#metal stamping

Photo

Cross-Stitch Style | Brass Sign Plate

4 notes

·

View notes

Link

Metal Stamping Market by Process (Embossing, Blanking, Bending, Coining, Flanging), Material Thickness (=0.4mm, >0.4mm), Press Type (Hydraulic Press, Mechanical Press, Servo Press), Material, End-Use Industry, Region - Trends and Forecast to 2028

2 notes

·

View notes

Text

So on a completely unrelated note, I’ve started a new hobby. And it seems to be sticking, I find it fun and engaging, and slightly challenging. I’ve starting stamping metal dog ID tags for pets!

On the down side, I’ve realised that my aptitude for making stupid mistakes like misspelling a very common word is extremely high under pressure and while I was practicing, I made this:

And it has become my dogs official harness tag.

14 notes

·

View notes

Text

Exploring Metal Stamping Services: From Concept to Practice

Metal stamping services are pivotal in manufacturing, offering efficient solutions for shaping metal components. This article delves into the intricacies of metal stamping, exploring its significance, applications, and considerations for selecting the right service provider.

What is Metal Stamping?

Metal stamping is a versatile manufacturing process that converts flat metal sheets into various shapes and forms. It involves using presses, dies, and tooling to apply force and manipulate the metal into the desired configuration. The process is commonly employed in automotive, aerospace, electronics, and appliances industries to produce a wide range of components with high precision and efficiency.

Process Overview

The metal stamping process typically begins with a flat sheet or coil of metal, which is fed into a stamping press. The press applies force to the metal using specialized dies, which are machined to the precise shape and dimensions of the desired part. The metal undergoes various operations such as blanking, piercing, forming, and bending as it progresses through the dies. Each operation is carefully controlled to achieve the desired shape and dimensions of the final part.

Blanking and Piercing

Blanking is the process of cutting the metal into a specific shape while piercing involves creating holes or openings in the metal sheet. These operations are typically performed in the initial stages of the stamping process to create the basic outline of the part and prepare it for further forming operations.

Forming and Bending

Forming and bending operations shape the metal into complex geometries and contours. This is achieved by applying controlled pressure to the metal using specialized tooling, which deforms the metal into the desired shape. Forming operations can include drawing, stretching, and deep drawing, depending on the part’s complexity.

Secondary Operations

After the primary forming operations are complete, the stamped parts may undergo secondary operations such as trimming, machining, welding, or assembly to achieve the final desired specifications. These secondary operations are often necessary to remove excess material, refine features, or join multiple components together.

0 notes

Text

Metal Stamping | Podjewellery.com.au

Customise and add personality to your hand stamped pieces with ImpressArt design stamps. These metal stamps are ideal for all your metal stamping projects.

0 notes

Text

The Asia-Pacific metal stamping market was at $83.57 billion in 2022 and is poised to reach $110.86 billion by 2028, growing at a CAGR of 4.82%.

APAC's undeniable dominance in the automotive metal stamping market is fueled by skyrocketing vehicle production. China set the pace with its staggering output of nearly 24 million passenger cars in 2022. Combine this with a thriving electronics industry - like South Korea's ICT goods export boom, soaring 18.9% year-on-year in 2022 - and you'll see the region's unmatched potential.

#industry#industry data#market research#marketreports#asia pacific#china#taiwan#india#bhutan#bangladesh#metal stamping#metal#metal stamping market

0 notes

Text

Aerospace and Defense Metal Stamping Market by Component (Housings and Enclosures, Assemblies, Brackets, Clips, Cylinders, Electrodes, Fasteners, Relays), Process (Embossing, Flanging), and Material (Aluminium, Steel) - Global Forecast to 2027

#Aerospace and Defense Metal Stamping Market#Aerospace and Defense#Metal Stamping Market#metal stamping#semiconductor#electronic#technology

0 notes

Text

Stamp Seal with a Toadstool Base. Manufactured in the 2nd half of the 19th century, presumed Russian origin. Materials are vermeil (silver gilded with gold), enamel paint and shell. From the Musée d'Art et d'Histoire, Geneva, inventory number: 018080.

(Source: mahmah.ch)

#stamp seal#wax seal#trinkets#mid 1800s#late 1800s#russian design#nature motif#animal motif#mushrooms#snails#metal#enamel#shell#red#grey

5K notes

·

View notes

Text

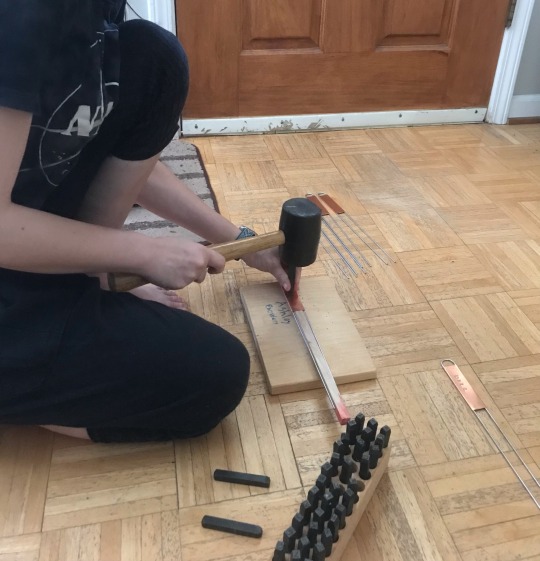

Quick fun project: stamping garden stakes. Came out very good for free spacing.

0 notes

Text

listing jewelry on etsy is incredibly draining. I wish I could just do everything at once, but I'll settle for posting a picture here

0 notes

Text

1 note

·

View note

Text

#sheet metal fabrication#sheet metal design#sheet metal manufacturing#metal punching#metal welding#metal stamping#metal shearing#metal forming

1 note

·

View note

Text

Trend Size ,Share Of Aerospace and Defence metal Stamping Market

Trend Size ,Share Of Aerospace and Defence metal Stamping Market

The increase in this market is primarily attributed to the growing demand for commercial aircraft, the growing demand for fighter planes amid rising security concerns worldwide, the growing demand for high-quality precision components, the increasing investments in metal stamping facilities, and the growing sophistication of technology. Additionally, it is anticipated that the developing economies in the Asia-Pacific and Latin American regions would open up profitable potential for market participants. The introduction of high-grade plastic materials in the aerospace and defence industries, however, is anticipated to partially restrain the expansion of this market.

To provide efficient analysis, Meticulous Research® has segmented this market on the basis of components (housings & enclosures, relays, switches, electrodes, assemblies, brackets, bushings, frames, shields, terminals, wire forms, clips/connectors/fasteners, cylinders, and other components), application (oxygen generating systems, power distribution systems and controllers, signal and power systems, flat connection systems, communication devices, large components, and other small components), sector (commercial aircrafts sector and military/defence aircrafts sector), process (blanking, embossing, bending, coining, deep drawing, flanging, and others), material (steel, aluminium, titanium, copper, and others), and geography (North America, Europe, Asia Pacific, Latin America, and Middle East and Africa).

Based on component, the clips/connectors/fasteners segment is estimated to command the dominant share of the overall aerospace and defence metal stamping market in 2020. The dominant position of this segment is mainly attributed to the rising demand for a variety of clips, connectors, and fasteners for the assembly and connection of various joint structures during aircraft manufacturing and aftermarket care of old airline fleets.

Based on application, the signal and power systems segment is estimated to command the largest share of the overall aerospace and defence metal stamping market in 2020. The large share of this segment is mainly attributed to the crucial role of power generation and lighting signal systems in aircraft travel, landing, and takeoff. However, the communication devices segment is expected to grow at the fastest CAGR during the forecast period.

Based on sector, the commercial & civil aircraft sector is estimated to command the largest share of the overall aerospace and defence metal stamping market in 2020. The high demand for metal stamped parts for the construction of civil & commercial aircraft is one of the major factors accelerating the growth of this sector. Moreover, the replacement of old fleets with new aircraft by various airlines to meet the regulatory standards on maintenance & safety and achieve fuel-efficiency with advances in new aircraft are further stimulating the growth of this sector.

Based on process, the blanking process segment is estimated to command the largest share of the overall market in 2020. The large share of this segment is mainly attributed to its ability to produce precise and superior quality metal workpieces in large volumes at low costs for the further processing of metal sheets. However, the bending process segment is expected to grow at the fastest CAGR during the forecast period.

Geographically, North America is estimated to command the largest share of the overall aerospace and defence metal stamping market in 2020. Leading position of the North America in aerospace and defence metal stamping market is primarily attributed to the presence of leading aircraft manufacturers and other tier 1 players in the value chain that generate huge demand for various metal stamped aircraft components. However, the Asia-Pacific region is slated to register the fastest growth during the analysis period.

𝑺𝒑𝒆𝒂𝒌 𝒕𝒐 𝑨𝒏𝒂𝒍𝒚𝒔𝒕:https://www.meticulousresearch.com/speak-to-analyst/cp_id=5103?utm_source=product&utm_medium=Social&utm_campaign=Product&utm_content=29-03-2023

The key players operating in the global aerospace and defence metal stamping market are American Industrial Company (U.S.), Keats Manufacturing Company (U.S.), Wiegel Tool Works Inc. (U.S.), Hudson Technologies (U.S.), K S Tooling Inc. (U.S.), AAA Tool and Machine Co. (U.S.), Pacific Metal Stampings Inc. (U.S.), Tempco Manufacturing Company, Inc. (U.S.), D&H Industries Inc. (U.S.), Klesk Metal Stamping Co. (U.S.), Clow Stamping Company (U.S.), ACRO Metal Stamping Co. (U.S.), National Die Company Inc. (U.S.), Henan Kathysia Industrial Co, Ltd., (China), Kölle GmbH (Germany), Forgeavia (France), and Weiss-Aug Co., Inc. (U.S.) among others.

The aerospace & defense metal stamping market is highly fragmented with the presence of many small private vendors in the market. Some of the key players operating in the global aerospace and defense metal stamping market are American Industrial Company (U.S.), Keats Manufacturing Company (U.S.), Wiegel Tool Works Inc. (U.S.), Hudson Technologies (U.S.), K S Tooling Inc. (U.S.), AAA Tool and Machine Co. (U.S.), Pacific Metal Stampings Inc. (U.S.), Tempco Manufacturing Company, Inc. (U.S.), D&H Industries Inc. (U.S.), Klesk Metal Stamping Co. (U.S.), Clow Stamping Company (U.S.), ACRO Metal Stamping Co. (U.S.), National Die Company Inc. (U.S.), Henan Kathysia Industrial Co, Ltd., (China), Kölle GmbH (Germany), Forgeavia (France), and Weiss-Aug Co., Inc. (U.S.), among others.

Scope of the report:

Aerospace and Defense Metal Stamping Market, by Component

Clips/Connectors/Fasteners

Cylinders

Switches

Bushings

Assemblies

Housings & Enclosures

Housings & Enclosures Market, by Type

Thermal Battery/Capacitor Housings & Enclosures

Other Housings & Enclosures

Housings & Enclosures Market, by Sector

Commercial Aircraft Sector

Military/Defense Aircraft Sector

Electrodes

Wire Forms

Shields

Relays

Terminals

Brackets

Frames

Other Components

Aerospace and Defense Metal Stamping Market, by Application

Signal and Power Systems

Power Distribution Systems and Controllers

Large Components

Flat Connection Systems

Oxygen Generating Systems

Communication Devices

Other Applications

Aerospace and Defense Metal Stamping Market, by Sector

Commercial & Civil Aircrafts Sector

Military/Defense Aircrafts Sector

Aerospace and Defense Metal Stamping Market, by Process

Blanking

Embossing

Bending

Coining

Deep Drawing

Flanging

Others

Aerospace and Defense Metal Stamping Market, by Material

Aluminium

Steel

Stainless Steel

Carbon Steel

Galvanized Steel

Cold-Rolled Steel

Titanium

Copper

Other Materials

Aerospace and Defense Metal Stamping Market, by Geography

North America

U. S.

Canada

Europe

France

U. K.

Germany

Italy

Spain

RoE

Asia-Pacific (APAC)

China

Japan

India

RoAPAC

Latin America

Middle East and Africa

𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕 @ https://www.meticulousresearch.com/download-sample-report/cp_id=5103?utm_source=sb&utm_medium=Social&utm_campaign=Product&utm_content=29-03-2023

0 notes

Text

The Art and Science Behind Stamped Metal: Crafting Innovation and Precision

Stamped metal, an intricate process blending artistry with technology, stands as a cornerstone in the world of manufacturing and design. This article delves into the captivating realm of stamped metal, exploring its techniques, applications, and the innovative fusion of craftsmanship and modern engineering.

Understanding Stamped Metal:

At its core, stamping involves the shaping or forming of metal sheets using specialized machinery and tools. This process often employs a press, dies, and precision tooling to cut, bend, or shape metal into desired designs or components. Materials commonly used in stamped metal processes include steel, aluminum, copper, and alloys, showcasing the versatility of this technique.

The Stamping Process:

Stamping typically begins with a flat metal sheet fed into a press, where the die—crafted specifically for the intended design—exerts immense force to shape the metal. The die, containing cavities or impressions of the desired pattern or part, molds the metal sheet under pressure, resulting in intricate shapes, textures, and patterns.

Applications Across Industries:

Stamped metal components find their application across a myriad of industries. In automotive manufacturing, stamped metal forms essential parts such as body panels, chassis components, and engine parts, showcasing the durability and precision achievable through this method. The electronics industry relies on stamped metal for producing intricate parts in devices like smartphones, laptops, and appliances, ensuring structural integrity and functionality.

Advantages of Stamped Metal:

The use of stamped metal offers several advantages. Its ability to produce high volumes of precise, consistent parts with minimal material waste contributes to cost-effectiveness in manufacturing. Additionally, stamped metal components often exhibit superior strength, durability, and dimensional accuracy, meeting stringent quality standards.

Innovation and Customization:

Advancements in technology have revolutionized the stamped metal industry, enabling greater customization and complexity in designs. Computer-aided design (CAD) software facilitates intricate die designs, while robotics and automation enhance efficiency and precision in the stamping process, allowing for the creation of highly detailed and complex metal parts.

Conclusion:

Stamped metal represents a harmonious blend of traditional craftsmanship and cutting-edge technology, playing a pivotal role in modern manufacturing and design. Its versatility, precision, and efficiency make it indispensable across various industries, showcasing the endless possibilities achievable through this intricate process. As technology continues to evolve, stamped metal remains at the forefront of innovation, shaping the world we live in with its precision and adaptability.

For more info visit here:-

stamping metal

0 notes

Text

The U.S. metal stamping market was valued at USD 48.81 billion in 2022 and is projected to reach USD 63.16 billion by 2028, growing at a CAGR of 4.39% during the forecast period.

Metal stamping technology is utilized in various industries, such as automotive, industrial machinery, aerospace, energy, medical, telecommunications, electronics, military & defense, appliances, construction, and more.

0 notes

Text

Aerospace and Defense Metal Stamping Market by Component (Housings and Enclosures, Assemblies, Brackets, Clips, Cylinders, Electrodes, Fasteners, Relays), Process (Embossing, Flanging), and Material (Aluminium, Steel) - Global Forecast to 2027

#Aerospace and Defense Metal Stamping Market#Aerospace and Defense Metal Stamping#Aerospace and Defense#Metal Stamping Market#metal stamping

0 notes