#Chemicalprocessing

Text

Nitric Acid Market Forecast: Examining Size, Share, and Growth Trajectories for the Forecast Period

The global nitric acid market size is expected to reach USD 35.9 billion by 2030, registering a CAGR of 2.4% from 2023 to 2030, as per the new report by Grand View Research, Inc. The growth is attributed to the rising demand for fertilizers by the agrarian economies of the world. The surge in the demand for fertilizers is witnessed by the excessive rise in demand for food. Fertilizer is the major application of nitric acid which caters to the maximum share across the global market. Farmers are adopting new technologies to speed up their crop yield to satisfy their excessive need. The product is also consumed in the manufacturing of adipic acid which is an important raw material in the development of Nylon 6, 6. Nylon 6, 6 is used extensively in the manufacturing of plastics and industrial carpets.

Nitric Acid Market Report Highlights

Nitrobenzene application witnessed the fastest growth rate with a CAGR of nearly 5.0%. This is attributed to the wide utilization of nitrobenzene in the construction industry.

Fertilizer application captures the major market share globally with nearly 80.53% in 2022. This is attributed to the excessive demand for food. Food consumption is increasing massively due to the rise in global population which is anticipated to trigger the demand for fertilizer even more in the forecast years.

Europe captures the major market share for the product across the globe due to the major players operating in the region. The demand in Central Europe is starting to take a leap. However, Eastern Europe is showing huge potential for expansion.

The global product market has become highly competitive due to the involvement of big companies in specialty chemical manufacturing. Big companies are integrating their business across the value chain to obtain maximum profit at the lowest investment.

The production of chemical fertilizers involves a substantial volume of additives and chemical-based substances which have an adverse effect on the environment. Also, nitric acid is considered a dangerous substance due to its ability to cause skin burn, and eye damage, It is therefore recommended to take precautionary measures.

For More Details or Sample Copy please visit link @: Nitric Acid Market Report

Nitric acid is produced by the reaction of nitrogen dioxide with water wherein the diluted nitric acid has distilled concentration of over 68%. There are majorly two types of the production process of the product which include weak nitric acid production and high-strength production. The high strength is produced under high-temperature conditions by first oxidizing ammonia, then is oxidation followed by absorption.

The global product market has become highly competitive due to the presence of big players in the industry. Big companies are constantly innovating the process through their extensive research and development. Also, the use of technology like mono-medium pressure process, mono-high pressure process, and dual pressure process are playing a major part in the making of the product overall.

A substantial amount of the product is consumed in the manufacturing of chemical fertilizers. However, these chemical fertilizers have an adverse effect on the environment. Fertilizer production utilizes various additives and preservatives to enhance their property and to give the optimum result. However, these additives can cause a significant soil nutrient loss and degradation of underground water reserves which are consumed by the general population.

#NitricAcid#ChemicalIndustry#IndustrialChemicals#ChemicalMarket#Manufacturing#NitrogenProducts#Agrochemicals#IndustrialApplications#ChemicalEngineering#NitrogenFertilizers#AcidMarket#NitricAcidProduction#NitricAcidUses#ChemicalProcessing#NitricAcidDemand#ChemicalSupply#ChemicalBusiness

0 notes

Text

Safety And Reliability Of Explosion-Proof Motors In Hazardous Environments

(Source – spikersolutions.com)

Explosion-proof motors play a critical role in industrial environments where flammable gases, vapors, liquids, or combustible dust are present. These specialized motors are designed to mitigate the risk of explosions by containing sparks and preventing ignition sources from igniting hazardous atmospheres. In this article, we explore the fundamentals, applications, design considerations, and benefits of explosion-proof motors (EPM) in various industries.

Understanding Explosion-Proof Motors

EPMs, also known as hazardous location motors, are engineered to operate safely in environments classified as hazardous due to the presence of combustible materials. These motors are constructed with robust enclosures that can withstand and contain internal explosions, preventing them from igniting the surrounding atmosphere.

The design of EPM is governed by stringent safety standards and regulations, such as those outlined by organizations like the National Electrical Code (NEC), the International Electrotechnical Commission (IEC), and Underwriters Laboratories (UL). These standards dictate the construction, materials, and testing requirements to ensure the motors’ suitability for hazardous locations.

Applications of Explosion-Proof Motors

EPM finds applications in a wide range of industries where the risk of explosions is present. Some common applications include:

Oil and Gas

In the oil and gas industry, explosion-proof motors power equipment such as pumps, compressors, and fans in refineries, drilling rigs, and petrochemical plants. These motors are essential for ensuring safe and reliable operation in hazardous environments where flammable gases and vapors are prevalent.

Chemical Processing

Chemical processing facilities utilize EPM to drive mixers, agitators, and conveyors in areas where volatile chemicals are handled. The motors’ ability to withstand the corrosive effects of chemicals and prevent ignition sources is crucial for maintaining plant safety and productivity.

Mining

EPMs are integral to mining operations, where the presence of combustible dust and methane gas poses significant explosion hazards. These motors power equipment such as conveyor belts, crushers, and ventilation fans in underground mines, providing reliable performance in challenging conditions.

Manufacturing

Manufacturing facilities with processes involving flammable materials, such as paints, solvents, and dust, rely on EPM to drive machinery and equipment. From textile mills to food processing plants, these motors ensure worker safety and regulatory compliance in hazardous work environments.

Pharmaceuticals

In pharmaceutical manufacturing, EPMs are used in equipment such as mixers, granulators, and tablet presses. These motors help mitigate the risk of explosions in areas where volatile chemicals and solvents are handled during drug production.

Design Considerations for Explosion-Proof Motors

Several key design considerations are essential for ensuring the effectiveness and safety of EPM:

Enclosure Construction

EPMs feature robust enclosures constructed from materials that can contain explosions, such as cast iron or aluminum. The enclosure design includes features like flame paths, labyrinth seals, and threaded joints to prevent the propagation of flames and hot gases.

Sealing and Gasketing

Proper sealing and gaskets are critical for preventing the ingress of flammable gases, vapors, or dust into the motor enclosure. EPMs are equipped with high-quality seals and gaskets to maintain the integrity of the enclosure and minimize the risk of ignition.

Temperature Class

Explosion-proof motors are classified based on their maximum surface temperature under normal operating conditions. Temperature classes, such as T1 to T6, indicate the maximum allowable temperature that the motor can reach without posing a risk of ignition. Selecting the appropriate temperature class is essential for compatibility with hazardous atmospheres.

Motor Protection

EPMs may incorporate additional protective features, such as thermal overload protection, bearing temperature monitoring, and explosion-proof conduit fittings. These safeguards help prevent motor failures and reduce the risk of ignition in hazardous locations.

Benefits of Explosion-Proof Motors

The use of EPM offers several benefits for industrial applications:

Enhanced Safety

EPMs provide a high level of safety by containing internal explosions and preventing them from igniting hazardous atmospheres. This helps protect personnel, equipment, and facilities from the devastating consequences of explosions.

Regulatory Compliance

Compliance with safety standards and regulations is a top priority in hazardous environments. EPMs are designed and tested to meet or exceed industry standards, ensuring regulatory compliance and peace of mind for facility operators.

Reliable Performance

EPMs are engineered for ruggedness and reliability, capable of withstanding harsh operating conditions and environmental challenges. Their robust construction and protective features contribute to long-term performance and minimal downtime.

Cost Savings

While the initial cost of EPMs may be higher than standard motors, the potential cost savings from preventing accidents, downtime, and property damage far outweigh the investment. The enhanced safety and reliability of these motors can result in significant long-term savings for industrial facilities.

Conclusion

Explosion-proof motors are indispensable components in hazardous environments where the risk of explosions is present. Engineered with robust enclosures, protective features, and compliance with stringent safety standards, these motors provide a safe and reliable solution for powering equipment in industries such as oil and gas, chemical processing, mining, manufacturing, and pharmaceuticals. By mitigating the risk of ignition and ensuring regulatory compliance, EPMs play a vital role in safeguarding personnel, equipment, and facilities from the potentially catastrophic consequences of explosions. As industries continue to prioritize safety and reliability, the demand for explosion-proof motors is expected to remain strong, driving further advancements in design, technology, and performance.

0 notes

Text

Chemical Processing Equipment

Chemical process equipment encompasses a wide array of machinery and devices utilized in chemical processing industries for converting raw materials into valuable products. From reactors and distillation columns to pumps and heat exchangers, these pieces of equipment facilitate various unit operations like mixing, separation, heating, and cooling. Each equipment type serves a specific purpose, contributing to the efficiency and safety of chemical processes.

#ChemicalEngineering#ProcessEquipment#ChemicalIndustry#ChemicalProcessing#Manufacturing#UnitOperations#Reactors#Distillation#HeatExchangers#Mixing#Separation#Safety#Efficiency#ChemicalPlant#EngineeringDesign#IndustrialEquipment#Pumps#Compressors#ChemicalReactions#EngineeringSolutions

1 note

·

View note

Text

Top Quality Chemical Process Equipments for industry From Mathesis

more details visit: https://www.mathesis.co.in/index.php

Carbon Steel IS 2062, SA 516 Boiler Quality all grades used in Unfired Pressure Vessels.

SS 316, SS 304, SS 310, SS 2205, SS TI.

Hastealloy C 22, C 276, Copper.

#industrial#industrial equipment#chemicalprocessing#industrial parts supplier#manufacturers#chemicalplant

0 notes

Text

Pneumatic Actuator Operated Ball Valve in Karnataka

Multitech Valves and Automation is a distinguished Indian company renowned for Manufacturer and Supplier Pneumatic Actuator Operated Ball Valve in Karnataka, India.

Specializing in producing highly efficient valves designed to regulate and direct various liquids, particularly suitable for high-pressure applications.

Our valves have garnered trust and recognition from diverse industries across India, attributing to their technological advancement, innovative engineering, and unwavering commitment to safety standards.

The exceptional skills and tireless efforts of our skilled technicians have played a pivotal role in establishing us as the leading manufacturers of manual valves in India.

Pneumatic ball valves control media flow (liquids or gases) via a rotating ball with a bore, operated by pneumatic actuators that convert compressed air energy into mechanical motion.

Depending on their operational mechanism, pneumatic actuator ball valves categorize as single-acting or double-acting.

Features:

Automation: Enables automated control of fluid flow.

Compact Design: Space-efficient design for various installation requirements.

Low Maintenance: Requires minimal maintenance efforts.

High Reliability: Ensures dependable performance in critical applications.

Applications:

Power Generation

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Food and Beverage Industry

HVAC Systems

Multitech Valves and Automation is Pneumatic Actuator Operated Ball Valve in Karnataka Including Badami, Belagavi, Chamarajanagar, Bhadravati, Bidar, Hassan, Bagalkot, Bidar, Chikkamagaluru, Kalaburagi, Kolar, Ballari, Belagavi, Bangalore Rural, Dakshina Kannada, Haveri, Kodagu, Bengaluru, Davangere, Halebid, Hassan, Hubballi-Dharwad, Kalaburagi, Kolar, Madikeri, Mandya, Mangaluru, Urban, Chitradurga, Vijayapura, Gadag, Tumakuru, Mysuru, Raichur, Shivamogga, Shravanabelagola, Shrirangapattana, Ramanagara, Kittur.

For more information and inquiries, feel free to contact us.

Read the full article

#ChemicalProcessing#Exporter#ExporterofPneumaticActuatorOperatedBallValveinKarnataka#India#Karnataka#Manufacturer#ManufacturerofPneumaticActuatorOperatedBallValveinKarnataka#PetrochemicalIndustry#PneumaticActuatorOperatedBallValve#PneumaticActuatorOperatedBallValveinKarnataka#PowerGeneration#SupplierofPneumaticActuatorOperatedBallValveinKarnataka

0 notes

Text

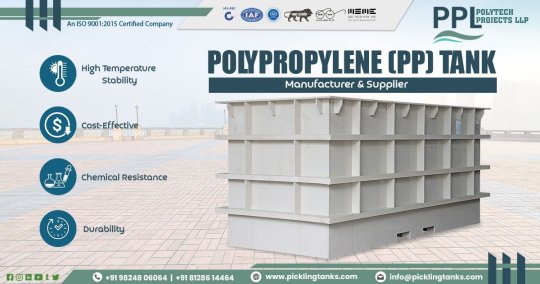

Supplier of PP Tank in Andhra Pradesh

Company Overview:

Polytech Projects LLP is a Manufacturer and Supplier of PP Tank in Andhra Pradesh, India.

The company is ISO 9001:2015 certified, specializing in crafting Polypropylene & HDPE Storage equipment, setting industry standards, and expanding possibilities.

Their product range includes Pickling Tanks, Storage Tanks, Plating Tanks, HDPE Tanks, Fume Hoods, Fume Extraction Systems, Wet Scrubbing Systems, Hot Dip Galvanizing Lines, Surface Treatment Lines, and more.

PP tank stands for polypropylene tank, a common type of plastic tank used for storing and transporting liquids, semi-liquids, and gases.

PP tanks are significantly lighter than metal tanks, making them easier to transport and install. They can withstand a wide range of temperatures, impacts, and exposure to chemicals without degrading.

Their recyclability allows for efficient resource utilization, reducing waste and minimizing environmental footprint.

Features of PP Tank:

Excellent chemical resistance

Durability

Lightweight construction

UV resistance

Corrosion resistance

Easy maintenance

Versatility in storage applications

Compliance with safety standards

Applications of PP Tank:

Chemical processing

Pharmaceuticals

Water treatment

Food and beverage

Agriculture

Electronics

Metal finishing

Service Coverage:

Polytech Projects LLP serves as a Manufacturer and Supplier of PP Tank in Andhra Pradesh, covering locations such as Adoni, Amaravati, Anantapurm, Chandragiri, Chittoor, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada, Kurnool, Machilipatnam, Rajahmundry, Srikakulam, Tirupati, Vijayawada, Visakhapatnam, Vizianagaram, and Yemmiganur.

For more information and inquiries, feel free to contact Polytech Projects LLP.

Read the full article

#Adoni#Agriculture#Ahmedabad#Amaravati#Anantapurm#AndhraPradesh#Chandragiri#Chemicalprocessing#Chittoor#Dowlaiswaram#Electronics#Eluru#Exporter#ExporterofPPTanks#Guntur#Kadapa#Kakinada#Kurnool#Machilipatnam#ManufacturerofPPTanks#Metalfinishing#Polypropylene&HDPEStorageequipment#PolypropyleneTank#Rajahmundry#Srikakulam#Supplier#SupplierofPPTankinAndhraPradesh#SupplierofPPTanks#SupplierofPPTanksinAndhraPradesh#SupplierofPPTanksinIndia

0 notes

Text

Supplier of Stainless Steel Bars in Andhra Pradesh

Mehmani Metal Industries is one of the leading Manufacturer and Supplier of Stainless Steel Bars in Andhra Pradesh, India.

Established in 2011, Meghmani Metal Industries is committed to delivering top-notch products to the metal industry.

We offer a wide array of stainless steel products, including plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats, meeting various industrial requirements with precision and excellence.

Stainless steel bars are solid, long, and straight metal pieces made from stainless steel. They are commonly used in various industries for structural support.

Stainless steel bars are known for their ability to withstand significant forces. The specific grade of stainless steel used will determine the exact strength, but many can bear high amounts of pressure and tension without bending or breaking.

Stainless steel square bars, like ASTM A276 Stainless Steel 316 Square Bar, offer superior strength for pressure vessels and corrosive environments, with unique finishes for various industries.

Stainless steel bars boast exceptional corrosion resistance, strength, and versatility. Available in various grades, shapes, and finishes, they serve diverse industrial needs effectively.

Stainless steel bars find wide-ranging applications across industries such as construction, automotive, aerospace, marine, food processing, and chemical processing.

Mehmani Metal Industries is one of the leading Manufacturers and Supplier of Stainless Steel Bars in Andhra Pradesh and locations like Adoni, Amaravati, Anantapurm, Chandragiri, Chittoor, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada, Kurnool, Machilipatnam, Rajahmundry, Srikakulam, Tirupati, Vijayawada, Visakhapatnam, Vizianagaram, Yemmiganur.

Feel free to contact us for more information and inquiries.

Read the full article

#Adoni#aerospace#Amaravati#Anantapurm#AndhraPradesh#Automotive#Chandragiri#chemicalprocessing#Chittoor#construction#Dowlaiswaram#Eluru#FoodProcessing#Guntur#India#Kadapa#Kakinada#Kurnool#Machilipatnam#Marine#Rajahmundry#Srikakulam#StainlessSteel316SquareBar#StainlessSteelBars#Stockiest#StockiestofStainlessSteelBarsinAndhraPradesh#StockiestofStainlessSteelBarsinIndia#supplier#SupplierofStainlessSteelBarsinAndhraPradesh#SupplierofStainlessSteelBarsinIndia

0 notes

Text

Wet Industrial Salt Manufacturer in India - Farmson Pharmaceutical Gujarat Pvt. Ltd.

Explore Farmson's high-quality wet industrial salt, manufactured with precision and expertise to meet diverse industrial needs. Whether it's for water treatment, chemical processing, or manufacturing, Farmson's wet industrial salt ensures optimal performance and reliability. We generate wet salt from MEE (Multiple Effective Evaporator) at both our plants I & II. Our product caters to the demand from textile sector, dyes & intermediaries and mines. Learn more about their superior products and how they can benefit your industrial operations.

Visit: https://www.farmson.com/products/wet-industrial-salt-manufacturer

0 notes

Text

Pipeline Projects Services in Bihar

Company Profile:

MH Infra Project is a leading provider of Interior & Exterior Turnkey Project Solutions and Pipeline project services in Bihar, India.

We specialize in providing comprehensive services for pipeline projects, catering to various industries and sectors.

Our expertise lies in designing, constructing, and maintaining pipelines for different purposes, ensuring efficiency, reliability, and compliance with industry standards.

Services Offered:

Design and Engineering: Our team of experienced engineers and designers offers custom solutions tailored to meet the specific requirements of each project.

Construction: We undertake the construction of pipelines, employing advanced techniques and equipment to ensure high-quality workmanship and timely completion.

Maintenance and Repair: We provide regular maintenance and repair services to ensure the longevity and optimal performance of pipelines.

Inspection and Testing: Our inspection and testing services help identify any issues or defects in pipelines, ensuring safety and compliance with regulations.

Rehabilitation and Upgradation: We offer rehabilitation and upgradation services to improve the efficiency and reliability of existing pipelines.

Benefits:

Expertise: Our team possesses extensive knowledge and experience in pipeline projects, ensuring the delivery of high-quality services.

Efficiency: We prioritize efficiency in project execution, optimizing processes to minimize costs and timelines.

Compliance: We adhere to regulatory standards and industry best practices, ensuring compliance with safety and environmental regulations.

Reliability: Our focus on quality and reliability ensures the longevity and performance of pipelines, minimizing downtime and operational disruptions.

Industries Served:

Oil and Gas

Water and Wastewater

Chemical Processing

Mining and Minerals

Utilities and Infrastructure

MH Infra Project Provide Pipeline Projects Services in Bihar Including Ara, Barauni, Begusarai, Bettiah, Bhagalpur, Bihar Sharif, Bodh Gaya, Buxar, Chapra, Darbhanga, Dehri, Dinapur Nizamat, Gaya, Hajipur, Jamalpur, Katihar, Madhubani, Motihari, Munger, Muzaffarpur, Patna, Purnia, Pusa, Saharsa, Samastipur, Sasaram, Sitamarhi, Siwan.

Please feel free to contact us with any questions or for additional information.

Read the full article

#Ara#Barauni#Begusarai#Bettiah#Bhagalpur#Bihar#BiharSharif#BodhGaya#Buxar#Chapra#ChemicalProcessing#Darbhanga#Dehri#DinapurNizamat#ensuringefficiency#Gaya#Hajipur#India#Jamalpur#Katihar#Madhubani#Manufacturer#MiningandMinerals#Motihari#Munger#Muzaffarpur#OilandGas#Patna#PipelineProjects#PipelineProjectsServices

0 notes

Text

Unlocking the Potential of UNS S32750 Super Duplex 2507 Sheets: A Comprehensive Guide

In the realm of modern engineering, where precision and durability are paramount, materials play a crucial role in determining the success of a project. Among the plethora of options available, one material stands out for its exceptional properties – UNS S32750 Super Duplex 2507 Sheets. Renowned for their resilience, corrosion resistance, and versatility, these sheets have become indispensable across various industries, from oil and gas to chemical processing and beyond.

Understanding UNS S32750 Super Duplex 2507 Sheets

UNS S32750, also known as Super Duplex 2507, is a super duplex stainless steel that offers a unique combination of properties. It derives its name from the dual-phase microstructure consisting of austenite and ferrite, which contributes to its exceptional strength and corrosion resistance. This grade of stainless steel contains elevated levels of chromium, molybdenum, and nitrogen, further enhancing its performance in challenging environments.

The Advantages of Grade S32750 Sheets

Corrosion Resistance: One of the most notable advantages of UNS S32750 sheets is their outstanding resistance to corrosion. They demonstrate excellent resistance to chloride-induced stress corrosion cracking, making them ideal for use in marine environments, offshore oil rigs, and chemical processing plants.

High Strength: With a higher tensile and yield strength compared to conventional austenitic stainless steels, Super Duplex 2507 sheets offer superior structural integrity, making them suitable for demanding applications where strength is critical.

Versatility: Whether it's in the form of sheets, plates, or coils, UNS S32750 stainless steel offers versatility in fabrication, allowing for the creation of custom components tailored to specific project requirements.

Applications Across Industries

UNS S32750 Super Duplex 2507 sheets find widespread applications across diverse industries:

Oil and Gas: From subsea pipelines to offshore platforms, these sheets are integral to the construction of equipment subjected to harsh operating conditions.

Chemical Processing: Super Duplex 2507 sheets excel in environments containing corrosive chemicals, providing long-term reliability for equipment such as reactors, heat exchangers, and storage tanks.

Desalination: With the growing demand for fresh water, the corrosion resistance of UNS S32750 sheets makes them a preferred choice for desalination plants, where seawater is converted into potable water.

Calico Metal: Your Trusted Partner in Stainless Steel Solutions

At Calico Metal, we understand the significance of sourcing high-quality materials for your projects. As a leading supplier of stainless steel products, including UNS S32750 Super Duplex 2507 sheets, we are committed to delivering excellence in both product quality and customer service.

With a focus on reliability, integrity, and innovation, Calico Metal has earned a reputation for being a trusted partner across industries. Our extensive inventory, coupled with stringent quality control measures, ensures that you receive premium-grade materials that meet your exact specifications.

Conclusion

In the realm of engineering excellence, the choice of materials can make all the difference. UNS S32750 Super Duplex 2507 sheets stand as a testament to the remarkable capabilities of stainless steel in meeting the most demanding requirements of modern industry. With their exceptional properties and versatile applications, these sheets continue to redefine the standards of performance and reliability.

When it comes to sourcing premium-grade stainless steel products, look no further than Calico Metal. With our unwavering commitment to quality and customer satisfaction, we are your trusted partner in unlocking the potential of stainless steel for your next project.

#UNS32750#SuperDuplex2507#StainlessSteelSheets#GradeS32750#CorrosionResistance#EngineeringMaterials#OilandGasIndustry#ChemicalProcessing#Desalination#CalicoMetal#MaterialScience#Fabrication#IndustrialApplications#EngineeringExcellence#QualityControl

0 notes

Text

Your vision, our precision. 🌐🔍 Petrochemical Refinery Plants that redefine standards. Call us now for the blueprint to your success!

#AdvancedBiofuel#PetrochemicalIndustry#RefineryPlants#ManufacturingExcellence#OilandGas#IndustrialEngineering#ChemicalProcessing#EnergyProduction

0 notes

Text

Flow Chemistry Solutions: Market Insights and Emerging Opportunities

The global flow chemistry market size is expected to reach USD 3.75 billion by 2030, according to a new report by Grand View Research, Inc. It is expected to expand at a CAGR of 11.2% from 2022 to 2030. Advantages over batch reactors and growing investments in the pharmaceutical and chemical industries are projected to boost the market growth. The COVID-19 pandemic has accelerated the need to move away from chemical commodities to specialty chemicals as per the requirement of customers. Moreover, the adoption of continuous manufacturing has increased due to the supply chain disruptions caused by the pandemic, which is expected to augment the demand for flow chemistry over the forecast period.

Flow Chemistry Market Report Highlights

The pharmaceuticals application segment is anticipated to expand at a lucrative CAGR of 12.0% from 2023 to 2030, in terms of revenue, due to the growing demand for technology that uses renewable energy sources and reduced manufacturing cost

By reactor type, microreactor is expected to witness significant growth over the forecast owing to the increasing demand for environmentally-friendly equipment and the ability to increase selectivity

Asia Pacific is estimated to expand at a significant CAGR of 12.4% over the forecast period on account of the rapidly growing petrochemical industries and a rise in academia and research in South Korea and Australia

In Europe, Germany accounted for the largest revenue share of over 30.0% in 2021 owing to the advanced infrastructure, growing pharmaceutical and chemical industries, and skilled workforce

For More Details or Sample Copy please visit link @: Flow Chemistry Market Report

Significant reductions in trash output and the eradication of non-renewable industrial methods are global environmental concerns. As a result, major economies are enacting policies to mitigate environmental damage. Several governments are implementing policies to meet the targets for reducing greenhouse gas emissions.

Continuous Stirred Tank (CST) reactor systems require little human involvement to operate, resulting in reduced labor costs associated with their deployment. Furthermore, both reactor systems have a high output rate, which leads to reduced production costs. The aforementioned factors are likely to boost the demand for CST reactor systems over the forecast period.

#ContinuousFlowChemistry#FlowChemistryIndustry#FlowChemistryMarket#GreenChemistry#ChemicalSynthesis#ChemicalEngineering#ChemicalProcessing#ChemicalReactionEngineering#PharmaceuticalManufacturing#FlowChemistrySystems#ChemicalProduction#FlowChemistryEquipment#FlowChemistryAnalysis#ScalableSynthesis#FlowChemistryApplications#ChemicalR&D#FlowChemistrySolutions

0 notes

Text

The Essential role of refinery Chemicals in oil Processing

Oil and gas is the key ingredient in manufacturing products, used by company and consumers everyday in addition to dominating the world economy. Chemtex Speciality Limited strenuously worked on the refinery industry to make a large contribution to the global economy through their upstream, downstream, midstream and other chemicals.

#refinerychemicals#oilfieldchemicals#drillingfluids#productionchemicals#demulsifiers#distillation#petrochemical#specialitychemical#chemicalprocessing#oilrefining#chemtex#chemtexltd#manufacturer#industry

1 note

·

View note

Text

Precision Mixing Made Simple with Dilution Tanks

Sodimate's dilution tanks stand as the ultimate solution for accurate and efficient chemical dilution. Crafted from top-notch materials and engineered for durability, these tanks are the go-to choice for businesses seeking reliability. Don't compromise on accuracy and efficiency. Elevate your operations with Sodimate's dilution tanks today. Contact us to learn more!

#DilutionTanks#MixingSolutions#PrecisionDilution#IndustrialMixing#ChemicalProcessing#LiquidAdditives#EfficientMixing#IndustrialEquipment#ProcessAutomation#QualityControl#IndustrialEngineering#EnvironmentalCompliance#ChemicalIndustry#TankSolutions#ManufacturingTech#ProductivityBoost

0 notes

Text

Mathesis ,Being leading Evaporators Manufacturers. We provide below types of Evaporators

Short Tube Horizontal Evaporators

Upward Flow (Climbing Film)

Downward Flow (Falling Film)

Forced Circulation

Agitated–Film Evaporators

For more information visit: https://www.mathesis.co.in/index.php

Plot No. B-35, BHEL-AIE, Ramachandrapuram, Hyderabad – 502032

+91 98857 04874

#industrial equipment#industrial#chemicalmachinery#chemicalprocessdesign#chemicalprocessing#manufacturers#equipmentsupply

0 notes

Text

Oil sealed vacuum pumps are commonly used in industries such as manufacturing, chemical processing, electronics, and research laboratories for tasks such as degassing, vacuum drying, distillation, and creating controlled atmospheres.

For more details, visit- https://www.acmeairequipments.com/product/oil-sealed-vacuum-pump/

#acmeairequipments#oilsealedvacuumpump#chemicalprocessing#vacuumdrying#researchlaboratories#electronics

0 notes