Text

Introducing our paddy straw dryer, a perfect blend of technology and efficiency. Designed to dry paper straws quickly and effectively, it ensures the straws maintain their shape and quality, ready for use. This machine is a must-have for businesses looking to provide eco-friendly alternatives to plastic straws. With its high drying capacity and energy-saving features, our Paper Straw Dryer not only helps in reducing your carbon footprint but also boosts your productivity. Choose Chuangfeng's Paper Straw Dryer, and take a step towards a greener and more sustainable future.

Advantages of Paper Straw Dryer

Our Paper Straw Dryer comes with a host of advantages that make it a standout choice for businesses.

Efficiency: With its high drying capacity, it can handle large volumes of paper straws, ensuring they are ready for use in no time.

Quality Assurance: The dryer is designed to maintain the shape and quality of the straws, preventing any deformation that can occur due to moisture.

Energy Saving: The machine operates on low energy consumption, making it an eco-friendly choice that helps reduce your carbon footprint.

Easy Operation: The Paper Straw Dryer is user-friendly with easy-to-understand controls, making it simple for anyone to operate.

Durability: Built with high-quality materials, the dryer is designed to last, providing a long-term solution for your paper straw drying needs.

Choose our Paper Straw Dryer, and experience the difference in quality, efficiency, and sustainability.

Function of Paper Straw Dryer

Our Paper Straw Dryer is a perfect blend of technology and efficiency, offering the following features:

Even Heating and Drying:

The paper core making machine ensures uniform heating, drying, and sterilization of paper straws, maintaining their shape and quality consistently.

Low-Temperature Sterilization for Commercial Asepsis:

Employing innovative low-temperature sterilization techniques, it achieves commercial-grade asepsis, promoting a healthier and safer usage of paper straws.

Versatile Functions - Drying, Sterilization, and Insect Eradication:

The dryer serves multiple purposes, functioning as a drying, sterilization, and insect eradication unit, providing energy efficiency and versatility.

Safety, Hygiene, and Eco-Friendliness:

Operating with safety and hygiene in mind, the machine is free from pollution. It offers flexible and convenient operation, easy control, and occupies minimal floor space.

0 notes

Text

Our paper straw single packaging machine is designed for environmental protection. Using advanced automation technology, each paper straw can be individually packaged quickly and accurately to ensure its hygiene and safety. Whether it's a restaurant, cafe or fast food restaurant, it can easily handle heavy use needs. Choose our pindividual straw packing machine to make every use full of environmental awareness and let us protect our earth together.

How Does Our Individual Straw Ping Machine Work?

Adopted with PLC controller; the main motor is equipped with variable frequency speed regulation; touch screen man-machine interface. Easy for parameters setting & operating.

The cutting section of our straw manufacturing machine adopted with numerical multi-blades cutting system. Servo synchronous tracking cutting system makes it higher precision and multi-blades cutting makes it higher efficient.

The single straw packing machine's body and main spare parts are made of stainless steel instead of painting. Ensure the hygiene and environmental protection of the products.

What to Expect from Our Paper Straw-Making Machines?

Embrace eco-friendliness with confidence by choosing our advanced individual straw packing machine from Chuangfeng. Here's what you can expect:

Cutting-Edge Technology: Our single straw packing machines incorporate state-of-the-art technology, ensuring the production of top-quality paper straws that are sturdy and durable.

Environmentally Conscious Production: Start your journey towards environmental conservation with small, yet impactful steps. Our paper straw packing machine craft paper straws, providing a sustainable alternative to traditional plastic straws.

High-Quality Output: Experience the excellence of Chuangfeng's machinery through the production of high-quality, reliable paper straws. Enjoy your drinks guilt-free, knowing you're contributing to a greener planet.

Expertise in Manufacturing: As one of the most professional paper straw and paper tube machines suppliers in China, Chuangfeng brings years of experience and expertise to the table, ensuring reliable and efficient equipment.

Unique Advantages: Benefit from Chuangfeng's distinctive advantages in paper straw and tube equipment manufacturing, setting us apart from others in the industry.

Make a conscious choice for the environment—choose Chuangfeng's Paper Straw Making Machines and make sustainability a way of life.

0 notes

Text

Environmentally friendly, start with a small paper straw. Our machine to make paper straws uses advanced technology to produce high-quality, sturdy, and durable paper straws, allowing you to enjoy your drinks while also contributing to the earth. Let us work together to protect the environment with practical actions, starting with using paper straws. Choose our paper straw manufacturing machine and make environmental protection a way of life.

Chuangfeng, one of the most professional paper straw and paper tube machine suppliers in China, has a lot of experience in China paper straw and tube equipment manufacturing. With years of production and practice, Chuangfeng has formed its advantages different from other paper straw and paper tube machine.

How Does Our Paper Straw-Making Machine Work?

Our paper straw-making machine is a specialized piece of equipment designed to produce paper straws efficiently and effectively. Here's a detailed explanation of how it operates:

The paper is rapidly fed through the paper feeder while the glue feeder ensures a consistent temperature to automatically stabilize the glue amount.

The High-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

Paper-making straws are dried by the electric dryer before being shaped into bendable grooves by the flexible bending machine.

The straws are then transported to the Paper straw dryer via a conveyor belt for further drying.

Finally, the Packaging machine processes the bendable straws into a U-shape, slices the bottom to create a bevel cut, and individually packs the U-shaped paper straws using BOPP film.

What to Expect from Our Paper Straw Making Machines?

To ensure environmental protection, paper straws produced by paper straw-making machines, particularly biodegradable ones, surpass plastic straws in sustainability. With the growing focus on environmentalism, these straws are poised to become the prevailing choice in the future.

As a result, there will be a significant increase in demand for paper straw-making machines compared to those for plastic straws. Currently, numerous industries are entering the paper straw manufacturing sector due to the substantial demand across various industries.

If you're considering establishing a paper straw manufacturing unit, the necessity for a paper straw-making machine is evident. These machines come in a variety of types, including manual, semi-automatic, and fully automatic models.

Available at different price points, you can select a machine that aligns with your business requirements and financial constraints. Purchasing from Chuangfeng, a reputable company, ensures access to high-quality, high-performance, and high-capacity paper straw-making machines for your operations.

Features of Paper Drinking Straws

The paper drinking straws crafted using our paper straw-making machine boast the following characteristics:

Longevity: When immersed in a beverage at a steady temperature, these paper straws can maintain their integrity for 2-3 hours without succumbing to sogginess. However, exposure to extremely hot or cold drinks may shorten their lifespan compared to usage at room temperature.

Environmentally Friendly: Paper straws unquestionably outshine plastic alternatives in terms of environmental friendliness. Increased usage of paper straws can significantly reduce the adverse impact on marine life, leading to a decline in deaths caused by plastic pollution. Studies indicate that even when disposed of outdoors, paper straws decompose entirely within 6 months, posing no threat to the environment.

Coated Paper Drinking Straws: Our paper straws are coated with water-based glue, also known as water-based adhesives, to enhance their durability and performance.

Paper Straw Making Machine Cost

The price of a paper straw manufacturing machine in China can vary significantly based on factors such as the machine's automatic paper splicing function and overall quality.

To better understand the pricing of paper straw-making machines in China, it's essential to determine your specific requirements for the machine.

Comparatively, a plastic straw costs approximately RMB 0.03, while a paper straw typically costs around RMB 0.1, representing a difference of more than threefold.

Indeed, paper straws come with a higher cost, and there is room for improvement in terms of user experience. However, certain industry insiders and experts suggest that finding environmentally friendly alternatives to plastic straws is feasible through the breakthrough and development of new materials and technologies.

Materials such as biodegradable bioplastics, paper, bamboo, wheat, various plant stalks, glass, metal, and other recyclable products can serve as substitutes for plastic, contributing to environmental sustainability.

0 notes

Text

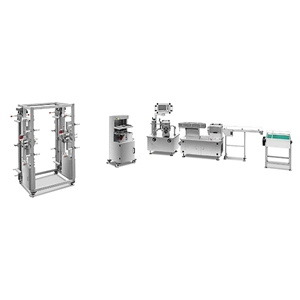

A U-shaped paper straw production line produces paper straws by winding, cutting, drying, bending, and packaging at one time.

U Shape Paper Straw Production Process:

1. The paper is swiftly fed through the paper feeder at high velocity, while the glue feeder automatically applies glue at a consistent temperature to stabilize the amount.

2. The CFXG-80 high-speed paper straw-making machine high-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

3. Following drying in the CFHG-50 paper straw dryer, and the CFBD-50 flexible bending machine creates bendable corrugations in the paper straws.

4. Finally, the CFPK-033 packaging machine processes the bendable straws into a U-shaped form, slices the straws into sharp shapes, and individually packs the U-shaped paper straws using BOPP film.

Key Components of U-shape Paper Straw Production Line:

Paper straw making machine: This machine forms the basic structure of the paper straw using paper rolls, adhesive, and other necessary materials.

Cutting machine: Responsible for cutting the paper straws to the desired length, including the U-shaped bend.

Drying machine: Used to dry the paper straws after production to ensure they maintain their structural integrity.

Bending machine: This machine adds the U-shaped bend to the paper straws, giving them their distinctive shape.

Packaging machine: Finally, the paper straws are packaged into bundles or boxes for distribution and sale.

The entire production line can realize high-intelligence production, and the entire assembly line can operate automatically, enabling one person to operate multiple machines. During the production process, failures such as pipe blockage and paper break will automatically stop, without the need for personnel to keep watch.

0 notes

Text

Environmentally friendly, start with a small paper straw. Our paper straw maker machine uses advanced technology to produce high-quality, sturdy, and durable paper straws, allowing you to enjoy your drinks while also contributing to the earth. Let us work together to protect the environment with practical actions, starting with using paper straws. Choose our paper straw manufacturing machine and make environmental protection a way of life.

Chuangfeng, one of the most professional paper straw and paper tube machine suppliers in China, has a lot of experience in China paper straw and tube equipment manufacturing. With years of production and practice, Chuangfeng has formed its advantages different from other paper straw and paper tube machine.

How Does Our Paper Straw-Making Machine Work?

Our paper straw-making machine is a specialized piece of equipment designed to produce paper straws efficiently and effectively. Here's a detailed explanation of how it operates:

The paper is rapidly fed through the paper feeder while the glue feeder ensures a consistent temperature to automatically stabilize the glue amount.

The High-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

Paper-making straws are dried by the electric dryer before being shaped into bendable grooves by the flexible bending machine.

The straws are then transported to the Paper straw dryer via a conveyor belt for further drying.

Finally, the Packaging machine processes the bendable straws into a U-shape, slices the bottom to create a bevel cut, and individually packs the U-shaped paper straws using BOPP film.

What to Expect from Our Paper Straw Making Machines?

To ensure environmental protection, paper straws produced by paper straw-making machines, particularly biodegradable ones, surpass plastic straws in sustainability. With the growing focus on environmentalism, these straws are poised to become the prevailing choice in the future.

As a result, there will be a significant increase in demand for paper straw-making machines compared to those for plastic straws. Currently, numerous industries are entering the paper straw manufacturing sector due to the substantial demand across various industries.

If you're considering establishing a paper straw manufacturing unit, the necessity for a paper straw-making machine is evident. These machines come in a variety of types, including manual, semi-automatic, and fully automatic models.

Available at different price points, you can select a machine that aligns with your business requirements and financial constraints. Purchasing from Chuangfeng, a reputable company, ensures access to high-quality, high-performance, and high-capacity paper straw-making machines for your operations.

Features of Paper Drinking Straws

The paper drinking straws crafted using our paper straw-making machine boast the following characteristics:

Longevity: When immersed in a beverage at a steady temperature, these paper straws can maintain their integrity for 2-3 hours without succumbing to sogginess. However, exposure to extremely hot or cold drinks may shorten their lifespan compared to usage at room temperature.

Environmentally Friendly: Paper straws unquestionably outshine plastic alternatives in terms of environmental friendliness. Increased usage of paper straws can significantly reduce the adverse impact on marine life, leading to a decline in deaths caused by plastic pollution. Studies indicate that even when disposed of outdoors, paper straws decompose entirely within 6 months, posing no threat to the environment.

Coated Paper Drinking Straws: Our paper straws are coated with water-based glue, also known as water-based adhesives, to enhance their durability and performance.

Paper Straw Making Machine Cost

The price of a paper straw manufacturing machine in China can vary significantly based on factors such as the machine's automatic paper splicing function and overall quality.

To better understand the pricing of paper straw-making machines in China, it's essential to determine your specific requirements for the machine.

Comparatively, a plastic straw costs approximately RMB 0.03, while a paper straw typically costs around RMB 0.1, representing a difference of more than threefold.

Indeed, paper straws come with a higher cost, and there is room for improvement in terms of user experience. However, certain industry insiders and experts suggest that finding environmentally friendly alternatives to plastic straws is feasible through the breakthrough and development of new materials and technologies.

Materials such as biodegradable bioplastics, paper, bamboo, wheat, various plant stalks, glass, metal, and other recyclable products can serve as substitutes for plastic, contributing to environmental sustainability.

0 notes

Text

A U-shaped paper straw production line produces paper straws by winding, cutting, drying, bending, and packaging at one time.

U Shape Paper Straw Production Process:

1. The paper is swiftly fed through the paper feeder at high velocity, while the glue feeder automatically applies glue at a consistent temperature to stabilize the amount.

2. The CFXG-80 high-speed paper straw-making machine high-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

3. Following drying in the CFHG-50 paper straw dryer, and the CFBD-50 flexible bending machine creates bendable corrugations in the paper straws.

4. Finally, the CFPK-033 packaging machine processes the bendable straws into a U-shaped form, slices the straws into sharp shapes, and individually packs the U-shaped paper straws using BOPP film.

Key Components of U-shape Paper Straw Production Line:

Paper straw making machine: This straw paper machine forms the basic structure of the paper straw using paper rolls, adhesive, and other necessary materials.

Cutting machine: Responsible for cutting the paper straws to the desired length, including the U-shaped bend.

Drying machine: Used to dry the paper straws after production to ensure they maintain their structural integrity.

Bending machine: This machine adds the U-shaped bend to the paper straws, giving them their distinctive shape.

Packaging machine: Finally, the paper straws are packaged into bundles or boxes for distribution and sale.

The entire production line can realize high-intelligence production, and the entire assembly line can operate automatically, enabling one person to operate multiple machines. During the production process, failures such as pipe blockage and paper break will automatically stop, without the need for personnel to keep watch.

0 notes

Text

Environmentally friendly, start with a small paper straw. Our paper straw maker machine uses advanced technology to produce high-quality, sturdy, and durable paper straws, allowing you to enjoy your drinks while also contributing to the earth. Let us work together to protect the environment with practical actions, starting with using paper straws. Choose our paper straw manufacturing machine and make environmental protection a way of life.

Chuangfeng, one of the most professional paper straw machine manufacturers in China, has a lot of experience in China paper straw and tube equipment manufacturing. With years of production and practice, Chuangfeng has formed its advantages different from other paper straw and paper tube machine.

How Does Our Paper Straw-Making Machine Work?

Our paper straw machine china is a specialized piece of equipment designed to produce paper straws efficiently and effectively. Here's a detailed explanation of how it operates:

The paper is rapidly fed through the paper feeder while the glue feeder ensures a consistent temperature to automatically stabilize the glue amount.

The High-speed paper straw machine winds and forms the adhesive paper layer, enabling multi-section cutting in a single operation.

Paper-making straws are dried by the electric dryer before being shaped into bendable grooves by the flexible bending machine.

The straws are then transported to the Paper straw dryer via a conveyor belt for further drying.

Finally, the Packaging machine processes the bendable straws into a U-shape, slices the bottom to create a bevel cut, and individually packs the U-shaped paper straws using BOPP film.

What to Expect from Our Paper Straw Making Machines?

To ensure environmental protection, paper straws produced by paper straw-making machines, particularly biodegradable ones, surpass plastic straws in sustainability. With the growing focus on environmentalism, these straws are poised to become the prevailing choice in the future.

As a result, there will be a significant increase in demand for paper straw-making machines compared to those for plastic straws. Currently, numerous industries are entering the paper straw manufacturing sector due to the substantial demand across various industries.

If you're considering establishing a paper straw manufacturing unit, the necessity for a paper straw-making machine is evident. These machines come in a variety of types, including manual, semi-automatic, and fully automatic models.

Available at different price points, you can select a machine that aligns with your business requirements and financial constraints. Purchasing from Chuangfeng, a reputable company, ensures access to high-quality, high-performance, and high-capacity paper straw-making machines for your operations.

Features of Paper Drinking Straws

The paper drinking straws crafted using our paper straw-making machine boast the following characteristics:

Longevity: When immersed in a beverage at a steady temperature, these paper straws can maintain their integrity for 2-3 hours without succumbing to sogginess. However, exposure to extremely hot or cold drinks may shorten their lifespan compared to usage at room temperature.

Environmentally Friendly: Paper straws unquestionably outshine plastic alternatives in terms of environmental friendliness. Increased usage of paper straws can significantly reduce the adverse impact on marine life, leading to a decline in deaths caused by plastic pollution. Studies indicate that even when disposed of outdoors, paper straws decompose entirely within 6 months, posing no threat to the environment.

Coated Paper Drinking Straws: Our paper straws are coated with water-based glue, also known as water-based adhesives, to enhance their durability and performance.

Paper Straw Making Machine Cost

The price of a paper straw manufacturing machine in China can vary significantly based on factors such as the machine's automatic paper splicing function and overall quality.

To better understand the pricing of paper straw-making machines in China, it's essential to determine your specific requirements for the machine.

Comparatively, a plastic straw costs approximately RMB 0.03, while a paper straw typically costs around RMB 0.1, representing a difference of more than threefold.

Indeed, paper straws come with a higher cost, and there is room for improvement in terms of user experience. However, certain industry insiders and experts suggest that finding environmentally friendly alternatives to plastic straws is feasible through the breakthrough and development of new materials and technologies.

Materials such as biodegradable bioplastics, paper, bamboo, wheat, various plant stalks, glass, metal, and other recyclable products can serve as substitutes for plastic, contributing to environmental sustainability.

0 notes

Text

The automatic paper tube labeling machine is a specialized piece of equipment designed to apply labels to paper tubes accurately and efficiently. This machine is commonly used in industries such as packaging, cosmetics, food and beverage, pharmaceuticals, and more, where labeled paper tubes are required.

Here's a brief overview of its functionality:

Material Loading: The process begins by loading the paper tubes into the machine. This can be done manually or automatically, depending on the machine model.

Label Application: The machine applies labels to the paper tubes using a variety of methods, such as pressure-sensitive adhesives, hot melt adhesives, or shrink sleeve labeling. The labels can be applied to any part of the tube, including the body, cap, or bottom.

Precision and Speed: The machine is designed to apply labels accurately and quickly, ensuring that each label is perfectly positioned and adhered. This precision and speed are crucial in maintaining high-quality standards and meeting production deadlines.

Quality Control: Many machines come with built-in quality control features that check for any irregularities or defects in the labeled tubes. This ensures that only high-quality products reach the end of the production line.

Collection: After the tubes are labeled, they are collected in a bin or on a conveyor belt. Some machines also have an automatic sorting feature that separates the tubes based on their sizes or labels.

As a common type of paper tube machine, the paper tube labeling machine is known for its efficiency, accuracy, and speed, capable of labeling large quantities of tubes in a short time. It's a valuable asset for businesses looking to streamline their production process and improve productivity. The machine's robust construction also ensures long-term durability, making it a worthwhile investment.

How Does Paper Tube Labeling Machine Ensure Accurate Branding?

The Paper Tube Labeling Machine plays a crucial role in ensuring accurate branding, which is vital for product recognition and marketing. Here’s how it achieves this:

Precision Label Placement: The machine is designed to apply labels accurately on the paper tubes. It ensures that each label is perfectly positioned, maintaining consistency across all products. This precision is crucial for maintaining a professional and consistent brand image.

High-Quality Label Application: The machine applies labels using various methods such as pressure-sensitive adhesives, hot melt adhesives, or shrink sleeve labeling. These methods ensure that the labels are securely adhered to the tubes and won’t peel off, fade, or get damaged during handling or transportation.

Versatility: The machine can handle a wide range of paper tube sizes and label designs. This versatility allows businesses to use different labels for different products, ensuring accurate branding for each product line.

Speed and Efficiency: The paper core machine can label a large number of tubes in a short time, ensuring that high volumes of products are branded accurately and quickly. This efficiency is crucial for meeting production deadlines and maintaining a steady supply of branded products in the market.

Quality Control: Many models come with built-in quality control features that check for any irregularities or defects in the labeled tubes. This ensures that only high-quality, accurately branded products reach the end of the production line.

In conclusion, the Paper Tube Labeling Machine ensures accurate branding by providing precision label placement, high-quality label application, versatility, speed, and quality control. It’s an invaluable tool for businesses looking to maintain a consistent and professional brand image.

Working Principle of Paper Tube Labeling Machine

The Paper Tube Labeling Machine operates on a sophisticated principle to ensure precise and efficient application of labels onto paper tubes in various industries:

Sensor Technology: Equipped with advanced sensors, the machine detects the position and orientation of each paper tube, ensuring accurate label placement.

Label Dispensing Mechanism: The labeling machine utilizes a precision label dispensing system that releases labels at the right moment, synchronizing with the speed and movement of the paper tubes.

Adaptive Adjustments: To accommodate different tube sizes, the machine often features adjustable settings, allowing quick and easy configuration for various diameters and lengths.

Roller and Belt System: A combination of rollers and belts moves the paper tubes through the labeling process, maintaining stability and preventing misalignment.

User-Friendly Interface: Typically, these machines come with an intuitive interface, enabling operators to set parameters, monitor the process, and make adjustments seamlessly.

High-Speed Operation: Designed for efficiency, the Paper Tube Labeling Machine operates at high speeds, contributing to increased production rates while maintaining labeling precision.

0 notes

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Text

A small paper tube cutting machine is a specialized piece of equipment designed to cut paper tubes or cores into precise lengths. This machine is essential in various industries, including textile, paper, printing, packaging, and more.

Here's a brief overview of its functionality:

Material Loading: The process begins by loading the paper tube or core into the machine. This can be done manually or automatically, depending on the machine model.

Setting the Length: The operator sets the desired length for the cut. Most machines have a digital control panel where you can input the exact measurements, ensuring high precision in every cut.

Cutting Process: The machine uses a sharp, durable blade to cut the paper tube. The cutting can be done either by a rotating blade, a guillotine-style blade, or a saw blade, depending on the machine model and the thickness of the paper tube.

Collection: After the tubes are cut, they are collected in a bin or on a conveyor belt. Some machines also have an automatic sorting feature that separates the tubes based on their sizes.

Quality Control: Many machines come with built-in quality control features that check for any irregularities or defects in the cut tubes.

The Paper Tube Cutting Machine is known for its efficiency, accuracy, and speed, capable of producing large quantities of cut tubes in a short time. It's a valuable asset for businesses looking to streamline their production process and improve productivity. The paper tube machine's robust construction also ensures long-term durability, making it a worthwhile investment.

Adaptable Designs and Customization Options of Paper Tube Cutting Machine

Paper Tube Cutting Machines are not only efficient and precise but also highly adaptable and customizable. They are designed to cater to a wide range of industries and applications, making them a versatile choice for businesses of all sizes. Here’s a look at the adaptable designs and customization options of these machines:

Size and Capacity: Paper Tube Cutting Machines come in various sizes and capacities to accommodate different production needs. Whether you need to cut small paper cores for thermal rolls or large paper tubes for industrial packaging, there’s a machine designed to meet your specific requirements.

Cutting Mechanism: Depending on the thickness and material of the paper tube, you can choose from different cutting mechanisms. These include rotating blades, guillotine-style blades, or saw blades. Some machines even offer interchangeable blades for added flexibility.

Control System: Most paper core machine feature a digital control system that allows you to set the exact length for the cut. Some advanced models may also offer programmable controls, where you can save your settings for future use.

Automation Level: From semi-automatic to fully automatic models, you can choose the level of automation that suits your production process. Fully automatic machines can load, cut, and sort the tubes with minimal human intervention, saving time and labor costs.

Custom Features: Many manufacturers offer custom features to meet unique business needs. These may include special safety features, dust extraction systems, automatic sorting mechanisms, and more.

With these adaptable designs and customization options, Paper Tube Cutting Machines can be tailored to fit your business needs perfectly. They offer a practical and efficient solution to cut paper tubes or cores accurately and quickly, enhancing your production efficiency and profitability.

Advanced Cutting Mechanisms in Our Paper Tube Cutting Machine

Our Paper Tube Cutting Machine stands as a pinnacle of precision and efficiency with its advanced cutting mechanisms. Specifically engineered for cutting paper tubes or cores into exact lengths, this specialized equipment plays a pivotal role across diverse industries. From textiles to paper, printing, and packaging, its versatility meets the demands of varied applications. The machine incorporates cutting-edge technology, ensuring accuracy and reliability in every operation. Whether crafting customized tubes for packaging or contributing to the seamless production processes in printing, our Paper Tube Cutting Machine signifies a commitment to excellence, streamlining workflows and enhancing overall productivity across multiple sectors.

0 notes

Text

The Chuangfeng paper tube manufacturing machine is a high-performance, efficient machine designed for the production of paper tubes. This paper pipe-making machine is renowned for its high-speed operation, precision engineering, and reliable performance. It is capable of producing a large number of paper tubes quickly and efficiently, making it an ideal choice for businesses in various industries such as packaging, textiles, and more.

Paper Tube-Making Machine Features:

The paper pipe making machine are suitable for Large & Thick cores like Stretch Film cores and Strong Industrial paper tubes & cores etc.

The main structure is constructed using thicker steel, which undergoes re-cutting and welding processes, ensuring enhanced stability and strength of the machine.

The main transmission utilizes gear speed reduction, resulting in low noise, minimal heat generation, high revolutions, and high torque.

The main motor employs a Vectorial high-torque inverter for speed adjustment.

It is outfitted with a hydraulic device for belt tension adjustment, featuring sensors for both belt tension and angle, allowing for automatic adjustments.

The machine is equipped with a synchronous cutting system, employing high-precision ball screws and high-performance servo motor drive for the cutting table.

A pulse length fixation control system, coupled with front feedback compensation functionality, ensures consistent length production across varying speeds.

Contact Chuangfeng for the paper tube-making machine price price!

Revolutionizing Sustainable Packaging with China Paper Tube Making Machines

Transform your brand's packaging sustainability effortlessly with our state-of-the-art Paper Tube Making Machines. Ideal for various applications, the paper pipe machine caters to industries such as cosmetics, food, and pharmaceuticals. Customize the diameter, length, and design of paper tubes to suit your product specifications. Revolutionize your cosmetic line by presenting products in eco-friendly paper tubes, promoting a luxurious yet sustainable image. In the food industry, our kraft paper tube-making machines enable the creation of sturdy, grease-resistant paper tubes for snacks and confectionery. For pharmaceuticals, ensure the safe and eco-conscious packaging of medicines.

Beyond versatility, our paper pipe-making machines significantly reduce waste and carbon footprint, contributing to a circular economy. Embrace the innovation of sustainable packaging that not only meets industry standards but exceeds them. Upgrade your packaging strategy with our Paper Tube Making Machines and make a lasting impression as an environmentally responsible brand, meeting the demands of conscious consumers.

0 notes

Text

Introducing our high-quality Paper Tube Machine, a perfect solution for all your paper tube production needs. This paper tube-forming machine is designed to produce paper tubes with precision and efficiency. It's capable of producing 20-100 paper tubes per minute, ensuring high productivity for your business. With its robust construction and easy operation, our paper pipe machine guarantees durability and reliability. Invest in our Paper Tube Machine and experience a significant boost in your production process.

As a professional paper tube machine manufacturer, Chuangfeng has decades of experience in paper tube machine projects, like the production line of food paper cans, potato paper cans, textile paper tubes, industrial paper tubes, etc. A comprehensive automatic tube-filling machine line to meet your needs.

Paper Tube Forming Machine Performance & Characteristics

The paper tube forming machine are suitable for Large & Thick cores like Stretch Film cores and Strong Industrial paper tubes & cores etc.

The main motor of the paper tube packaging machine is equipped with variable frequency speed regulation; and a touchscreen man-machine interface. Easy for parameters setting & operating.

The Servo motor synchronism tracking cutting system lets the core pipe-making machine cut at a higher precision; with an error of ≤ 0.15mm.

All the brands of components like Motor; Inverter; PLC; and Touch Screen can be customized.

Contact us for the paper tube machine price!

Test Standard of Paper Tube Machine

Complies with the provisions of the following European directives:

Machinery Directive 2006/42/EC

Electromagnetic Compatibility Directive 2014/30/EU

EN ISO 12100:2010

EN 415-10:2014

EN 60204-1:2018

EN IEC 61000-3-2:2019+A1:2021

EN 61000-3-3:2013+A2:2021

EN IEC 61000-6-1:2019

EN IEC 61000-6-3:2021

1 note

·

View note