#Metal Stamping Parts

Text

Unlocking the Potential of Metal Stamping Parts

When it comes to precision engineering and manufacturing, metal stamping parts take center stage. These versatile components play a pivotal role in various industries, and their importance cannot be overstated. In this article, we delve into the world of metal stamping, exploring its significance, applications, and the factors that make it a cornerstone of modern manufacturing.

The Art of Metal Stamping

Metal stamping, often referred to as pressing, is a manufacturing process that involves shaping, cutting, or forming metal sheets into desired shapes and sizes. This process utilizes a combination of dies and stamping presses, ensuring high precision and repeatability in producing intricate metal components.

The Applications Are Endless

Automotive Industry

In the automotive sector, metal stamping parts are the unsung heroes that contribute to the structural integrity and aesthetic appeal of vehicles. From body panels to engine components, these parts are vital for creating safe and efficient automobiles.

Electronics and Appliances

In the world of electronics and appliances, metal stamping parts find their place in circuit boards, heat sinks, and enclosures. Their durability and thermal conductivity make them ideal for ensuring the reliability of electronic devices.

Aerospace Engineering

In the aerospace industry, where precision and performance are non-negotiable, metal stamping parts are used in critical applications. They find their way into aircraft components, ensuring safety and efficiency at 30,000 feet.

Medical Equipment

When it comes to life-saving medical equipment, precision and reliability are paramount. Metal stamping parts are employed in manufacturing medical devices, guaranteeing the highest quality and performance standards.

Key Benefits of Metal Stamping

Precision and Consistency

Metal stamping offers unparalleled precision and consistency, making it a preferred choice for industries where tight tolerances are essential.

Cost-Efficiency

The high-speed nature of metal stamping processes ensures a cost-efficient production method, saving both time and money.

Material Versatility

From stainless steel to aluminum, metal stamping can be applied to a wide range of materials, providing flexibility in design and functionality.

The Role of Innovation

As technology advances, the world of metal stamping is not left behind. Innovations such as computer-aided design (CAD) and advanced die materials have elevated the capabilities of metal stamping parts to new heights. This continual evolution ensures that metal stamping remains a cornerstone of manufacturing excellence.

Conclusion

In conclusion, metal stamping parts are the unsung heroes of the manufacturing world, shaping industries and propelling progress. Their precision, versatility, and cost-efficiency make them indispensable in various applications, from automobiles to aerospace. As innovation continues to push the boundaries of what's possible, the role of metal stamping parts in shaping our future is undeniable. So, the next time you see a car on the road or a medical device in action, remember the silent contribution of metal stamping in making it all possible.

0 notes

Text

#cnc machined parts#injection Mold Plastic Manufacturer#cnc Machining Parts#parts for Cnc Router#cnc Parts Online#Plastic Injection Molding#Plastic Molding#Plastic Injection Molding Services#Metal Stamping Parts#Molding Abs Plastic#Abs Plastic Molds#Abs Plastic Injection Molding#Plastic Injection Molding Process#Cnc Machining Precision Components#Cnc Parts Supply#Custom Plastic Parts

0 notes

Text

1 note

·

View note

Text

In daily life, household appliances can be seen everywhere. Home appliances rely on high-quality and high-precision parts to operate. Tenral designs and manufactures complex metal stamping parts for home appliance manufacturers.

0 notes

Text

#Sheet metal stamping companies#Metal stamping parts#Stamped Parts#Oil Pan#Oil Sump Manufactures#Window Regulator#Crossmember#Fuel Tank Strap#stamped parts manufacturers#metal stamped parts manufacturers#fuel tank strap manufacturers#oil pan manufacturers in usa#oil pan manufacturers#oil pan under car

0 notes

Text

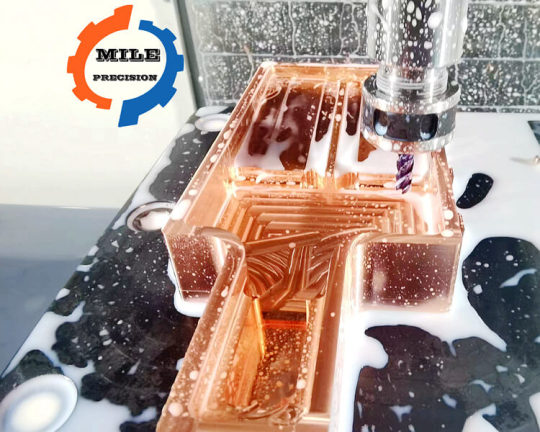

Low Volume Manufacturing Expertise in CNC Machined Aluminum

Discover the epitome of low volume manufacturing excellence with our CNC machining expertise in aluminum. From concept refinement to prototype delivery, our dedicated team ensures the highest quality and accuracy in every custom machined aluminum part.

#sheet metal manufacturing#low volume manufacturing#cnc milling services#aluminum die casting#sheet metal stamping#cnc machining services#cnc machined parts#cnc aluminum#aluminum prototype manufacturing#low volume cnc machining

0 notes

Text

Precision Craftsmanship Unraveling the Shade of Expertise in Metal Stamping Manufacturing

In the symphony of manufacturing, where perfection and trustability harmonize to produce masterpieces, essence stamping manufacturers crop as virtuosos, adroitly orchestrating the metamorphosis of raw essence into intricately designed factors. This blog post peels back the layers to unveil the moxie woven into the fabric of essence stamping manufacturing, slipping light on the intricate cotillion of technology, artificer, and invention that defines this pivotal assiduity.

The Symphony of Expertise

At the core of essence stamping manufacturing lies a marriage between professed artificer and slice- edge technology. High- tech stamping presses, frequently equipped stamping parts manufacturer with computer numerical control( CNC) systems, enable manufacturers to achieve unequaled perfection and speed in shaping essence wastes. This community of mortal moxie and technological prowess is the foundation of the indefectible prosecution of essence stamping processes.

Meticulous Design and Engineering

The trip begins with a design — a scrupulous design that encapsulates the customer’s vision and conditions. Essence stamping manufacturers employ a skeleton of professed masterminds complete in Computer- backed Design( CAD) software. This stage is where creativity meets functionality, as masterminds craft intricate designs that will latterly be restated into palpable, perfection- finagled factors.

Customization for Every Nuance

The true mark of moxie in essence stamping falsehoods in the capability to feed to different and intricate conditions. Essence stamping manufacturers understand that each design is unique, challenging a customized approach. Whether it’s a complex automotive part or a delicate electronic element, manufacturers competently conform their processes to insure the end product meets exact specifications.

Accoutrements Mastery

The palette for essence stamping tradesmen includes an array of essence — each with its own characteristics and challenges. Aluminum for its featherlight versatility, sword for its robust strength, or bobby for its conductivity; learning the complications of these accoutrements is pivotal. Essence stamping manufacturers parade an in- depth understanding of material parcels, opting the right amalgamation for the intended purpose.

Artificer in Action

The essence stamping process is a ballet of perfection and control. As the dies descend with orchestrated delicacy, essence wastes are converted into intricate shapes and forms. This cotillion demands not only technological finesse but also the nuanced touch of educated drivers who insure that each print, cut, and bend is executed faultlessly.

Quality Assurance as a Virtue

Excellence in essence stamping manufacturing goes hand in hand with unvarying commitment to quality. Rigorous quality assurance protocols are bedded at every stage of product. From the original design attestations to the final examination of stamped factors, manufacturers leave no room for error. This commitment ensures that each piece leaving the product line isn’t just a product; it’s a testament to the fidelity to perfection and artificer.

Nonstop Learning and Innovation

The world of essence stamping manufacturing is dynamic, with technological advancements and assiduity trends constantly evolving. Expert essence stamping manufacturers stay ahead of the wind through nonstop literacy and a commitment to invention. espousing state- of- the- art technologies, exploring new accoutrements , and refining processes are the pillars upon which these manufacturers make their heritage of excellence.

In the grand shade of manufacturing, essence click here stamping manufacturers are the virtuosos, weaving together moxie, technology, and artificer to produce factors that form the backbone of innumerous diligence. Their commitment to perfection, customization, and quality assurance sets them piecemeal as necessary contributors to the flawless integration of art and engineering in the world of manufacturing. As the assiduity marches forward, essence stamping manufacturers will continue to be the maestros, orchestrating the symphony of excellence in every stamped print.

0 notes

Text

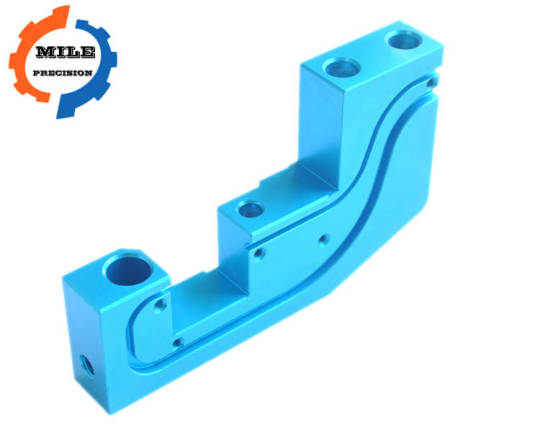

We are an experienced Custom precision machining services supplier, manufacturer in China

Our main industrial part products include turned parts, CNC machined parts, metal stamping parts and CNC milling.

Products include: hydraulic parts, pneumatic components, auto parts, medical equipment, photographic equipment, injection molding machine parts, etc.

OEM parts manufacturers,

Welcome to our website www.milemetal.com

Contact Us [email protected]

NINGBO MILE PRECISION MACHINERY CO.,LTD

#cnc milling#cnc machining#cnc turning#metal parts#oem parts#oem#stainless steel#stamping#casting#forging#auto parts

0 notes

Text

Top Metal Stamping Companies in the Australia in 2022

The importance of metal stamping has been on the increase for several years and that we square measure currently one supply for a range of complicated comes. We have detected that there square measure a great deal of prestigious brands everywhere the planet, particularly within the Australia. They are noticeably centered on quality instead of amount and from our expertise, we will assure you that they are doing a good job. We managed to compile an inventory of the highest ten metal stamping firms within the Australia that may vary in quality. It took a while to dig them out, however we will say that they're a number of the foremost prestigious firms within the state.

0 notes

Text

Stamping — also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press, a tool and die surface form the metal into the desired shape. Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal.

DESCRIPTION OF STAMPING PARTS

What Are The Steps In Stamping?

Common Metal Stamping Processes

Blanking. When required, blanking is the first step of the stamping process.

Piercing. If a part requires slots, holes, or other cutouts, piercing can be employed.

Drawing.

Bending.

Air Bending.

Bottoming and Coining.

Forming.

Pinch Trimming.

DETAILS OF STAMPING PARTS

Can Steel Be Stamped?

One of the most commonly used metals for metal stamping is steel. However, not all steel alloys are alike, and each type has its own unique qualities. Selecting a steel alloy for a metal stamping project depends on the application's specific requirements.

0 notes

Text

Metal Stamping Parts: Crafting Excellence in Precision Engineering

In the realm of precision engineering and manufacturing, metal stamping parts have emerged as a cornerstone of innovation and efficiency. These meticulously crafted components play a pivotal role in various industries, from automotive to electronics, by enabling the mass production of intricate metal pieces with unparalleled accuracy. In this comprehensive article, we will delve into the world of metal stamping parts, exploring their applications, manufacturing processes, and the transformative impact they have on modern industrial practices.

Understanding Metal Stamping Parts

What Are Metal Stamping Parts?

Metal stamping parts is a manufacturing process that involves shaping flat sheets or coils of metal into desired shapes using a stamping press and tooling. This process is known for its versatility and efficiency in producing a wide range of metal components, from simple brackets to complex automotive parts.

Precision at its Core

One of the primary reasons metal stamping parts have gained prominence is their exceptional precision. Through carefully designed tooling and precise control over the stamping process, manufacturers can consistently produce parts that meet stringent tolerances and specifications. This level of precision is indispensable in industries where even minor deviations can lead to catastrophic consequences.

Applications of Metal Stamping Parts

The versatility of metal stamping parts is a testament to their significance in modern manufacturing. Let's explore some of the key industries where these parts play a pivotal role:

Automotive Industry

In the automotive sector, metal stamping parts are the driving force behind the production of vehicle components such as body panels, chassis parts, and engine components. Their ability to maintain uniformity and quality in high-volume production makes them indispensable in this industry.

Electronics and Consumer Goods

Metal stamping is widely used in the production of electronic components, including connectors, brackets, and shielding enclosures. The precision and cost-effectiveness of this process contribute to the efficiency and affordability of consumer electronics.

The Metal Stamping Process

Understanding the metal stamping process is essential to appreciate its contribution to precision engineering. Here's a step-by-step overview:

1. Material Selection

The process begins with the selection of the appropriate metal material, which can range from aluminum and steel to specialized alloys depending on the component's requirements.

2. Tooling Design

Tooling, including dies and punches, is meticulously designed to create the desired shape. Precision tooling is essential for maintaining accuracy throughout production.

3. Blank Preparation

The metal sheet or coil, known as a blank, is prepared for stamping. This may involve cutting, cleaning, or other pre-processing steps.

4. Stamping

The blank is fed into the stamping press, where it undergoes the stamping process. The press exerts tremendous force to shape the metal into the desired form based on the tooling design.

5. Quality Control

Quality control measures, including inspections and measurements, are rigorously carried out to ensure that each stamped part meets the specified tolerances and quality standards.

6. Finishing and Assembly

After passing quality control, stamped parts may undergo finishing processes such as painting, plating, or welding, depending on the application. They are then assembled into final products.

Advantages of Metal Stamping Parts

Metal stamping parts offer numerous advantages that have solidified their position as a preferred manufacturing method:

1. High Precision

The ability to achieve micron-level precision ensures that metal stamping parts are of the highest quality, meeting even the most stringent industry standards.

2. Cost Efficiency

Metal stamping is highly efficient in producing large quantities of parts with minimal material wastage, making it a cost-effective choice for high-volume production.

3. Rapid Production

The speed at which metal stamping can produce parts is unmatched, making it ideal for industries with tight production schedules.

4. Material Variety

Metal stamping can work with a wide range of metals and alloys, providing flexibility for various applications.

Conclusion

In the world of precision engineering, metal stamping parts have elevated manufacturing to unprecedented levels of accuracy and efficiency. From automobiles to consumer electronics and aerospace, their impact is profound and far-reaching. These meticulously crafted components are the bedrock of modern industries, enabling the mass production of high-quality metal parts that drive innovation and excellence.

0 notes

Text

Injection Mold Plastic Manufacturer: A Key Player in the Plastic Industry

Mold Plastic Manufacturer: A vital part of making plastic products is an injection mold plastic maker. An established technique for the mass manufacture of plastic components, injection molding uses molds that are created and produced by a professional business. These producers are working very hard to make sure that plastic parts are produced effectively, responsibly, and affordably for various industries. read more

Source:https://justpaste.it/injection-mold-plastic

#cnc machined parts#manufacturing plant#Plastic Injection Molding Services#Metal Stamping Parts#Molding Abs Plastic#Abs Plastic Molds#Abs Plastic Injection Molding#Plastic Injection Molding Process#Cnc Machining Precision Components#Cnc Parts Supply#Custom Plastic Parts

0 notes

Text

#Non-standard precision machining#precision#cnc swiss#precision parts#cnc turning#Precision machining manufacturer#shaft#The main processing methods of metal parts are: machining#stamping#precision casting (investment casting)#powder metallurgy#metal injection molding. Machining refers to the process of changing the dimensions or properties of a workpiece by means of a mechanical d#Stamping is a forming processing method that relies on press and die to exert external force on plate#strip#pipe and profile to produce plastic deformation or separation#so as to obtain the required shape and size of the workpiece (stamping parts). There are also special processing#laser processing#electric discharge processing#ultrasonic processing#electrolytic processing#particle beam processing and ultra-high speed processing. Turning#milling#forging#casting#grinding#CNC machining#CNC center all belong to machining.

0 notes

Text

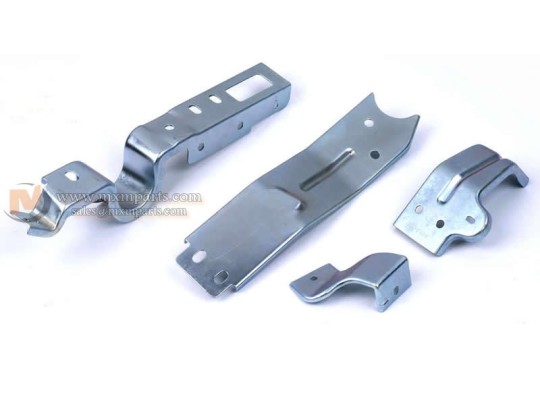

China metal stamping parts manufacturer Custom sheet metal strips.

#metal stamping#china metal parts#china supplier#mxmparts#stamping#stamping parts#sheet metal strips#metal parts#sheet metal parts#sheet metal component#stamping factory

1 note

·

View note

Text

Tenral works with manufacturers in the HVAC industry to supply them with reliable metal parts. Whether it is metal stamping parts or machined parts, we can provide the most professional solutions.

Tenral has many years of experience in metal stamping and deep drawing, which enables us to cooperate with more customers in the international plumbing industry. Moreover, we understand the specific requirements of the plumbing industry for metal fittings, durability and corrosion resistance, so we will definitely choose the best manufacturing solution for you.

1 note

·

View note

Text

#stamped parts manufacturers#metal stamped parts manufacturers#fuel tank strap manufacturers#oil pan manufacturers in usa#oil pan manufacturers#oil pan under car#Oil Pan#Oil Sump Manufactures#Window Regulator#Crossmember#Fuel Tank Strap#Stamped Parts#Sheet metal stamping companies#Metal stamping parts

0 notes