#SS Tubes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

All about Welded Pipes and Tubes: It’s Uses

There are several types of pipes and tubes available in the market. The difference in pipes and tubes are highly important for a certain company or industry. Many industries have their entire operation based on the functionality of tube and pipes. It has numerous applications which are the key functions of an industry or enterprise.

Pipes and tubes are built in various ways to perfectly attain the requirement for the applications. The thickness must be perfectly accurate to hold the content pipes or tube is containing’s. Built of the tubes and pipes must be strong, so that they don’t crack or break. Materials also have plenty of value from which the pipes and tubes are manufactured. Many advanced features are used to make sure the proper quality is attained that satisfy the clients for their entire requirements.

Welded tubes and welded pipes are commonly used by plenty of industries. They can be manufactured in a specific way as two ends are joined which can be joined into several ways to attain the required shape and size.

What is the Difference between Pipes and Tubes?

Pipes and tubes might occur similar to plenty of people. There aren’t plenty of differences between tubes and pipes but the small differences surely creates a gap in their applications. The sizes, lengths or height of the pipes and tubes are similar. Pipes are round in shape and tubes aren’t necessary to have a round shape. Tube comes in plenty of shapes, including square, rectangle, round and plenty more.

The build also is a bit different between the two. Tube tubes are built to handle much denser substances that usually come in lines that are longer. Pipes are made to contain light substances which are easy to carry. Thus the application of tubes and pipes is widely different.

Types of Pipes and Tubes

There are two types of pipes and tubes: Welded and Seamless. Welded and seamless are manufacturing types which result in different products. Welded pipes are manufactured when two ends are joint by using a filler metal to connect the two ends. It has plenty of ways to ensure numerous sizes. The pricing of welded tubes and pipes are certainly cheaper than others.

Seamless pipes and tubes are made without any weld. There is no joint on the surface of the pipe or tube. They are constructed using a single metal billet. It leads to better structural capabilities and the building is extremely rigid. There are no crevices and cracks as there are no connections. The benefits certainly come with extra price.

Features of Welded Tubes and Welded Pipes

There are numerous features of welded pipes and tubes that makes them a leading contender for an industry or business to purchase. It is prominently compared with seamless tube and pipes, which has one major benefit over welded core strength. A well welded pipe or tube also has excellent capabilities and features which can be utilized by several industries efficiently.

Features of Welded Tubes:-

Excellent Surface Finish

Corrosion Resistant

U Bending Facility

Can Produced with NDT Requirements

Can Handle Multiple SS Grades

Stabilized Heat Treatment

Manufactured in Plenty of Size.

Less Costly

Features of Welded Pipes:-

Radiography/Radioscopy for better Weld Quality

Solution Annealing Heat treatment

Hydro Testes

Ultrasonic and Eddy Testes

Can be Manufactured in Numerous Sizes

Less Costly

Welded pipes and welded tubes can be manufactured using various types of materials:-

Brass

Molel

Stainless Steel

Stainless Steel also comes in plenty of grades and specification:-

SS 409 Welded Tubes

SS 410 Welded Tubes

SS 420 Welded Tubes

SS 441 Welded Tubes

Uses of Welded Tubes and Welded Pipes:-

Natural Gas

Petroleum

Chemical Industry

Electric Power

Water Supply

Steam Heating

Hydropower Pressure Pipe

Thermal Power

Long-Distance Piling

Construction

Steel Structure Engineering

SPP Metals and Alloys is one of the leading Stainless Steel tube manufacturers in India and stainless steel pipe exporter overseas. They have a broad range of stainless steel grades which are applicable in plenty of industries. SPP Metal & Alloys have plenty of Stainless steel products that are featured in multiple variations in their list.

#Stainless Steel Pipes#Stainless Steel Tubes#SS Pipes#Stainless Steel#SS Tubes#Welded Tubes#Welded Pipes

0 notes

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF:

TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada:

Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic:

Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak:

Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser:

Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD:

LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India

CNC punching services in pune

Best MIG Welding Machine

Pre-Treatment for Surface Preparation in pune

Best CNC bending services India

Best SS fabrication services in India

Best spot welding services in pune

Best tube, pipe, and angle cutting services in pune

Best automotive manufacturers in pune

Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

#MS Tube Mill Plant manufacturer in Ahmedabad#ss tube mill machine manufacturers in Ahmedabad#pipe mill machine manufacturers in Ahmedabad#tube mill manufacturer in Ahmedabad#pipe polisher machine manufacturer in Ahmedabad

3 notes

·

View notes

Text

Time to sketch out tattoos I want on my abdomen. 🖕🏼🤬🖕🏼

#tiger’s roar#roe v wade#reproductive rights#reproductive care#reproductive coercion#misogyny#sexism#afab health#women’s health#at least I’m meeting with the caseworker today#I feel safer demanding a List of gynochologists from her vs my male&church member pcp#my therapist helped walk me through How to ask for ss assistance help when prepping for today’s meeting#which…can take years. and I want my tubes out NOW

3 notes

·

View notes

Text

Exploring the Versatility and Benefits of Stainless Steel Coil Tubes

Stainless steel coil tubes are indispensable components in various industrial applications, prized for their durability, corrosion resistance, and versatility. From heat exchangers to instrumentation, these tubes play a crucial role in numerous processes across diverse industries. Let's explore the intricacies of stainless steel coil tubes, their uses, benefits, and why they're the preferred choice for many applications.

Stainless steel coil tubes are precisely engineered cylindrical structures made from high-quality stainless steel alloys. They are manufactured by winding stainless steel strips into a continuous coil and then welding the edges to form a seamless tube. This unique construction offers several advantages over traditional straight tubes, making them ideal for various applications.

Application of Stainless Steel Coil Tubes

Heat Exchangers: Stainless steel coil tubes are commonly used in heat exchangers due to their excellent thermal conductivity and corrosion resistance. They efficiently transfer heat between two fluids without risk of contamination or degradation.

Instrumentation and Control Systems: In industries such as pharmaceuticals, food processing, and chemical manufacturing, stainless steel coil tubes are essential components in instrumentation and control systems. Reliability and precision make them suitable for measuring and regulating fluid flow, temperature, and pressure.

Hydraulic and Pneumatic Systems: These tubes are also integral to hydraulic and pneumatic systems, where they facilitate the transmission of fluids and gases under high pressure. Their resistance to corrosion and high temperatures ensures long-term performance and safety in demanding environments.

Oil and Gas Industry: SS coil tubes are used in piping systems for transporting crude oil, natural gas, and various chemicals in oil refineries, petrochemical plants, and offshore drilling operations. Their durability and resistance to corrosion make them well-suited for these harsh environments.

Benefits of Stainless Steel Coil Tubes

Corrosion Resistance: Stainless steel coil tubes exhibit exceptional corrosion resistance, making them suitable for applications where exposure to corrosive substances is daily.

High Strength: These tubes are manufactured from high-strength stainless steel alloys, providing excellent structural integrity and durability, even under extreme conditions.

Ease of Installation: The flexible nature of coil tubes allows easy installation in tight spaces and complex configurations, reducing the need for additional fittings and minimizing installation time and costs.

Customization: Stainless steel coil tubes can be customized in dimensions, wall thickness, and surface finish to meet specific application requirements, ensuring optimal performance and efficiency.

Conclusion

Stainless steel coil tubes are indispensable components in various industrial sectors, offering unmatched durability, corrosion resistance, and versatility. Whether in heat exchangers, instrumentation systems, or hydraulic applications, these tubes play a vital role in ensuring the efficiency and reliability of critical processes. With their numerous benefits and customizable options, stainless steel coil tubes are preferred for engineers and manufacturers seeking high-performance tubing solutions.

0 notes

Text

How to Choose the Right Stainless Steel Tube for Your Project

Choosing the right stainless steel tube for your project is crucial to ensure optimal performance, durability, and cost-effectiveness. With a wide range of options available, it's essential to consider several critical factors before making your selection. Here's a guide to help you navigate the decision-making process:

Define Your Requirements

Begin by clearly defining your project's requirements. Consider the intended application, environmental conditions, required dimensions, pressure, temperature, and corrosion resistance.

Determine whether the tube will be used for structural support, fluid transport, heat exchange, or another purpose. This will influence the choice of material and specifications.

Material Selection

Stainless steel tubes are available in various grades, each offering unique properties suited to specific applications. The most common grades include 304, 316, 321, and 347.

When selecting the stainless steel grade, consider the environmental conditions and potential exposure to corrosive substances. For example, marine or chemical processing applications may require a higher corrosion-resistant grade like 316 or duplex stainless steel.

Consider Manufacturing Standards

Determine whether your project requires compliance with specific manufacturing standards or certifications, such as ASTM (American Society for Testing and Materials) or ASME (American Society of Mechanical Engineers). These standards ensure that the tubes meet quality and performance requirements.

Evaluate Tube Dimensions and Specifications

Take precise measurements and consider the required dimensions of the SS tube, including outer diameter (OD), wall thickness, and length.

Evaluate the tube's specifications, such as seamless or welded construction, and whether additional finishing processes like polishing or electropolishing are necessary for your application.

Assess Mechanical Properties

Consider the mechanical properties of the stainless steel tube, including tensile strength, yield strength, elongation, and hardness. These properties determine the tube's ability to withstand mechanical stress and deformation under load.

Factor in any specific performance requirements, such as high-temperature or impact resistance, and select a stainless steel grade that meets those criteria.

Cost Considerations

Balance performance requirements with budget constraints when selecting the stainless steel tube for your project. While high-performance grades may offer superior corrosion resistance and mechanical properties, they may come at a higher cost.

Evaluate the total cost of ownership, considering factors such as initial purchase price, maintenance requirements, and the expected service life of the tube.

Consult with Experts

If you're unsure which stainless steel tube is best for your project, consult with experts or suppliers specializing in stainless steel products.

Experienced professionals can provide valuable insights and recommendations based on their expertise and knowledge of industry best practices.

By carefully considering these factors and consulting with experts when needed, you can confidently choose the right stainless steel tube for your project, ensuring optimal performance, longevity, and cost-effectiveness.

0 notes

Text

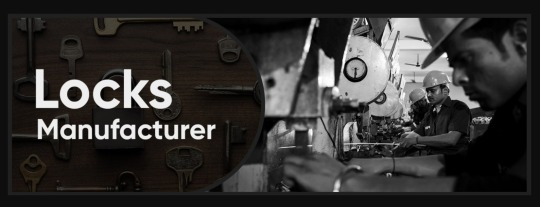

Unlocking Excellence: The Leading Lock Manufacturer in Patna @ Aligarh Locks

Lock Manufacturer in Patna at Aligarh Locks, every lock is a masterpiece crafted with precision and care. Our team of skilled artisans combines traditional techniques with modern technology to create locks that are not just secure but also aesthetically pleasing.

We believe in building long-lasting partnerships based on trust and integrity. That's why we work closely with architects, builders, and security experts to provide tailored solutions for residential, commercial, and industrial applications.

#Lock Manufacturer#Door Lock Manufacturers#Locks and Hardware#Lock Shop#ss tube manufacturers and traders in bihar and patna#Best Shutter Lock in Patna

0 notes

Text

Benefits of Stainless Steel 904L for Your Business

Unravelling the Superior Qualities of Stainless Steel 904L

Stainless steel 904L is a remarkable alloy that stands head and shoulders above the competition. Boasting an unparalleled combination of corrosion resistance, strength, and durability, this superior grade of stainless steel is the clear choice for demanding applications.

Unlike standard 304 or 316 stainless steel, 904L contains higher levels of nickel and copper, making it exceptionally resistant to a wide range of corrosive environments. Whether you're facing exposure to harsh chemicals, saltwater, or extreme temperatures, 904L stainless steel will rise to the challenge, maintaining its structural integrity and pristine appearance.

But the advantages of 904L don't stop there. This alloy also exhibits impressive mechanical properties, with superior tensile strength and hardness that outperform many other stainless steel grades. When you need a material that can withstand heavy loads, intense pressure, or rigorous use, 904L is the clear frontrunner.

Across a diverse array of industries – from chemical processing and marine applications to pharmaceutical equipment and aerospace engineering – the unrivaled qualities of 904L stainless steel make it the go-to choice for those who demand the best. Invest in 904L, and you'll be rewarded with a material that outshines the competition in every way.

Corrosion Resistance: The Unbeatable Superpower of 904L Stainless Steel

904L stainless steel is the unparalleled champion when it comes to corrosion resistance. Outperforming even the mighty 316L, this superalloy is the clear choice for applications where corrosion is the enemy.

Forged in the crucible of harsh environments, 904L laughs in the face of chemicals, acids, and saltwater that would quickly defeat lesser metals. Its unique composition, rich in chromium, nickel, and molybdenum, creates an impenetrable shield against even the most relentless corrosive forces.

Don't settle for anything less than the best. When corrosion resistance is mission-critical, 904L stainless steel is the unbeatable solution that will safeguard your investments for the long haul. Its superior performance is simply unmatched.

Exceptional Durability: Elevating Your Products to New Heights

When it comes to building a brand that stands the test of time, exceptional durability is non-negotiable. In today's fast-paced, high-demand market, consumers expect products that not only meet their needs but also withstand the rigours of everyday use. By prioritising durability in your product design and manufacturing processes, you can elevate your offerings to new heights, solidifying your reputation and cultivating a loyal customer base.

Durable products instil confidence and trust in your brand. Customers are more likely to invest in items they know will last, reducing the need for frequent replacements or repairs. This translates to increased customer satisfaction, positive word-of-mouth, and a stronger, more sustainable business model. Embrace the power of exceptional durability, and watch your products rise above the competition.

Versatility Unleashed: Unlocking Endless Possibilities with 904L Stainless Steel

When it comes to materials that push the boundaries of performance and durability, 904L stainless steel stands tall as a true game-changer. This remarkable alloy, with its exceptional corrosion resistance and unparalleled versatility, is revolutionising industries across the globe, unlocking endless possibilities for innovation and excellence.

Forged in the crucible of modern engineering, 904L stainless steel is the embodiment of resilience and adaptability. Its unique chemical composition, which includes higher levels of nickel, chromium, and molybdenum, grants it an unrivalled resistance to a wide range of corrosive environments, from harsh chemicals to extreme temperatures. This makes it an indispensable choice for applications where reliability and longevity are paramount.

But the true power of 904L stainless steel lies in its versatility. This material seamlessly transitions between diverse industries, from pharmaceutical and chemical processing to marine and offshore environments. Its ability to withstand the most demanding conditions ensures that products and components crafted with 904L maintain their integrity, even in the face of the toughest challenges.

Embracing the future with 904L stainless steel means unlocking new frontiers of innovation. Whether it's designing cutting-edge medical devices, constructing state-of-the-art offshore platforms, or engineering groundbreaking industrial equipment, this material's unparalleled performance capabilities open up a world of possibilities. By harnessing the power of 904L, visionaries and industry leaders can push the boundaries of what's possible, driving progress and transforming the landscape of their respective fields.

Conclusion: Embrace the Future with Stainless Steel 904L - The Unbeatable Choice for Your Business

Stainless steel 904L is the clear choice for businesses seeking uncompromising quality and performance. This advanced alloy offers unparalleled corrosion resistance, exceptional durability, and a sleek, modern aesthetic that will elevate the look and feel of any application.

Embracing the future with 904L stainless steel is a strategic decision that will pay dividends for your business. Its superior corrosion-resistant properties ensure your investments are protected, even in the harshest environments. The material's exceptional strength and longevity translate to reduced maintenance costs and extended product lifespans, making it a sound financial choice.

Beyond its practical benefits, 904L stainless steel also boasts a sophisticated, polished appearance that can enhance the visual appeal of your products or facilities. This versatile material seamlessly integrates with a wide range of design styles, allowing you to create a cohesive, high-end look that resonates with your customers.

The future is bright for businesses that choose 904L stainless steel. Invest in this unbeatable material and unlock a world of possibilities for your company. Elevate your standards, protect your assets, and make a lasting impression – all with the power of 904L stainless steel.

#stainless steel 904l#stainless steel 904l flanges#904l stainless steel pipe#904l stainless steel tube#904l stainless steel sheet#904l stainless steel plate#904l stainless steel bar#904l stainless steel price#904l material#904l steel price#steel 904l#alloy 904l#ss 904l material properties#904l price

0 notes

Text

Sarthak Tubemill's precision SS tubing machines in Ahmedabad

Elevate production with Sarthak Tubemill's precision SS tubing machines in Ahmedabad.

Sarthak Tubemill's commitment to excellence shines through in every stainless steel tubing machine produced in Ahmedabad.

Read More: https://www.sarthaktubemill.com/stainless-steel-tubing-machines-india.html

#SS tubing machines in Ahmedabad#SS tubing machines#SS tubing machines India#SS tubing machines Manufacturer

0 notes

Text

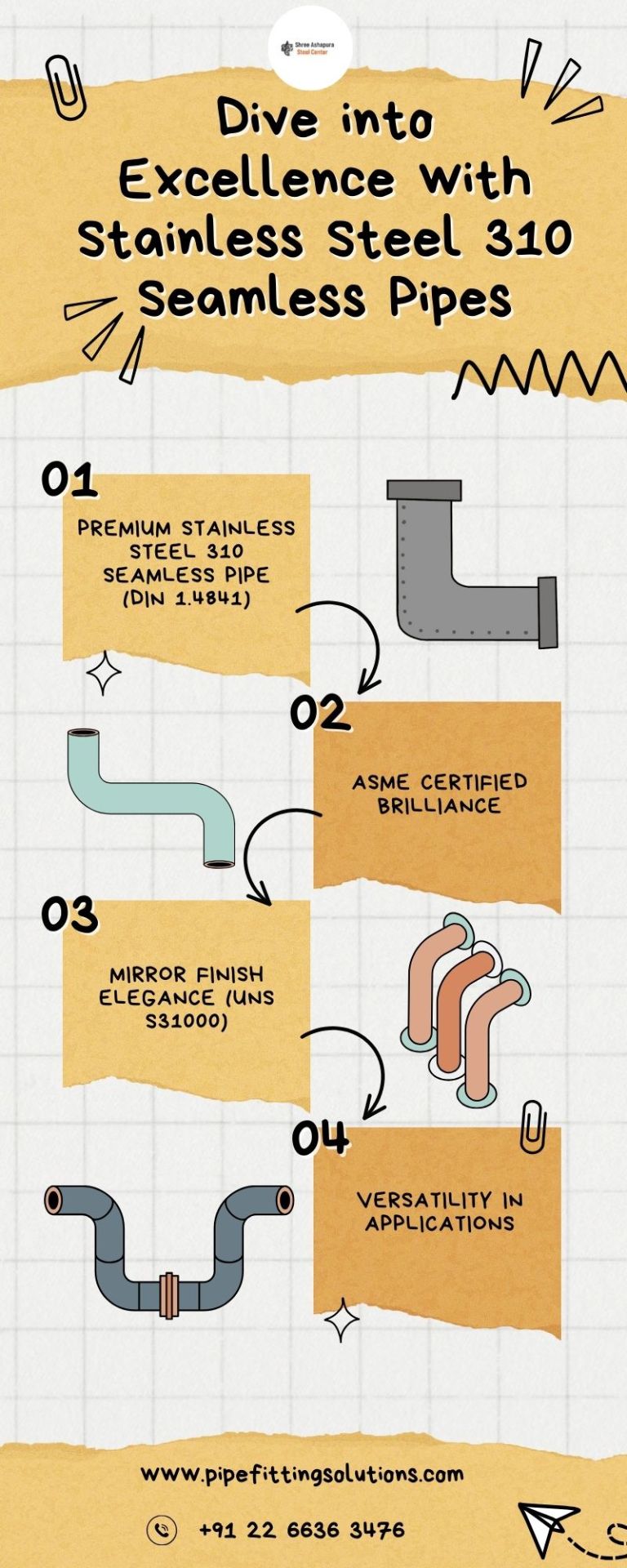

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

Benefits of Stainless Steel Welded Tubes in Industrial Applications

Stainless steel welded tubes are a vital trouble in numerous industrial packages, providing a massive kind of blessings that make them crucial in manufacturing procedures. As a main welded tube provider, SPP Alloys is familiar being the significant stainless steel welded tubes supplier in industrial application. In this blog post, we're capable of discovering the advantages of the usage of stainless steel welded tubes, specially SS409, SS420, and SS441, and why choosing the proper provider is crucial for ensuring exquisite products.

Superior Corrosion Resistance

The primary advantages of stainless steel welded tubes is their first-rate resistance to corrosion. Stainless steel grades like, SS409, SS420, and SS441 l are specially designed to withstand the harsh environmental conditions. It makes them perfect for applications wherein exposure to corrosive elements as a scenario is high. Industries together with chemical processing, oil and gasoline, and marine engineering depend on stainless steel welded tubes to ensure lengthy-term sturdiness and reliability in hard environments.

High Strength and Durability

Stainless metallic welded tubes offer advanced power and sturdiness, making them appropriate for a big variety of industrial programs. Whether it is for structural aid, fluid transportation, or warm temperature exchanger structures, SS409, SS420, and SS441 welded tubes offer the essential robustness to resist heavy hundreds and excessive temperatures. As a provider of welded tubes, it is essential to offer products that meet the highest requirements of energy and sturdiness to make certain the protection and performance of commercial operations.

Versatility in Fabrication

Another advantage of stainless steel welded tubes is their versatility in fabrication. These tubes can be without difficulty shaped, welded, and machined to meet precise layout necessities, providing flexibility in production methods. Whether it's customizing tube lengths, creating complicated geometries, or incorporating distinctive quit finishes, stainless steel welded tubes provide producers with the liberty to evolve to diverse industrial needs without compromising on excellent and overall performance.

Cost-Effectiveness and Long-Term Savings

While the initial funding in stainless steel welded tubes can be higher than other materials, their long-term price-effectiveness makes them a preferred choice for masses of business packages. The inherent corrosion resistance and durability of SS409, SS420, and SS441 welded tubes bring about minimal protection requirements and prolonged service life, in the long run leading to giant charge savings through the years. Choosing a good dealer of welded tubes is crucial to make certain the reliability and integrity of the tubes, at the side of contributing to lengthy-term economic financial savings for commercial operations.

Conclusion

Stainless metal welded tubes, mainly those grades SS409, SS420, and SS441, offer a multitude of advantages. It makes them integral in various commercial applications. These grades characteristic advanced corrosion resistance and excessive strength to versatility in fabrication and long-term fee-effectiveness, those welded tubes play a vital role in ensuring the efficiency and reliability of business processes.

SPP Alloys being the leading welded tube supplier, it's far essential to prioritize excellence, consistency, and customer delight. To meet the diverse industrial wishes of more than one customer and make contributions to the development of producing technology. Selecting the proper provider of welded tubes is essential to harness as a stainless-steel welded tubes supplier for industrial success.

#welded tube supplier#welded tubes inc#supplier of welded tubes SS409#Welded Tubes SS420#Welded Tubes SS420 supplier#Welded Tubes SS 441 Supplier

0 notes

Text

Everything You Need to Know About Stainless Steel Tube

Stainless steel tubing is becoming increasingly popular in various industries due to its durability, corrosion-resistant properties, and wide range of uses. From medical equipment to industrial piping, this material offers numerous benefits that make it an attractive option. Stainless Steel Tube Suppliers offer a wide range of stainless steel tubing, serving diverse industries with various grades, sizes, and finishes. They provide materials for construction, manufacturing, and industrial applications, ensuring access to quality stainless steel tubes.

Properties of Stainless Steel Tube

Stainless steel tubing is a type of steel that is made from a combination of both chromium and steel. It is an alloy with high corrosion resistance, making it a preferred choice in various applications. Another notable property of stainless steel is its strength and durability; it can withstand exposure to high temperatures and harsh environments. Finally, it is very easy to clean and maintain, which makes it ideal for applications where hygiene is important.

Applications of Stainless Steel Tube

One of the main applications of stainless steel tubes is in the medical industry. It is used to produce surgical instruments such as needles, scalpels, and more. The material's biocompatibility and sterilization capabilities make it a preferred choice for medical applications. Additionally, it is also widely used in the chemical, food processing, and oil and gas industries.

Types of Stainless Steel Tube

There are several types of stainless steel tubing available in the market. The three most commonly used are austenitic, ferritic, and martensitic. Austenitic is the most commonly used because it is easy to weld, form, and fabricate. Ferritic is less pliable and easier to weld than austenitic, while martensitic is known for its hardness.

Benefits of Using Stainless Steel Tube

Stainless steel tubing offers several benefits, making it a preferred choice for many applications. It is durable, corrosion-resistant, and easy to clean and maintain. It can be made in various sizes and shapes to suit different applications, making it versatile. Additionally, it is recyclable, making it eco-friendly.

Conclusion

Stainless steel tubing is becoming increasingly popular in various industries due to its exceptional properties and benefits. The material's durability, corrosion-resistant properties, and ease of maintenance make it an ideal choice for many applications. Whether you are in the medical, food processing, or oil and gas industry, stainless steel tubing can help ensure your equipment is strong, long-lasting, and operates efficiently. We hope this guide has given you the knowledge to make an informed decision when choosing stainless steel tubing for your next project.

1 note

·

View note

Text

#Hydraulic Hoses#PTFE Hoses#PTFE Tubes#Convoluted PTFE Hose Manufacturers#Convoluted Hoses#High Pressure PTFE Hose#Threaded Pipe Connector#Threaded Connector#SS Wire Braided Convoluted Hoses#PTFE Hoses Aerospace#PTFE Plain Hoses#Two Axis Pipe Connector#Fixed Flange Connector#Copper Ended Connector#Dash 2 PTFE Hoses

1 note

·

View note

Text

Top Manufacturer of Stainless Steel Coil Tubing

As a leading manufacturer of stainless steel coil tubing, we specialize in crafting precision-engineered solutions that meet the exacting standards of our clients. Our expertise in producing SS coil tubes ensures seamless performance and reliability in fluid transport applications across various industries. With a focus on quality and durability, our stainless coil tubing exemplifies excellence in both design and construction. Leveraging advanced manufacturing techniques, we deliver stainless steel coil tubing that excels in corrosion resistance and longevity, providing long-term value to our customers. Trust in our commitment to innovation and craftsmanship as we continue to set the benchmark for excellence in stainless steel coil tubing manufacturing.

0 notes

Text

Sleek and Strong: The Modern Marvel of Stainless Steel Tubes

In an era where innovation meets aesthetics, stainless steel tubes have carved their niche as a preferred material in various industries and applications. Their sleek appearance and remarkable strength have made them a contemporary marvel, meeting the needs of both form and function.

The Unyielding Strength

Stainless steel tubes are celebrated for their exceptional strength. These tubes are engineered to withstand extreme pressures, making them a reliable choice for critical applications in industries such as construction, automotive, and manufacturing. This resilience ensures longevity and performance that stands the test of time.

Corrosion-Resistant Champion

One of the standout qualities of stainless steel tubes is their resistance to corrosion. Unlike many other materials, stainless steel doesn't succumb to rust, which is especially important in applications where exposure to moisture, chemicals, and other harsh elements is a constant threat. This resistance guarantees that stainless steel tubes maintain their integrity, even in adverse conditions.

Versatility in Design

Beyond their robust nature, stainless steel tubes offer versatility in design. They come in various shapes and sizes, making them adaptable to an array of architectural and structural needs. Whether it's for handrails, support structures, or decorative elements, stainless steel tubes seamlessly blend with modern and traditional design aesthetics.

Easy Maintenance

Stainless steel tubes are known for their low maintenance requirements. They do not require special coatings or treatments to maintain their appearance and performance. This not only reduces the overall cost of ownership but also makes them a practical choice for long-term projects.

Sustainability at its Core

In an age when sustainability is paramount, stainless steel tubes are an eco-conscious choice. These tubes are fully recyclable, reducing the environmental impact. Choosing stainless steel tubes is not only a smart investment in quality but also in the future of our planet.

Stainless steel tubes embody the fusion of strength and style. Their durability, corrosion resistance, design flexibility, and low maintenance make them a prime choice in various industries. As we move forward in a world that demands both aesthetics and substance, stainless steel tubes are here to stay, offering a blend of modern marvel and timeless appeal.

0 notes