#Monel 400 Tube Fittings

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Interesting Facts About Monel Tube Fittings

Generally, Monel Tube Fittings are used for piping systems, heat exchangers, shafts, valves, and chemical plant equipment. These fittings are available in different types and sizes. They are highly durable and offer corrosion resistance in seawater and marine applications. They are also preferred for power generation, hydrocarbon, oil, and gas processing equipment. The material has excellent weldability and leak tightness. Monel 400 is a nickel-copper alloy with a higher percentage of nickel and a small amount of silicon. It is a solid solution alloy with high corrosion and erosion resistance. It has a density of 8.8 gm/cm3.

Typical applications of Monel Tube Fittings include marine engineering, nuclear power plants, and chemical and hydrocarbon processing equipment. They are renowned for their corrosion resistance and excellent weldability. They are made using modern tools and are tested for quality assurance. The production process is carried out by observing the producers' quality standards and manufacturing guidelines. The production process includes testing the material for quality assurance and a heat treatment chart.

The ASME SB 564 UNS N04400 Bulkhead Union is a Monel Fittings designed to connect a pipe to a tank. It is made of age-hardenable alloy. It is used in chemical and hydrocarbon processing equipment, valves, pumps, and metal tools. The Monel inventory is continuously evolving to meet the needs of the industry. These Monel Fittings are known for their durability and resistance to hydrogen fluoride and steam. They are perfect for transferring piping in oil refineries.

Monel 400 Compression Tube Fittings are used for chemical and hydrocarbon processing equipment and marine and oil and gas applications. It has good corrosion resistance to oxidizing environments, hydrofluoric acid, hydrochloric acid, steam, and seawater. They are also suitable for heat exchangers and heat pump equipment. The fittings are easy to rework and have a higher resistance to high-pressure environments. The materials of these fittings are nickel, copper, manganese, and iron. They are also compatible with thermosets and plastic materials. In addition, Monel Instrumentation Tube Fittings are manufactured by the standards laid down by the manufacturer. The producers of these fittings consider international product standards to ensure that the product meets the customer's requirements. They produce the fittings using modern tools and are tested for quality assurance.

Monel Instrumentation Tube Fittings can be purchased in various sizes, shapes, and grades. These fittings are used in valves, pumps, heat exchangers, compressors, and other hydrocarbon and chemical equipment. They are also ideal for oil and gas processing, heat exchangers, and hydraulic applications.

2 notes

·

View notes

Text

Buttweld Fittings: Benefits and Limitations for Industrial Applications.|Metalforgeindia

Buttweld fittings play a important characteristic in numerous commercial business organisation programs, providing a reliable and inexperienced method for turning into a member of pipes and tubes. In this blog, we are able to delve into the benefits and limitations of buttweld fittings, with a focal point on well-known substances at the component of Monel 400, Alloy 20, SMO 254, and UNS N06600.

Introduction to Buttweld Fittings:

Buttweld fittings are pipe fittings used to connect pipes and tubes through welding. They are designed to create a clean and non-save you go together with the waft of fluid inside the piping system, with none obstructions or leakage elements. Buttweld fittings are to be had in numerous sizes and patterns, collectively with elbows, tees, reducers, and caps, taking into consideration flexible configuration alternatives.

Benefits of Buttweld Fittings:

1. Strength and Durability: Buttweld fittings are said for his or her brilliant energy and durability, making them appropriate for immoderate-stress and immoderate-temperature applications. They can withstand harsh working conditions and provide extended-term reliability.

2. Leak Resistance: The seamless creation of buttweld fittings gets rid of functionality leakage elements, ensuring a respectable and leak-free connection amongst pipes and tubes. This feature is important in industries wherein fluid containment is vital.

3. Smooth Flow: Buttweld fittings provide a clean transition amongst pipes and tubes, minimizing turbulence and pressure drops in the fluid go along with the glide. This ensures inexperienced operation and maximum ideal commonplace elegant standard performance of the piping tool.

4. Versatility: Buttweld fittings are to be had in a huge style of substances, sizes, and configurations to wholesome severa business necessities. From elegant carbon metal fittings to critical alloys like Monel 400 and Alloy 20, there can be a buttweld turning into for each software.

5. Corrosion Resistance: Certain materials carried out in buttweld fittings, collectively with Monel 400, Alloy 20, SMO 254, and UNS N06600, provide awesome corrosion resistance homes. This makes them suitable for use in corrosive environments, at the factor of chemical processing vegetation and offshore oil rigs.

Limitations of Buttweld Fittings:

1. Complex Installation: Installing buttweld fittings calls for professional welders and specialized systems that can upload complexity and charge to the set up method. Improper welding strategies can bring about defects and compromise the integrity of the piping device.

2. Cost: Buttweld fittings also can additionally have a better initial charge in contrast to brilliant styles of fittings, usually due to the welding machine and the use of top fee substances collectively with Monel 400 and Alloy 20. However, their extended-term reliability and sturdiness regularly justify the investment.

Three. Space Constraints: Buttweld fittings require a particular enough location for welding, which also can pose annoying conditions in tight or constrained regions. Proper making plans and layout layout are vital to ensure accessibility for welding and protection sports activities.

Popular Materials for Buttweld Fittings:

1. Monel 400: Monel 400 is a nickel-copper alloy recognized for its exquisite corrosion resistance in numerous environments, which includes seawater and chemical processing plants. Monel 400 buttweld fittings are notably achieved in marine and offshore applications.

2. Alloy 20: Alloy 20 is a in particular alloyed austenitic stainless-steel that gives advanced resistance to sulfuric acid and precise acidic compounds. Alloy 20 buttweld fittings are generally applied in chemical processing, pharmaceutical, and meals processing industries.

3. SMO 254: SMO 254 is an excessive-alloy austenitic stainless-steel with remarkable resistance to chloride-brought on pressure corrosion cracking and pitting corrosion. SMO 254 buttweld fittings are tremendous for packages regarding aggressive media collectively with seawater and brine.

4. UNS N06600: UNS N06600, moreover referred to as Inconel 600, is a nickel-chromium alloy famend for its excessive temperature energy and oxidation resistance. UNS N06600 buttweld fittings are applied in aerospace, thermal processing, and furnace additives.

Buttweld fittings provide numerous blessings, along with facet energy, durability, leak resistance, clean go with the drift, and flexibility. However, they'll have boundaries at the aspect of complex installation, price, and vicinity constraints. By selecting the right material, which encompass Monel 400, Alloy 20, SMO 254, or UNS N06600, and considering the unique requirements of the software program application application, groups can harness the general functionality of buttweld fittings for his or her industrial operations.

#Buttweld Fitting#Monel ma 400#Alloy 20 Buttweld Fittings#SMO 254 Buttweld Fittings#UNS N06600 Buttweld Fittings

0 notes

Text

Benefits & Application of SS 904L Tube Fittings

Stainless Steel 904L Tube Fittings is a non-stabilized austenitic stainless steel with low carbon content. This high alloy stainless steel Tube Fittings is added with copper to improve its resistance to strong reducing acids, such as sulphuric acid. The steel is also resistant to stress corrosion cracking and crevice corrosion. Stainless Steel 904L tube Fittings is non-magnetic, and offers excellent formability, toughness and weldability. For More Info Visit Our Site:-

0 notes

Text

Monel Fasteners: Strength and Durability in Industrial Construction

Fasteners are of paramount importance when it comes to industrial construction. These seemingly small components play a crucial role in holding structures together. Among the myriad choices available, Monel fasteners stand out for their exceptional strength and durability. Jay Steel Corporation, we take pride in being a leading Monel fasteners manufacturer and supplier, offering unparalleled strength and durability for a wide range of industrial applications. Our commitment to quality extends to our diverse range of Monel alloy products, including Monel 400 Products and Monel K500 Products, available in various forms such as Monel Wire Mesh, Monel Round Bar, Monel Strips Sheet & Plats, Monel Tube & Pipe, Monel Fittings, Monel Flanges, and welding rods so that our customers can choose the one that will perfectly suit their project requirements!

In this blog post, we will explore the remarkable qualities of Monel fasteners and why they are considered a preferred choice in industrial construction.

Understanding Monel:

Monel is a nickel-copper alloy known for its corrosion resistance, high strength, and durability. The alloy primarily consists of nickel (approximately 67-70%) and copper (about 28-34%), with small amounts of iron, manganese, carbon, and silicon. The unique combination of these elements results in a material with superior properties that make it ideal for challenging industrial environments.

Strength Beyond Compare:

Monel fasteners are renowned for their remarkable strength, making them a reliable choice for heavy-duty applications in industrial construction. The high nickel content in Monel contributes to its exceptional tensile strength and resistance to deformation under extreme loads. This characteristic ensures that structures secured with Monel fasteners maintain their integrity even in the face of intense pressure and stress.

Corrosion Resistance:

One of the primary challenges in industrial construction is the corrosive nature of various environments. Monel fasteners excel in this regard, as they exhibit outstanding resistance to corrosion, particularly in harsh conditions such as exposure to saltwater, acids, and alkalis. This corrosion resistance significantly extends the lifespan of structures and reduces maintenance costs over time.

Durability in Diverse Environments:

Monel fasteners are versatile and well-suited for use in diverse industrial environments. Whether in chemical processing plants, marine applications, or oil and gas facilities, Monel's durability remains unwavering. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking further enhances its suitability for challenging construction scenarios.

Temperature Stability:

Industrial construction often involves exposure to extreme temperatures, and Monel fasteners are designed to withstand such conditions. The alloy maintains its strength and structural integrity across a wide temperature range, making it a reliable choice for projects that face temperature fluctuations, whether in cold or scorching heat.

Ease of Fabrication and Installation:

Despite its impressive strength, Monel is also known for its malleability, which makes it relatively easy to fabricate into various fastener shapes. This characteristic simplifies the manufacturing process and contributes to the ease of installation, saving both time and resources in construction projects.

Final Words!

With a strong focus on quality Monel fasteners and alloy products, Jay Steel Corporation emerges as a leader in industrial construction. With a comprehensive range of Monel offerings and a global presence, we continue to contribute to the success of diverse industrial projects. Recognizing the global demand for top-notch Monel alloy products, Jay Steel Corporation serves as a reliable exporter to various countries, including Thailand, Singapore, Malaysia, India, Germany, Russia, France, Nigeria, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, the United Kingdom, and Italy. Our commitment to quality and competitive pricing has established us as a trusted partner in international markets. Choose us for your Monel Alloys Solutions that go beyond expectations, ensuring the resilience and longevity of your constructions.

#Monel Wire Mesh#Monel fasteners 400#Monel fasteners K500#Monel fasteners 400 Supplier#Monel fasteners K500 Exporters

0 notes

Text

Understanding Monel 400 Tee: Applications and Advantages

What are Monel 400 Tees?

Monel 400 Tees are piping fitting types with a T-shaped structure with three openings. They are designed to connect three pipes or tubes of different diameters with 90-degree angles, and their ends are threaded or welded to secure the connection.

Monel 400 Tee gets its name from the material it is made of. Monel 400 is an alloy of nickel, copper, and iron and is well-known for its excellent corrosion resistance, high strength, and toughness.

These properties make Monel 400 an ideal material for use in environments with seawater, chemicals, and hydrofluoric acid

Applications of Monel 400 Tees

Monel 400 Tee is widely used in different industries such as marine engineering, petrochemical, chemical, and non-industrial applications such as architecture and sculpture.

In marine engineering applications, Monel 400 Tees are part of cooling systems, seawater pipelines, and waste disposal systems.

In petrochemical and chemical industries, they are used to transfer chemicals and acids and for high-pressure applications. Similarly, they are used in the architecture industry to create a unique structure finish and ensure a seamless but reliable water supply.

Thus, the Monel 400 Tee is a versatile piping component that can withstand harsh environmental conditions, making it the ideal material for various applications.

Advantages of Monel 400 Tees

One of the main advantages of Monel 400 Tees is its excellent corrosion resistance. This property makes it ideal for applications where contact with seawater and chemicals is common.

Furthermore, Monel 400 Tees have high strength, hardness, and good flexibility and toughness, ensuring their durability in high-pressure and high-temperature applications.

The mechanical properties of the Monel 400 Tee also make it easy to weld and provide a reliable connection between pipes. Additionally, Monel 400 has excellent resistance to reducing and oxidizing acids, which is another reason it is widely used in the petrochemical industry.

0 notes

Text

Exploring the Advantages of Inconel Tube Suppliers.

High-performance nickel-chromium superalloys like Inconel are lauded for their superior corrosion resistance, high-temperature stability, and mechanical strength, among other desirable qualities. Inconel tubes, an essential component in many sectors, capitalize on these qualities to provide dependable performance in rigorous settings.

Knowledge and direction are provided by nickel alloy suppliers, who have experience with this unique material. Because of their in-depth familiarity with Inconel alloys, they can confidently advise clients on which alloy is best for their needs. With their help, you can be sure to get Inconel tubes that are tailor-made to your project.

Inconel tube suppliershave a wide variety of Inconel alloys, each optimized for a certain set of performance characteristics. Suppliers can supply Inconel tubes with the desired properties, such as high temperature resistance, superior corrosion resistance, or both. These metals are optimized for use in extreme conditions, making them ideal for industries including chemical processing, aerospace, and high-temperature production.

Inconel plate suppliersprovide customization options since they know that many projects call for unique approaches. Tube length, diameter, wall thickness, and polish may all be tailored to your specifications. This adaptability guarantees that your Inconel tubes will meet all of your requirements.

Quality control is a top priority for all reputable Hastelloy plate suppliers. They only use high-quality components from reputable suppliers, and they have rigorous quality control procedures in place. The Inconel tubes you receive will be both reliable and long-lasting thanks to the company's dedication to quality.

When it comes to certifications and requirements, Monel plate suppliersmake sure their products are up to par. Suppliers make sure their Inconel tubes are up to par with whatever standards are in place, whether they American Society for Testing and Materials standards, ASME standards, or international standards.

ResoluteInconel round barsuppliers have a wide range of Inconel tubes in many different diameters, wall thicknesses, and alloys, and they always deliver on time. Because we have so many Inconel tubes, we can provide you the ones you need quickly. Services that guarantee on-time delivery further guarantee that your project will not be delayed.

Inconel fasteners manufacturersprovide solutions that fit your budget and needs for performance. They can help you strike the optimal balance between quality and cost by recommending the appropriate Inconel alloy and tube parameters.

Inconel tube vendors provide after-sale services including warranties and help for problems that may emerge with the product. You can rest easy knowing you will receive consistent support and updates on how your Inconel 625 tube is doing.

You cannot get the proper Inconel tubes for your purposes without the assistance of dependable Inconel tube suppliers. Inconel 625 plate is used widely. Their knowledge, variety of alloys, customization possibilities, and dedication to quality may make a big impact for your projects in industries like aerospace, chemical processing, high-temperature manufacturing, and any others that require excellent performance and endurance. Working with a reputable Inconel tube supplier gives you access to products that consistently exceed expectations and last for years.Monel 400 plate has the finest results.

0 notes

Text

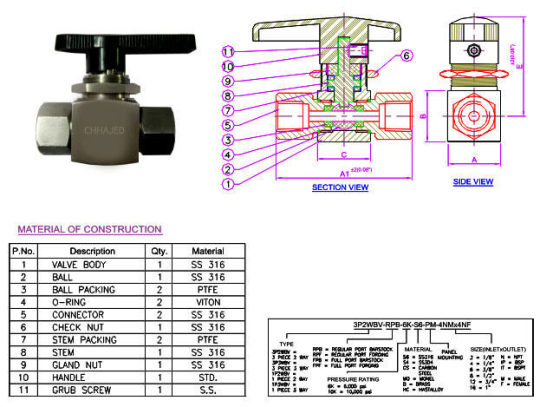

Ball Valve Suppliers in India

2 WAY BALL VALVE F X F (PANEL MOUNTING)

Features :

1. SS 316 construction for corrossion resistance, full or reduced bore for excellent flow.3 piece design.peek/delrin seat for better performance.

2. Ball hard chrome plated for smooth operation.

Physical Features :

Pressure rating 400 kg/cm2

Material Options :

1. Brass, SS 316, carbon steel, bronze, hastalloy, monel, etc.

2. Optional kel-f, viton packing available with high pressure valves

Standards : BS 5750; ISO 9001-2000; MSS SP-99

Testing :

1. For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

2. Working pressure : 6000 psi (431 bar)

Hydro Tests :

1. Performed with pure water at 1-1/2 times of the working pressure.

2. Other tests like helium, seismic are availbale upon request.

End Connections : End connections available in NPT / BSPP / BSPT / JIC / SAE

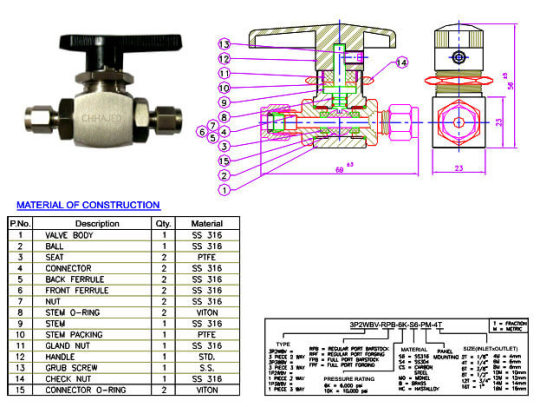

2 BALL WAY PANEL MOUNTING TUBE X TUBE

Features :

1. SS 316 construction for corrossion resistance, full or reduced bore for excellent flow.flexible 3 piece design. Anti blow out internally

2. Ball hard chrome plated for smooth operation.

3. Loaded stem for safety. 90° Smooth operation.

Physical Features :

Pressure rating 400 kg/cm2

Material Options :

1. Brass, SS 316, carbon steel, bronze, hastalloy, monel, etc.

2. Optional kel-f, packing available with high pressure valves

Standards : BS 5750

Testing :

1. Each valve is tested with nitrogen at 1000 psi

2. For seat and seal leakage with a leakage rate of 0.1 std. Cm3/min.

Hydro Tests :

1. Performed with pure water at 1-1/2 times of the working pressure.

2. Other tests like helium, seismic are availbale upon request.

End Connections : Variety of end connections 1/4" to 1" npt, bsp male or female threaded or 1/4", 3/8", 1/2" powerlok single or twin ferrule tube fitting ends.

0 notes

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Text

Overview of Monel alloy k 500

Monel K500 is a nickel-copper alloy that has the corrosion resistance of Alloy 400 and high-strength corrosion fatigue and erosion resistance. At MV Super Alloys, we take pride in being the leading Monel K500 Alloy stockist, trader, importer, supplier, and exporter in India. With a vast range of Monel K500 Alloy forms available, including pipes, tubes, round bars, coils, shims, strips, wires, sheets, and plates, we cater to diverse project requirements.

Monel K500

In this comprehensive article, we delve into the intricacies of Monel Alloy K500, highlighting its exceptional properties, its uses, applications, and the reasons why it outperforms other materials in the industry.

Overview of Monel K500 Alloys

Monel K-500 (UNS N05500) is an alloy consisting of nickel and copper, which has been age-hardened to achieve superior strength compared to Monel 400. Remarkably, it maintains these impressive mechanical properties even in high temperatures up to approximately 650 degrees Celsius. Furthermore, its exceptional corrosion resistance allows it to withstand harsh environments containing both chemicals and chlorides. With its unique combination of physical and mechanical characteristics, it is extensively employed in multiple challenging applications.

Properties of Monel k500 Alloys

Monel K500 is a nickel-copper alloy that offers excellent corrosion resistance and high strength. Here are some of the properties of Monel 2,4375 alloys:

Excellent corrosion resistance in various environments (seawater, acids, alkalis)

High strength and mechanical properties at room and elevated temperatures

Non-magnetic, suitable for applications requiring low magnetic interference

Good ductility, easily formed and fabricated

Resistant to wear and abrasion

Low coefficient of thermal expansion for dimensional stability

High fatigue strength for dynamic loading applications

Weldable using standard techniques

Limited temperature range (up to approximately 650°C or 1200°F)

Forged Monel K500 Equivalent

Standard - Monel K500

UNS - N05500

WNR. - 2,4375

Monel K500 Alloy Chemical Composition

The Monel alloy k 500 chemical composition typically includes the following elements:

Grade - Monel K500 Alloy

AI - 2.30 - 3.15

C - 25 max

Cu - 27.0-33.00

Fe - 2.0

Mn - 1.5 max

Ni - 63.0

Ti - 35 -85

S - 0.1 max

Si - 5 max

Physical Properties of Monel K500 Alloys

The UNS N05500 alloy exhibits exceptional strength at elevated temperatures, thereby rendering it a highly suitable material for deployment in high-temperature application domains such as boilers or furnace components. Furthermore, its non-magnetic nature renders it highly compatible with the use of electromagnetic equipment or electronic devices. Its low thermal expansion coefficient also exemplifies its utility in precision parts requiring constricted tolerances when exposed to temperature fluctuations.

Physical Properties - Metric

Density - 8.45g/cm

Melting - 1338°C

Physical Properties - Imperial

Density - 0.305 Ib/in3

Melting - 2440°F

Mechanical Properties of Monel K500 Alloys

Understanding the Monel K 500 mechanical properties is essential for assessing its suitability for specific applications.

Here are some key mechanical properties of Monel K500:

Monel K500 possesses exceptional tensile strength and flexibility, making it an ideal material for engineering applications, including but not limited to pipe fittings or valves that require both strength and flexibility. Additionally, it exhibits remarkable resistance to fatigue, which grants it superior performance when compared to other materials subjected to repeated loading cycles or stress fatigue conditions.

Hardness (HB)- 27-35 HRC

Ultimate Tensile Strength (N/mm2) - 970-1000

Proof Stress - 690-760

Monel k500 specification & Standards

Product Forms - Sheet, Plate

ASTM - B575

ASME - SB 575

DIN - 17744

Product Forms - Strips

ASTM - B575

ASME - B 575

DIN - 17744

Product Forms - Rod, bar, Forging

ASTM - B 574, B 564

ASME - B 574, B 564

DIN - B 574 , B 564

Product Forms - Wire

ASTM -

ASME -

DIN - 17744, 17753

Monel K500 Uses

Monel K500, a nickel and copper alloy, is renowned for its remarkable strength, resistance to corrosion, and ability to withstand extreme temperatures. It is a favored material in diverse industrial settings, including desalinization systems, oil refining operations, and the manufacturing of valves, pumps, shafts, and fasteners. Its application in these industries is particularly valuable because of its durability and reliability.

Additionally, Monel K500 exhibits exceptional resistance to loss of strength even when exposed to high temperatures up to 1200°F, which makes it an indispensable component in airplane manufacturing, among other applications. Its unparalleled strength and versatility have made it a crucial material for the production of long-lasting and reliable products across many industries.

Applications of Monel K500 Alloys

Monel K500 is a nickel-copper alloy that offers excellent corrosion resistance, high strength, and good mechanical properties at both room and elevated temperatures. There are numerous industries in which it is used.

Here are some common applications of Monel K500 alloys:

Marine and Offshore Industry

Oil and Gas Industry

Chemical Processing

Pump Shafts and Impellers

Doctor Blades and Scrapers

Oil-well drill Collars and Instruments

Electronic Components

Springs

Valve trim

Aerospace Industry

Electronics and Electrical Industry

Medical Equipment

Heat Exchangers and so on.

Final Thoughts!..

Monel Alloy K500 is a superior choice for high-performance applications, thanks to its well-balanced chemical composition, impressive mechanical properties, and adherence to industry specifications. The Monel K500 specification ensures that this alloy meets stringent standards, making it suitable for a wide range of demanding projects. As the leading Monel 2,4375 alloys supplier in India, MV Super Alloys is committed to providing you with the highest quality products that meet your project requirements. Whether you need Monel K500 Round Bars, sheets, plates, or any other form, we have a comprehensive inventory to cater to your needs. As a leading Monel K500 Alloy importer & Stockist in India, we supply the raw material with Material Test Certificate (MTC). In addition to providing high-quality products, MV Super Alloys also offers exceptional customer service and competitive pricing.

For more information on Monel Alloy K500 and how it can benefit your projects, feel free to visit our website or contact our knowledgeable team. Our team is here to help you every step of the way.

#Monel alloy k 500 chemical composition#Monel k500 round bar#Monel k 500 mechanical properties#Monel k500 specification

0 notes

Text

Prominent Manufacturer and Exporter of Monel Alloy 400 Fasteners, Monel 400 Fasteners. We offer Premium quality Monel 400 Fasteners at best price. We have Wide range of Fasteners such as Stud Bolts, Nuts, Fasteners etc. Contact Us and Book Now. JFE is the best manufacturer of buttweld and forged pipe fittings, flanges, fasteners, bars, pipes and tubes of high quality of various grades and materials in Mumbai, India

#Monel Alloy 400 Fasteners#UNS N04400 Monel Fasteners#Alloy 400 Monel Fasteners#Monel 400 Stud Bolts#Monel Werkstoff Nr. 2.4360 Fasteners#Monel UNS N04400 Fasteners#Monel Alloy 400 Stud Bolts Manufacture in India.

0 notes

Text

A Comprehensive Guide to Monel Pipe Fittings Manufacturing and Quality

Monel Pipe Fittings Manufacturing and Quality

These fittings are constructed using a nickel-copper alloy that offers excellent resistance against acidic or alkaline environments and can withstand extreme temperatures without losing strength or flexibility.

These materials can be found in marine engineering, hydrocarbon processing and many other applications where reduced conditions exist. Furthermore, these products offer resistance against stress corrosion cracking and crevice corrosion.

What are Monel Pipe Fittings?

Monel Pipe Fittings are metal connections used across multiple industries. Made from various materials and seamless or welded construction methods, they have become indispensable parts of today's industrial infrastructure.

Fittings are used to connect pipes. Various fittings include tube bends, tees, end caps, and more.

These fittings, typically constructed from stainless steel or aluminium, can be found across various industries - including chemical and petrochemical plants.

They can also be utilized in the marine industry, where they resist seawater and steam exposure, salts and acidic solutions, and stress corrosion cracking.

Monel is a nickel-copper alloy widely utilized by the pipe industry. As an advanced material, Monel provides excellent resistance against steam, seawater, salts and acidic solutions and shows exceptional mechanical properties even at lower temperatures.

Monel 400 Pipe Fittings

Monel 400 Pipe Fittings come in various shapes and sizes to meet various industrial applications that demand superior components.

These pieces can be forged or welded depending on their use; they are typically used to join pipe and tube components.

Pipe fittings come in all sorts of shapes and sizes. Most frequently seen examples of pipe fittings include elbows, tees, and reducers.

Bend radii for these pipe components may range from 1D to 10D and can even be manufactured at short radiuses.

These fittings can be welded using both buttweld and socket weld methods, making them a popular choice among pipe manufacturers because of their durable yet easy production process. Resistant to water and steam, they can withstand temperatures from subzero up to 1000degF (54degC).

Monel 400 Seamless Pipe Fittings

Monel 400 is an ideal solution for marine and chemical engineering projects due to its corrosion-resistant qualities, offering protection from seawater, steam, salt, caustic solutions and caustic solutions. It is often chosen due to its versatility.

Monel 400 is designed for various applications and has seamless or welded construction. Common uses for Monel 400 include pipe fittings, valves, pumps and shafts,

Monel 400 alloy is used widely across industries that require corrosion-resistant alloys for their products or equipment - such as chemical processing equipment, hydrocarbon processing, marine engineering and other applications that entail extensive chemical exposure.

Alloy 400 is highly resistant to stress corrosion cracking in most environments, particularly those with low sulfur levels. Furthermore, Alloy 400's high flexibility makes shaping and machining much more straightforward, making it suitable for use in various piping systems with extreme temperatures and pressure conditions.

Monel 400 Welded Pipe Fittings

Welded Monel 400 Pipe Fittings are one of the most widely-used piping used across industries due to their exceptional corrosion resistance. Furthermore, these fittings can withstand oxidizing and reducing chemicals while remaining functional in various environments.

Furthermore, they can withstand exposure to fluorine-based chemicals in an application and environments containing high concentrations of caustic solutions like those found in marine engineering applications.

FRP pipes have become one of the most reliable choices for chemical and hydrocarbon processing applications, marine engineering, seawater purification systems and heat exchangers/power generation systems. Furthermore, their excellent strength/flexibility makes them great choices for hydraulic/pneumatic applications, and they are available in numerous forms, sizes and specifications.

0 notes

Text

Technical specifications for stainless steel pipe fittings

There are many different types of pipe fittings on the market. Each of them has different purposes and leads to different results. For example, an elbow is designed to change the flow direction between two different pipes. On the other hand, pipe joints, as the name suggests, reduce the flow in many places. The connection type T looks like the letter "T" and can join the stream from several input sources. Some accessories are well-known in various industries.

For example, cross-pipe fittings are more commonly found in fire sprinklers, where they are often found in sprinkler systems. The type of pipe fittings used in a particular business or facility depends on the type of business involved and its specific needs. Forged fittings suppliers specialize in industrial products for companies involved in equipment manufacturing, mining, oil refining, chemical manufacturing, steel and aluminium manufacturing, utilities, transportation, and construction.

Stainless steel pipe fittings suppliers is a leading and most powerful manufacturer of stainless steel pipe fittings. Stainless steel pipe fittings are of special quality and strength for long life, high pressure, and error-free operation. Product differentiation is based on the excellent finish of stainless steel pipe fittings with minimal edge burrs.

The main reason is that they have excellent warehousing and storage facilities for finished and semi-finished products. They are prepared according to the customer's urgent needs. Stainless steel pipe fittings are manufactured to withstand extremely high pressures and product warranties.

Elbows, t-shirts, reducers, caps, short ends, nipples, couplings, crosses, couplings, sockets, cutouts, welds, threads, elbows etc. IBR test certification under manufacturer and third-party inspection. A lot of attention is paid to packaging and packaging. Stainless steel fittings are packed in a cardboard box with plastic film and bubble wrap. At the request of the buyer, plugs are supplied for both ends.

What are the benefits of using stainless steel pipe fittings and valves?

Stainless steel is one of the most reliable metals on the market and is used outside the industry. Choosing stainless steel over cheaper products has several advantages. It is durable. A typical stainless steel pipe can be used for more than 100 years. This is because stainless steel contains chromium, which makes it resistant to corrosion.

It is also resistant to high levels of heat and fire. Other advantages of stainless steel are its cleanliness and impact resistance, as it is easier to keep clean than other metals. It can require a lot of pressure and can also be changed during production to suit the company's specific needs.

Why do you need sanitary pipe fittings?

The need for sanitary items is only immediately obvious in some industries. However, it is needed, not just in the industry. Small businesses specializing in general food production also rely on plumbing fixtures. Health regulators often expect this in these industries.

Tube fittings suppliers carry a variety of Stainless Steel Pipe Fittings in Carbon Steel, Stainless Steel, High Nickel Alloy - F467 NiCu 400 (Monel), and Commercial Stainless Steel 304, 316. They offer Stainless Steel Pipe Fittings at great prices.

0 notes

Text

We are one of the leading importers, stockists and suppliers and manufacturer of Stainless Steel. We offer a wide range of raw materials both LONG & FLAT Products to meet a variety of applications/production Requirements i.e. Stainless Steel Pipes, Stainless Steel Tubes, Stainless Steel Sheets, Stainless Steel Plates, Stainless Steel Strips, Stainless Steel Rods, Stainless Steel Bars, Stainless Steel Wires angels, Stainless Steel Pipe,17-4ph bar and rods, 15-5 ph bars and rods, nickel bars and rods, nickel pipe and tubes, nickel sheet, nickel plates, nickel coils, nickel flanges, alloy bars and rod, alloy pipes and tubes, alloy plates, alloy sheets, alloy coils, alloy flanges, duplex rods, duplex bars, duplex coils, duplex sheet, duplex plate, duplex pipes, duplex tubes, carbon steel rods, carbon sheet bars, carbon steel pipes, carbon steel tubes, carbon steel plates, carbon steel coils, carbon steel sheets, carbon steel, aluminium bars and rods, auminium pipes and tubes, aluminium sheets, coils, plates, aluminium flanges, fittings as per International Codes / Standards.

#stainlesssteel#stainlesssteelbars#stainlesssteelbar#stainlesssteelrods#stainlesssteel304rod#stainlesssteelpipes#stainlesssteeltubes#stainlesssteelcoils#stainlesssteelsheet#aluminium#aluminiumpipe#aluminiumsheet#stainlesssteelplates#stainlesssteelflanges#forgedfitting#buttweldfitting#aluminiumtubes#aluminiumplate#aluminiumcoils#aluminiumbars#aluminiumrods#nickel#duplex#superduplex#hastelloy#alloy#hastelloybar#hastelloyrod#hastelloyplate#hastelloycoils

0 notes

Text

Usage of Alloy 20 Instrumentation Tube Fittings

Alloy 20, also known as Carpenter 20, is a nickel-iron-chromium austenitic alloy that was developed for maximum resistance to acid attack, specifically sulfuric acid. This superalloy has excellent resistance to general corrosion, pitting, and crevice corrosion in chemicals containing chlorides and sulfuric, phosphoric, and nitric acids. It also contains niobium for stabilization against sensitization and resultant intergranular corrosion.For More Info Visit Our Site:-

0 notes

Photo

Nufit Piping Solutions - Manufacturer, exporter & supplier of Stainless Steel 316 Instrumentation Tube Fittings - Male Connector, Female Connector, Union, Tee, Cross, Tube End, Front Ferrule, Back Ferrule with end connection Male Threaded, Female Threaded, Tube End Available in SS 304, 304L, 316, 316L, Duplex Steel 2205 (UNS S31803, S32205), Super Duplex Steel S32750, S32760, Inconel 600, 625 (N06600, N06625) Monel 400 (N04400), Hastelloy C276 (N10276), Brass, Copper Alloy, Aluminium Bronze For more details, visit us at Https://fittingsmanufacturer.com For your requirement, mail us at [email protected] #ssInstrumentationfittings #instrumentationfittings #Tubefittings #sstubefittings #maleconnector #femaleconnector #unionfitting #uniontee #tubing #oilngas #oilngasindustry #manufacturer #exporter #tubefittingsmanufacturer #tubefittingsexporter #nufit #nufitpipingsolutions #india #instagood #instadaily #instalike #follow #newpost (at Singapore, Singapore) https://www.instagram.com/p/CjvM8Y6o3AB/?igshid=NGJjMDIxMWI=

#ssinstrumentationfittings#instrumentationfittings#tubefittings#sstubefittings#maleconnector#femaleconnector#unionfitting#uniontee#tubing#oilngas#oilngasindustry#manufacturer#exporter#tubefittingsmanufacturer#tubefittingsexporter#nufit#nufitpipingsolutions#india#instagood#instadaily#instalike#follow#newpost

0 notes