#Modular Robotics Market analysis

Text

Modular Robotics Market Analysis Report|2022-2030

This report analyzes key players, including their market share, market size, growth drivers, and company profiles. The purpose of this research report is to provide an in-depth analysis of the market overview, prevalent trends, demand, and recent changes that are affecting the global modular robotics market.

The study also discusses product launches, market expansion, strategic growth analysis, market potential analysis, and technological advancements. It provides market size, prospective expansion, trends, and leading competitors’ expansion plans.

With the help of this report, you will be able to gain insight into the competitors’ positioning, market scope, growth potential, and future prospects.

Our report provides in-depth insights into the leading players in the global modular robotics market for the next few years. To gain a stronghold in the global modular robotics market, these key participants have adopted various business strategies. As a result, other businesses can gain a better understanding of how market leaders maintain dominance and expand their customer bases to secure a majority share.

There are a number of major players in the modular robotics market, including:

ABB, Midea Group (Kuka Ag), Fanuc, Yaskawa Electric Corporation, Kawasaki Heavy Industries Ltd., Denso Robotics, Universal Robots, Nachi-Fujikoshi Corp., Mitsubishi Electric Corp., Omron Corporation.

Request Sample Report: https://www.nextmsc.com/food-preservative-market/request-sample

As part of this study, we will examine how COVID-19 impacted and altered the global modular robotics market environment. Demand, consumption, transportation, consumer behavior, supply chain management, exports, imports, and manufacturing are among the factors considered in the study. Furthermore, analysts have highlighted the elements that can help businesses identify opportunities in the near future and stabilize the industry.

Some of the key advantages discussed in this study report are a neutral outlook on market performance, recent industry trends, competitive landscapes and key players’ strategies, potential and niche segments, and geographical regions contributing to promising growth.

Furthermore, the report provides historical, current, and future market sizes, along with a geographical forecast.

Depending on their type, the global modular robotics market is divided into:

· SCARA Modular Robots

· Articulated Modular Robots

· Collaborative Modular Robots

· Cartesian Modular Robots

· Parallel Modular Robots

· Others

o Spherical

o Cylindrical

Global modular robotics market applications can be categorized into:

· Logistics

· Aerospace & Defense

· Healthcare

· Food & Beverages

· Automotive & Transportation

· Manufacturing

· Media & Entertainment

· Others

Inquire Before Buying: https://www.nextmsc.com/food-preservative-market/inquire-before-buying

A comprehensive analysis of all of the critical features of the global modular robotics industry has been conducted in the latest study. Market size, competition, development trends, niche markets, market drivers and challenges, SWOT analysis, Porter’s five forces analysis, value chain analysis, and so on are covered from a macro-level to a micro-level.

According to the report, markets are categorized based on their type, end-users, applications, and regions, among other factors.

In order to be able to target products, sales, and marketing strategies accordingly, decision-makers must be familiar with the market segments. Businesses can advance product development by being guided on how to develop products tailored to meet the needs of different market segments.

Key stakeholders can use this market research report to develop plans for supporting the company’s success by using statistics, tables, and graphs. It provides an in-depth analysis of the modular robotics market across all major geographic regions, including North America, Asia-Pacific, Latin America, the Middle East, and Africa.

This report examines the dynamics of several regions in order to gain a clearer picture of the global market.

For more insights, please visit, https://www.nextmsc.com

#modular robotics market#modular robots#artificial intelligence#ict and media#global markets#market growth#market share#market size#market trends#market value#market analysis#market forecast

0 notes

Text

Modular Robotics Market - Forecast (2022 - 2027)

The Global Modular Robotics Market is forecast to reach $11,514.9 million by 2026, growing at CAGR 10.8% during the forecast period 2021-2026. Modular Robotics generally refer to self-configurable articulated robots which are capable of carrying out variety of tasks through autonomous and dynamic change of geometric structures. These kinds of human robot interactions have been growing popular among industrial sectors including automotive, manufacturing, healthcare and many others owing to better optimization, flexibility and robustness. Technological advancements towards integrating advanced technologies like AI, Industrial Internet of Things edge computing and so on along with capability of improving organizational productivity standards are some of the major factors affecting the market growth of modular robotics. Moreover, increasing automation across healthcare sectors to optimize medical treatment processes is further analyzed to create a positive impact on the market growth of modular Selective Compliance Assembly Robot Arm (SCARA) robotics.

Modular Robotics Market Report Coverage

The report: “Modular Robotics Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Modular Robotics Market.

By End Users: Food & Beverages, Automotive, Healthcare, Electrical & Electronics, Chemicals, Metals & Machinery, Others

By Geography: North America (U.S, Canada and Mexico), Europe (UK, Germany, Italy, France, Netherlands, Spain and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and Rest of APAC), South America (Brazil, Argentina and Rest of South America), and RoW (Middle East and Africa)

Key Takeaways

Collaborative robots is expected to have a major contribution during the forecast period 2021-2026 in the global modular robotics market owing to high investments towards research and development activities.

Key players such as Mitsubishi Electric Corporation, Yaskawa Electric Corporation and so on are the major drivers boosting the growth of modular robotics within the APAC region.

Request Sample

Modular Robotics Market Segment Analysis – By Robot Type

Based on robot type, the modular robotics market has been segmented into Cartesian robots, Collaborative robots (Cobots), Articulated robots, Scara robots, Parallel robots and others. Collaborative robots or cobots registered highest share in the global the modular robotics market in 2020 at 26.5%. Collaborative robots generally refer to those types of robots which are capable of performing tasks by physically interacting with workers across an industrial workspace. As cobots can be conveniently placed anywhere or relocated depending on user needs, it helps in eliminating any kind of non-production activities during the production hours, thereby ensuring optimum flexibility, efficiency and production capabilities for various end use industries. Additionally, these robots are designed with human involvement and collaboration, ensuring a safer work environment specifically in application areas including medical, food & beverages and so on where human errors can create major work disruptions. Features such as easy operation, affordability coupled with deployment of options like plug and play and CAD programming have been also affecting its market growth. Owing to technological advancements related to controllers, various robotic modules and many others, adoption of collaborative robots can eventually rise across major end use verticals like manufacturing, electronics, medical as well as others in the long run.

Modular Robotics Market Segment Analysis – By End Users

By End users, the global modular robotics market has been segmented into Food & Beverages, Healthcare, Electrical & Electronics, Metals & Machinery, Automotive, Chemicals with many others. Healthcare sector is analyzed to witness a significant growth in the market at 14.6% through 2026 due to growing shift towards automating medical treatment procedures such as performing surgeries, conducting diagnostic tests and many others with optimum flexibility and ease. Since the hospitals involve conducting varied demanding procedures which needs high amount of accuracy and precision while elimination high human intervention, demand towards self-configurable robots will eventually rise in the long run. In September 2019, Medtronic PLC launched a robot-assisted surgical platform, capable of supporting laparoscopic applications. This modular and upgradable designed architecture involves foot pedals in order to help the surgeons interact with the patients or staffs during procedures. Such developments act as a prime source towards modernizing the medical surgery procedures within healthcare sector. In October 2020, CMR Surgical announced about introducing Versius surgical robotic system within a leading France based public health centre, Argenteuil Hospital. This robotic system was meant to reinforce its shift towards accessible and adaptable surgical robotics across global healthcare units in the near future.

Inquiry Before Buying

Modular Robotics Market Segment Analysis – By Geography

APAC region is anticipated to have a significant growth in the modular robotics market over the forecast period. With growing dominance of industrial sectors including automotive and electronics mainly across China, India, Japan and others along with increasing shift towards Industry 4.0 trends has been acting as major factors impacting the need towards modular robotics. High investments towards research and development activities as well as increased support towards upgrading healthcare facilities will also help in aiding the growth of modular robotics across the region. Presence of some major market players including Mitsubishi Electric Corporation, Yaskawa Electric Corporation, Toshiba Machine Co Ltd. with many others has been also propelling high market demands towards modular robots. In August 2020, Mitsubishi Electric announced about launching a series of collaborative robots named MELFA ASSISTA within Indian markets. These robots are coupled with safety features like collision detection alongside complying with international safety and robotic standards in order to serve end-use customers with optimum productivity, flexibility as well as faster automation. Such developments are further meant to create a positive impact on the growth of modular robotics market in the long run.

Modular Robotics Market Drivers

Technological advancements like edge computing

Rise of technological advancements such as edge computing can be considered as a major driving factor for the modular robotics market. Integrating edge computing services within modular robots help the end use industries to have easier implementation owing to elimination of equipments like switches, servers or routers. Since edge computing offers capability of achieving real-time predictive maintenance within assembly lines as well as varied plant operations, thereby aiding the need towards modular robots across major industries. Adoption of modular robots with edge computing device integration including sensors and others are getting popular due to providing benefits like continuous monitoring timely defects of the robots, eliminating plant shutdowns or work disruptions, thus saving costs. Moreover, this technology acts beneficial in raising the standards for both processes as well as product quality manufactured using modular robots. In June 2020, ADLINK Technology announced about launching a real-time ROS 2 robot controller, named ROScube-X series specifically designed for advanced robotic applications. This controller offers compatibility with NVIDIA JetPack SDK resources and can perform robotic applications demanding high performance AI computing capability while minimizing power consumption. Such factors are further set to boost the demand towards advanced robotic modules within the modular robotics market over the forecast period.

Schedule a Call

Improves work productivity

The capability of modular robots towards improving work productivity standards across various industry verticals is also analyzed to be one of the major drivers creating significant market growth. Modular robots are capable of offering benefits including versatility, configurability as well as scalability which increases fault tolerance, thereby eliminating the need for assembly between parts. As compared to conventional industrial robots, these self-configurable modular robots can be easily transformed from one form to another depending on consumer requirements, which helps the end users to spend on variable types of robotic systems. Owing to its versatile nature, modular robots are getting higher adoption within industry verticals including pharmaceuticals, manufacturing, healthcare and so on, optimizing the performance standards of these environments. In addition to this, modular robots are more robust compared to conventional counterparts, as individual modules are generally considered unimportant which undergoes replacement overtime. Also, these robots can eventually compensate for damages either by reconfiguring or autonomous part replacement, thus making it a better alternative owing to its easy handling of complications. Such factors have been highly promoting the growth of modular robotics across demanding industries like pharma, healthcare, manufacturing among others in the long run.

Modular Robotics Market Challenges

High costs

Designing and integration complexities of modular robots cause high manufacturing costs which can be considered as one of the major challenges impeding the market growth. Designing hardwares or softwares for these robots needs to be integrated with advanced technologies from time to time in order to ensure better work optimization, causing the manufacturers to spend on costly components. Additionally, complexities on robotic development by combining features including precision, robustness, functionality and so on creates the need for skilled expertise. Operating these self-configurable modular robots across end use verticals like medical, food & beverages, automotive and many others can be complex at times, thus need for training of the workforce becomes highly essential. Such factors help in raising its purchasing costs, creating lesser adoption from small as well as mid-size organizations, restraining its market growth.

Buy Now

Modular Robotics Market Landscape

Partnerships and acquisitions along with product launches are the key strategies of the players in the modular robotics market. The major key players in the modular robotics market include ABB Ltd., Mitsubishi Electric Corporation, Yaskawa Electric Corporation, KUKA, Toshiba Machine Co Ltd., Denso Corporation, Universal Robots, Rethink Robotics, Yamaha Motor Co Ltd. and FANUC.

Partnerships/Product Launches/Acquisition

In July 2020, one of the leading custom robotics company, named Advanced Intelligent Systems announced about introducing a modular UV light disinfection robot. This autonomous robot was developed to offer critical support for hospitals, senior care facilities as well as healthcare workers dealing with safety issues during or after the COVID-19 pandemic, thereby eliminating human intervention.

In May 2020, Motiv Space Systems announced about launching a space-rated modular robotic arm system, named xLink. This system offers exceptional adaptability while accommodating varied applications meant for space rated robotic manipulation.

For more Electronics Market reports, please click here

#Modular Robotics Market#Modular Robotics Market price#Modular Robotics Market share#Modular Robotics Market analysis#Modular Robotics Market trends#Modular Robotics Market report#Robotics

1 note

·

View note

Text

Scaffolding Market Projections: Global Industry Analysis and Forecast (2023-2032)

The Global Scaffolding Market is projected to witness significant growth, with its value expected to surge from USD 74,826.17 million in 2023 to USD 1,25,347.93 million by 2032, reflecting a robust CAGR of 5.90%.

The scaffolding market is experiencing robust growth driven by the expansion of the construction industry worldwide. Scaffolding, essential for providing temporary support and access during construction, maintenance, and repair of buildings and other structures, is witnessing increased demand due to rising urbanization, infrastructural development, and the surge in commercial and residential construction projects. Advances in scaffolding technology, such as modular and lightweight systems, are enhancing safety, ease of assembly, and cost-effectiveness, further boosting market adoption. The growing emphasis on worker safety is leading to stringent regulations, compelling construction companies to adopt high-quality scaffolding systems that comply with safety standards.

Additionally, the renovation and refurbishment of existing buildings, driven by the need to upgrade aging infrastructure and improve energy efficiency, are contributing to the market's growth. The market is also seeing significant investments in the development of innovative scaffolding solutions, including automated and robotic systems, which enhance efficiency and reduce labor costs. The increasing prevalence of high-rise buildings and complex architectural designs necessitates advanced scaffolding systems that can provide stable and secure platforms at elevated heights. However, the market faces challenges such as the high cost of advanced scaffolding systems and the need for skilled labor to ensure proper installation and dismantling.

Scaffolding is integral to construction, providing essential support and access for various tasks. Here’s a detailed look at how scaffolding is used in construction areas:

Elevated Work Access: Scaffolding provides a stable and secure platform for workers to perform tasks at heights. This includes installing windows, painting, plastering, bricklaying, and other finishing work on building exteriors and interiors.

Structural Support: During the construction of tall buildings and structures, scaffolding offers temporary support. This ensures that materials and workers can be safely positioned to construct, maintain, or repair various sections of the building.

Safety and Stability: Scaffolding ensures worker safety by providing guardrails, toe boards, and safe access routes to work areas. It minimizes the risk of falls and accidents, which is crucial in maintaining a safe construction site.

Material Handling: Scaffolding systems often include platforms and hoists that facilitate the movement of materials to higher levels. This makes the transportation of heavy construction materials more efficient and less labor-intensive.

Bridge Construction: In bridge construction, scaffolding supports workers and materials, allowing them to work on sections of the bridge that are above ground or over water. It provides a stable platform for assembling and connecting bridge components.

Renovation and Maintenance: Scaffolding is widely used in renovation and maintenance projects for existing structures. It allows workers to access hard-to-reach areas, carry out repairs, and perform upgrades without causing damage to the structure.

Complex Architectural Designs: For buildings with unique or complex architectural designs, scaffolding can be customized to fit unusual shapes and angles, providing the necessary support and access for construction workers.

Facade Work: Scaffolding is essential for facade work, including cladding, cleaning, and restoration. It allows workers to perform these tasks safely and efficiently, ensuring the exterior of the building is completed to high standards.

Demolition: In demolition projects, scaffolding can provide access and support for the controlled dismantling of structures. It ensures that workers can safely reach all parts of the building and remove materials systematically.

Event and Temporary Structures: Scaffolding is also used in the construction of temporary structures such as stages, viewing platforms, and grandstands for events. It provides the necessary stability and safety for these temporary installations.

Market Trends:

The scaffolding market is experiencing several notable trends that are shaping its growth and development. One key trend is the increasing adoption of modular and lightweight scaffolding systems, which offer enhanced flexibility, ease of assembly, and improved safety. These systems are becoming popular due to their cost-effectiveness and efficiency in reducing labor time. Another significant trend is the growing emphasis on worker safety, driving the demand for advanced scaffolding solutions that comply with stringent safety regulations. This includes the integration of safety features such as guardrails, toe boards, and secure access points. Additionally, there is a rising focus on sustainable scaffolding materials, such as aluminum and fiberglass, which are lightweight, durable, and environmentally friendly.

The market is also witnessing technological advancements, including the use of automation and digital tools for scaffolding design and installation. These technologies enhance precision, reduce errors, and optimize resource utilization. The ongoing urbanization and infrastructure development in emerging economies are further fueling the demand for scaffolding, particularly in regions like Asia Pacific and Latin America. Moreover, the trend towards high-rise and complex architectural projects is driving the need for specialized scaffolding solutions that can accommodate unique design requirements.

Key Player Analysis-

ADTO Industrial Group Co. Ltd.

Altar Group LLC

Wilhelm Layher Holding GmbH

Step up Scaffold

KHK Scaffolding & Formwork LLC

Waco Kwikform Limited

Safway Group Holding LLC

PERI GmbH

ULMA C Y E

S. COOP.

More About Report- https://www.credenceresearch.com/report/scaffolding-market

The scaffolding market presents several growth opportunities driven by evolving industry demands and technological advancements. Key growth opportunities include:

Urbanization and Infrastructure Development: Rapid urbanization and infrastructure development, particularly in emerging economies, are major drivers for the scaffolding market. Increasing investments in residential, commercial, and industrial construction projects create significant demand for scaffolding systems.

Technological Advancements: The adoption of advanced technologies such as automated scaffolding systems, digital design tools, and modular scaffolding solutions offers growth opportunities. These technologies improve efficiency, safety, and cost-effectiveness, attracting more construction companies to invest in modern scaffolding systems.

Sustainability Trends: There is a growing emphasis on sustainable construction practices, which includes the use of eco-friendly scaffolding materials like aluminum and fiberglass. These materials are lightweight, durable, and recyclable, making them attractive options for construction companies looking to reduce their environmental footprint.

Safety Regulations and Standards: Stringent safety regulations and standards in the construction industry drive the demand for high-quality, compliant scaffolding systems. Companies offering innovative solutions that enhance worker safety and meet regulatory requirements have significant growth potential.

Renovation and Maintenance Projects: The increasing need for renovation and maintenance of existing infrastructure, including historical buildings, bridges, and commercial structures, provides opportunities for scaffolding companies. These projects often require specialized scaffolding systems that can adapt to various structural configurations and heights.

High-Rise and Complex Structures: The trend towards constructing high-rise buildings and complex architectural designs necessitates specialized scaffolding solutions. Companies that can provide customized scaffolding systems to meet these unique requirements are well-positioned for growth.

Geographic Expansion: Expanding into new geographic markets, especially in regions with booming construction activities such as Asia Pacific, Latin America, and Africa, presents significant growth opportunities. Establishing a presence in these regions can help scaffolding companies tap into the rising demand for construction and infrastructure development.

Rental Services: The increasing preference for scaffolding rental services over purchasing, due to cost savings and flexibility, is a growing trend. Companies that offer rental services with a wide range of scaffolding options can capitalize on this demand, providing a steady revenue stream.

Training and Certification Programs: Offering training and certification programs for construction workers on the safe use and installation of scaffolding systems can differentiate companies in the market. These programs not only enhance safety but also build customer trust and loyalty.

Public-Private Partnerships: Collaborating with government bodies and private sector entities on large-scale infrastructure projects can open up substantial opportunities. Public-private partnerships often involve significant construction activities, requiring reliable and efficient scaffolding solutions.

Segments:

Based on Type

Supported

Suspended

Rolling

Aerial Lifts

Others

Based on Application

Residential

Commercial

Industrial

Based on Material

Aluminum

Wood

Steel

Browse the full report – https://www.credenceresearch.com/report/scaffolding-market

Browse Our Blog: https://www.linkedin.com/pulse/scaffolding-market-projections-global-industry-analysis-6khof

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Modular Construction Market to be Worth $189.1 Billion by 2031

Meticulous Research®, a leading global market research company, has published a report titled "Modular Construction Market Size, Share, Forecast, & Trends Analysis by Product (Permanent, Relocatable), Method (Closed, Open), Material (Wood, Steel, Concrete), Application (Residential, Commercial, Industrial, Healthcare) - Global Forecast to 2031."

According to this latest report, the global modular construction market is projected to reach $189.1 billion by 2031, growing at a CAGR of 6.9% from 2024 to 2031. The market's growth is driven by several factors, including cost-efficient installation, a shortage of skilled labor, and the need for faster project execution. Additionally, rising urbanization, the global affordable housing crisis, and a focus on sustainable building practices are expected to create further market opportunities. However, growth may be restrained by the perception that modular construction is limited to commercial projects, as well as manufacturing and transportation challenges.

A key trend in the market is the integration of digital technologies, automation, robotics, and artificial intelligence (AI).

The global modular construction market is segmented by product, method, material, and application. The report also evaluates competitors in various end-user industries and analyzes the market at the regional and country levels.

Product Segmentation

The market is divided into permanent modular construction (PMC) and relocatable modular construction (RMC). In 2024, the PMC segment is expected to hold the largest share of approximately 65%. This is due to the growing need for controlled manufacturing conditions, increased use in industrial buildings, and applications in residential construction.

Conversely, the RMC segment is projected to experience higher growth during the forecast period. This growth is driven by the demand for temporary facilities on construction sites, emergency shelters, and temporary retail spaces.

Method Segmentation

The market is also segmented into closed and open modular construction methods. In 2024, the closed modular construction segment is expected to hold the largest market share, attributed to the demand for high-quality buildings, cost reduction through material waste minimization, and the avoidance of weather-related project delays.

The open modular construction segment is projected to witness higher growth, driven by the demand for design flexibility and customization, and its use in public and cultural buildings.

Material Segmentation

Materials used in modular construction include wood, steel, concrete, and others. In 2024, the steel segment is expected to account for the largest share of approximately 43%. Its large market share is due to its strength, flexibility, and recyclability, making it ideal for durable modular structures. The steel segment is also anticipated to grow at the highest rate, driven by its use in commercial buildings, manufacturing facilities, and distribution centers.

Application Segmentation

The market applications include residential properties, commercial spaces, healthcare facilities, educational institutions, government and public sector buildings, aerospace and defense, and others. The residential properties segment is expected to hold the largest share of approximately 56% in 2024, due to the demand for cost-effective housing solutions, temporary shelters, and urban housing to address shortages and affordability issues. This segment is also projected to grow at the highest rate.

Regional Segmentation

Geographically, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2024, North America is expected to hold the largest share of approximately 40%, driven by technological advancements, a shortage of skilled labor, demand for scalable modular spaces, and a focus on sustainability.

The Asia-Pacific region is expected to register the highest growth rate of approximately 8.5%, driven by rapid urbanization, the need for affordable housing, and government initiatives for smart cities and infrastructure development.

Key Players

Key players in the modular construction market include ATCO Ltd. (Canada), Guerdon, LLC (U.S.), Skanska AB (Sweden), Bouygues Construction (France), KLEUSBERG GmbH & Co KG (Germany), Lendlease Corporation (Australia), Red Sea International (Saudi Arabia), Bechtel Corporation (U.S.), Honomobo (Canada), WillScot Mobile Mini Holdings Corp. (U.S.), SG Blocks, Inc. (U.S.), Speed House Group of Companies (UAE), CIMC Modular Building Systems Holdings Co., Ltd. (China), Wernick Group (Holdings) Ltd. (U.K.), Giant Containers Inc. (Canada), Premier Modular Limited (U.K.), and LAING O'ROURKE (U.K.).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5820

Key questions answered in the report-

Which are the high-growth market segments based on product, method, material, application, and geography?

What was the historical market for the modular construction market?

What are the market forecasts and estimates for the period 2024–2031?

What are the major drivers, restraints, opportunities, and challenges in the modular construction market?

Who are the major players, and what shares do they hold in the modular construction market?

What is the competitive landscape like in the modular construction market?

What are the recent developments in the modular construction market?

What are the different strategies adopted by the major players in the modular construction market?

What are the key geographic trends, and which are the high-growth countries?

Who are the local emerging players in the global modular construction market, and how do they compete with the other players?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Modular Construction Market#Closed Modular Construction#Open Modular Construction#Permanent Modular Construction (PMC) And Relocatable Modular Construction (RMC)#Off-site Construction Modular Buiding#Prefabricated Buildin

0 notes

Text

Robot End Effector Market 2023-2028 - Market Insights with Size and Demand Forecast Analysis

At a compound annual growth rate (CAGR) of 13.5%, the global robot end effector market is projected to increase from USD 2.3 billion in 2023 to USD 4.3 billion by 2028. The primary factors propelling the growth of the robot end effector market are the expanding need for modular end effectors, rising cobot usage, automation penetration in SMEs, and growing industry use in the food, pharmaceutical, and warehousing sectors.

Due to its numerous uses in a variety of industries, including automotive, electrical & electronics, food & beverage, and pharmaceutical, the robot end-effector market is expected to grow rapidly. To expand in the robot end effector market, several major competitors in the industry use a variety of tactics, including partnerships, collaborations, product launches, and acquisitions.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Opportunity: The need for soft grippers has increased because to advancements in robotics.

Soft robotics developments along with the growing demand for handling small objects have accelerated the development of soft grippers. These end effectors are constructed from pliable, soft materials, in contrast to conventional grippers, which are composed of stiff materials. In the past, the majority of end effectors could only work with fixed-size and -shaped objects. But industry standards are gradually moving in the direction of using parts that can grip and control a wide range of things. The gripper arms' delicate composition makes them suitable for delicate uses, like handling delicate goods in the food and beverage or glass manufacturing industries.

Challenge: Problems with end effector integration and interoperability with current facilities.

In any factory or production unit, interoperability is a critical function. For the purpose of connecting and coordinating different end effector systems, a modular framework for both hardware and software must exist. The focus is on the interchangeable hardware between the end effector and robot arm in addition to the software side, which is utilized for programming, diagnosing, and monitoring. In the history of the robot end effector market, there have been instances where a customer purchased a robot arm and an end effector independently, and the setup proved to be quite difficult from the start.

Managing the greatest number of applications for end effectors over the course of the projection.

The market for handling applications was driven by technological advancements in end effectors. In contrast to 3D-oriented grippers, which can handle workpieces in challenging settings due to their construction and anti-corrosion capabilities, smart grippers have the ability to measure, identify, and monitor the target object in real time while handling them. The end effector market for handling applications is further driven by the ongoing advancements in dexterous robotic hands, which are robotic hands shaped like human hands with 3/4 fingers and a thumb design that allows for greater handling flexibility.

Throughout the projection period, the food and beverage industry is anticipated to have the greatest CAGR.

The expansion of packaged and processed foods in developing nations offers end effectors a great deal of potential. End effectors are mostly needed in the food and beverage industry for handling applications because the final products are edible. This industry also needs precision systems to handle fragile workpieces that are easily damaged and spilled upon. The anticipated rise is also influenced by increased automation, the development of soft grippers, and human-robot collaboration (HRC) grippers in emerging nations. One reason for the rapid expansion in the food and beverage business is increased automation at different points in the supply chain.

Asia Pacific will have the fastest rate of growth during the projection period.

Over the last ten years, the robot end effector market in Asia Pacific has grown faster than the fully developed markets in Europe and the Americas. This can be attributed to a number of factors, including low production costs, easy access to reasonably priced labor, lax emission and safety regulations, and government programs encouraging foreign direct investments (FDIs).

0 notes

Text

Finishing Lines Market to Reach US$ 11 Bn by 2031

Demands for high-speed, energy-efficient, and flexible surface treatment processes in various industries such as automotive, oil & gas, aerospace, and electronics, are identified as key Finishing Lines Market growth factors. Automotive finishing is a remarkably lucrative segment and an in-depth study by TMR found that the automotive industry held a major Finishing Lines Market share in 2021. The market's overall value was pegged at US$ 7.1 Bn in 2021.

The rise in demand for metal finishing in multiple industries is boosting the Finishing Lines Market size. New design advancements and technological innovations in components used in finishing lines have enabled firms to tap into the vast demand for products among metal fabricators. Furthermore, introducing integrated booths/ovens has expanded the horizon, indicating recent Finishing Lines Market trends.

Request Sample Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85182

Market Segmentation:

By Service Type: Installation & Integration, Maintenance & Support, Upgrades & Retrofits

By Sourcing Type: In-house Manufacturing, Outsourced Solutions

By Application: Paint Finishing, Surface Treatment, Assembly & Inspection

By Industry Vertical: Automotive, Aerospace & Defense, Electronics, Furniture & Woodworking, Metal Fabrication

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Regional Analysis:

North America: Leading market due to extensive industrialization, technological expertise, and investments in automation.

Europe: Strong presence of automotive and aerospace industries driving demand for advanced finishing solutions.

Asia Pacific: Emerging as a key market with rapid industrial growth, especially in automotive and electronics sectors.

Latin America, Middle East & Africa: Witnessing steady growth supported by infrastructure development and manufacturing expansions.

Market Drivers and Challenges:

Drivers:

Automation and Robotics: Increasing adoption of robotic finishing systems for precision and efficiency gains.

Quality Assurance Demands: Growing focus on achieving impeccable surface finishes and product aesthetics.

Environmental Regulations: Shift towards eco-friendly coatings and surface treatment methods to comply with sustainability norms.

Challenges:

Initial Investment Costs: High upfront costs associated with advanced finishing line technologies and automation.

Skilled Workforce: Demand for skilled technicians and engineers proficient in operating and maintaining automated systems.

Complexity in Integration: Seamless integration of diverse finishing processes and equipment poses technical challenges.

Market Trends:

Industry 4.0 Integration: Incorporating IoT, AI, and data analytics for real-time monitoring and predictive maintenance.

Advanced Coating Technologies: Development of high-performance coatings for enhanced durability and aesthetics.

Modular and Scalable Solutions: Flexible finishing line configurations to accommodate varying production needs and future expansions.

Future Outlook:

The finishing lines market is poised for continued innovation and growth, driven by rapid industrial automation adoption, demand for superior product finishes, and sustainability imperatives shaping coating and treatment technologies.

Key Market Study Points:

Technology Landscape: Analyzing advancements in robotic systems, coating materials, and digital integration.

Market Dynamics: Understanding factors influencing market growth, including regulatory trends and industry shifts.

Competitive Landscape: Assessing key players, their product offerings, partnerships, and market strategies.

End-User Insights: Identifying specific needs and challenges across industry verticals for targeted solutions.

Regional Market Dynamics: Evaluating market trends, growth drivers, and competitive scenarios across different regions.

Competitive Landscape:

Major players in the finishing lines market include Eisenmann SE, Dürr AG, FANUC Corporation, Venjakob Maschinenbau GmbH & Co. KG, and Gema Switzerland GmbH. These companies focus on product innovation, customization capabilities, and strategic collaborations to maintain a competitive edge in the market.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=85182<ype=S

Recent Developments:

Launch of compact and modular finishing line solutions for small to medium-scale manufacturers.

Integration of AI-based quality control systems for real-time defect detection and correction.

Partnerships between equipment manufacturers and coating specialists to offer comprehensive finishing solutions.

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

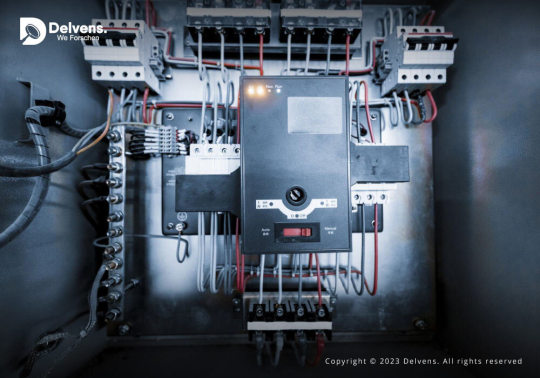

Industrial Controls Market – Trends Forecast Till 2030

Industrial Controls Market analysis report figures out market landscape, brand awareness, latest trends, possible future issues, industry trends and customer behaviour so that the business can stand high in the crowd. It includes extensive research on the current conditions of the industry, potential of the market in the present and the future prospects from various angles. This Industrial Controls Market report comprises of data that can be pretty essential when it comes to dominating the market or making a mark in the Semiconductors & Electronics industry as a new emergent. To bestow clients with the best results, Industrial Controls Market research report is produced by using integrated approaches and latest technology.

Download Free Sample Report at: https://www.delvens.com/get-free-sample/industrial-controls-market

Industrial Controls Market by Type (Distributed Control System, Supervisory Control & Data Acquisition System, Manufacturing Execution System, Programmable Logic Controller (PLC), Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP), Human Machine Interface (HMI) and Others), Component (Modular Terminal Blocks, Relays & Optocouplers, Surge Protectors, Marking Systems, Printing, Ferulles Cable Lugs, Handtools, Testers, Enclosure Products, PCB Connectors & Terminals, Heavy Duty Connectors, Analog Signal Conditioner, Electronic Housings, Power Supplies, Industrial Ethernet, and Remote IO), Application and End User (Automotive, Utility, Electronics & Semiconductors, Oil and Gas, Chemical and Petrochemical, Power, Life Sciences, Food and Beverage and Mining), and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America), global opportunity analysis and Industry Forecast, 2023-2030. The global Industrial Controls market size was estimated at USD 140 billion in 2023 and is projected to reach USD 239.9354 billion in 2030 at a CAGR of 8% during the forecast period 2023-2030.

Industrial Controls Market Competitive Landscape:

ABB Ltd.

Emerson Electric Corporation

Honeywell International Incorporation

Kawasaki Robotics control system

Mitsubishi Electric Factory Automation

Omron Corporation

Rockwell Automation Inc.

Siemens AG

Schneider Electric SA

Yokogawa Electric Corporation

Endress+Hauser AG

General Electric

GLC Controls Inc.

Industrial Controls Market Recent Developments:

In July 2022, IBM acquired Databand.ai, a leading provider of data observability software that helps organizations fix issues with their data, including errors, pipeline failures, and poor quality, before it impacts their bottom line.

In July 2022, Sap acquired Askdata to strengthen its ability to help organizations take better-informed decisions by leveraging AI-driven natural language searches. Users are empowered to search, interact, and collaborate on live data to maximize business insights.

Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/industrial-controls-market

Industrial controls systems refer to various automation devices, machines and equipment used in industry. They are developed to better control and monitor industrial processes and automate tasks to increase efficiency and reliability while improving quality. These systems include a variety of controls systems such as supervisory control and data acquisition or SCADA, programmable logic controllers or PLCs, and distributed controls systems or DCS.

They can help automate processes, critical infrastructure or remote monitoring and management. They also help collect data from remote devices, monitor the operation of distributed factories, and perform automated electromechanical processes. Rapid adoption of cloud-based services and growing automation trends in industry are important factors for the global industry. Market dominance. Automation helps industries achieve better accuracy and quality while reducing costs.

Growth is driven by the demand for intelligent controls systems and automation in various industries, mass production in industry and the adoption of industrial controls systems in various end-uses such as automotive and mining, as well as increasing R&D investments. in the industrial control market. However, increasing cyber-attacks, lack of authentication procedures, lack of experienced professionals and awareness of industrial security solutions are restraining the growth of the industrial controls market. In addition, the deployment of a smart grid to protect critical infrastructure against cyber-attacks and cloud computing for industrial controls systems creates lucrative opportunities for the industrial surveillance market.

Scope of the Industrial Controls Market Report:

The Industrial Controls Market is segmented into various segments such as type, component, End user and region:

Based on type

Distributed control system (DCS)

Supervisory control & data acquisition system (SCADA)

Manufacturing execution system (MES)

Programmable Logic Controller (PLC)

Product Lifecycle Management (PLM)

Enterprise Resource Planning (ERP)

Human Machine Interface (HMI)

Others

Based on the component

Modular terminal blocks

Relays & optocouplers

Surge protectors

Marking systems

Printing

Ferulles cable lugs

Handtools

Testers

Enclosure products

PCB connectors and terminals

Heavy duty connectors

Analog signal conditioner

Electronic housings

Power supplies

Industrial ethernet

Remote IO

Based on the End user

Automotive

Utility

Electronics & semiconductors

Mining

Oil and Gas

Chemical and Petrochemical

Power

Life Sciences

Food and Beverage

Others

Based on Application

Automotive

Pharmaceutical

Oil & Gas

Electrical Power

Others

Based on Network

Fieldbus

Communication Router

Firewall

MODEMS

Remote Access Points

Based on region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Industrial Controls Market Regional Analysis:

North America to Dominate the Market

North America is on the brink of the fourth industrial revolution. The data generated is used for high-volume production, while the data is integrated into various production systems throughout the supply chain. The region is also one of the world's largest automotive markets, with more than 13 major automotive manufacturers operating. The automobile industry was one of the largest income generators in the region. Due to significant adoption of industrial control systems and automation technologies in the automotive industry, the region offers a huge opportunity for market growth.

Several key vendors operating in the country are launching new upgrades to support the growth of smart factories along with the development of industrial control systems. Such technological development indicates regional growth in the studied market.

Direct Purchase of the Industrial Controls Market Research Report at: https://www.delvens.com/checkout/industrial-controls-market

Browse Related Reports:

12V Lithium-Ion Battery Market

Pressure Sensor Market

Industrial Valves Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-3290-6466

#consulting company#strategic advisory firm#best market reports#trending reports#market analysis reports#syndicated reports#Industrial Controls Market#Industrial Controls

0 notes

Text

Lab Furniture Market Huge Growth in Future Scope 2024-2030 | GQ Research

The Lab Furniture market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Lab Furniture market showcased a significant presence, boasting a valuation of US$ 937 billion. This underscores the substantial demand for Lab Furniture technology and its widespread adoption across various industries.

Get Sample of this Report at https://gqresearch.com/request-sample/global-lab-furniture-market/

Projected Growth: Projections suggest that the Lab Furniture market will continue its upward trajectory, with a projected value of US$1.78 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 6.10 %, reflecting a steady and robust growth rate for the Lab Furniture market over the coming years.

Technology Adoption: In the Lab Furniture market, technology adoption is crucial for enhancing functionality, ergonomics, and durability of laboratory furniture solutions. Advanced manufacturing techniques such as computer-aided design (CAD), CNC machining, and robotic assembly enable the production of customized furniture that meets the specific requirements of different laboratory settings. Additionally, technology integration for features like adjustable height desks, modular storage solutions, and integrated power and data connectivity enhances the usability and versatility of lab furniture.

Application Diversity: Lab furniture serves a wide range of applications across various industries including research laboratories, educational institutions, healthcare facilities, pharmaceutical companies, and industrial R&D centers. Each application has unique requirements in terms of equipment layout, workspace organization, and safety considerations. Lab furniture solutions range from laboratory benches and casework to fume hoods, cleanroom furniture, and specialized storage cabinets, catering to diverse needs across different sectors.

Consumer Preferences: Consumer preferences in the Lab Furniture market are influenced by factors such as quality, functionality, customization options, and compliance with industry standards and regulations. End-users prioritize furniture solutions that offer durability, chemical resistance, and easy maintenance to withstand the rigorous demands of laboratory environments. Additionally, ergonomic design features that promote user comfort and safety, along with flexible configurations to accommodate evolving research needs, are highly valued by consumers.

Technological Advancements: Technological advancements in the Lab Furniture market focus on improving safety, efficiency, and user experience. Innovations such as anti-microbial surfaces, chemical-resistant coatings, and fire-retardant materials enhance the safety and hygiene of laboratory furniture. Moreover, advancements in materials science lead to the development of lightweight yet durable materials like composite panels and high-pressure laminates, offering improved performance and longevity. Additionally, integration of IoT sensors and smart monitoring systems enables real-time tracking of equipment usage, maintenance schedules, and environmental conditions within laboratory spaces.

Market Competition: The Lab Furniture market is characterized by intense competition among manufacturers, driven by factors such as product quality, innovation, pricing, and customer service. Major players compete for market share by offering comprehensive product portfolios, timely delivery, and responsive after-sales support. Moreover, customization capabilities and ability to provide tailored solutions for specific laboratory requirements are essential for gaining a competitive edge in this market. Strategic partnerships with laboratory equipment suppliers, architects, and facility managers also play a significant role in expanding market presence and enhancing competitiveness.

Environmental Considerations: Environmental considerations are increasingly important in the Lab Furniture market, with a growing focus on sustainability and eco-friendly practices. Manufacturers are adopting environmentally friendly materials such as recycled steel, sustainable wood, and low-emission laminates to reduce the environmental impact of furniture production. Additionally, efforts are made to optimize packaging materials, minimize waste generation, and implement recycling programs for end-of-life furniture components. Furthermore, compliance with environmental regulations and certifications such as LEED (Leadership in Energy and Environmental Design) demonstrates a commitment to sustainability and responsible stewardship of resources within the industry.

Top of Form

Top of FormRegional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

WALDNER Holding SE & Co. KG

GE Healthcare Services

Kewaunee Scientific

Yamato Scientific Co.Ltd

Kottermann GmbH

Thermofisher Scientific

Mott Manufacturing Ltd.

Labconco Corporation

The research report provides a comprehensive analysis of the Lab Furniture market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-lab-furniture-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Exploring AWS Batch for Large-Scale Simulations

Simulations play a precarious role in various industries, containing automotive, robotics, engineering, and scientific research. These simulations allow businesses and researchers to investigate complex systems, train machine learning models, and make expectations without the need for costly physical prototypes or time-consuming real-world experiments. AWS Batch multi-container jobs provide a valuable tool for running significant simulations efficiently and cost-effectively.

What is AWS Batch?

AWS Batch is a fully managed batch computing service It dynamically provisions compute resources (such as EC2 instances or Fargate containers) based on the submitted batch jobs.

Batch eliminates the need for manual infrastructure management.

Users define job dependencies, resource requirements, and priorities, and AWS Batch handles the rest, including scheduling, execution, and monitoring.

Why AWS Batch need?

Using the AWS Management Console, CLIs, or SDKs, you package the code for your batch jobs, define their dependencies, and then submit your batch job using AWS Batch. AWS Batch makes it easy to integrate with a variety of well-known batch computing workflow engines and languages (such as Pegasus WMS, Luigi, Nextflow, Metaflow, Apache Airflow, and AWS Step Functions) once you provide the execution parameters and task requirements.

With the ability to employ On-Demand or Spot Instances depending on your work requirements, AWS Batch effectively and dynamically prepares and scales Amazon Elastic Container Service (ECS), Amazon Elastic Kubernetes Service (EKS), and AWS Fargate compute resources. To help you get started quickly, AWS Batch provides compute environment specifications and preset job queues.

How AWS Batch Optimizes Your Industries

AWS Batch provides a fully managed service for running batch computing jobs at scale. Its dynamic provisioning, resource optimization, and automated scheduling enhance operational efficiency for various industries. Here’s a closer look at how AWS Batch specifically benefits different sectors:

Automotive

Accelerating Simulation Development: When working with autonomous vehicles (AV) and advanced driver assistance systems (ADAS), multi-container support allows engineers to develop simulations with modular components representing sensors, traffic, and 3D environments. This simplifies development, speeds up iteration, and eases debugging.

Boosted Resource Management: AWS Batch switches the scaling, scheduling, and cost-efficiency parts of consecutively large-scale simulations, releasing automotive engineers to attention on innovation and problem-solving.

Finance

Rearrangement Operations and Dropping Errors: AWS Batch presets resource allocation and job scheduling for computationally intensive tasks like pricing, market analysis, and risk management. This automation reduces the potential for manual errors and optimizes the decision-making process.

Enhanced Post-Trade Analytics: Batch enables the efficient end-of-day processing of massive data sets, providing critical insights for informed trading strategies in the next cycle.

Fraud Detection: Batch integrates with AWS machine learning for the automated analysis of large datasets, helping uncover irregular patterns and potential fraud.

Life Sciences

Accelerating Drug Discovery: AWS Batch aids in streamlining multiple life sciences applications with its efficient job handling, including computational chemistry, modeling, molecular dynamics, and genomic sequencing analysis. This assists research scientists in the drug screening process, potentially leading to the development of more effective therapies.

Optimized DNA Sequencing Analysis: Secondary analysis after the initial processing of genomic sequences can be automatically managed and streamlined through AWS Batch, minimizing errors and contributing to faster research results.

Digital Media

Scalable Content Creation: Batch facilitates the dynamic scaling of media packaging and the automation of media supply chains, reducing resource bottlenecks and manual intervention.

Efficient Content Rendering and Transcoding: AWS Batch allows for the automation of content rendering and file-based transcoding workflows, leading to greater efficiency and less manual dependency.

Key Takeaways

Across these diverse industries, AWS Batch delivers the following core benefits:

Simplified Management: Batch’s fully managed nature eliminates infrastructure management requirements.

Modular Design: Multi-container support allows for flexible and modular simulations structure.

Cost Optimization: Batch leverages options like Spot Instances and Savings Plans for optimal cost-efficiency.

Focus on Core Business: By handling infrastructure and job scheduling complexities, AWS Batch allows organizations to concentrate on their core areas of expertise.

Multi-Container Jobs: Key Benefits

Modular Design: Multi-container jobs allow users to break simulations into smaller components—for example, a container representing the environment, one for sensors, and another for monitoring. This eases development and troubleshooting by separating different simulation elements.

Team Collaboration: Teams can work independently on their specific component, reducing bottlenecks and fostering collaboration.

Optimization: AWS Batch handles scaling, scheduling, and cost optimization. Users focus on simulation development rather than infrastructure.

No Additional Cost: This feature is available within AWS Batch without any extra charges.

How to Use AWS Batch Multi-Container Jobs

Create Containers: Package simulation components into separate Docker containers.

Define Job: In the AWS Batch console, create a job definition, specifying:

Container images

Resource requirements (CPU, memory)

Dependencies between containers

Submit Jobs: Jobs can be submitted via the console, API, or CLI.

Monitor: AWS Batch provides tools for monitoring job status, resource utilization, and logs.

Cost Optimization with AWS Batch

Reserved Instances and Savings Plans: Reduce costs on predictable compute workloads.

Spot Instances: Leverage cost-effective surplus compute capacity.

Fargate: Pay only for the resources used by your containers.

Automatic Scaling Scale your resources to match demand.

Additional Considerations

Data Management and Transfer: Efficiently manage data used and generated by simulations, potentially using services like Amazon S3.

Networking: Ensure appropriate networking configuration for communication between containers and with external resources.

Security: Implement security best practices (IAM roles, encryption) to protect sensitive data and your AWS environment.

AWS Batch multi-container jobs offer a dominant and flexible clarification for running large-scale simulations on AWS. By combining modularity, ease of management, and cost optimization, this article empowers businesses and researchers to accelerate innovation through simulation-driven development and experimentation.

Read more on Govindhtech.com

0 notes

Text

Modular Construction Market : Size, Share & Trends Analysis Report (2018-2032)

The global market for Modular Construction is expected to grow between 2023 and 2032 due to technological advancements, quality control, cost savings, government support, and regulations.

The Global Modular Construction Market was valued at USD 115.00 Billion in 2022 and is projected to reach USD 204.84 Billion by 2032, registering a CAGR of 5.90 % for the forecast period 2023-2032.

Global Modular Construction Market Drivers

Technological advancements: BIM is a digital representation of the physical and functional characteristics of a building. This allows architects, engineers, and construction professionals to create detailed 3D models of structures. BIM fosters collaboration, improves project visualization, and improves the entire process of designing and planning modular construction projects. Advances in manufacturing technology, such as automation and robotics, have streamlined the production of modular components. These techniques ensure manufacturing accuracy, reduce errors, and improve the overall efficiency of the manufacturing process. Robotics can be used with high precision for tasks such as cutting, welding, and assembling modules.

Quality control: A controlled manufacturing environment allows for more effective identification and elimination of errors during the manufacturing stage. Quality control measures can help identify problems early and minimize the need for rework or corrections during on-site assembly. This contributes not only to improving quality but also to reducing costs. Quality control ensures that modular construction projects comply with local building codes, regulations, and industry standards. This is especially important to obtain regulatory approval and ensure the safety and structural integrity of the modular construction. Modular construction companies often seek third-party certification to verify the quality of their processes and products.

Cost Saving: The controlled environment of a modular factory environment allows for more efficient use of labor. Skilled workers can specialize in specific tasks on your production line to minimize downtime and optimize productivity. This specialization and efficiency reduce labor costs compared to on-site construction, where a variety of factors can cause delays and inefficiencies. Modular construction often requires precise material planning and sourcing. The controlled manufacturing process allows excess material to be reused in other modules and projects, minimizing material waste. Reducing waste helps reduce material and disposal costs.

Government support, and regulations: Developers and builders who opt for modular construction methods that are certified as sustainable or energy-efficient can receive financial incentives from numerous governments. By doing this, modular construction can become more competitive with traditional methods by lowering its upfront costs. Governments are putting tighter restrictions on the construction sector as worries about resource depletion and climate change grow. Due to its ability to meet these requirements with less waste and energy consumption, modular construction is becoming a more appealing option for developers looking to get their projects approved.

Global Modular Construction Market – Merger and Acquisitions

COOEC-Fluor Completes Module Program for KIPIC Al-Zour Project in Kuwait (2021)

COOEC -Fluor Corporation announced that its joint venture COOEC-Fluor Heavy Industries, Co., Ltd. fabrication yard in Zhuhai, China, has safely completed the entire module program for the Kuwait Integrated Petroleum Industries Company (KIPIC) Al-Zour project in Kuwait. “The COOEC-Fluor yard completed the modular program over 24 months from the start of steel fabrication to load out of the last modules,” said Chris Vertanness, vice president and director of operations at the yard.

Etex acquires a majority stake in leading French offsite construction company e-Loft (2021)

International building materials specialist Etex announces it has acquired a majority stake in leading French offsite construction company e-Loft. The company becomes part of Etex’s New Ways division, which develops sustainable, industrialized and modular construction solutions. As such, the acquisition is a key milestone on Etex’s strategic roadmap and an enabler of our ambition to shape the future of construction by “inspiring ways of living”.

Modulaire Group continues to strengthen its presence in the UK with the acquisition of Procomm (2021)

Modulaire Group, the leading modular space leasing business in Europe and Asia Pacific, is pleased to announce the completion of the acquisition of Procomm Site Services Ltd (“Procomm”). Procomm is a leading provider of portable modular accommodation in the UK with a broad range of end markets including general construction, the public sector, and petrochemicals.

SG ECHO to Collaborate with ATCO Structures on National Modular Fleet Rollout (2021)

SG Blocks, Inc. (“SG Blocks” or the “Company”), a leading designer, innovator, and fabricator of modular structures, announced today that SG ECHO would be engaging in a collaborative effort with ATCO Structures & Logistics, a one-stop provider of integrated energy, housing, transportation, and infrastructure solutions. ATCO has committed 20 units to be produced by SG ECHO as a part of a national rollout of modular fleet units throughout the U.S. With this, SG ECHO has the opportunity to continue providing ATCO with ongoing support through this initiative, which will require continued production over several years.

Algeco further strengthens its Nordic presence with the acquisition of Wexus Group (2020)

Algeco Group, the leading modular space leasing business in Europe and Asia Pacific, today announced that it has agreed to acquire Wexus Group AS (“Wexus”) from Norvestor Equity AS and other shareholders. Wexus is a leading provider of high-quality modular building solutions in the Nordic region. Headquartered in Norway, Wexus also has operations in Sweden and a modern production facility in Estonia. Wexus operates a fleet of c. 1,600 units, has c. 110 employees and revenues of c. USD35m (297 million NOK) in 2019.

Challenges Impacting the Global Modular Construction Market

Transportation Cost: Large modular units can be expensive to ship to the construction site, particularly if the project is far from the manufacturing facility. It is important to carefully weigh this cost consideration against the total cost savings realized from modular construction.

Regulation Challenges: Building codes and regulations might not always mesh well with modular construction techniques. Modular construction adoption may be slowed down in some areas by the complexity of navigating the regulatory environment and getting approvals for modular projects.

Site Accessibility and Assembly: Transportation and installation of modular units may be impacted by site accessibility issues, particularly in urban settings. The overall efficiency of the modular construction process may be impacted by space constraints or challenging site conditions, which may call for more complicated logistics.

Integration with Traditional Construction: Coordination issues may arise when combining modular and conventional construction techniques on a single project. Project management and communication must be done well to guarantee a smooth integration between modules and on-site construction operations.

Download Sample Report : https://isayresearch.com/sample/2303

Contact Us

iSay Solutions LLC

166 Geary St. 15th Floor Suite #212, San Francisco, California 94108, United States

Contact no. :+14156709191

Email Id : [email protected]

0 notes

Text

Understanding Regulatory Influences on the Automated Guided Vehicle Market

Automated Guided Vehicle Market Overview:

The market share of automated guided vehicles worldwide reached over USD 3.39 billion, growing at a compound annual growth rate of 7.50% between 2022 and 2030.

Automated Guided Vehicles (AGVs) have emerged as indispensable tools in modern material handling and logistics operations, revolutionizing the way goods are transported within warehouses, manufacturing facilities, and distribution centers. The global automated guided vehicle market has experienced remarkable growth in recent years, driven by factors such as advancements in robotics, increasing demand for automation, and the need for efficient and cost-effective intralogistics solutions. This article provides an in-depth overview of the automated guided vehicle market, including segmentation analysis, key takeaways, and regional insights.

Get a free sample report of Automated Guided Vehicle Market

By Segmentation:

1. Type:

a. Tow Vehicles: Tow vehicles are designed to tow carts, trailers, or other materials within a facility, streamlining material movement and reducing manual handling.

b. Unit Load Carriers: Unit load carriers are AGVs capable of transporting individual loads such as pallets, bins, or containers, optimizing storage and retrieval processes in warehouses and distribution centres.

c. Forklift AGVs: Forklift AGVs mimic the functionality of traditional forklift trucks, enabling automated pallet handling, stacking, and retrieval tasks in industrial settings.

d. Assembly Line AGVs: Assembly line AGVs are specifically designed to transport components or sub-assemblies along production lines, facilitating lean manufacturing and just-in-time delivery processes.

2. Navigation Technology:

a. Laser Guidance: AGVs equipped with laser navigation systems use lasers to detect and navigate along predefined paths, offering high precision and flexibility in dynamic environments.

b. Magnetic Guidance: Magnetic guidance systems utilize magnetic tape or markers embedded in the floor to guide AGVs along designated routes, suitable for indoor applications with clear pathways.

c. Vision Guidance: Vision-based navigation systems rely on cameras and computer vision algorithms to recognize landmarks and navigate AGVs autonomously, providing versatility and adaptability in changing environments.

d. Inertial Guidance: Inertial guidance systems use sensors such as accelerometers and gyroscopes to track AGV movement and orientation, enabling precise positioning and navigation without external infrastructure.

Key Takeaways:

1. Increased Efficiency and Productivity: AGVs automate repetitive material handling tasks, reducing reliance on manual labor, minimizing errors, and optimizing workflow efficiency, leading to higher productivity and throughput in intralogistics operations.

2. Enhanced Safety and Reliability: AGVs are equipped with advanced safety features such as collision avoidance systems, obstacle detection sensors, and emergency stop mechanisms, ensuring safe operation in dynamic environments and reducing the risk of accidents.

3. Scalability and Flexibility: The modular design and configurable functionality of AGVs allow for scalability and flexibility in adapting to changing production requirements, enabling businesses to optimize operations and respond to market demands effectively.

4. Integration with Industry 4.0: AGVs play a crucial role in the implementation of Industry 4.0 initiatives by enabling seamless connectivity, data exchange, and real-time monitoring within smart factories, facilitating data-driven decision-making and process optimization.

Regional Insights:

1. North America: The United States and Canada lead the North American AGV market, driven by widespread adoption of automation, technological innovation, and the presence of key players in industries such as e-commerce, automotive, and manufacturing.

2. Europe: Countries like Germany, the UK, and France are prominent markets for AGVs in Europe, fueled by stringent safety regulations, emphasis on efficiency and sustainability, and investments in smart logistics solutions.

3. Asia Pacific: China, Japan, and South Korea are key markets in the Asia Pacific region, driven by rapid industrialization, urbanization, and increasing demand for automation in manufacturing, warehousing, and e-commerce sectors.

4. Latin America and the Middle East & Africa: These regions offer growth opportunities for AGV market players due to expanding industrial activities, infrastructure development, and adoption of automation technologies to enhance competitiveness and operational efficiency.