#trim winder machine

Text

Trim Winder Machine Manufacturers

Blueeye Machine, located in Ahmedabad, is specialised in the manufacture of trim winders, which are designed to meet the needs of the industries that require precise winding solutions for a variety of materials.

#trim winder machine#trim winder machine manufacturer#trim winder machine supplier#trim winder machine in india#trim winder machine manufacturer in Ahmedabad

0 notes

Text

tips for buying your embroidery machine

Embroidery Machine Essentials: 10 Tips for Navigating the Market and Choosing the Perfect Machine

Embroidery machines have revolutionized the crafting world, allowing individuals to add intricate designs and personal touches to their creations. Whether you're a seasoned sewist or a curious newcomer, investing in an embroidery machine can open up a world of possibilities. However, with a vast array of options available, selecting the right machine can be a daunting task. To help you navigate the market and make an informed decision, here are 10 essential tips for buying your embroidery machine:

1. Define Your Needs and Goals

Before embarking on your machine search, take a moment to reflect on your embroidery aspirations. Will you be primarily embroidering clothing, home décor items, or wearable crafts? Do you envision creating intricate designs or simple embellishments? Identifying your priorities will help narrow down your options and ensure you choose a machine that aligns with your specific needs.

2. Set a Realistic Budget

Embroidery machines range in price from affordable entry-level models to high-end professional machines. Determine how much you can comfortably spend and factor in additional costs, such as software, supplies, and maintenance. Setting a budget will prevent you from overspending and ensure you prioritize the features that matter most.

3. Consider Hoop Size and Stitch Capacity

Hoop size determines the maximum embroidery area you can create. If you plan to embroider large items like blankets or jackets, prioritize a machine with a larger hoop. Similarly, stitch capacity refers to the number of stitches the machine can execute per minute. For intricate designs, consider a machine with a higher stitch capacity to ensure smooth and efficient embroidery.

4. Evaluate Operating System and Software

Embroidery machines typically use a proprietary software platform that enables you to upload, edit, and transfer designs. Familiarize yourself with the software's features and ease of use. Some machines offer compatible software suites for enhanced functionality, while others rely on USB connections or other methods for design transfer.

5. Assess Needle Placement and Thread Tension

The placement of needles can significantly impact the quality of your embroidery. Machines with multiple needles allow for faster stitching and more complex designs. Thread tension plays a crucial role in creating consistent and professional-looking embroidery. Check the machine's needle arrangement and tension adjustment mechanisms to ensure they align with your desired level of craftsmanship.

6. Explore Embroidering Features and Applications

Some machines offer advanced features like automatic thread cutting, bobbin-winders, and lettering tools, while others focus on basic embroidery functions. Consider the features that are most important to you, such as automatic thread color changes, automatic thread trimming, and the ability to embroider over multiple layers of fabric.

7. Research and Read User Reviews

Once you've narrowed down your options, extensively research the specific models you're considering. Read user reviews, watch online demonstrations, and consult with experienced embroidery enthusiasts to gain insights into the machines' performance, strengths, and limitations.

8. Consider Local Service and Support

Ensure the embroidery machine you choose is backed by a reputable brand with a strong customer service network. Check for local dealers or authorized service centers in your area to ensure prompt support in case of any technical issues or warranty claims.

9. Test Drive Potential Machines

If possible, visit a local sewing or embroidery store and test drive the machines that interest you. This will provide you with hands-on experience, allowing you to gauge the machine's ease of use, operation, and overall performance.

10. Seek Expert Advice

Don't hesitate to seek guidance from experienced sewers, embroidery enthusiasts, or qualified professionals at sewing or craft stores. Their insights and recommendations can be invaluable in making an informed decision that aligns with your skills, goals, and budget.

Embroidery machines can be an investment, but with careful consideration and informed decisions, you can find the perfect machine to enhance your creative endeavors and bring your embroidery dreams to life. By following these essential tips, you'll be well-equipped to navigate the market, select the right machine for your needs, and embark on a rewarding journey of personal expression and artistic exploration.

More tips

- Determine Your Needs: Before purchasing an embroidery machine, it's important to determine what you'll be using it for. Are you a professional embroiderer or will you be using it for personal projects? Will you be embroidering on a variety of materials or just one type? Answering these questions will help you narrow down your options and ensure that you purchase a machine that will meet your needs.

Research Different Brands and Models: There are many different brands and models of embroidery machines on the market. Take the time to research different options and compare features. Look for machines with a good reputation for reliability and durability.

Consider the Size of the Embroidery Area: The size of the embroidery area is another important factor to consider. If you plan on embroidering large projects, you'll want to look for a machine with a larger embroidery area. On the other hand, if you'll mostly be working on smaller projects, a smaller embroidery area may be sufficient.

Look for a Machine with a Large Embroidery Field: A large embroidery field will allow you to work on larger projects, and also give you more flexibility when it comes to placement of your designs. This also means that you can do larger designs, or do more than one designs at a time.

Check for Built-in Patterns and Designs: Many embroidery machines come with a variety of built-in patterns and designs. This can be a great feature if you're just starting out, as it will give you a good selection of designs to work with. If you're more experienced, you may prefer a machine that allows you to create and edit your own designs.

Consider the Number of Needles: The number of needles on an embroidery machine can have a big impact on the quality of your finished projects. Look for a machine with at least two needles, as this will allow you to change thread colors more easily.

Check for a Good Lighting System: Good lighting is essential for precision embroidery. Look for a machine with a bright, adjustable light that will illuminate your work area and make it easier to see your designs.

Consider the Price: Embroidery machines can be quite expensive, so it's important to consider the price when making your decision. Look for a machine that offers the features you need at a price you can afford.

Look for a Good Warranty: A good warranty can provide peace of mind and protect your investment in case something goes wrong with your machine. Look for a machine with a warranty of at least one year.

Consider the Brand Reputation: Research the brand reputation of the machine you are buying. This will give you an idea of the customer support you can expect, as well as the quality of the machine you are buying.

In conclusion, when it comes to buying an embroidery machine, it's important to consider your needs, research different brands and models, and look for a machine with a large embroidery area, built-in patterns and designs, a good number of needles, a good lighting system, a good warranty, and a good brand reputation. By following these tips, you'll be well on your way to finding the perfect embroidery machine for your needs.

Read the full article

0 notes

Text

Automatic Plastic Multilayer Blown Film Machine Manufacturer

Adroit Extrusion Manufacturer Automatic Plastic Multilayer Blown Film Machine Manufacturer in Ahmedabad, Gujarat, India.

Adroit Extrusion is a Manufacturer, Exporter, and Supplier of Monolayer, ABA, two-layer, three-layer, five-layer, and seven-layer setups.

Blow Film Plant Accessories like Vertical Granule Mixer with Dryer, Extrusion Process Control, Gusset Board Assembly, Trim Recycling Machine, Hopper Loader, Plastic Granule and Powder Mixer, Plastic Recycling Machine, Bubble Slit, Assembly.

Adroit Extrusion is an ISO 9001:2015 certification, ensuring top-notch manufacturing standards globally.

Professionals examine our offered Multilayer Blown Film Line Machine to ensure perfection and compliance with standards.

7/5 LAYER BARRIER

The development of barrier films, driven by the growing demands of the packaging industry, has led to the adoption of complex symmetrical and asymmetrical structures.

Furthermore, the industry has observed the emergence of EVOH and basic PA/PE structures.

A 7-layer blown film line installs a modern cylindrical spiral die, featuring short polymer flow passageways that minimize dwell time.

This proves particularly beneficial when handling heat-sensitive materials as it reduces polymer degradation and speeds up material changeover.

Manufacturers customize blown film lines with seven layers based on the desired film type. They incorporate advanced automation features such as automated thickness control, gravimetric mixing and dosing, extrusion control, a non-contact type IBC system, and a fully automatic surface winder adaptable to various applications.

These systems offer user-friendly operation with integrated touch screen-based supervisory process control.

Adroit Extrusion is an Automatic Plastic Multilayer Blown Film Machine Manufacturer in Ahmedabad, Gujarat, India, and a Supplier and Exporter of Automatic Plastic Multilayer Blown Film Machine in Oman and various locations like Sohar, Seeb, Rustaq, Nizwa, Khasab, Barka, Liwa, Nakhl, Quriyat.

For further details and inquiries, please feel free to contact us.

Read the full article

0 notes

Note

dumb question but is your bobbin wound correctly? one time i had a similar problem and rewinding my bobbin (and trimming off excess thread) helped

i got this ask forever ago im sorry i didnt see it. uhhh... you know, thats a distinct possibility? the bobbin winder on my machine is p messed up, so my wound bobbins r a lil messed up too.

so... ill keep an eye on that, tho i *think* that rn my main problem is judt. being bad at using yhr machine lol (sewing cutves....)

0 notes

Link

Inspection Rewinding Machine for separate industries and for dissimilar applications per client’s requirement. Inspection Rewinding Machine Manufacturer with heavy duty fabric inspection doctoring, non-woven, film inspection rewinding with slitting system, doctoring inspection rewinding machine, inspection cum Rewinder machine, doctoring rewinding machine, rewinding machines. For More Information Visit Our Website: krishnaengineeringworks.com

#Inspection Rewinding Machine#Doctoring Inspection Rewinding Machine#Doctoring Rewinding Machine#Doctoring Machine#Rewinding Machine Rewinding Machine for Sale#Trim Winder Machine

3 notes

·

View notes

Link

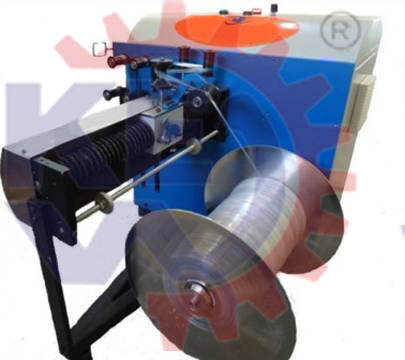

Krishna Engineering Works is biggest manufacturer of high reliability of trim winder. Trim Winder machine is fully mechanical controlled traversing, Trim winder is variable speed motor running under closed loop tension control from a precision dancer. For more information visit our website krishnaengineeringworks.com or contact us at [email protected]

5 notes

·

View notes

Link

KEW ENGG MFG PVT LTD Trim Rewinder includes many features for high reliability of trim winding. Trim Rewinder is used for any winding and unwinding application that reduces material waste to guide the web and achieves high productivity with minimal manpower. Trim Rewinder Machine are highly appreciated by our customers and are widely used in a number of demanding applications in the converting industry.

#Trim Rewinder Machine#Trim Rewinder#Trim Winder#Trim Winder Machine#Trim Winder For Slitting Machine#Slitter Trim Winding Machine#High Speed Trim Winder Machine#High Speed Auto Trim Rewinder#Trim Film Rewinder#Semi-Automatic Trim Winder

1 note

·

View note

Link

We are Manufacturer, exporter & supplier Of High Speed Trim Rewinder, Trim Winder Machine, Trim Winding Machine, Trim Rewinder Machine. High quality equipment Trim Winder Rewinder Machine Manufacturer, Rewinder Unwinder Machine. This, together with the inbuilt pineapple winding technology, ensures optimum winding of the trim and therefore increases the reliability. The lightweight web guide roll assembly traverses for high-speed operation with the spool running in a fixed position.

#Trim Rewinder#Trim Rewinder Machine#Trim Winding Machine#Trim Winding Machine Manufacturer#Trim winder machine#Rewinder Unwinder Machine#Trim Winder Machine Manufacturer#Trim Rewinders#Trim Rewinder winder

0 notes

Link

Trim Winder for Slitter winding Machine Supplier In Cádiz province Spain

https://api.whatsapp.com/send?phone=918128986711

#TrimWinderforSlitterwindingMachine #Cádiz province #Spain

1 note

·

View note

Link

#TrimWindingMachineforSlitterrewindingMachine

Trim Winder for Slitter winding Machine Offered By FusionTech International Manufacturers in Cádiz province Spain

https://www.fusiontechintl.com/products/trim-winder-machine.html

https://api.whatsapp.com/send?phone=+918128986711

https://www.youtube.com/watch?v=m4UpvcK8CWE

#Cádizprovince #Spain

#TrimWinderforSlitterwindingMachine

1 note

·

View note

Text

High Speed Trim Winder Manufacturers

Blue Eye Technology is a main maker, providers and exporter of Trim Winder Machine. Trims viably and proficiently for better productivity.For more information visit blueeyemachines.

#high speed trim winder#high speed trim winder manufacturer#high speed trim winder supplier#high speed trim winder exporter#high speed trim winder in india#high speed trim winder manufacturer in Ahmedabad

0 notes

Text

Brother persona prs100 Reviews

Brother Persona PRS100: Embroidering Your Dreams into Reality - A Comprehensive Review

For embroidery enthusiasts yearning for a machine that pushes boundaries and ignites creativity, the Brother Persona PRS100 emerges as a captivating contender. But is it truly the "persona" of embroidery perfection, or does it have cracks hidden beneath its sleek exterior? This in-depth review delves into the machine's features, functionality, and user experience to unravel its strengths, weaknesses, and suitability for different embroidery aspirations.

Technical Specifications:

Single-needle embroidery machine

Large 5" x 7" embroidery field

136 built-in designs, 11 fonts, and 10 lettering styles

Wireless connectivity via Bluetooth®

Color touchscreen LCD display

Automatic thread detection and trimming

Built-in bobbin winder and thread cutter

USB port for design transfer

5-year limited warranty

Unveiling the Persona:

First impressions matter, and the Persona PRS100 doesn't disappoint. Its sleek, modern design and user-friendly layout inspire confidence. The color touchscreen LCD display is bright and responsive, making navigation and design selection a breeze. The spacious 5" x 7" embroidery field allows for generous design possibilities, while the included hoops cater to various project sizes.

Embroidering Bliss:

The embroidery experience itself is where the Persona truly shines. The machine boasts smooth, quiet operation, ensuring peaceful stitching sessions. The automatic thread detection and trimming take the hassle out of thread changes, and the built-in bobbin winder saves time. Stitching quality is generally impeccable, with consistent tension and precise details.

Embroidering Beyond the Basics:

But the Persona's true strength lies in its extra features. Wireless connectivity unlocks a world of design possibilities through the PES Design app. Download new designs, edit existing ones, and even personalize lettering directly on your smartphone or tablet. Additionally, the built-in camera allows for precise design positioning on any fabric type.

A Few Snags Along the Way:

However, the Persona isn't without its imperfections. Some users report occasional thread breaks, particularly with finer threads. The built-in designs, while decent, might feel limited for experienced embroiderers seeking unique options. Furthermore, the learning curve can be steeper for beginners compared to simpler machines.

Unveiling the Verdict:

So, is the Brother Persona PRS100 the ultimate embroidery dream machine? It depends. For experienced embroiderers seeking superior functionality, wireless connectivity, and a spacious embroidery field, it ticks many boxes. The learning curve might be steeper, but its features and quality output justify the investment for those with specific goals.

However, for beginners or those on a tighter budget, simpler, more user-friendly options might be more suitable. Consider your experience level, design needs, and budget before making a decision.

Additional Points to Consider:

Brother customer service: Generally praised for being helpful and responsive.

Availability of accessories and resources: Wide range of hoops, threads, and tutorials available.

Community and online support: Large online community offering tips and troubleshooting advice.

In Conclusion:

The Brother Persona PRS100 stands as a powerful and versatile embroidery machine, capable of transforming your visions into stunning reality. If you're an experienced embroiderer ready to unleash your creativity and embrace advanced features, this machine deserves serious consideration. However, for beginners or those with simpler needs, alternative options might be more fitting. Ultimately, the persona you choose should perfectly fit your embroidery journey.

Read the full article

0 notes

Text

Assembly method and working conditions of the sand core

1. Shan brush: also known as paint pen, paint brush, roller brush, and casting brush. It is mainly used to remove the parting sand on the pattern, apply paint to the surface of the cavity and the sand core, and is also used to moisten the sand at the edge of the pattern to facilitate mold lifting and repair. 2. Scraper: Also known as trowel, the most widely used tools in repairing are flat head, pointed head and round head. They are mainly used to repair the larger surface of molding sand (core), excavate pouring riser and cut Grooves and casting ribs, trimming of sand blanks and soft and hard sand beds, lifting the reinforcement nails on the surface of the sand mold into the sand mold, etc. 3. Pressure spoon: used to repair the small plane of the sand cavity, and to set up a pouring system. It has an arc-shaped surface at one end and a flat surface at the other end, and the inclination of the spoon handle is 30 degrees. Commonly used are standard pressure spoon, single flush pressure spoon and double flush pressure spoon. 4. Lifting hook: also known as sand hook and tie hook. Mainly used for repairing the deep and narrow bottom and side walls of the sand mold (core), extracting the sand scattered in the deep and narrow cavity. When using it, it is necessary to repair and lift the sand vertically to prevent the shape and size of the repaired surface and wall from being inaccurate or to damage the sand when lifting sand. A set of lifting hooks are divided into several types according to the width of the lifting head and the length of the lifting handle, which are selected according to the size and depth of the cavity part when repairing. 5. Bamboo stalks: also known as semi-circle, used to repair the vertical arc-shaped inner wall and its bottom surface. When using, hold the handle by hand and press the inner wall or bottom surface of the sand mold trimming part. 6. Autumn leaves: Both ends are spoon-shaped, used to trim the curved surface or narrow concave surface of the sand cavity. 7. Hammer hook: Also known as round head, it is used to trim round, arc-shaped grooves, flange surfaces, etc.

It has a wide range of use. 8. Flange hook: also known as flange stem, used to repair the deep and narrow arc surface of the sand mold (core), the narrow sides of the flanges at both ends of the pipe castings, etc. 9. Forming trowel: The forming trowel is a group of trowels, including right-angle photons, egg-shaped photons, internal and external angles, etc. Its working face has various shapes, small volume and easy to use. It is mainly used for trimming the inner and outer rounded corners, square corners, round and arc-shaped surfaces of the smooth sand cavity. 10. Hand winder: also known as leather tiger, a common tool for hand styling. It is used to blow away the sand scattered in the cavity. Do not use excessive force or touch the sand mold during use to avoid damage to the sand mold. 11. Core brace: also known as mud core brace, cast card, brace, support iron, brace head, core clip, core top, cast roof, I-shaped card, I-shaped brace, cast nail. It is a metal component used to support the sand core or local sand mold during sand mold assembly. In the casting process, when the sand mold or sand core cannot maintain its correct position, the core support with a certain thickness and shape and surface treatment can be used to maintain the correct position of the sand mold or sand core in the cavity. The shape of the core support: the shape of the core support should be selected according to the shape, size, assembly method and working conditions of the sand core. The ends of the core braces are made into larger supporting surfaces. Double-pillar core braces are generally used to support larger sand cores, single-pillar core braces are used for medium-sized sand cores, small castings are cooled faster, and thin sheet core braces are commonly used. Wet molding sand generally uses single-sided core braces to support the core brace One end of the surface is attached to the sand core, and the other end is pressed against the harder support outside the cavity. Requirements for core brace: The core brace should be fused with the casting, and the core brace should be made of metal with the same composition as the casting. The surface of the core support should be clean, free of rust and oil stains, and subjected to anti-rust treatment, and the surface should be zinc or tin.

The placement of the core support: the height of the double-sided core support is the wall thickness of the casting, that is, the distance between the cavity and the sand core. Although the wall thickness of the casting is specified on the drawing, bronze gear in actual production, due to various reasons, it is often If there is a discrepancy, if the core brace needs to be set, the height should be the actual distance between the sand core and the sand mold; when the single-sided core brace is placed, when the sand core with a larger mass is placed in the wet mold sand, due to the strength and hardness of the wet mold sand Both are lower, and a core support with a larger contact surface needs to be selected to prevent the core support from being pressed into the molding sand. When using a single-sided core brace, one end of the core brace should rest on a hard support. The core brace must be placed firmly to prevent movement or fall. If there is a gap, it should be tightly plugged with a core brace sheet. The core brace should be plugged on the inner surface of the cavity. The supporting surface of the core brace should be in contact with the surface of the cavity or the sand core. It is more reliable to place the core brace on the inclined surface. There must be a sufficient number of core supports and they should be evenly distributed. The core stay cannot be put into the cavity prematurely to prevent water vapor from condensing on its surface and causing defects such as blowholes in the casting. 12. Air shovel: It is mainly used for deburring of casting sand and deburring of large, medium and small castings, shovel cutting of weld groove, correction of stone and concrete wall and brick wall opening work. 13. Tamping machine: powered by compressed air, it is suitable for tamping of sand castings of medium-sized castings, and can also be used for operations such as concrete and bricks.

1 note

·

View note

Link

Sai Converting - Get all contact details of trim winder machine manufacturers and suppliers in Ahmedabad, Gujarat, Delhi, India. Find latest info of trim winder machine in India.

#trim winder machine#trim winder machine manufacturers#trim winder machine suppliers#trim winder machine in India#trim winder machine manufacturers in Ahmedabad India

0 notes

Link

We have have been manufacturing, exporting and supplying are leading perfect quality Trim Rewinder Machine Manufacturer, Exporter and supplier for Paper, Film, LDPE, BOPP, HDPE, Polyester, Pouch, Trim Rewinder, Trim Winder Machine, Trim Winding Machine, Slitting Rewinder Machine, Trim Rewinder Machine Manufacturers, Slitter Machine Manufacturer, for different industry and different material. Heavy Duty equipment for high durability. Also, different type of heavy duty Pneumatic Brake Powder Brake.

#Trim Rewinder Machine#Trim Rewinder Machine Manufacturer#Trim Rewinder#Trim Winder Machine#Trim Winder Machine Manufacturer#Trim Winding Machine#Trim Winding Machine Manufacturer#Slitting Rewinder Machine#Slitting Rewinder Machine Manufacturer#Trim Rewinder Machine s#Trim Rewinder Machines#Trim Rewinder Machine Manufacturers#Slitter Machine Manufacturer

1 note

·

View note

Link

We are leading manufacturer, exporter, and supplier of Rewinder Unwinder Machine, Roll to Roll Processing Machines for various types of process like Rewinding Machine, Slitting Rewinding, Doctoring Rewinding, Winding Rewinding Machine, Winder Rewinder Machine, Jumbo Roll to Small Roll Rewinding machine, Folding, Fold Open, Converting, Corona Treatment, Inspection, Trim Rewinding Machine, Printing, Coating, Laminating, Flexo Printing, Batch Printing etc.

#Rewinder Unwinder Machine#Rewinder Unwinder Machine Manufacturer#Rewinder Unwinder#Unwinder Rewinder#Unwinder Rewinder Machine#Unwinder Rewinders#Rewinding Machine#Rewinding Machine Manufacturer#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding

1 note

·

View note