. Moreover, owing to their excellent strength and toughness at the time of exposure to hot and automotive fluids, polyamides are used for automotive thermal management and other applications areas including gears, bushes, cams, bearings, and weatherproof coatings, etc.

BASF SE (Germany), SABIC (Saudi Arabia), LyondellBasell Industries Holdings BV (Netherlands), LG Chem (South Korea), DuPont (US), Covestro AG (Germany), Evonik Industries AG (Germany), Solvay (Belgium), Arkema SA (France), Borealis AG (Austria), LANXESS (Germany), DSM (Netherlands), Toray Industries Inc. (Japan), Mitsui Chemicals (Japan), Celanese Corporation (US), Toyota Boshoku Corporation (Japan), Faurecia SA (France), TOYODA GOSEI Co., Ltd. (Japan), INEOS (UK), Sumitomo Chemicals Co. (Japan), Ltd., UBE Industries (Japan), Mitsubishi Engineering Plastics Corporation (Japan), Formosa Plastics Corporation (Taiwan), EMI Chemi Holdings (China), and Momentive Performance Materials (US) are some of the leading players operating in the automotive plastics market for passenger cars. These players have adopted the strategies of acquisitions and partnerships to enhance their position in the market.

#Automotive Plastics Market for Passenger Cars#plastics for electric vehicle market#automotive bioplastic market#global automotive plastics market#automotive plastic additives market#plastic car#automotive plastics#plastic car part#automotive injection molding#automotive injection#use of plastic in automobile#polypropylene in cars#automotive plastic manufacturers#injection molding in automotive industry#automotive plastics suppliers#automotive plastic injection molding companies#automotive injection molding companies#COVID 19 impact on Automotive Plastics Market#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Industry#Automotive Plastics#automotive plastics market industry share#automotive plastics market industry size#automotive plastics market industry trends

0 notes

Text

Maybe if I think of my homework as researching for a case for Lockwood & Co. I'll actually get it done.

#lockwood and co#“why do you need a 15 page paper on potential areas of innovation in automotive plastics?”#“It's to hunt ghosts!”#“How???”#If it was for my metals processing class I could totally convince myself of its use in-universe

29 notes

·

View notes

Photo

Quadlock mirror bar Spacer to 7/8". Preferably printed in TPU. Link to STL file in bio Filament: Sunlu PLA Infill: 50% Infill Pattern: Triangle Supports: Not Needed, printed laying flat. #tinkercad #Ender3v2 #Ender3 #Ender #Ender3Pro #automotive #automotiveparts #automotive3dprinting #Honda #Grom #PLA #3DPrinting #PETG #MSX125 #plastic #handle #Cura #3dprint #mirror #mount #quadlock https://www.instagram.com/p/CpKlWZqO0YT/?igshid=NGJjMDIxMWI=

#tinkercad#ender3v2#ender3#ender#ender3pro#automotive#automotiveparts#automotive3dprinting#honda#grom#pla#3dprinting#petg#msx125#plastic#handle#cura#3dprint#mirror#mount#quadlock

2 notes

·

View notes

Text

Injection Mold Suppliers China

Whether you are looking for plastic injection molding or custom injection molding experts at Injection Mold Suppliers in China can fulfill all your needs. Hsmolds.net is all set to serve you the best quality product you want. Order it now!

#plastic injection#plastic parts#injection machine#medical device#automotive#industrial#manufacturing

4 notes

·

View notes

Text

#Global Automotive Plastic Intake Manifold Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

Innovative Applications of Electric Vehicle Plastics in Automotive Design

As the automotive industry undergoes a paradigm shift towards electrification, the integration of advanced materials has become increasingly crucial. Among these materials, electric vehicle plastics stand out for their versatility, sustainability, and performance.

Enhancing Vehicle Performance

Weight Reduction: One of the primary advantages of electric vehicle plastics is their ability to significantly reduce the weight of vehicle components. By replacing traditional materials like metal and glass with lightweight plastics, automakers can improve fuel efficiency and overall vehicle performance.

Optimizing Aerodynamics: Electric vehicles often rely on streamlined designs to maximize efficiency and range. Electric Vehicle Plastics play a key role in achieving these aerodynamic profiles by enabling the creation of complex shapes and contours that minimize drag and enhance airflow.

Transforming Interior Comfort and Functionality

Customization Options: Electric vehicle plastics offer unparalleled design flexibility, allowing for the creation of custom interior features tailored to the preferences of drivers and passengers. From ergonomic controls to innovative storage solutions, these plastics enhance both comfort and functionality.

Noise Reduction: Electric vehicles are known for their quiet operation, and electric vehicle plastics contribute to this acoustic comfort by damping vibrations and reducing noise transmission within the cabin. This creates a more serene driving experience for occupants.

Get More Insights On This Topic: Electric Vehicle Plastics

#Electric Vehicle Plastics#Automotive Sustainability#Green Technology#Lightweight Materials#Eco-friendly Innovation#Sustainable Mobility#Electric Vehicle Components#Environmental Conservation

0 notes

Text

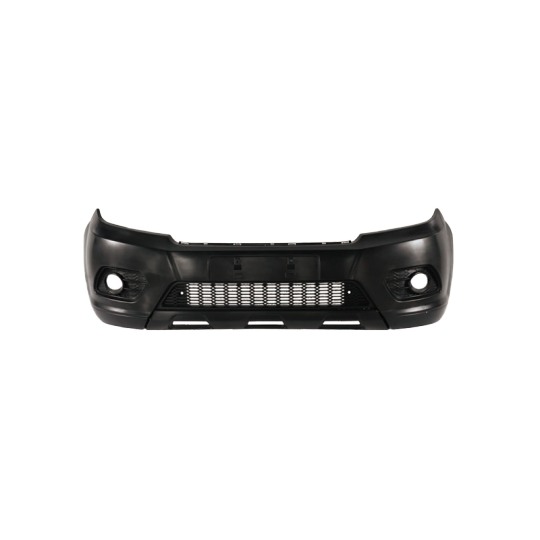

🚗 Looking for top-notch automotive plastic parts? Look no further! 🇨🇳 Our Automotive Plastic Parts Manufacturer in China delivers unparalleled quality and precision. With cutting-edge technology and a commitment to excellence, Automotive Plastic Parts Manufacturer China ensures your vehicles perform at their peak. From interior trim to exterior components, our skilled craftsmen meticulously craft each piece to perfection. Trust Automotive Plastic Parts Manufacturer China for reliability, durability, and innovation. Elevate your automotive experience today with Automotive Plastic Parts Manufacturer China! Don't settle for less - choose the best! 🌟 #Automotive #PlasticParts #Manufacturer #China 🚀

0 notes

Text

Design key points and technical summary of automobile headlight reflector injection molds.

Car headlight reflector (also known as reflector) is a part of car headlight lighting system that has a reflection function to avoid direct light. It is located inside lens and decorative frame, is assembled with lens. Reflector can be seen from outside of car light through lens. Plastic parts are exterior parts with aluminum-plated surfaces. They are high-gloss electroplated parts with…

View On WordPress

#automobile headlight reflector injection molds#automobile headlight reflector molds#automobile mold design#automotive molds#automotive plastic parts#BMC material injection molding process#core-pulling mechanism#design of automotive molds#Design of demoulding system#die-casting molding process#gating system design#injection mold#injection molding process#mold design#mold processing#Mold structure analysis#Mold working process#molded parts#molded plastic part#molding#plastic parts#Structural analysis of plastic parts#temperature control system design#thermoplastic injection mold#thermoplastic plastic molding#thermosetting injection molding#thermosetting plastic injection molding

0 notes

Text

Advancing Protection: The Power of Nano Coating for Plastic Surfaces

In an era where durability, longevity, and aesthetics are paramount, the quest for advanced protective solutions has led to the emergence of nano coatings. Among these revolutionary innovations, Nano Coating for Plastic Surfaces stands out as a game-changer in the realm of surface protection. Let's delve into the transformative capabilities of Nano Ceramic Coating for Plastic and explore how it elevates the safeguarding of plastic surfaces to unprecedented levels.

Understanding Nano Coating for Plastic Surface

Nano coating, also known as nanocoating or nanoparticle coating, involves the application of nano-sized particles onto a surface to create a protective layer. This layer, composed of nanoparticles, exhibits remarkable properties such as superhydrophobicity, oleophobicity, and resistance to various environmental factors. When applied to plastic surfaces, nano coating forms an invisible shield that enhances durability, repels contaminants, and preserves the pristine appearance of the material.

The Science Behind Nano Ceramic Coating for Plastic

Nano Ceramic Coating for Plastic harnesses the power of ceramic nanoparticles to deliver unparalleled protection. These nanoparticles bond chemically with the surface, creating a robust and durable barrier. Unlike traditional coatings, nano ceramic coatings penetrate deep into the microscopic pores of the plastic, ensuring comprehensive coverage and long-lasting performance. The result is a surface that repels water, oils, dirt, and other contaminants with ease, thereby reducing the need for frequent cleaning and maintenance.

Key Benefits of Nano Coating for Plastic Surface

Superhydrophobic and Oleophobic Properties: Nano coatings for plastic surfaces with superhydrophobic and oleophobic properties, meaning they repel water and oils effortlessly. This not only keeps the surface clean but also prevents water damage and oil stains, extending the lifespan of the plastic.

Enhanced Durability: By forming a protective barrier, nano coatings shield plastic surfaces from scratches, abrasions, and other forms of wear and tear. This enhances the durability of the material, ensuring it retains its integrity and appearance over time.

UV Resistance: Nano ceramic coatings provide UV resistance, protecting plastic surfaces from the harmful effects of prolonged sun exposure. This prevents fading, yellowing, and degradation caused by UV rays, preserving the aesthetics of the plastic.

Easy-to-Clean Effect: Thanks to their non-stick properties, surfaces treated with nano coatings are easy to clean and maintain. Dust, dirt, and other contaminants simply slide off the surface, requiring minimal effort for upkeep.

Environmental Friendliness: Nano coatings are eco-friendly alternatives to traditional chemical-based coatings. They are non-toxic, solvent-free, and pose no harm to the environment or human health, aligning with sustainability goals.

Applications of Nano Coating for Plastic Surface

Nano coating for plastic surfaces finds diverse applications across various industries and settings:

Automotive: Protects car bumpers, trims, and interior plastic components from environmental damage and UV exposure.

Electronics: Shields electronic devices, casings, and displays from scratches, water damage, and fingerprint smudges.

Medical: Ensures the cleanliness and longevity of medical equipment, plastic housings, and devices in clinical settings.

Consumer Goods: Enhances the durability and aesthetics of plastic furniture, appliances, and household items.

Conclusion: Embracing Advanced Protection

In an age where performance, longevity, and sustainability are paramount, Nano Coating for Plastic Surface emerges as a transformative solution. With its superhydrophobic, oleophobic, and UV-resistant properties, Nano Ceramic Coating for Plastic elevates surface protection to unprecedented levels. By embracing these advanced coatings, industries and consumers alike can safeguard their plastic surfaces, ensuring durability, aesthetics, and environmental responsibility for years to come.

0 notes

Text

multi color car damper mold

China 2k mold maker, offer bi material automotive damper mold, double injection plastic damper mold, multi color car damper mold, dual mold air motorized flaps

#China mold#2 component mold#bi material mold#multi shot mold#two color automotive damper mold#2k plastic damper mold#rotary mold car damper#double air motorized flaps mold

0 notes

Text

Automotive Plastics Market for Passenger Cars Anticipated to be Valued at US$ 30.8 Billion by 2026- Exclusive Report by MarketsandMarkets™

The global automotive plastics market is growing rapidly, and there is a big opportunity for businesses to get involved. This market is expected to reach USD 30.8 billion by 2026, so now is the time to get started. There are many different types of plastics that are used in vehicles, and each has its own benefits. Businesses that can provide high-quality automotive plastics will be in high…

View On WordPress

#Automotive Plastics#Automotive Plastics Industry#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Market for Passenger Cars#automotive plastics market industry share#automotive plastics market industry size#COVID 19 impact on Automotive Plastics Market

0 notes

Text

Asia Pacific accounted for the largest share of the automotive plastics market for passenger cars in 2020. The countries considered for the study in Asia Pacific are China, Japan, India, South Korea, Thailand, Indonesia, among others. Asia Pacific is a leading manufacturing hub for the automotive industry owing to the increasing passenger vehicle production in China and India. The vehicle production in these countries is growing at a rapid rate because of the presence of major automotive players such as Honda, Toyota, Hyundai, and Nissan. Manufacturers such as BMW and Volkswagen have already set up manufacturing units in these countries. In terms of geography, Asia has the highest production of electric vehicles, making it the largest market for plastic for EVs. Such factors are expected to fuel the growth of the automotive plastics market for passenger cars in the region.

#Automotive Plastics Market for Passenger Cars#plastics for electric vehicle market#automotive bioplastic market#global automotive plastics market#automotive plastic additives market#plastic car#automotive plastics#plastic car part#automotive injection molding#automotive injection#use of plastic in automobile#polypropylene in cars#automotive plastic manufacturers#injection molding in automotive industry#automotive plastics suppliers#automotive plastic injection molding companies#automotive injection molding companies#COVID 19 impact on Automotive Plastics Market#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Industry#Automotive Plastics#automotive plastics market industry share#automotive plastics market industry size#automotive plastics market industry trends

0 notes

Text

*vibrates gently* the reason automotive design in particular will have stagnated due to the problem is because modern designs are dependent on materials engineering developments in plastics and aluminum alloys, both fields which would have been neglected in favor of iron and silver-glass ceramics in the Lockwood & Co. universe.

#lockwood and co#lockwood and co netflix#listen if i make a post related to my major can i count it as studying?#the true use of my automotive plastics class#dude I could go on SUCH a long materials rant about Lockwood and co ahhh

45 notes

·

View notes

Text

What are the Advancements in 3D Printing High-Performance Plastics?

3D printing tech has gone from strength to strength at a rapid rate, altering more than a few industries. Amongst the several 3D printing applications, plastic 3D printing is really a game changer, offering adaptability, cost-efficiency, and innovation. The utmost new progressions in plastic 3D printing have pushed the limits of what was formerly thought conceivable. This blog will help you…

View On WordPress

#3D Printing High-Performance Plastics Market#Additive Manufacturing#Aerospace Components#automotive parts#Chemical Durability#Competitive Landscape#Healthcare Industry#Heat Resistance#Industrial Prototypes#Investors#Manufacturers#Market Segments#Medical Devices#Regional Influences#Strength

0 notes