#Heat Exchanger Manufacturer

Text

Pioneering Solutions for a Connected Tomorrow

Explore the cutting-edge world of Industrial Heat Transfer Inc. Immerse yourself in a hub of innovation, where groundbreaking technologies and solutions converge to shape a connected future. Discover how IHT is revolutionizing industries, driving progress, and unlocking new possibilities.

1 note

·

View note

Text

Heat Exchanger Manufacturer in India – Galaxy

Galaxy INDUSTRIAL EQUIPMENT is one of the leading heat exchanger manufacturers in India supply 7 service various heat exchangers viz shell & tube, plates, heat exchangers, semi welded & welded plate exchangers. GALAXY is a Fluid Mixing Equipment manufacturing company with integrated engineering solutions. This enables us to provide high efficiency process design and detailed mechanical design.

0 notes

Video

Water to water heat exchangers are responsible for exchanging heat between waste water and freshwater. The heat transfer process between the liquids does not involve direct contact or mixing of the two. If you are looking for the best quality Water Heat Exchanger then you should contact AIC Heat Exchanger - which offers Complete Heat Transfer Solutions.

#aicheatexchangers#DoubleWall#heat exchanger#water to water heat exchanger#Double Wall Heat Exchanger#shell and tube heat exchangers#brazed plate heat exchangers#Shell and Tube Heat Exchanger#Heat Exchanger Manufacturer#heat exchangers market#USA

0 notes

Photo

Heat Exchanger Manufacturer in India

Website : https://www.anikaindustries.co.in/

Anika Plants And Equipment's Industries located in Indore (the largest industrial hub in Madhya Pradesh), is a reckoned among the leading companies offering high end solutions. Established in 2011

#Heat Exchanger Manufacturer in India#Heat Exchanger Manufacturer#Heat Exchanger Manufacturer in Indore

0 notes

Text

Third Party Inspection/NDT services In India

AV Engineers provides inspection to business organizations in plants & machinery (Solar, Cement, Sugar, chemical and Pharmaceuticals), power generation, marines, oil, gas, Petroleum installations, Pressure vessels, Boilers, Heat Exchangers and site inspections We also provide inspection services for power cables, transformers. our services include Vendor Development,Total quality management.Vendor pre evaluation, Inspection and Expediting Services,Pre-Shipment Inspection,NDT inspection and testing like Radiography and many more.

For more details please visit our website -

#manufacturer#supplier#fabrication#thirdpartyinspection#heat exchangers#siteinspection#NDT inspection#radiography

0 notes

Text

Stainless Steel 904L Heat Exchanger Tubes Stockists

INTRODUCTION:

Stainless Steel 904L Heat Exchanger Tubes crafted to meet both national and international standards of quality using premium raw materials.

DESCRIPTION:

The SS 904L Seamless Heat Exchanger Tubes we offer come in various sizes, catering to the diverse requirements of our valued customers, all at competitive market rates. At Metinox Overseas, we prioritize precision engineering and stringent quality control to ensure optimal performance and longevity of our products.

Stainless steel 904L, renowned for its exceptional corrosion resistance properties, finds extensive utility in heat exchanger applications. These tubes exhibit high resistance to both crevice and stress corrosion cracking in chloride environments, making them ideal for industries such as chemical processing, petrochemicals, pharmaceuticals, and more.

904L Stainless Steel Heat Exchanger Tubes Standard Specifications :

Specifications : ASTM A249 / ASME SA 249

Size Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Lengthup : to 20 m (65.62 ft) Length & Customed Required Length

Form : Seamless, Welded, Round, U Bent Tube, Shell and Tube

Ends : Plain End, Beveled End, Treaded

Processing Service : Bending, Welding, Decoiling, Punching, Cutting, Moulding

Technique : Cold drawn, Cold rolled, Hot rolled, Extrusion Tube manufacturer in India

BENEFITS:

Corrosion Resistance: Stainless steel 904L boasts superior resistance to corrosion in various aggressive environments, including those containing sulfuric acid, phosphoric acid, and chloride ions.

High Temperature Resistance: These heat exchanger tubes maintain their mechanical properties at elevated temperatures, making them suitable for applications involving high heat transfer rates.

Longevity: With excellent durability and resistance to degradation, stainless steel 904L heat exchanger tubes offer a prolonged service life, reducing the need for frequent replacements and maintenance.

Versatility: The versatility of 904L stainless steel allows for its utilization in diverse industries, ranging from chemical processing to marine environments.

Cost Efficiency: Despite its initial investment, stainless steel 904L proves cost-effective over the long term due to its extended lifespan and minimal maintenance requirements.

SPECIFICATION:

Metinox Overseas provides stainless steel 904L heat exchanger tubes in various specifications to cater to the specific requirements of different applications. These specifications include dimensions, wall thickness, lengths, and surface finishes, ensuring compatibility and seamless integration into existing systems.

PRODUCT OVERVIEW:

Metinox Overseas prides itself on offering a comprehensive range of stainless steel 904L heat exchanger tubes meticulously manufactured to exacting standards. Their products undergo rigorous quality checks to guarantee impeccable performance and reliability. With a commitment to customer satisfaction, Metinox Overseas ensures prompt delivery and excellent after-sales support.

CONCLUSION:

Stainless steel 904L heat exchanger tubes stand as a testament to innovation and reliability in industrial heat transfer applications. With their superior corrosion resistance, high temperature capabilities, and longevity, they serve as indispensable components across various sectors. Metinox Overseas emerges as a trusted partner, providing premium quality 904L stainless steel heat exchanger tubes to meet the diverse needs of industries worldwide.

CONTACT US:

For inquiries and orders, please reach out to Metinox Overseas:

Email: [email protected]

Phone: +91-98199 80997 / +91-70212 61928

Experience the excellence of stainless steel 904L heat exchanger tubes with Metinox Overseas – your trusted supplier for premium quality solutions.

0 notes

Video

youtube

Mastering Stainless Steel Heat Exchanger Tube Expansion | SINOAK Machinery

Video Description:

Take a deep dive into the world of precision manufacturing with SINOAK as we explore the expansion process of stainless steel heat exchanger tubes. This video provides an inside look at how our advanced equipment and innovative techniques deliver consistent, high-quality results for the HVAC industry.

Video Highlights:

Introduction to Tube Expansion: Learn about the importance of the tube expansion process in manufacturing efficient, durable stainless steel heat exchangers.

Live Demonstration: Watch as our equipment expertly expands stainless steel tubes to create a perfect fit, ensuring optimal heat transfer and reliability.

Precision Engineering: Explore the design and engineering principles behind our tube expander that make it suitable for various stainless steel tube sizes and applications.

Client Success Stories: Hear from our satisfied clients about how this tube expansion technology has improved their manufacturing processes, resulting in better performance and cost savings.

Future Innovations: Discover upcoming enhancements and technological advancements SINOAK is developing to further revolutionize tube expansion in the heat exchanger industry.

Why Choose SINOAK:

Advanced Technology: Our tube expander uses the latest technology to achieve precision tube expansion for stainless steel heat exchangers.

Quality Assurance: Each expanded tube undergoes rigorous quality checks to ensure the highest level of reliability and durability.

Custom Solutions: Our equipment is customizable to meet specific production requirements, enabling manufacturers to achieve their unique production goals.

Stay Connected:

Find out more about our innovative equipment at [https://allsayok.com/].

Reach us directly with inquiries or requests at [[email protected]].

Follow us on WhatsApp and WeChat at +8615688803399 to stay updated on the latest in industrial manufacturing.

Experience the future of tube expansion for stainless steel heat exchangers with SINOAK. Don't forget to like, share, and subscribe for more industry insights and manufacturing technology updates.

#youtube#Stainless Steel Heat Exchanger Tube Expansion Process SINOAK Machinery HVAC Equipment Production Advanced Manufacturing Techniques Industria

0 notes

Text

0 notes

Text

A Guide To Properly Cleaning the Fluoropolymer Heat Exchanger Bundle (nichefpp.com)

0 notes

Text

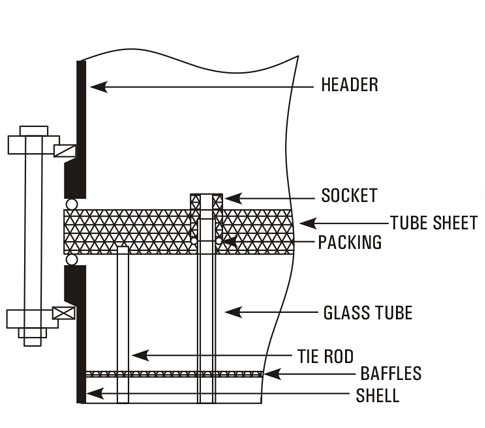

Shell and Tube Heat Exchanger manufacturer & dealers | Goel Scientific | Canada

We Serve the Best, Long Lasting Shell and Tube Heat Exchanger, Shell and Tube Heat Exchanger Products, manufacturer, Goel Scientific Canada USA

#Best#Top#We Serve the Long Lasting Shell and Tube Heat Exchanger#Shell and Tube Heat Exchanger Products#manufacturer#Goel Scientific Canada USA

0 notes

Text

Nickel Alloy Tubes

Nickel Alloy Tubes

KRYSTAL GLOBAL ENGINEERING LIMITED (Formally Known as Krystal Steel Manufacturing Private Limited) is a Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

We are dedicated to help our customers gain a competitive advantage by supplying a wide range of products such as Tubes, Pipes, U Tubes, Coil Formed Tubes.

KRYSTAL has well established “State of Art” facilitates with continuous enhancement of the product and services to serve the customers across the globe.

Tap here to know more about: https://krystalgeltd.com

#Bright Annealed tubes#Buy Seamless Tubes and Pipes#capillary tubes#Heat Exchanger Tubes Manufacturer#Inconel alloy#Instrumentation Tube#Seamless Tube Suppliers#Seamless Heat Exchanger Tube#Hydraulic Tubes Manufacturer#Manufacturer of Instrumentation Tubes#Manufacturer of Seamless tubes & Pipes#Manufacturer Heat Exchanger Tubes#Manufacturer of Stainless Steel Pipe#Manufacturer of Stainless Steel Tube and Pipe#Manufacturer of Stainless Steel Tubes#Monel alloy#Nickel Alloy Tubes#seamless pipe manufacturer#stainless steel bright annealed tubes manufacturers#stainless steel manufacturer in india#Stainless Steel Pipe manufacturers in India#Stainless Steel Pipe Manufacturing Company In Vadodara#Stainless Steel Seamless Pipes#stainless steel seamless tubes

0 notes

Text

Plate Type Heat Exchanger Maintenance

Maximizing Plate Type Heat Exchanger Performance through Comprehensive Maintenance

Are you having problems with your gasket plate heat exchanger? Are there leaks outside or inside the unit, or are there unexpected drops in pressure? If you need further support, experienced and qualified troubleshooters are at your service. They will offer you immediate on-site and off-site support to resolve any issues relating to your equipment. They will pinpoint the cause of unplanned shutdowns, ensuring you get the best possible performance from your equipment. Furthermore, they will be able to identify and prevent dangerous situations, to improve the working conditions of staff.

Rely on Colt Equipment’s (p) Ltd for high-quality heat exchangers and Water Cooled Compressors. Their top-notch products ensure optimal performance and reliability in various industrial settings.

What leak problems are you experiencing with your gasket plate heat exchanger?

You may experience various leakage problems with your heat exchanger units. It is essential to identify the causes of your problems in order to get them resolved in time. Here are the possible problems you may experience:

Gasket leaking due to aging

Fluids leaking externally, while seals are partially visible on the side of the plate block, fluids are leaking externally, seals are cracked and leaking from the side

External leaks and seals are loose when opened

Swelling or melting of the seal

Maintenance Procedures for Plate Heat Exchangers

One of the peculiar characteristics of plate heat exchangers is easy maintenance. In fact, looking at the matter from a theoretical point of view and on paper, it would seem so, how do we proceed in practice? After determining that the exchanger is not performing as it is "dirty", there are two ways to clean it:

CIP (cleaning in place) or chemical washing

Disassembly and complete washing (regeneration)

The first system cleaning in place or chemical washing is decidedly simpler but does not always allow you to obtain the desired effect it may not address deeply embedded or inaccessible residues and contaminants, leading to incomplete cleaning outcomes. In such cases, during Plate Type Heat Exchanger Maintenance work, disassembly and complete regeneration is a must.

The cleaning and maintenance procedures for plate heat exchangers (disassembly/reassembly) may vary depending on the various models, but fundamentally they are quite similar.

In any case, the maintenance process involves meticulous steps to ensure optimal performance post-cleaning or regeneration:

Honeycomb: once reassembled, the plate pack must have a honeycomb pattern on the side, otherwise it means that the pack has been assembled incorrectly.

Shifting: be careful when closing the plate pack to respect the sequence of the tie rods, otherwise, you run the risk of shifting the plates, which can lead to leaks and poor pressure resistance.

Tightening Dimension: you don't need a torque wrench to close a plate exchanger, but a simple measuring tape. Measure the internal distance between the two drums, it must correspond to a height indicated by the manufacturer, which is always given by:

Molding depth + plate thickness * number of plates

Conclusion Regular maintenance is the key to ensuring the longevity and efficiency of plate-type heat exchangers, especially in systems involving water-cooled compressors. By identifying and addressing common issues like leaks promptly and following proper Shell Tube Type Heat Exchanger in indiia, you can optimize the performance of your equipment. Whether choosing cleaning in place or disassembly and regeneration, prioritize thoroughness to guarantee the continued reliability of your plate heat exchanger. Remember, a well-maintained system not only reduces downtime but also enhances the overall working conditions for your staff.

#Pressure Vessel Manufacturers#Screw Air Compressor (VFD)#Plate type heat exchangers#Pressure Vessels#Air receivers#Compressor spare parts#Fabrication facility

0 notes