#Grade B7 Bolts

Video

youtube

🏗🌏Make Fixing Dexterity👉FIXDEX threaded rods & B7 & din975

#youtube#HDG threaded rods#galvanized threaded rod#galvanised rod#galv threaded rod#hot dipped galvanized threaded rod#threaded rod galvanised#m20 galvanised threaded bar#Threaded Rod Galvanized#A193 B7#b7 threaded rod#astm a193#b7 bolts#b7 studs#a193 b7 bolts#b7 stud bolts#stud bolt a193 b7#astm a 193 gr b7#b7 bolt material#a193 b7 threaded rod#a193 b7 round bar#A193 Grade B7 Bolts#Grade B7 Bolts#Stainless Steel ASTM A193 B7 Bolts Manufacturer

0 notes

Text

Importance of Material Grade in Heavy Hex Bolts | Roll Fast

Roll Fast is a renowned manufacturer and exporter of heavy hex bolts for the construction of petrochemical industries. Heavy Hex Bolts are designed for use in a variety of high-temperature, high-strength industrial applications, such as steel fabrication and general construction. We also offer heavy hex bolts to structural grade ASTM a307, a325, and a490 specifications. They feature a thicker head than standard or regular hex bolts and offer a greater bearing surface that distributes the clamping load over a wider area. Heavy hex bolts are heavy profile hexagon bolts with large widths across flats and high head height. Also known as heavy hex head bolts or heavy hex structural bolts, these heavy hex bolts are commonly manufactured in high tensile grade 5, 8, 8.8, 10.9, 12.9, a193 grade b7, b7m, b8, b8m, b16, a320 grade l7, l7m, stainless steel, and other material.

visit source url : https://www.roll-fast.com/industries-served/petrochemical-industries/heavy-hex-bolts.html

0 notes

Text

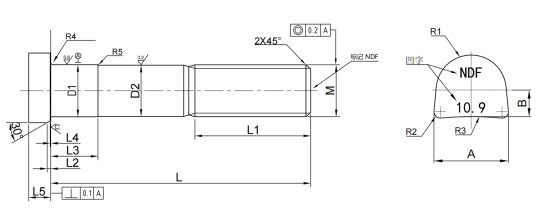

Stud | full Threaded | Double Ended Bolts Manufacturer | BigBoltnut

Bigboltnut is a manufacturer and distributor of a variety of products in the form of Studs bolts, full threaded, hub bolts, split shafts, reduction shafts and more. These steels include stainless steel, carbon steel and grade 8.8, 10.9, 12.9, SS304, SS316, SS316L, SS316 S31, B7, L7, 8M, B8 etc. It is made of alloy steels. These are used in heavy duty applications and are widely used. in wind turbines. We export Stud Bolts as per ASME B1.1, DIN 965, DIN 976, A193, A320, DIN 2510 etc. or as per customer requirements. The manufacturing process of bolts starts with band saw cutting, focusing on one corner and chamfering on both corners, CNC (to reduce shaft diameter, shaft length, bore diameter, working surface etc.), heat treatment (Dowa). high temperature furnace), wire spinning, testing, final inspection, packaging and shipping.

We are Manufacturer Exporter of many types of stud bolts like

Full threaded Bolts

Hub Bolts

Double ended stud bolts

Blade studs

Threaded Rods

Reduced shank stud bolts

Source url: https://www.bigboltnut.com/product/stud-bolts.html

0 notes

Text

Leading B7 Stud Bolts Manufacturers in India

Delta Fitt Inc. is the leading ASTM A193 Grade B7 Stud Bolts Manufacturers in India and B8 Stud Bolts Manufacturers in India. Stud bolts are used to secure structures in a variety of applications, including architectural and industrial installations.

B7 Stud Bolts, manufactured by top B7 Stud Bolt Manufacturer in India, take centre stage. Learn about their competitive advantages, production insights, and market significance. Examine the benefits, analyse crucial considerations, and identify industry difficulties.

Watch for future developments that will shape the evolution of stud bolts. Choose B7 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.As a B7 Stud Bolts suppliers in India, Elevate your projects with the robust reliability of B7 Stud Bolts. Secure success now!

Looking for top-notch Stud Bolt Manufacturers in India? Look no further than Delta Fitt Inc. We deliver quality studs for your industrial needs.

Product: B7 Stud Bolts Manufacturer in India

For more details, contact us at: [email protected]

#B7StudBoltsManufacturersinIndia#B7StudBoltssuppliersinIndia#StudBoltsManufacturerinIndia#B8StudBoltsManufacturerinIndia

0 notes

Text

Purpose of choosing ASTM A193 grade strength

Alloy steel bolting materials meeting ASTM A193 Grade B16 criteria are the norm for strain vessels, valves, flanges, and fittings meant to face up to excessive temperatures and pressures. The maximum frequent users of these applications are the petrochemical, oil & gas, and power generation fields.

The chemical make-up of grade B16 bolts is as follows: silicon (0.15-zero.35%), chromium, manganese, phosphorus, sulfur, vanadium, and carbon. Grade B16 bolts are the maximum broadly used sort of alloy metal amongst numerous versions. These bolts' precise composition offers them with exquisite resistance to oxidation and sulfidation in addition to excessive temperature power.

To make certain that Grade B16 bolts are suitable and reliable for use in excessive-temperature and high-strain settings, the ASTM A193 widespread specifies necessities for his or her manufacturing, warmth treatment, and testing.

Could you explain the differences between B16 and B7 bolts?

While B7 and B16 bolts have similar features, what sincerely distinguishes them are their mechanical houses and material composition.

Enterprises coping with accelerated temperatures and pressures regularly make use of bolts with the B7 and B16 classifications. This is specially actual for the petrochemical, power era, and oil and gasoline sectors.

In order to achieve the required hardness and electricity, the medium carbon alloy metallic (4140) used to create B7 bolts and ASTM A193 B8 Bolts is often heated to the best temperature and then tempered. They have minimal yield and tensile strengths of 105 ksi and 125 ksi, respectively.

But the metal used to make B16 bolts is a higher alloy metal with molybdenum, chromium, and vanadium combined collectively. B16 bolts are stronger and extra proof against oxidation and sulfidation in warm conditions way to those additives. Moreover, B16 bolts have minimal yield and tensile strengths which can be corresponding to B7 bolts.

Use B7 bolts for packages desiring high energy and mild temperature resistance; use B16 bolts for packages requiring better energy and stronger resistance to oxidation and sulfidation at immoderate temperatures. B7 bolts are the endorsed desire while some diploma of heat resistance is vital.

Materials that are comparable to ASTM A193 Grade B16 consist of:

DIN EN 10269 1.4980:

European standard addresses bolts composed of a robust and heat-resistant chromium-molybdenum alloy steel.

ISO 898-1 class 10.9:

For bolts composed of alloy steels comparable to ASTM A193 Grade B16, International Standard ISO 898-1 class 10.9 provides mechanical criteria.

BS 1501-640B:

One can use British standard BS 1501-640B to fabricate fastening materials with characteristics comparable to ASTM A193 B8C bolts and ASTM A193 Grade B16. This general applies to high-power steel plates which have gone through heat remedy.

JIS SCM 4:

This Japanese business well-known specifies what to do with low-alloyed steels which have mechanical characteristics and chemical compositions equivalent to ASTM A193 Grade B16 and ASTM A193 B8M Stud Bolt.

It's vital to hold in mind that at the same time as the chemical composition and mechanical traits of numerous materials may be equal, their manufacturing methods, warmth remedy methods, and trying out requirements may additionally range. These variations may have an impact on the materials' performance for particular applications. It is advisable to study the pertinent material requirements and get advice from an experienced engineer or metallurgist when selecting bolting materials for applications involving high temperatures and pressures.

0 notes

Text

Horseshoe head hub bolts

Horseshoe head hub bolts are fasteners used to secure wheels to the hub of a vehicle. They are typically made of steel and have a horseshoe-shaped head that allows them to be tightened using a wrench or socket. The horseshoe shape of the head provides a larger surface area for the wrench or socket to grip, which helps to distribute the force of the tightening more evenly and prevent the head from rounding out.

Horseshoe head hub bolts are commonly used in applications where the bolt needs to be tightened securely and may be subject to frequent adjustments, such as in machinery or equipment. The flat surface of the horseshoe head provides a large area for tightening, which can help distribute the clamping force evenly and prevent damage to the hub or shaft.

Outer diamater of thread: M14-M24

Heat treatment grade: 10.9/12.9

Surface treatment:

Phosphating/ Galvanizing/ Zinc-nickel alloy/ Zinc-aluminium coated

Material: 40Cr/35CrMo/SCM435/42CrMo/B7

Performance and application scenarios:

Suitable for drive axles for commercial buses, coaches, mining, engineering, light trucks, medium trucks, heavy trucks, trailers, etc.

Yield greater than or equal to 940MPa, tensile strength greater than or equal to 1040MPa, absorption energy -20°CKV/J greater than or equal to 27.

Fatigue resistance, safe and reliable during service, suitable for extremely cold and hot environment.

0 notes

Text

Ananka

Q1) Are there specific hex bolts designed for high-temperature environments?

Ans) Certainly, there are specific categories of hex bolts meticulously designed to excel in high-temperature settings. These specialized hex bolts are meticulously crafted from materials capable of enduring elevated temperatures without compromising their mechanical attributes or structural integrity. Here are several instances of hex bolts tailored for high-temperature applications:

1. Heat-Resistant Stainless Steel Hex Bolts: Hex bolts constructed from stainless steel alloys such as 310, 316, and 321 are frequently chosen for high-temperature environments. These alloys incorporate elements like chromium, nickel, and molybdenum, enhancing their resilience against oxidation and corrosion at elevated temperatures.

2. Inconel Hex Bolts: Inconel, a group of nickel-chromium-based superalloys, possesses remarkable resistance to high temperatures, oxidation, and corrosion. Inconel hex bolts find prominent usage in sectors like aerospace, petrochemicals, and industries confronting extreme heat.

3. Hastelloy Hex Bolts: Hastelloy, another lineage of nickel-based alloys, is renowned for its exceptional corrosion resistance and performance under high-temperature conditions. Hastelloy hex bolts often feature in applications exposed to harsh chemical environments and elevated temperatures.

4. Titanium Hex Bolts: Titanium hex bolts, noted for their lightweight nature and commendable strength at high temperatures, are favored in industries such as aerospace and chemical processing. These hex bolts effectively balance heat resistance and corrosion resistance.

5. Alloy Steel Hex Bolts: Certain alloy steels, including ASTM A193 Grade B7, undergo heat treatment to cater to high-temperature requirements. These hex bolts find common application in pressure vessels, boilers, and piping systems that operate at elevated temperatures.

6. Ceramic-Coated Hex Bolts: In specific scenarios, hex bolts can be coated with ceramic materials, furnishing them with a thermal barrier. This coating empowers the hex bolts to endure elevated temperatures while retaining their mechanical properties.

When selecting hex bolts for high-temperature environments, meticulous consideration should be given to factors such as the specific temperature range, the presence of corrosive elements, and the mechanical prerequisites of the application. Consulting experts or referring to industry standards is advised to make an informed choice regarding the most suitable type of hex bolts that can offer reliable performance under the desired high-temperature conditions.

Hastelloy Fasteners

Q2) Are there hex nuts specifically designed for high-temperature applications?

Ans) Yes, indeed, hex nuts tailored for high-temperature applications are available. These specialized hex nuts are meticulously fashioned from materials capable of enduring elevated temperatures without compromising their structural soundness. Here are several instances of hex nuts designed specifically for high-temperature environments:

1. Heat-Resistant Stainless Steel Hex Nuts: Hex nuts crafted from stainless steel alloys such as 310, 316, and 321 are commonly employed for high-temperature scenarios. These alloys incorporate elements like chromium, nickel, and molybdenum, bolstering their capacity to withstand oxidation and corrosion in elevated temperature settings.

2. Inconel Hex Nuts: Inconel, a lineage of nickel-chromium-based superalloys, enjoys renown for its exceptional resistance to high temperatures, oxidation, and corrosion. Inconel hex nuts are frequently harnessed in aerospace, petrochemical, and similar industries where extreme heat prevails.

3. Hastelloy Hex Nuts: Hastelloy, another category of nickel-based alloys, is esteemed for its remarkable corrosion resistance and performance in high-temperature environments. These hex nuts find favor in scenarios involving harsh chemicals and elevated temperatures.

4. Titanium Hex Nuts: Boasting lightweight attributes and commendable strength at high temperatures, titanium hex nuts find their niche in sectors like aerospace and chemical processing, where both heat resistance and corrosion resistance are paramount.

5. Alloy Steel Hex Nuts: Certain alloy steels, such as ASTM A194 Grade 7, are subject to heat treatment to suit high-temperature requisites. These hex nuts commonly find purpose in pressure vessels, boilers, and piping systems functioning at elevated temperatures.

6. Ceramic-Coated Hex Nuts: In certain instances, hex nuts can be treated with ceramic coatings that confer thermal insulation, enabling them to withstand elevated temperatures while preserving their structural integrity.

When opting for hex nuts tailored for high-temperature environments, meticulous contemplation of factors such as the specific temperature range, the presence of corrosive agents, and the mechanical prerequisites of the application is indispensable. Seeking counsel from experts or referring to industry standards is a prudent step in ascertaining the most fitting type of hex nuts capable of delivering reliable performance under the desired high-temperature conditions.

Carbon Steel Fasteners

Q3) What are the implications of using the wrong size or type of plain washer?

Ans) Using the wrong size or type of plain washer in a fastened assembly can have several significant implications, potentially leading to compromised joint integrity, safety hazards, and functional issues. Here are some of the implications:

1. Reduced Clamping Force: The primary function of a plain washer is to distribute the load and provide a larger surface area for even pressure distribution. Using a washer that is too small or not suitable for the application can lead to uneven clamping force, resulting in insufficient joint compression. This can cause components to come loose over time and reduce the overall stability of the assembly.

2. Increased Stress Concentrations: Choosing a washer with inadequate dimensions or material properties can lead to localized stress concentrations. These concentrated stress points can weaken the fastened components, making them more prone to deformation, cracking, or failure under load.

3. Loss of Friction Control: Plain washers can help control friction between the fastener and the material being fastened. Incorrectly sized or inappropriate washers may not provide the necessary friction management, potentially leading to loosening of the joint due to vibration or other external forces.

4. Potential for Galling or Seizing: If the wrong type of washer material is used, such as a washer with a rough surface, there's a risk of galling (metal-to-metal adhesion) or seizing between the washer and the fastener head or nut. This can make future disassembly difficult or even cause damage to the fastener and washer.

5. Inadequate Load Distribution: Using a washer that doesn't match the shape or size of the fastener head or nut can result in poor load distribution. This may lead to indentations, deformations, or damage to the components being fastened, reducing their overall lifespan.

6. Leakage and Seal Failure: In applications involving gaskets or seals, using the wrong size washer can lead to improper compression of the gasket, resulting in leaks or seal failure. This is particularly critical in environments where sealing integrity is crucial, such as fluid or gas systems.

7. Compromised Aesthetics and Functionality: In certain applications, the aesthetics of the assembly might matter. Using the wrong size or type of washer can lead to misalignment, improper fit, or visible gaps, affecting both the appearance and the functionality of the assembly.

8. Safety Hazards: Depending on the application, using incorrect washers can compromise the safety of the assembly. In critical structures, machinery, or equipment, failure due to incorrect washers can lead to accidents, injuries, or costly downtime.

To avoid these implications, it's crucial to select plain washers that are appropriate for the specific application. This includes considering factors like washer size, material, shape, and load-bearing capacity. It's recommended to follow manufacturer guidelines, industry standards, and engineering best practices to ensure that the chosen plain washers provide effective load distribution, proper clamping force, and overall joint integrity.

Stainless Steel Fasteners Manufacturers in Mumbai

Q4) Are there stud bolts specifically designed for high-temperature applications?

Ans) Yes, there are stud bolts specifically designed to excel in high-temperature applications. These specialized stud bolts are crafted from materials that can withstand elevated temperatures without compromising their mechanical properties or structural integrity. Here are a few examples of stud bolts designed for high-temperature environments:

1. Heat-Resistant Stainless Steel Stud Bolts: Stainless steel alloys like 310, 316, and 321 are commonly chosen for stud bolts in high-temperature applications. These alloys contain elements like chromium, nickel, and molybdenum, which enhance their resistance to oxidation and corrosion at elevated temperatures.

2. Inconel Stud Bolts: Inconel is a family of nickel-chromium-based superalloys renowned for their exceptional resistance to high temperatures, oxidation, and corrosion. Inconel stud bolts are frequently used in industries such as aerospace, petrochemicals, and power generation, where extreme heat is encountered.

3. Hastelloy Stud Bolts: Hastelloy is another family of nickel-based alloys known for their excellent corrosion resistance and high-temperature performance. Hastelloy stud bolts are often used in environments involving harsh chemicals and elevated temperatures.

4. Titanium Stud Bolts: Titanium stud bolts are lightweight and possess good strength at high temperatures. They find application in industries such as aerospace, chemical processing, and marine, where both heat resistance and corrosion resistance are essential.

5. Alloy Steel Stud Bolts: Some alloy steels, such as ASTM A193 Grade B7, are heat-treated and designed for high-temperature applications. These stud bolts are commonly used in pressure vessels, boilers, and piping systems operating at elevated temperatures.

6. Ceramic-Coated Stud Bolts: In certain cases, stud bolts can be coated with ceramic materials that provide a thermal barrier, allowing them to endure higher temperatures while maintaining their mechanical properties.

When selecting stud bolts for high-temperature environments, it's crucial to consider factors such as the specific temperature range, the presence of corrosive elements, and the mechanical requirements of the application. Consulting with experts or referring to industry standards is recommended to choose the appropriate type of stud bolts that can reliably perform under the desired high-temperature conditions.

Phosphor Bronze Bolts

0 notes

Text

Carbon Steel Flanges: Experts’ Top Recommendations for Optimal Performance

Carbon steel flanges are widely used in various industries due to their excellent durability, strength, and cost-effectiveness. However, to ensure optimal performance and longevity, it is crucial to follow experts’ recommendations. In this article, we will discuss the top recommendations from experts for carbon steel flange performance.

Material Selection: Choosing the right carbon steel material is the first step to ensure optimal performance. Experts recommend selecting carbon steel with the appropriate grade and composition for the specific application. Factors like corrosion resistance, temperature stability, and pressure requirements should be considered when choosing the material.

Flange Design: The design of carbon steel flanges should be in accordance with industry standards and specifications, such as ASME B16.5 or API 605. It is essential to ensure proper dimensions, bolt hole sizes, flange face type, and class ratings. Using flanges designed for specific applications helps in preventing leakage and ensures a secure connection.

Flange Surface Finish: Experts emphasize the importance of achieving the correct surface finish for carbon steel flanges. A smooth surface finish reduces the risk of corrosion, enhances sealing performance, and prevents gasket damage. Commonly used surface finishes include an oil-based rust preventive coating or an epoxy-based paint finish.

Gasket Selection: The selection of the appropriate gasket is critical for achieving optimal performance in carbon steel flange joints. Gaskets should be compatible with the operating conditions, such as temperature, pressure, and fluid type. It is recommended to use gaskets made of materials like graphite, PTFE (Polytetrafluoroethylene), or spiral wound gaskets for better sealing capabilities.

Bolt Selection and Torque: Proper bolt selection and tightening torque are crucial for achieving a leak-free connection. Experts advise using bolts made from high-strength carbon steel or alloy steel, such as ASTM A193 Grade B7, and complying with standard specifications, such as ASME B18.2.1. Following the recommended bolt torque values ensures proper tensioning and prevents flange leakage.

Proper Installation: Correct installation practices play a vital role in the performance of carbon steel flanges. Experts suggest cleaning the flange surfaces thoroughly and removing any dirt or debris. It is important to align the flanges properly and apply an even bolt load during the tightening process. Over-tightening or uneven loading can lead to flange distortion or gasket failure.

Regular Inspection and Maintenance: Regular inspection and maintenance are essential for ensuring continued optimal performance of carbon steel flanges. Periodic checks for leaks, corrosion, or damage should be conducted. Any detected issues should be addressed promptly to prevent further deterioration or failure. It is recommended to follow industry guidelines for maintenance activities like bolt retightening or gasket replacement.

Corrosion Prevention: Carbon steel flanges are susceptible to corrosion, especially in harsh environments. Experts recommend applying suitable corrosion protection strategies, such as the use of coatings or cathodic protection techniques. Regular cleaning, painting, or applying anti-corrosion coatings can significantly enhance the longevity and performance of carbon steel flanges.

Training and Expertise: Having trained personnel with expertise in carbon steel flanges and their installation is crucial for optimal performance. Experts suggest providing comprehensive training to technicians and engineers involved in flange installation and maintenance. This ensures that best practices are followed, reducing the risk of errors or improper handling.

0 notes

Text

Supplier of Stainless Steel Fasteners in Sanand

Luvana Metal Corporation is ISO 9001:2015 certified. Supplier of Stainless Steel Fasteners in Sanand.

Luvana Metal is a prominent supplier, producer, and exporter of high-quality Stainless Steel Angles, Channels, Flats, Circles, Patti, Patta, and SS Fasteners.

The market highly admires Luvana Metal for its expertise in designing and manufacturing a comprehensive variety of SS Nuts & Bolts.

Luvana Metal actively develops these fasteners in accordance with set industrial norms and actively subjects them to rigorous quality checks to ensure perfection on all parameters.

The Stainless Steel Nut Bolt can come under B7, B16, B8, B8M, and so on.

These different grades also differentiate the chemical compositions.

There are alloy steel, chromium molybdenum vanadium alloys, heat treated, and many other types.

The sizes range differently such as the M10 Stainless Steel Nuts.

These fasteners actively find usage in various industrial applications such as high-pressure, high-temperature environments, valves, flanges, fittings, pressure vessels, chemical applications, petroleum applications, and more.Benefits of Stainless Steel FastenersCorrosion resistance: Stainless steel is highly resistant to corrosion, making it suitable for use in a variety of harsh environments.

Strength: Stainless steel is strong and durable, making it suitable for use in high-stress applications.

Ductility: Stainless steel is ductile, making it easy to machine and form.

Appearance: Stainless steel has a bright, shiny appearance that can be enhanced with polishing or other finishing treatments.

Versatility: Stainless steel fasteners are available in a variety of sizes, shapes, and finishes, making them suitable for a wide range of applications.Luvana Metal Industries is a Supplier of Stainless Steel Fasteners in Sanand.

For more details, please have a professional conversation with you / your team.

Read the full article

#heattreated#LuvanaMetalCorporation#Sanand#StainlessSteelFasteners#Strength#SupplierofStainlessSteelFastenersinSanand

0 notes

Text

Moving into the flanged stainless steel realm.

When joining two tubes, a flange is an essential component. In most cases, it joins the ends of two tubes with a threaded connection or some other type of welding. Therefore, there are primarily two types of fasteners: threaded attachment flanges and welding flanges. Flanges, a gasket, and a number of bolts and nuts are needed whenever two tubes are ready to be linked together via a flange junction.

The first step is to place the gasket in between the seals. Once that's done, you may tighten the bolts. When the surface pressure of a gasket reaches a critical point, it deforms to fill in any gaps or imperfections in the sealing surface, thereby sealing the joint. Duplex pipe suppliers have proven invaluable.

One sort of removable connection is a flange junction. It appears that there are two sorts of removable parts, namely container flanges and tube flanges. You can benefit greatly from working with Duplex tube suppliers.

There are three different types of sealing faces, each suited to a different pressure range and set of circumstances: planar sealing faces for low pressure, uneven sealing faces for moderate pressure, and tongue and groove sealing faces for high pressure and combustible, explosive, or poisonous material. Most of the time, Indian factories that make Duplex flanges are reliable.

It's well knowledge that different types of flanges can withstand varying amounts of pressure and media. The gasket used in the connection really plays a crucial role. Gaskets made from non-metallic plates have been mass-produced. The company that makes forged parts has been doing a fantastic job. Duplex pipe fittings are actually very good.

Asbestos rubber sheets, asbestos plates, polyethylene workbooks, and so on all have sizes that are specified by various norms. A typical latex gasket, for instance, has a temperature limit of 120? In corrosive environments, acid-resistant asbestos has seen extensive application. Copper, aluminum, 10 steel, or some other type of stainless steel sheet may be used if the pressure is high enough. You might be able to get a wide selection of Duplex round bar.

Despite their apparent simplicity, fasteners serve important purposes and have grown in prominence across practically all sectors of the economy. Vehicles and machinery are joined together by fasteners. Most people in the modern world like to make use of them. Duplex forged fittings made of stainless steel are highly recommended.

In fact, flange is a technique in and of itself. Indeed, these are the DIN system, the ANSI scheme, and the JIS system. The previous systems' pressure requirements and sealing face types are identical. Most customers today choose Copper nickel plate.

The third option is also not often used. In addition, the GB standard, the specific chemical standard, the mechanical requirement, and the pressure vessel benchmark must all be followed while fabricating flanges. Pipes and tubes are the backbone of the manufacturing sector. These innovations have made up for human shortcomings by doing work that people can't. The quality of the A193 grade B7 bolts has been excellent.

0 notes

Text

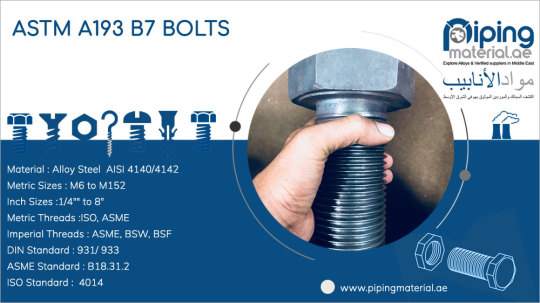

Differentiating A193 B7 Bolts from Other Bolt Grades: What Sets Them Apart?

The importance of selecting the correct bolt grade for a given application cannot be overstated. Among the plethora of bolt grades available, A193 B7 stands as a popular choice renowned for its remarkable strength and durability. In this blog post, we will delve into the distinctive characteristics that differentiate A193 B7 bolts from other bolt grades, offering you valuable insights into why they are favored across diverse industries.

Strength and Material Composition:

A193 B7 bolts are made from a high-strength alloy steel known as chromium-molybdenum steel. This alloy composition gives these bolts exceptional tensile strength, making them suitable for applications that require robust fasteners capable of withstanding heavy loads and high-pressure environments.

Heat Treatment Process:

A193 B7 bolts stand apart due to their unique heat treatment process, which plays a crucial role in their distinctive characteristics. These bolts undergo a meticulous quenching and tempering procedure, where they are subjected to elevated temperatures and swiftly cooled to attain the desired level of hardness and strength. This specialized heat treatment significantly improves the mechanical properties of the bolts, bolstering their tensile strength, yield strength, and impact resistance.

High-Temperature Applications:

A193 B7 bolts are engineered to excel in high-temperature environments, making them well-suited for various applications. The presence of chromium-molybdenum steel in their composition grants these bolts exceptional resistance to oxidation and creep at elevated temperatures. As a result, they find wide applications in industries such as petrochemical, power generation, and oil and gas, where exposure to high temperatures is common.

Corrosion Resistance:

Another notable characteristic of A193 B7 bolts is their corrosion resistance. Although they are not stainless-steel bolts, their alloy composition grants them a level of corrosion resistance, especially in mildly corrosive environments. However, for applications in highly corrosive conditions, additional protective coatings may be required to ensure long-term durability.

Versatility and Compatibility:

A193 B7 bolts are compatible with a wide range of nuts and washers, making them highly versatile for different applications. Their standardized dimensions and threads allow for easy integration into various structural and mechanical systems.

Conclusion:

A193 B7 bolts stand out from other bolt grades due to their exceptional strength, heat treatment process, high-temperature capabilities, corrosion resistance, and compatibility. These qualities make them a popular choice in industries such as construction, oil and gas, power generation, and more. Understanding the unique characteristics of Buy A193 B7 bolts helps engineers and professionals make informed decisions when selecting fasteners for their specific applications.

Remember, when working with bolts, always consult the appropriate standards and specifications to ensure you choose the correct bolt grade and adhere to proper installation practices.

0 notes

Text

Benefits of using Full-threaded Stud bolts | Roll Fast

Full-threaded stud bolts are non-headed bolts, these are in the form of a rod and have threads from end to end. A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends. The fully threaded studs have no head, are threaded along their entire length, and have a higher tensile strength. We offer full-threaded stud bolts in different grades like 8.8, 10.9, 12.9, B7, B8, L7, B16, and more for petrochemical industries. The most common application of these studs is in industries like manufacturing, plumbing, construction, petrochemical, and automobile manufacturing. Fully Threaded Studs are ideal for making custom assemblies using thread-locking adhesive and along with that, they can also be used for custom applications based on individual requirements. The fully threaded studs have no head, are threaded along their entire length, and have a higher tensile strength. The thread may extend along the complete length of the rod.

visit source URL : https://www.roll-fast.com/industries-served/petrochemical-industries/full-threaded-stud-bolts.html

0 notes

Text

Stainless Steel Stud Bolts Manufacturer and exporter in India | BigboltNut

These Stud bolts are manufactured in stainless steel, carbon steel and alloy steel grades like 8.8, 10.9, 12.9, SS304, SS316, SS316L, SS316 S31, B7, L7, 8M, B8 etc. These are used in critical applications and are widely used in wind mill installations. we offer Stud bolts According to ASME B1.1, DIN 965, DIN 976, A193, A320, DIN 2510 etc. or as per customer requirement. BigBoltNut manufactured bolt and nut for wind mill, Aerospace, Railways, bridge Construction.

Source Url: https://www.bigboltnut.com/product/stud-bolts.html

0 notes

Text

What is a Stud Bolt? Types, Grades, and Standards

Delta Fitt Inc., your dependable Stud Bolts Manufacturers in India, Welcome to the realm of precise fasteners. We are well-known for our attention to quality and perfection, and we specialise in creating stud bolts, which serve as the foundation of solid connections in a range of sectors. Consider Delta Fitt Inc, where each bolt is a testament to great engineering.

What is a Stud Bolt?

Stud bolts are specialist fasteners used to provide secure and long-lasting connections in a variety of applications. These threaded rods include bolts at both ends and a unique design that includes an unthreaded centre part. Stud bolts are key structural components in the construction, oil & gas, petrochemical, and power generation industries, due to their high tensile strength and ease of installation.

Their threaded design enables for simple installation, making them useful in situations needing frequent disassembly. Stud bolts are dependable components in the fastener landscape, helping to maintain structural and mechanical stability.

Types of Stud Bolts

Fully Threaded Stud Bolts:

Ideal for applications requiring maximum thread engagement. Commonly used in scenarios where both ends need to be screwed into different components.

Double-End Stud Bolts:

Threaded on both ends, allowing for versatile applications.Used when components need to be tightened from both ends simultaneously.

Tap-End Stud Bolts:

Features threads on one end and a chamfered point on the other. Useful in situations where quick alignment and engagement are necessary.

Continuous Thread Stud Bolts:

Uninterrupted threading for the entire length.Suitable for heavy-duty applications where strength is paramount.

Top 3 ASTM Standard Stud Bolt Grades

ASTM A193 Grade B7 Stud Bolts:

B7 stud bolts, known for their high tensile strength and durability, are integral in critical applications. As reputable B7 Stud Bolts Manufacturers in India,We assure precision engineering and provide sturdy solutions for sectors where secure fastening is critical. Deltafitt Inc can supply B7 stud bolts that fulfill high quality requirements, assuring reliability in a variety of industrial environments.

ASTM A193 Grade B8 Stud Bolts:

B8 stud bolts, synonymous with corrosion resistance and exceptional performance, play a crucial role in demanding environments. As leading B8 Stud Bolts Manufacturers in India, Delta Fitt specializes in producing these bolts with precise engineering, providing dependable solutions for industries that require corrosion-resistant fastening. Count on us to supply high-quality B8 stud bolts that satisfy demanding quality requirements, assuring longevity and consistent performance in a wide range of industrial applications.

ASTM A193 Grade B8M Stud Bolts:

B8M stud bolts are known for their corrosion resistance, making them perfect for use in harsh situations. We excel in producing these bolts with precision engineering as a trusted B8M stud bolts manufacturer in India. Our B8M stud bolts are reliable solutions for industries that require corrosion protection, offering endurance and consistent performance across a wide range of industrial applications. Count on us for high-quality B8M stud bolts that exceed stringent quality requirements while delivering long-lasting fastening solutions.

Visit Delta Fitt for Choosing the Best Stud Bolts

Finally, Stud bolts are hidden fastener shining examples, securing structures and components across a wide range of industries. From construction to oil and gas, the kinds, selection criteria, and adherence to standards are critical for their successful usage. Understanding the subtleties of stud bolts enables industries to assure project safety, dependability, and lifespan.

Delta fitt, obtained the best stud bolts by top Stud Bolt Manufacturer in India, takes centre stage. Learn about their competitive advantages, manufacturing strategies, and market position. Examine the benefits, emphasise key aspects, and learn about industry challenges. Consider the future danger of stud bolt expansion. Choose best quality stud bolts like B7 & B8 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these stud bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.

As a Stud Bolt Suppliers in India, Elevate your projects with the robust reliability of Stud Bolts. Secure success now!

#stud bolt manufacturers in india#B7 Stud Bolts Manufacturer in India#B8 Stud Bolts Manufacturers in India#stud bolt manufacturers

0 notes

Text

The many features and uses of stainless steel explored.

Stainless steel serves a wide variety of purposes. Stainless steel is a low carbon steel that is easy to work with and has excellent corrosion and rust resistance. The steel is coated in a tiny coating of chromium oxide, which is invisible to the human eye yet prevents rust and corrosion.

If it is indeed chemically or mechanically damaged, it can heal itself. The versatility of ASTM A193 B6 Bolts is endless.

One of stainless steel's most prominent selling qualities is its resilience in the face of extreme heat. The fact that it functions effectively in production is an additional benefit. Using stainless steel greatly speeds up the production process. Astm a193 grade b7 bolts manufacturers in India are very popular.

The fabrication of stainless steel is widely employed in the field of architectural metalwork. The catering and food production businesses make heavy use of it. Stainless steel may be cut using a variety of tools, including water jets, lasers, plasma cutters, and more. ASTM A193 B7 Threaded Rod is manufactured by a large number of firms.

Fabricators of structural steel source raw steel and form it into the required shapes for a given construction project. Engineers, architects, and steel producers are working together more than ever before to create the best in fabrication. The ASTM A193 B7 Socket Head Cap Screws consistently have high-quality.

Before being shipped out, every final product undergoes rigorous quality control inspection. The production process would not be possible without the use of both manufacturing techniques and human labor. In terms of yearly output and consumption, it appears that China dominates the market for raw steel. They use a lot of steel since they manufacture so many cars. In fact, some of the finest achievements in the globe have come from using ASTM A193 B7 Anchor Bolts.

There are a few thousand different steel shapes, but they're all made with the same methods. Each type of steel is distinguished by its own particular set of defining chemical components, physical characteristics, and environmental conditions. A large number of people in Singapore choose metal sheets. ASTM A193 B7 Eye Bolt might be of the quality you want.

Jobs in the manufacture of structural steel have migrated to India and other developing countries because of globalization because of lower labor costs there. India is widely recognized as the greatest and most cost-effective location for steel production services. It's crucial to take into account regional norms and regulations when selecting a structural steel subcontractor. ASTM A193 B7m Bolts are available at a reasonable price.

Find an experienced steel fabrication company if you need steel fabricated into anything from stairs to a footbridge to a solid door frame or anything else you might need built out of steel. For the best service that guarantees appropriate finishing and installation without breaking the bank, seek out the best fabricators in the business. Most people across the world have benefited greatly from the use of ASTM A193 B8 Bolts.

0 notes

Text

Round head knurled hub bolts

Round head knurled hub bolts are a type of fastener that is used to secure a hub to a shaft or other component. The head of the bolt is typically round in shape and has a knurled surface for grip. Knurling is a manufacturing process that creates a pattern of small ridges on the surface of the bolt, providing a better grip for tightening or loosening the bolt.

Round head knurled hub bolts are commonly used in applications where the bolt needs to be tightened securely and may be subject to frequent adjustments, such as in machinery or equipment. The knurled surface provides a better grip, making it easier to tighten or loosen the bolt with a wrench or pliers. The round head design allows for a large surface area for tightening, which can help distribute the clamping force evenly and prevent damage to the hub or shaft.

These bolts are typically made from high-strength steel or other durable materials and are finished with a rust-resistant coating, such as zinc or black oxide to protect against corrosion. They come in a variety of sizes and thread types to fit different applications.

Round head knurled hub bolts are a reliable and durable fastener solution that is commonly used in a variety of industrial, automotive, and manufacturing applications.

Outer diamater of thread: M12-M24

Heat treatment grade: 10.9/12.9

Surface treatment:

Phosphating/ Galvanizing/ Zinc-nickel alloy/ Zinc-aluminium coated

Material: 40Cr/35CrMo/SCM435/42CrMo/B7

Performance and application scenarios:

Suitable for commercial buses, coaches, mining, engineering, light trucks, medium trucks, heavy trucks, trailers, etc.

Yield greater than or equal to 940MPa, tensile strength greater than or equal to 1040MPa, absorption energy -20°CKV/J greater than or equal to 27.

Fatigue resistance, safe and reliable during service, suitable for extremely cold and hot environment.

1 note

·

View note