#Global Computer-Aided Design (CAD) Software Market trends

Text

Global Mobile Virtual Network Operator (MVNO) Market Size and Trends Analysis, 2027 | VynZ Research

The Global Mobile Virtual Network Operator (MVNO) Market Research Report published by VynZ Research offers first-hand data, qualitative and quantitative analysis by industry analysts, and inputs from industry experts and stakeholders across the entire chain. The research examines current market trends, macroeconomic factors, regional analysis in-depth, as well as market attractiveness by segment.

The Global Mobile Virtual Network Operator (MVNO) Market is anticipated to be valued at USD 95.2 billion by 2027, registering a market growth rate 7.8% CAGR during the 2021-2027. The Market research offers SWOT analysis of competitors including external environment analysis and PEST analysis. Furthermore, the Market study provides business methods for dealing with COVID-19 impact on the Market.

Get a sample copy of the market report: https://www.vynzresearch.com/ict-media/mvno-market/request-sample

Segmentation Analysis:

The study report examines significant market characteristics and latest developments, as well as research about relevant market segments and sub-segments, in-depth.

Segmentation of the Global Mobile Virtual Network Operator (MVNO) Market

By Type

Discount

Media

Business

Retail

Roaming

Migrant

M2M

Telecom

By Operation Model

Reseller MVNO

Full MVNO

Service Operator MVNO

By End User

Consumer

Enterprise

Prominent Leading Companies and Regional Outlook of Global Mobile Virtual Network Operator (MVNO) Market Share Analysis

The report also covers the market's major strategic developments, such as R&D, M&A, agreements, novel product launches, collaborations, partnerships, joint ventures, and regional growth of the market's competing firms on a global and regional scale.

Furthermore, the study includes Porter's five forces analysis of the industry to understand the impact of various factors on the growth of the market, such as bargaining power of suppliers, rivalry among competitors, the threat of new entrants, threat of substitutes products or service, and bargaining power of supplier.

The major industry players across the value chain for Global MVNO Market include:

IBM Corporation

Appsee

Swrve

TUNE

Localytics

Amplitude

AppDynamics

Heap

AppsFlyer

App Annie

Taplytics

Apptentive

Kochava

MOENGAGE

CleverTap

Some of the frequently asked questions addressed in the report include:

- What are the trends and drivers impacting the Global Mobile Virtual Network Operator (MVNO) Market?

-Preparation of SWOT and PESTLE analysis of competitors in the market.

-What are the regions covered in the report and the opportunities prevalent in the region leading to the growth of the market?

-What are the segments covered in the report and the strategies adopted by Industry Players in the Report?

-What are the innovative technologies in the market that are covered and their outlook?

-What are the regulations initiated by the government so as to expand the market?

- What are some recent trends that may have an impact on the product/service and return on investment (ROI)?

More Reports by VynZ Research:

Global Advanced Analytics Market – Analysis and Forecast (2021-2027)

Global RegTech Market – Analysis and Forecast (2021-2027)

Global Internet of Things (IoT) Market - Analysis and Forecast (2021-2027)

Global Computer-Aided Design (CAD) Software Market - Analysis and Forecast (2021-2027)

About Company:

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. VynZ have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities. The company focuses on providing valuable insights on various technology verticals such as Chemicals, Automotive, Transportation, Energy, Consumer Durables, Healthcare, ICT and other emerging technologies.

#Global Mobile Virtual Network Operator (MVNO) Market#Global Mobile Virtual Network Operator (MVNO) Market size#Global Mobile Virtual Network Operator (MVNO) Market share#Global Mobile Virtual Network Operator (MVNO) Market demand#Global Mobile Virtual Network Operator (MVNO) Market outlook

2 notes

·

View notes

Text

Innovation Unleashed: China's Mold Maker Revolution

Innovation is the driving force behind progress, and nowhere is this more evident than in China's mold making industry. As a pivotal component of the manufacturing process, mold makers play a crucial role in shaping the future of various industries, from automotive and aerospace to electronics and consumer goods. In this article, we explore the innovative revolution unfolding within China's mold making sector, uncovering the groundbreaking technologies, forward-thinking approaches, and transformative impacts driving the industry forward.

The Rise of China's Mold Making Powerhouses

China's mold making industry has undergone a remarkable transformation in recent years, evolving from a regional player to a global powerhouse. This ascent can be attributed to several factors, including investments in technology, advancements in manufacturing processes, and a skilled workforce.

Today, China's mold makers are renowned for their expertise, precision, and efficiency, earning accolades and recognition on the international stage. With a focus on innovation and continuous improvement, they are pushing the boundaries of what is possible and revolutionizing the mold making landscape.

Harnessing Advanced Technologies

Central to the mold maker revolution in China is the adoption of advanced technologies that enhance precision, efficiency, and quality. From computer-aided design (CAD) software to computer numerical control (CNC) machining, mold makers leverage cutting-edge tools and techniques to optimize the design and fabrication of molds.

Computer simulation software allows mold makers to visualize and analyze mold designs in a virtual environment, identifying potential issues and optimizing performance before production begins. This not only reduces time-to-market but also minimizes costs and waste, making the manufacturing process more efficient and sustainable.

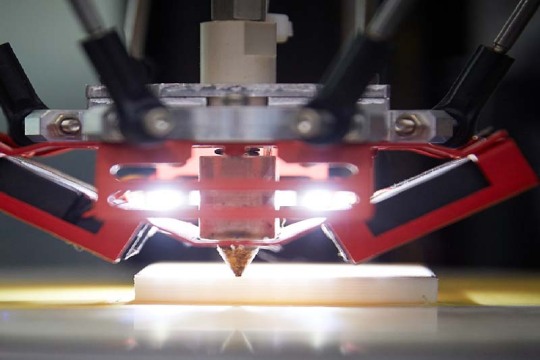

Additive Manufacturing: A Game-Changer

One of the most transformative technologies driving the mold maker revolution in China is additive manufacturing, also known as 3D printing. Additive manufacturing allows mold makers to create intricate and complex geometries with unprecedented precision and accuracy, opening up new possibilities for design and innovation.

By layering material to build up a 3D object, additive manufacturing eliminates many of the limitations of traditional manufacturing methods, such as machining and casting. This enables mold makers to produce molds with intricate details and complex shapes that would be difficult or impossible to achieve using conventional techniques.

Customization and Personalization

In addition to its ability to create complex geometries, additive manufacturing offers unparalleled flexibility and customization. Mold makers can easily modify designs and iterate on prototypes, allowing for rapid development and testing of new ideas.

This customization and personalization are particularly valuable in industries such as automotive and aerospace, where components must meet strict performance standards and regulatory requirements. Additive manufacturing enables mold makers to tailor molds to specific applications, resulting in optimized performance and enhanced product quality.

Collaboration and Partnerships

Collaboration and partnerships are fundamental to the success of China's mold makers, enabling them to leverage expertise and resources from across the industry. By working closely with customers, suppliers, and research institutions, mold makers gain valuable insights into emerging trends and technologies, driving innovation and growth.

Through collaborative efforts, mold makers can tackle complex challenges and explore new opportunities for advancement. Whether it's developing new materials, refining manufacturing processes, or improving quality control measures, collaboration allows mold makers to stay at the forefront of innovation and maintain their competitive edge in the global marketplace.

Sustainability and Environmental Responsibility

In recent years, there has been a growing emphasis on sustainability and environmental responsibility in the manufacturing industry, and China's mold makers are leading the way in this regard. Many mold makers have implemented eco-friendly practices and initiatives to minimize their environmental footprint and promote sustainable manufacturing. Find more info Zinc Die Casting

From using recycled materials and energy-efficient processes to reducing waste and emissions, mold makers are taking proactive steps to protect the planet and preserve its resources for future generations. By prioritizing sustainability, they are not only reducing costs and enhancing efficiency but also making a positive impact on the environment and society as a whole.

Conclusion: Shaping the Future of Manufacturing

In conclusion, China's mold maker revolution is driving innovation and shaping the future of manufacturing on a global scale. With a focus on harnessing advanced technologies, embracing additive manufacturing, fostering collaboration and partnerships, and prioritizing sustainability, mold makers are pushing the boundaries of what is possible and revolutionizing the industry.

As they continue to innovate and evolve, China's mold makers will play a pivotal role in shaping the future of various industries, driving progress and advancement in the years to come. With their expertise, creativity, and dedication to excellence, they are poised to lead the way in the mold making revolution and unlock new possibilities for manufacturing around the world.

0 notes

Text

The Rising Demand for Customized Solutions: Bespoke Units Market Outlook

Introduction:

In today's fast-paced world, consumers are increasingly seeking products and services that reflect their unique tastes and preferences. This quest for individuality has fueled a surge in demand for customized solutions across various industries, including the Bespoke Units Market. According to a study by Next Move Strategy Consulting, the global Bespoke Units Market size is predicted to reach USD 766.99 million with a CAGR of 7.1% by 2030, underlining the growing importance of personalized offerings in the market. This article aims to explore the factors driving the rising demand for bespoke units, the evolving landscape of customization, and the opportunities and challenges facing industry players.

The Shift Towards Customization:

In the past, consumers had limited options when it came to purchasing goods and services. Mass-produced items dominated the market, offering little room for personalization or creativity. However, as consumer preferences have evolved, so too has the demand for customized solutions. Today's consumers are seeking products that not only meet their functional needs but also reflect their individual style and personality. This shift towards customization has been particularly evident in the bespoke units market, where consumers are increasingly opting for tailor-made furniture, storage solutions, and interior design services.

Request for a sample, here: https://www.nextmsc.com/bespoke-units-market/request-sample

Meeting Consumer Expectations:

One of the key drivers behind the rising demand for bespoke units is the desire for personalized experiences. Unlike off-the-shelf products, bespoke units offer consumers the opportunity to collaborate with designers and craftsmen to create products that are truly unique. Whether it's a custom-built wardrobe, a bespoke kitchen island, or a made-to-measure shelving unit, consumers have the freedom to customize every aspect of their purchase, from materials and finishes to dimensions and functionality. This level of customization ensures that the final product not only meets but exceeds the customer's expectations, resulting in greater satisfaction and loyalty.

Driving Factors Behind the Demand:

Several factors have contributed to the growing demand for customized solutions in the bespoke units market. Firstly, increased disposable income has empowered consumers to prioritize quality and individuality over mass-produced alternatives. With more spending power at their disposal, consumers are willing to invest in products that are tailored to their specific needs and preferences. Additionally, advancements in technology have made it easier for manufacturers to offer personalized experiences while maintaining efficiency and affordability. From computer-aided design (CAD) software to advanced manufacturing techniques, technology has played a crucial role in streamlining the customization process and expanding the range of options available to consumers.

Industry Innovation and Adaptation:

As the demand for bespoke units continues to grow, industry players are innovating and adapting to meet evolving consumer needs. Design firms are investing in cutting-edge technologies such as 3D printing and augmented reality to enhance the customization process and create immersive shopping experiences. For example, some companies are using virtual reality (VR) technology to allow customers to visualize their customized products in real-time, helping to reduce uncertainty and improve decision-making. Moreover, sustainability has emerged as a key concern for consumers, leading to a growing demand for ethically sourced materials and environmentally friendly production methods. Industry stakeholders are responding to this trend by incorporating sustainable practices into their manufacturing processes, such as using recycled materials or reducing waste.

Market Outlook and Opportunities:

The outlook for the bespoke units market is highly promising, with ample opportunities for growth and expansion. As urbanization and globalization continue to reshape consumer lifestyles, the demand for customizable solutions is expected to soar across both residential and commercial sectors. In particular, emerging markets present significant opportunities for industry players looking to capitalize on evolving consumer preferences and trends. By offering innovative products, personalized experiences, and sustainable solutions, companies can position themselves for success in this rapidly growing market.

Challenges and Considerations:

While the prospects for the bespoke units market are undoubtedly bright, there are also challenges and considerations that industry players must navigate. One of the main challenges is balancing customization with cost-effectiveness. While consumers value personalized experiences, they are also conscious of price and value. Therefore, companies must find ways to offer customization without significantly inflating costs or compromising on quality. Additionally, maintaining consistency and scalability can be challenging in a market characterized by individualized products and services. Companies must invest in robust systems and processes to ensure that they can efficiently manage custom orders while meeting customer expectations.

Inquire before buying, here: https://www.nextmsc.com/bespoke-units-market/inquire-before-buying

1. Talent and Skill Shortages: Craftsmanship and skilled labor are essential components of the bespoke units market. However, finding and retaining talented artisans and craftsmen can be challenging, particularly in regions where traditional skills are in decline. Companies may need to invest in training programs or explore alternative sourcing strategies to address talent shortages and maintain quality standards.

2. Supply Chain Complexity: The customization process often involves sourcing materials from multiple suppliers, each with its own lead times and quality standards. Managing this complex supply chain can be challenging, particularly when dealing with unique or bespoke materials. Companies must establish robust relationships with suppliers and implement effective inventory management strategies to ensure a steady flow of materials while minimizing lead times and costs.

3. Intellectual Property Concerns: Customized products often involve unique designs, configurations, and features that may be subject to intellectual property (IP) protection. Companies must navigate legal and regulatory frameworks to ensure that they are not infringing on existing patents or trademarks when developing and offering customized solutions. This may involve conducting thorough IP searches, securing appropriate licenses, or seeking legal advice to mitigate the risk of infringement claims.

4. Customer Education and Communication: Effective communication is essential in the bespoke units market, where customers play a significant role in the design and customization process. However, customers may have limited knowledge or experience when it comes to designing bespoke products, leading to misunderstandings or unrealistic expectations. Companies must invest in customer education initiatives and clear communication channels to ensure that customers understand the customization process, available options, and associated costs.

5. Data Security and Privacy: In an increasingly digitalized world, companies collect and store vast amounts of customer data as part of the customization process. This data may include personal preferences, design specifications, and payment information, making it a valuable target for cyberattacks and data breaches. Companies must implement robust data security measures and adhere to strict privacy regulations to protect customer information and maintain trust and confidence in their brand.

6. Market Saturation and Differentiation: As the demand for customized solutions continues to grow, the bespoke units market is becoming increasingly saturated with competitors vying for market share. Companies must differentiate themselves from competitors by offering unique value propositions, innovative products, and exceptional customer experiences. This may involve investing in branding and marketing initiatives, leveraging customer testimonials and reviews, or introducing exclusive product lines to stand out in a crowded market.

Conclusion: In conclusion, the rising demand for customized solutions in the bespoke units market reflects a fundamental shift in consumer behavior and expectations. With increasing disposable income, advancements in technology, and a growing focus on sustainability, consumers are seeking products that are not only functional but also personalized and unique. Industry players that can effectively capitalize on this trend by offering innovative products, personalized experiences, and sustainable solutions stand to benefit from significant opportunities for growth and success. As we look towards the future, the bespoke units market is poised to thrive, offering consumers endless possibilities for personalized expression and creativity.

0 notes

Text

Engraved Cylinders And Rubber Roll Market Poised for Striking Growth: Key Insights Unveiled

The Engraved Cylinders And Rubber Roll market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Engraved Cylinders And Rubber Roll market showcased a significant presence, boasting a valuation of US$ 5.13 Billion. This underscores the substantial demand for Engraved Cylinders And Rubber Roll technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-engraved-cylinders-and-rubber-roll-market/

Projected Growth: Projections suggest that the Engraved Cylinders And Rubber Roll market will continue its upward trajectory, with a projected value of US$ 7 Billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4.30 %, reflecting a steady and robust growth rate for the Engraved Cylinders And Rubber Roll market over the coming years.

Technology Adoption: In the Engraved Cylinders and Rubber Roll market, technology adoption is revolutionizing traditional manufacturing processes. From computer-aided design (CAD) software to advanced machining techniques, manufacturers are integrating cutting-edge technologies to enhance precision, efficiency, and product quality.

Application Diversity: The versatility of engraved cylinders and rubber rolls enables their application across a diverse range of industries. From printing and packaging to textiles and automotive, these components play a crucial role in various manufacturing processes, highlighting their significance and widespread adoption.

Consumer Preferences: As consumer demands evolve, manufacturers in the Engraved Cylinders and Rubber Roll market are prioritizing attributes such as durability, performance, and customization. By understanding consumer preferences and market trends, industry players can tailor their products to meet the needs of specific applications and industries.

Technological Advancements: Continuous technological advancements are driving innovation in the Engraved Cylinders and Rubber Roll market. From the development of advanced materials to the implementation of automation and digitalization, these advancements are enhancing product capabilities, production efficiency, and overall competitiveness.

Market Competition: Intensifying competition among manufacturers is fueling innovation and product differentiation in the Engraved Cylinders and Rubber Roll market. As companies vie for market share, there is a growing emphasis on delivering superior quality products, efficient manufacturing processes, and responsive customer service to gain a competitive edge.

Environmental Considerations: Environmental sustainability is becoming an increasingly important consideration in the Engraved Cylinders and Rubber Roll market. Manufacturers are exploring eco-friendly materials, energy-efficient production methods, and waste reduction strategies to minimize their environmental footprint and meet regulatory requirements.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Trub GmbH & Co. KG

Stork Prints B.V.

Zimmer Austria GmbH

GE Plastics

BASF SE

Sumitomo Rubber Industries Ltd.

Toyo Rubber Industry Co. Ltd.

Bridgestone Corporation

Goodyear Tire & Rubber Company

Michelin Group

The research report provides a comprehensive analysis of the Engraved Cylinders And Rubber Roll market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-engraved-cylinders-and-rubber-roll-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Taiwan's Tech Haven - Decoding Circuit Board Manufacturing.

Manufacturing advanced circuit boards requires precision, expertise, and cutting-edge technology. In Taiwan, a global leader in electronics manufacturing, the process is taken to a whole new level. As a hub of innovation and technology, Taiwan has become synonymous with top-notch circuit board production. Pcb-togo.com stands out as a key player in this landscape, providing insight and solutions for circuit board manufacturing that meet the highest industry standards. Let's explore into the intricate world of circuit board manufacturing in Taiwan and uncover the secrets behind this tech haven.

Taiwan's Rise to Tech Prominence

Historical Development of Taiwan's Tech Industry

A pivotal moment in Taiwan's tech industry can be traced back to the 1960s when the government prioritized investing in education and infrastructure, laying the groundwork for a future tech powerhouse. With a strong focus on engineering and innovation, Taiwan began producing its first electronic components, paving the way for the development of a robust circuit board manufacturing sector.

Policy and Government Support for Tech Growth

Government policies played a crucial role in nurturing Taiwan's tech industry. By offering incentives, subsidies, and a conducive regulatory environment, the government encouraged both local and foreign investment in the sector. This support not only fueled the growth of existing tech companies but also attracted new players to establish a presence in Taiwan, solidifying its position as a global tech hub.

Taiwan's proactive approach in providing comprehensive support for tech growth has yielded impressive results. The government's continuous efforts in fostering innovation, providing research and development grants, and promoting collaborations between academia and industry have contributed significantly to the country's tech prominence on the world stage.

Circuit Board Manufacturing in Taiwan

The Basics of Circuit Board Production

For those unfamiliar with the intricacies of circuit board production, it involves a complex process of designing, prototyping, and manufacturing intricate electronic circuits on a board made of non-conductive material. This includes printing conductive pathways, soldering components, and testing for functionality.

Pcb-togo.com's Role in the Ecosystem

An integral player in Taiwan's thriving tech ecosystem, Pcb-togo.com specializes in providing high-quality circuit boards with quick turnaround times. With a focus on customer satisfaction and cutting-edge technology, they cater to the diverse needs of businesses ranging from small startups to large corporations.

Circuit board manufacturing in Taiwan has evolved to meet the demands of the rapidly growing tech industry. With a combination of advanced technologies, skilled workforce, and efficient processes, Taiwan has solidified its reputation as a global hub for electronics manufacturing. Pcb-togo.com's commitment to quality and innovation further enhances Taiwan's position as a leader in the field.

Innovations and Advancements

Cutting-Edge Technologies and Techniques

To stay on the forefront of circuit board manufacturing, companies like Pcb-togo.com are leveraging cutting-edge technologies and techniques. From advanced computer-aided design (CAD) software to state-of-the-art automated assembly lines, these innovations are revolutionizing the industry. Not only do these advancements improve efficiency and precision, but they also allow for the production of more complex and compact circuit boards that are necessary for today's electronic devices.

How Pcb-togo.com Stays Ahead of the Competition

An integral part of Pcb-togo.com's success lies in their ability to stay ahead of the competition. By continuously investing in research and development, they are able to adopt the latest technologies and optimize their manufacturing processes. Stays abreast of market trends and customer demands, Pcb-togo.com ensures that they are always one step ahead in delivering high-quality circuit boards that meet the evolving needs of their clients.

Navigating the Market with Pcb-togo.com

Understanding the Global Supply Chain

Once again, in the competitive landscape of circuit board manufacturing, understanding the global supply chain is crucial. With Pcb-togo.com, you can navigate the intricate web of suppliers and manufacturers effortlessly, ensuring a smooth and efficient production process.

Custom Solutions and Service Excellence

On the forefront of technology, Pcb-togo.com offers custom solutions tailored to meet your specific requirements. Their commitment to service excellence guarantees a seamless experience from design to delivery, making them the go-to choice for all your circuit board needs.

This dedication to custom solutions and service excellence sets Pcb-togo.com apart from the competition. Their team of experts works closely with clients to understand their unique needs and deliver quality products on time and within budget. With a focus on innovation and customer satisfaction, Pcb-togo.com ensures that every project is a success.

Summing up

Now, after decoding the intricacies of circuit board manufacturing in Taiwan, provided by Pcb-togo.com, it is evident that Taiwan's tech industry has solidified its position as a global tech haven. The expertise, efficiency, and advanced technology showcased in the process highlights Taiwan's commitment to innovation and precision. Partnering with a reputable company like Pcb-togo.com ensures the highest quality circuit boards for a wide range of applications. As technology continues to advance, Taiwan's tech sector remains at the forefront, setting the standard for excellence in manufacturing.

Original Sources: https://themediumblog.com/taiwans-tech-haven-decoding-circuit-board-manufacturing/

0 notes

Text

Insights into the Global Dental Equipment Industry

The dental equipment market shines brightly, offering a comprehensive array of tools and technologies that empower dental professionals to provide optimal oral healthcare. Projected to reach a staggering USD 23.8 billion by 2029, this market is witnessing robust growth fueled by advancements in technology, rising dental awareness, and an increasing global focus on preventative care. Let's delve into the latest statistics, explore the key trends shaping the industry, and examine the challenges and opportunities that lie ahead.

Market Size and Share: A Lucrative Smile

The global dental equipment market size is estimated to be around USD 19.2 billion in 2024. This impressive figure highlights the crucial role dental equipment plays in enabling dentists and hygienists to deliver high-quality care. While the market share of dental equipment within the overall healthcare industry varies depending on methodology, it's estimated to be between 2% and 3%. This share reflects the growing importance of advanced equipment in modern dentistry.

Regional Variations: A Global Market with Diverse Needs

The Asia Pacific region currently holds the largest market share in the dental equipment market, accounting for around 40% of the global market in 2021. This dominance is attributed to factors like a growing middle class with rising disposable income, increasing government investments in healthcare infrastructure, and a focus on improving oral health awareness. However, North America and Europe are also witnessing significant growth due to technological advancements and a focus on minimally invasive procedures.

Market Drivers: A Multifaceted Force for Growth

Several key factors are propelling the dental equipment market forward:

Technological Advancements: The constant development of innovative technologies is revolutionizing dentistry. Digital X-rays, computer-aided design and computer-aided manufacturing (CAD/CAM), and laser dentistry are driving efficiency, precision, and patient comfort during procedures.

Rising Dental Awareness: Public health campaigns and increased media attention on the importance of oral hygiene are leading to a growing demand for preventative and restorative dental care. This necessitates the use of advanced equipment for accurate diagnosis and treatment.

Growing Geriatric Population: The aging population globally signifies a growing need for specialized dental equipment catering to implant dentistry, periodontal treatments, and oral care solutions for denture wearers.

Increased Focus on Minimally Invasive Procedures: Minimally invasive procedures like laser dentistry and cone beam CT scans are gaining popularity due to their patient-centric approach, shorter recovery times, and improved treatment outcomes.

Market Trends: Embracing Innovation and Efficiency

The dental equipment market is brimming with exciting trends that shape how dentistry is practiced:

Artificial Intelligence (AI) Integration: AI-powered diagnostic tools and treatment planning software are emerging, offering improved accuracy and efficiency in dental care.

Cloud-Based Dentistry: The adoption of cloud-based solutions for dental imaging and patient data management is on the rise, promoting data security, remote collaboration, and improved workflow.

Teledentistry Gains Traction: Teledentistry platforms allow for remote consultations and patient monitoring, improving accessibility to dental care for geographically remote areas or those with limited mobility.

Focus on Patient Comfort: Manufacturers are prioritizing patient comfort by developing equipment with reduced noise levels, improved ergonomics, and features that minimize discomfort during procedures.

Challenges and Opportunities: Navigating the Evolving Landscape

Despite its rapid growth, the dental equipment market faces some key challenges:

High Cost of Equipment: Advanced dental equipment can be expensive, posing an investment hurdle for smaller dental practices. This creates a need for financing options and cost-effective solutions.

Cybersecurity Concerns: The increasing reliance on digital technology and patient data storage necessitates robust cybersecurity measures to protect sensitive information.

Need for Skilled Professionals: Advanced equipment requires skilled professionals to operate it effectively. Training and education initiatives are crucial to ensure a skilled workforce that can leverage new technologies.

The Future of Dental Equipment: A Brighter, More Connected Future

The dental equipment market presents a dynamic and exciting space for growth. By embracing technological advancements, focusing on affordability and accessibility, and prioritizing patient comfort and safety, dental equipment companies can ensure they continue to offer innovative solutions for a healthier and brighter smile for everyone. The future of dentistry promises to be a connected, technologically driven space, offering a more personalized and efficient dental care experience.

0 notes

Text

https://www.advancemarketanalytics.com/reports/94341-global-dental-cad-cam-market

Dental CAD-CAM Market Study Reveal explosive growth potential

Advance Market Analytics released a new market study on Global Dental CAD-CAM Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Dental CAD-CAM Forecast till 2029*.

In Recent times, CAD-CAM technology is widely used in dentistry to construct dental restorations and prostheses. CAD-CAM system allows dentists or laboratory technicians to automate the fixed restoration process and complete all processes in a single or two visits. CAD-CAM technology is the best option for dental professionals as it helps to eliminate the outsourcing cost. However, the chairside CAD-CAM technique is highly used by dentist professionals for scanning the preparation and then fabricating the restoration in the milling device.

Key Players included in the Research Coverage of Dental CAD-CAM Market are:

Ivoclar Vivadent (Liechtenstein), Dentsply Sirona (United States), 3Shape (Denmark), Align technology (United States), Zimmer Biomet (United States), Planmeca (Finland), exocad GmbH (Germany), Kelkar Dynamics LLP. (India), Roland DGA Corporation (United States), Institut Straumann AG (Switzerland), Datron AG (Germany), vhf camfacture AG (Germany), Dental wings Inc. (Canada), Amann Girbach AG (Austria)

What's Trending in Market: Advancements in Computer-Aided Design and Manufacturing and Use of Virtual Articulators in the CAD-CAM Technology

Rising demand for Cloud-based Dental CAD Software Among the Users Due to Flexibility and Avoid Downtime

Challenges: Quality Concerns Due to Quick Process and Requirement of Skilled Workforce

Opportunities: High Growth of CAD-CAM Systems for Dentistry in Emerging Economies like China, India, and Singapore

Market Growth Drivers: Demand for Laboratory CAD-CAM Systems in Dentistry for Tooth Construction and Restoration Process

Increased Adoption of CAD-CAM Systems in Dental Clinics to Reduce Waiting Time, Outsourcing Costs, and Improve Accuracy

The Global Dental CAD-CAM Market segments and Market Data Break Down by Type (Practices CAD-CAM Systems, Laboratories CAD-CAM Systems), Application (Crowns, Inlays, Onlays, Veneers, Bridges, Dentures, Other Implant-Supported Restorations), Components (Digital Impressions, CAD Software (Cloud, On-Premises)), End Users (Hospitals, Dental Clinics, Laboratories, Others), Dimension (2D Images, 3D Images)

Get inside Scoop of the report, request for free sample @: https://www.advancemarketanalytics.com/sample-report/94341-global-dental-cad-cam-market

To comprehend Global Dental CAD-CAM market dynamics in the world mainly, the worldwide Dental CAD-CAM market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

0 notes

Text

Analyzing Market Trends - Architectural CAD Software Industry Insights

Architects and professionals in the construction industry are increasingly turning to technology to drive innovation and enhance productivity. The advent of Architectural Computer-Aided Design (CAD) software has revolutionized the collaborative efforts of architects, engineers, and designers in bringing their projects to life. With the architectural CAD software market expanding and evolving, there are abundant investment opportunities for those who are well-informed. Understanding the dynamics of the architectural CAD software market is crucial, as it mainly focuses on software solutions that aid in the creation and management of digital models of buildings and structures. This technology has significantly improved design precision, project visualization, teamwork, and cost efficiency.

Increasing Demand

The global demand for architectural CAD software is on the rise due to the growth of the construction industry, urbanization, and the focus on sustainability goals.

Technological Advancements

Continuous advancements in software capabilities, such as 3D modeling, Building Information Modeling (BIM), and cloud-based collaboration, are driving the growth of the market.

Industry-Specific Needs

Different sub-sectors within the architecture and construction industry have specific software requirements, leading to the creation of niches and specialized offerings.

Market ConsolidationLarger companies often acquire smaller ones to expand their product portfolios and customer bases, leading to market consolidation.

Global ExpansionArchitectural CAD software providers are actively targeting global markets, creating attractive opportunities for investors.

Market Segmentation

To effectively strategize in this market, investors and stakeholders need to have a clear understanding of its segmentation. This includes the different types of software available, the target end-users, the deployment models, and the geographical regions in which the market operates.

Software Types CAD software can be classified into three main types - 2D CAD, 3D CAD, and BIM software. Each type has its unique features and applications, catering to specific needs within the industry.

End-usersThe target users of CAD software are diverse and can include architects, engineers, contractors, and other professionals in the AEC industry. Understanding the specific requirements and preferences of these end-users is crucial for successful market penetration.

Deployment ModelsCAD software can be installed on-premises or accessed through cloud-based platforms. The choice of deployment model can have implications for cost, accessibility, and scalability, and should be carefully considered based on the needs of the target market.

Strategies for Smart Investors

Expanding Your PortfolioThe practice of diversification is an essential approach to risk management. Within the realm of architectural CAD software, this entails exploring investments in various software categories, end-user sectors, and geographic locations. By distributing investments across multiple domains, the adverse effects of market fluctuations can be minimized, thereby diminishing overall risk.

Stay InformedIn the fast-paced world of technology, knowledge is power. Investors and stakeholders must stay informed about the latest trends and developments in the industry. This can be achieved by regularly monitoring industry news, attending conferences, and engaging with industry experts. By staying abreast of emerging technologies and market shifts, investors can gain a significant advantage.

Assess Market TrendsIdentifying and capitalizing on current market trends is a strategic move. For example, the growing emphasis on sustainable and green building practices has created opportunities for software providers specializing in BIM and energy-efficient design. By staying attuned to these trends, investors can identify potential investment opportunities and position themselves for success.

The architectural CAD software market is a dynamic and expanding sector that presents numerous opportunities for smart investors and stakeholders. By understanding market dynamics, staying informed, and implementing strategic approaches like diversification, trend analysis, and a user-centric focus, investors and stakeholders can make informed decisions to capitalize on the growth and innovation within this industry. Sree Cadd offers one of the top architectural cadd courses in Kerala, Thamilnadu. As technology continues to shape the future of architecture and construction, those who invest wisely and strategically will be well-positioned to benefit from this ever-evolving market.

0 notes

Text

Transformative Precision: Unleashing the Power of CNC Technology in Modern Manufacturing

Computer Numerical Controls (CNC) is a technology that plays a pivotal role in modern manufacturing processes. It involves the use of computers to control machining tools and equipment, transforming traditional manual operations into automated, precise, and efficient processes. CNC systems rely on programming languages to dictate the movements and operations of cutting, milling, and drilling tools, ensuring a high level of accuracy and repeatability in the production of intricate components. This technology has revolutionized industries ranging from aerospace and automotive to electronics and healthcare, allowing for the mass production of complex parts with minimal human intervention.

Key Components and Functionality of CNC:

The heart of a CNC system lies in its ability to interpret digital designs and execute precise movements. The key components include the CNC controller, which interprets the programmed instructions, and the machine tool, which carries out the physical operations. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are crucial in creating the digital models and generating the CNC code. The demand for CNC machines is driven by the need for high-precision manufacturing, increased efficiency, and reduced production times. CNC technology enables manufacturers to achieve tight tolerances and intricate designs, resulting in improved product quality and competitiveness.

Demand Drivers for CNC Technology:

The demand for CNC technology is fueled by several factors. Firstly, industries are constantly seeking ways to enhance efficiency and reduce production costs, and CNC machining provides a solution by minimizing material wastage and human errors. Secondly, the increasing complexity of product designs necessitates the precision and repeatability that CNC machines offer. Thirdly, as global markets become more competitive, manufacturers are adopting CNC technology to stay ahead by delivering high-quality products at competitive prices. Additionally, the versatility of CNC machines, capable of handling various materials and producing a wide range of components, further contributes to their increasing demand across industries.

Future Trends and Innovations:

Looking ahead, the demand for CNC technology is expected to continue growing as industries embrace Industry 4.0 and smart manufacturing. Integration with IoT (Internet of Things), AI (Artificial Intelligence), and machine learning is likely to further enhance the capabilities of CNC machines, making them smarter and more adaptable to changing production requirements. The evolution of CNC technology will not only focus on improving precision and efficiency but also on sustainability, as manufacturers seek eco-friendly solutions. The ongoing advancements in CNC technology are set to redefine the landscape of manufacturing, providing innovative solutions to meet the evolving needs of diverse industries.

0 notes

Text

CAM Software Market Will Hit Big Revenues In Future | Biggest Opportunity Of 2024

Computer-aided manufacturing (CAM) software is the tool which is used to automate the manufacturing processes. CAM software is in widespread use by the engineers, architects, designers for manufacturing and designing objects, specifically computer numerical control (CNC) machining. CAM is the result of the computer-aided process for both, computer-aided designing and computer-aided engineering. The model generated in CAD and tested in CAE can be the input for CAM software, which helps in controlling the machine tool. The main application of this tool is in controlling the manufacturing plant. the CAM software use assemblies formed to generate toolpath that drives machine tools to turn designs into the physical parts.

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/33655-global-cam-software-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global CAM Software Market, offers a detailed overview of the factors influencing the global business scope. CAM Software Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the CAM Software The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Autodesk Inc. (United States), Vero (United Kingdom), Delcam (United Kingdom), PTC (United States), Siemens (Germany), Dassault Systemes (France), Cimatron (Israel), DP Technology (United States), Missler Software (France), NTT Data Engineering System (Japan), BobCAD-CAM (United States), Breton (Italy), JPS - VETIGRAPH (France), LANG (Germany), Lantek Sheet Metal Solutions S.L (Spain), OPEN MIND (United States), TopSolid (France), ZWSOFT (China), SCHOTT SYSTEME GmbH (Germany)

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

0 notes

Text

Product Engineering Companies: Pioneers of Innovation

In the ever-evolving world of technology, product engineering companies stand at the forefront, pioneering innovation and crafting the future. These organizations are not just manufacturing entities; they are the architects of groundbreaking products that transform industries and shape our daily lives. This article delves into the realm of product engineering companies, exploring their roles, processes, and the impact they have on the global market.

The Essence of Product Engineering Companies

Product engineering companies specialize in the conception, development, design, and testing of new products. Unlike traditional manufacturing firms that primarily focus on production, these companies are involved in every phase of the product lifecycle, from the initial idea to its launch in the market. This holistic approach ensures that the end products are not only innovative but also reliable, user-friendly, and scalable.

The essence of these companies lies in their ability to integrate engineering expertise with creative problem-solving skills. They employ a multidisciplinary team of engineers, designers, and project managers who work collaboratively to turn complex problems into simple, effective solutions. By leveraging advanced technologies and methodologies, such as CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and agile development processes, they are able to accelerate product development and improve efficiency.

The Role of Innovation and Technology

Innovation is the lifeblood of product engineering companies. In a competitive landscape, the ability to innovate—to create new products or improve existing ones—is what sets these companies apart. This relentless pursuit of innovation is driven by a deep understanding of market needs and trends, as well as a commitment to research and development (R&D).

Technology plays a pivotal role in enabling innovation. From artificial intelligence (AI) and the Internet of Things (IoT) to additive manufacturing and blockchain, emerging technologies are harnessed to develop products that are smarter, more connected, and more sustainable. These technological advancements not only enhance product functionality but also open up new possibilities for innovation.

Impact on Industries and Society

The impact of product engineering companies extends far beyond the technology sector. They are instrumental in driving progress across a wide range of industries, including healthcare, automotive, aerospace, consumer electronics, and renewable energy. By introducing innovative products, these companies contribute to improving efficiency, reducing costs, and enhancing the quality of life.

For instance, in the healthcare industry, product engineering companies have developed wearable devices that monitor vital signs, smart prosthetics that mimic natural movement, and telemedicine platforms that enable remote patient care. In the automotive sector, they are at the helm of developing electric vehicles, autonomous driving technologies, and connected car systems that promise to revolutionize transportation.

Moreover, product engineering companies play a crucial role in addressing global challenges such as climate change and resource scarcity. By focusing on sustainable product design and adopting green manufacturing practices, they are helping to reduce environmental impact and promote a more sustainable future.

For More Info:-

best app development companies

business analytics software

0 notes

Text

Revolutionizing Precision by CNC Components Manufacturers

CNC (Computer Numerical Control) is a machining technology. Products are created by removing material from a so-called workpiece using various cutting tools. At the same time, the production process is automated by software – the tool or workpiece moves according to the code, and the machine operator performs only auxiliary operations, such as changing tools or setting the workpiece. CNC machining by CNC components manufacturers makes it possible to produce high-precision parts from a CAD (computer-aided design system) file with excellent physical and mechanical properties. Due to the high level of automation, CNC machining is competitive for single pieces & short runs, as well as for serial and mass production.

CNC manufacturing process

The CNC manufacturing process of a product can be broken down into four main steps:

1. An engineer designs a CAD model.

2. A technologist based on CAD/CAM software prepares a control program for the CNC machine.

3. The operator inserts the tool, and workpiece into the CNC machine and starts the control program.

4. The CNC machine performs all the processing operations – material removal.

CNC Machine Applications Industries

Aerospace

The aerospace industry encompasses all modes of air transport, from massive Airbus A380 aircraft that carry hundreds of passengers to spacecraft designed to fly to the International Space Station, the Moon, and even Mars. Aerospace technology is characterized by incredible precision that is difficult to achieve with conventional tools, which is why CNC machines by CNC-turned parts manufacturers were the perfect solution.

CNC in Aviation

The CNC machine plays a crucial role in the fast and accurate production of the parts that are used in the operation of every component of the aircraft. Such tools are used to create engine parts, cockpit equipment, aircraft skin, wings, and other parts.

CNC in the space industry

CNC is used at NASA, SpaceX, and Roscosmos enterprises to provide rockets with parts of any size and shape with incredibly high fitting accuracy. They produce spare parts for engines, computer equipment, parts for various systems, and spacecraft hulls.

Car

Car shop manager Rocky Helms has a lot of work to do. He oversees the workshop of the world-famous racing team Richard Childress Racing (RCR). The company's 24 employees work two shifts a day to produce the 170,000 parts needed to service the RCR.

The workshop itself occupies 7,000 square meters on a 210,000 square meter campus. Since its inception in 1969, RCR has played 17 championships and won more than 200 times in three NASCAR Major Series, including three Daytona 500 races (1998, 2007, 2018) and three Brickyard 400 races (1995, 2003, 2011).

To increase the production of cars and maintain maximum productivity in the workshop, the RCR is equipped with the latest material handling technologies, including the Roland MODELA MDX-540 benchtop mill.

According to Helms, the machine can do the work in 10 minutes that a person does in 10 hours. RCR uses Roland to mill engine and brake parts, wheel discs, and shock absorbers. The device is also used to create carbon fiber parts & to engrave identification numbers on parts.

Medical

In the space industry, it is customary to say: "There is no repair shop in space." The quality, precision, and reliability of each part must be impeccable because once it leaves the planet, it just has to work. The same applies to the medical field. If the prosthetic implant does not work properly, it affects the health and well-being of the patient. When the operation is complete, the part simply needs to function.

Global trends indicate that the need for medical implants will increase, as will the competition in the market. According to Seco Tools, about five major suppliers are vying for 85 percent of the orthopedic parts market, with more than 200 companies vying for the remaining 15 percent.

The manufacturing process of orthopedic implants includes cutting, grinding, 3D printing, and other operations on CNC devices by CNC machining parts factory. The machine performs roughing, finishing, milling, T-slot machining, chamfering, and deburring. The goal is to achieve the required surface finish, reducing the need for time-consuming manual processing. Five-axis milling and grinding machines provide advantages when working with complex shapes and contours of prosthetic implants. Thanks to CNC, the production time is significantly reduced & the accuracy is increased. Modern technology is capable of processing almost any material, including titanium and ceramics.

0 notes

Text

Global Computer Aided Design (CAD) Market: Information by Technology, Application and Regional Outlook Forecast 2023 to 2030

Global society and the economy are being affected by the Covid-19 pandemic. The effects of this epidemic are spreading and disrupting the supply chain every day. The COVID-19 problem is causing the stock market to be uncertain, the supply chain to be significantly slowed down, corporate confidence to be declining, and client segment panic to be growing. The pandemic's overall impact is having an impact on how many different industries produce their products. This research on " Computer Aided Design (CAD) Market” analyses the effects of Covid-19 on numerous business sectors and international markets. Additionally, the studies highlight market trends and projections through 2031 while accounting for the COVID -19 Situation.

The global Computer-Aided Design (CAD) market is gearing up for a transformative year in 2023, characterized by innovative technologies that are reshaping the landscape of design and engineering. With a focus on emerging market trends, substantial growth projections, and the forces propelling this design revolution, the CAD sector is charting the course for a future of unparalleled creativity and efficiency.

Free Sample Copy of This Report @ https://www.econmarketresearch.com/request-sample/EMR001

Key Trends Redefining Design Innovation:

Cloud-Based CAD Solutions: The CAD market is witnessing a surge in cloud-based solutions, enabling designers and engineers to collaborate seamlessly, access projects from anywhere, and leverage the power of real-time collaboration. Cloud-based CAD platforms are enhancing flexibility and efficiency in design workflows.

Integration of Artificial Intelligence (AI): The integration of AI in CAD software is revolutionizing the design process. AI-powered tools are automating repetitive tasks, optimizing designs, and providing intelligent insights, thereby accelerating the pace of innovation and allowing designers to focus on creative aspects.

3D Printing Integration: CAD software is increasingly integrated with 3D printing technologies, facilitating a smoother transition from digital design to physical prototypes. This convergence is fostering rapid prototyping, reducing time-to-market, and unlocking new possibilities for manufacturing and product development.

Check Discount for This Report: https://www.econmarketresearch.com/request-discount/EMR001

Anticipated Market Growth:

The CAD market is poised for substantial growth, driven by factors such as the increasing demand for sophisticated design tools, advancements in technology, and the growing adoption of CAD across diverse industries. With a projected compound annual growth rate (CAGR) of [insert percentage], the market is set to redefine the way designers and engineers approach their work.

Forces Steering and Challenges to Overcome:

Industry 4.0 and Digital Transformation: The wave of Industry 4.0 and digital transformation initiatives across industries is a major driver for CAD adoption. However, companies must navigate the challenges associated with upskilling the workforce and integrating CAD systems into existing workflows.

Data Security and Privacy Concerns: As CAD software relies heavily on digital data, ensuring the security and privacy of sensitive design information is a critical concern. The CAD market is actively addressing these challenges through robust encryption, secure collaboration features, and compliance with data protection standards.

Designing a Future of Innovation:

As the CAD market continues to evolve, industry leaders are actively collaborating to overcome challenges and unlock the full potential of digital design technologies. The focus remains on empowering designers and engineers with tools that foster creativity, efficiency, and a seamless design-to-production journey.

Speak to Analyst @ https://www.econmarketresearch.com/industry-report/computer-aided-design-cad-market/

Computer Aided Design (CAD) Market Key Players:

· Autodesk, Inc.

· Bentley Systems, Inc.

· Hexagon AB

· Oracle

· PTC

· Siemens

· Dassault Systems SolidWorks Corp.

· BobCad-Cam, Inc.

· CNC Software, Inc.

· 3D Systems Corporation

· Advanced Computer Solution Ltd

· Beijing Generous Digital Technology

· Graphisoft

· Solidworks Corporation

Segmentation: -

By Product

1. 2D

2. 3D

By Component

· Service

· Solution

· By Deployment

On-Premises

· Cloud

By Application

· Aerospace & Defense Industry

· Shipbuilding Industry

· Automobile & Train Industry

· Machine Tool Industry

· Building & Construction

By Region

· North America

· Latin America

· Europe

· Asia Pacific

· Middle East & Africa

About Us:

Econ Market Research is an all-inclusive resource for providing useful insight gleaned through industry research. Through our syndicated and consulting research services, we assist our clients in finding solutions to their research needs. Industries including semiconductor and electronics, aerospace and defence, automobiles and transportation, healthcare, manufacturing and construction, media and technology, chemicals, and materials are among our areas of expertise.

Contact Us:

Econ Market Research Private Limited.

E-mail: [email protected]

Phone: +1 812 506 4440

Website: - https://www.econmarketresearch.com

Connect with us at LinkedIn | Facebook | Twitter | YouTube

0 notes

Text

Model-Based Manufacturing Software Market to Witness Excellent Revenue Growth Owing to Rapid Increase in Demand

Latest released the research study on Global Model-Based Manufacturing Software Market, offers a detailed overview of the factors influencing the global business scope. Model-Based Manufacturing Software Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Model-Based Manufacturing Software The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Siemens AG (Germany), General Electric (United States), PTC, Inc. (United States) , Dassault Systèmes SE (France), Autodesk, Inc. (United States), SAP SE (Germany), HCL Technologies Ltd. (India) , Oracle Corporation (United States), Aras Corporation (United States), Anark Corporation (United States)

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/185488-global-model-based-manufacturing-software-market?utm_source=Organic&utm_medium=Vinay

Model-Based Manufacturing Software Market Definition:

Model-based manufacturing software is a revolutionary approach to working with manufacturing data that focuses on models rather than traditional paper for all production operations throughout the life cycle of a product. It is a thorough and cost-effective tool for assessing and documenting the properties of a system. From the beginning to the end of the merchandise life cycle, model-based software development and system design rely on the use of formal, composable, and manipulable models. A common thread is the fact that modelling languages are domain-specific. This means they give developers concepts that are tailored to capture the important characteristics of their application domain.

Market Trend:

Increasing Adoption of IoT and Cloud- based Platforms

Market Drivers:

Evolving Software Capabilities

Market Opportunities:

Growing e-commerce Sector

The Global Model-Based Manufacturing Software Market segments and Market Data Break Down are illuminated below:

by Type (MES (Manufacturing Execution Software) Based Systems, ERP (Enterprise Resource Planning) Based Systems, MRP (Material Requirements Planning) Based Systems, CAD (Computer Aided Design) & PLM (Product Lifecycle Management) Based Systems, Others), Deployment Mode (On-premises, Cloud Based), Industry (Aerospace & Defense, Automotive, Construction, Retail, Power & Energy, Food & Beverages, Others), Offering (Solutions, Services)

Region Included are: North America, Europe, Asia Pacific, Oceania, South America, Middle East & Africa

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

Enquire for customization in Report @: https://www.advancemarketanalytics.com/enquiry-before-buy/185488-global-model-based-manufacturing-software-market?utm_source=Organic&utm_medium=Vinay

Strategic Points Covered in Table of Content of Global Model-Based Manufacturing Software Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Model-Based Manufacturing Software market

Chapter 2: Exclusive Summary – the basic information of the Model-Based Manufacturing Software Market.

Chapter 3: Displayingthe Market Dynamics- Drivers, Trends and Challenges of the Model-Based Manufacturing Software

Chapter 4: Presenting the Model-Based Manufacturing Software Market Factor Analysis Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying market size by Type, End User and Region 2015-2020

Chapter 6: Evaluating the leading manufacturers of the Model-Based Manufacturing Software market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by manufacturers with revenue share and sales by key countries (2021-2026).

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, Model-Based Manufacturing Software Market is a valuable source of guidance for individuals and companies in decision framework.

Data Sources & Methodology

The primary sources involves the industry experts from the Global Model-Based Manufacturing Software Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects.

In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age.

For Early Buyers | Get Up to 20% Discount on This Premium Report: https://www.advancemarketanalytics.com/request-discount/185488-global-model-based-manufacturing-software-market?utm_source=Organic&utm_medium=Vinay

What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

1 note

·

View note

Text

"Glimmers of Artistry: Exploring Jewellery Designing Courses in Pune"

Pune, a city renowned for its rich heritage and cultural diversity, has emerged as a hub for education, innovation, and creativity. In the realm of artistic expression, the field of jewellery designing has gained prominence, offering individuals a platform to unleash their creativity and delve into the world of exquisite craftsmanship. Jewellery designing courses in Pune stand as gateways to this captivating realm, providing aspiring designers with the skills, knowledge, and expertise to excel in this artistic niche.

Jewellery designing courses in Pune encompass a comprehensive curriculum that blends traditional techniques with modern trends, catering to the evolving demands of the industry. These courses cover a spectrum of subjects, including design fundamentals, gemology, metalwork, CAD (Computer-Aided Design), rendering techniques, and understanding market trends. Students are introduced to various materials, gemstones, and metals, enabling them to experiment and create unique, aesthetically appealing jewellery pieces.

The courses are meticulously crafted to foster creativity, encouraging students to explore innovative design concepts and develop their signature style. Practical sessions, workshops, and hands-on training play a pivotal role in honing the technical skills required for crafting jewellery. Under the guidance of experienced instructors and industry professionals, students learn the art of conceptualizing, designing, and producing jewellery pieces that reflect craftsmanship and elegance.

What sets jewellery designing courses in Pune apart is the integration of traditional craftsmanship with modern technology. Students are exposed to CAD software and 3D printing techniques, enabling them to translate their design ideas into digital formats and create prototypes, thus bridging the gap between traditional artisanal skills and contemporary design practices.

The city of Pune, known for its artistic heritage and vibrant atmosphere, serves as an inspiring backdrop for budding jewellery designers, especially those enrolling in Jewellery Designing Short Courses in Pune. Its amalgamation of cultural influences, historical significance, and modern aesthetics provides an enriching environment for students to draw inspiration and infuse elements of Pune's heritage into their designs.

Furthermore, these courses often offer opportunities for industry exposure through internships, collaborations with jewellery houses, and participation in design exhibitions or showcases. Such practical experiences enable students to understand market dynamics, trends, and consumer preferences, preparing them for a seamless transition into the professional realm of jewellery design.

Upon completion of jewellery designing courses in Pune, graduates possess a diverse skill set and a robust portfolio showcasing their design acumen. Many institutes also offer placement assistance, connecting graduates with reputed jewellery brands, design studios, or entrepreneurial opportunities, allowing them to embark on rewarding careers in the thriving jewellery industry.

In conclusion, jewellery designing courses in Pune, especially those offering opportunities to Learn Jewellery Designing Courses in Pune, stand as avenues for aspiring designers to delve into the fascinating world of jewellery craftsmanship. These courses blend creativity, technical expertise, and market insights, nurturing talent and empowering individuals to sculpt their artistic visions into exquisite pieces that resonate with the ever-evolving tastes of the global jewellery market.

0 notes

Text

The Intersection of Fashion and Technology in the USA

Introduction

The landscape of fashion in the USA is undergoing a transformative journey at the crossroads of tradition and technology. Within this dynamic intersection, Apparel manufacturers, pioneers in the global apparel industry, are redefining the way we perceive and consume fashion. Clothing manufacturers in America are at the forefront of this evolution, seamlessly blending innovation with craftsmanship. As the demand for sustainable practices rises, American clothing manufacturers are leading the charge, introducing eco-friendly initiatives. This introduction encapsulates the essence of a burgeoning industry where the convergence of tradition and cutting-edge technology propels American apparel manufacturers to new heights, shaping a future where style and innovation coalesce in every stitch and seam.

Evolution of Technology in Apparel Manufacturing

The evolution of technology in apparel manufacturing has been a hallmark of the journey undertaken by USA clothing manufacturers. From the early days of the Industrial Revolution to the contemporary era of digital innovation, technology has been a driving force shaping the very fabric of the American fashion industry. Clothing manufacturers in USA have witnessed a transformative shift in their production processes, with automation, computer-aided design (CAD), and robotics becoming integral to the manufacturing landscape. This technological evolution has not only streamlined and expedited production but has also elevated the precision and quality of American-made garments.

American clothing manufacturers have adeptly embraced these innovations, utilizing technology as a tool for efficiency and excellence. The integration of cutting-edge machinery and software has allowed for intricate designs, faster production cycles, and enhanced customization capabilities. In this ever-evolving landscape, apparel manufacturers in the USA are not merely keeping pace with technological advancements; they are actively driving the industry forward.

The embrace of technology by American clothing manufacturers reflects a commitment to staying at the forefront of global fashion trends. This evolution is not just about efficiency; it's a testament to the resilience and adaptability of the industry. As technology continues to advance, clothing manufacturers in America stand poised to redefine the boundaries of what is possible, ensuring that the USA remains a hub of innovation and excellence in the realm of apparel manufacturing.

USA Clothing Manufacturers Embrace Innovation

In the dynamic landscape of the American fashion industry, clothing manufacturers in the USA stand as trailblazers, actively embracing innovation to redefine the standards of excellence. These manufacturers, encompassing a diverse range from sustainable clothing manufacturers to American denim manufacturers, are at the forefront of integrating cutting-edge technologies into their production processes. The commitment to innovation extends beyond mere operational efficiency; it's a strategic approach to stay ahead in a global market.

Clothing manufacturers in America showcase a keen understanding of the transformative power of innovation. From automation and artificial intelligence to sustainable practices, these manufacturers employ a holistic approach to elevate the quality and appeal of their products. Sustainable clothing manufacturers, in particular, are driving positive change by adopting eco-friendly materials and production methods, aligning with the increasing consumer demand for environmentally conscious fashion.

The embrace of innovation by American clothing manufacturers is not only reshaping the industry but is also fostering a culture of continuous improvement. Case studies abound, illustrating how these manufacturers leverage technology not only to streamline processes but to enhance design capabilities, foster creativity, and respond to evolving consumer preferences. The amalgamation of technology with craftsmanship positions American apparel manufacturers as not just producers of clothing but as architects of style and sustainability.

In a global market where innovation is the key to staying competitive, USA clothing manufacturers exemplify adaptability and foresight. By actively embracing innovation, they not only meet the demands of the present but also set the stage for a future where American-made apparel is synonymous with both quality and ingenuity.

Sustainable Tech in American Apparel

Sustainable technology is emerging as a defining feature within the realm of American apparel, as clothing manufacturers in the USA, particularly sustainable clothing manufacturers and sportswear manufacturers, commit to eco-conscious practices.

This transformative shift signifies a departure from conventional manufacturing methods, as the industry increasingly integrates sustainable tech into its core ethos. American clothing manufacturers are investing in innovative processes and materials that reduce environmental impact, addressing the growing consumer demand for ethical and sustainable fashion.