#metal additive manufacturing applications

Photo

metal parts manufacturing companies

#what is metal additive manufacturing#metal parts#post processing of 3d printed#metals manufacturing company#metal products manufacturers#metal parts manufacturing companies#metal manufacturers in india#metal companies in india#metal additive manufacturing systems#metal additive manufacturing services#metal additive manufacturing service providers#metal additive manufacturing post processing#metal additive manufacturing materials#metal additive manufacturing machine#metal additive manufacturing in india#metal additive manufacturing companies#metal additive manufacturing applications#metal additive manufacturing#metal 3d printing services in india#metal 3d printing service bangalore#metal 3d printing raw material#metal 3d printing rapid prototyping#metal 3d printing process#metal 3d printing post processing#metal 3d printing manufacturing#metal 3d printing india#metal 3d printing in rapid prototyping#metal 3d printing in mumbai

0 notes

Text

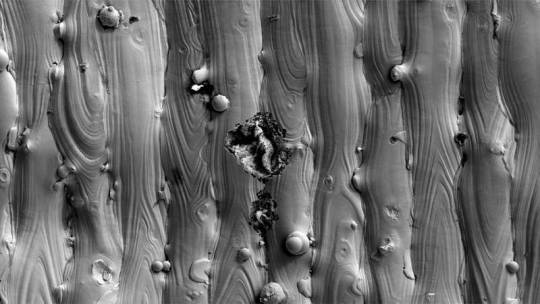

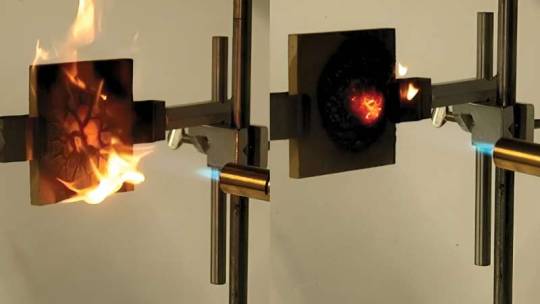

Researchers uncover culprits behind pitting corrosion in 3D-printed stainless steel

Like a hidden enemy, pitting corrosion attacks metal surfaces, making it difficult to detect and control. This type of corrosion, primarily caused by prolonged contact with seawater in nature, is especially problematic for naval vessels.

In a recent paper published in Nature Communications, Lawrence Livermore National Laboratory (LLNL) scientists delved into the mysterious world of pitting corrosion in additively manufactured (3D-printed) stainless steel 316L in seawater.

Stainless steel 316L is a popular choice for marine applications due to its excellent combination of mechanical strength and corrosion resistance. This holds even more true after 3D printing, but even this resilient material isn't immune to the scourge of pitting corrosion.

Read more.

#Materials Science#Science#Corrosion#3D printing#Additive manufacturing#Stainless steel#Steel#Materials Characterization

10 notes

·

View notes

Text

by Australian Institute for Bioengineering and Nanotechnology (AIBN)

Researchers at The University of Queensland (UQ) are developing new 4D printing technology that produces shape-shifting liquid metals for soft robotics.

4D printing is an extension of 3D printing, where solid objects are created using materials that can change shape when exposed to certain stimuli like heat, water or light.

At UQ's Australian Institute for Bioengineering and Nanotechnology (AIBN), researchers are printing 4D structures using new liquid metal polymers that can be coaxed into performing a range of mechanical tasks with infrared lasers.

Lead researchers Dr. Liwen Zhang and Dr. Ruirui Qiao said the unique preparation methods developed by their lab allow them to produce 4D designs that are solid and durable while also being able to bend, grasp, lift, and release items five times their weight, or revert to a pre-programmed shape.

"4D printing takes traditional 3D printing and adds a new dimension—the dimension of time," Dr. Zhang said. "Our method allows us to produce smart liquid metals that can be customized, shaped and prompted to change over time without needing wires or circuits.

"This is a new era for robotics applications and a game-changer for additive manufacturing."

4D printed objects are usually prepared with a 3D printer using specific ingredients that give the finished product new qualities and abilities.

#robot#robotics#3d printing#Australian Institute for Bioengineering and Nanotechnology#soft robotics

14 notes

·

View notes

Text

Homebrew Magic Items (5e): Grave Knight’s Regalia

Despite the lofty titling, the ‘regalia’ of a grave knight is usually quite far from fine. Formed during and in the aftermath of the great necromantic plagues, the grave knights were something between a mendicant chivalrous order, a collective of mercenaries, and a series of local militias, all trained and more importantly equipped with the sole aim of laying or destroying unquiet dead. While many localised knights were simply local villagers or watchmen trained and outfitted for the purpose, for almost four centuries a core mendicant order of true knights have also existed, and it is this core of knights who train others and maintain the knowledge and manufacture of the ‘knightly regalia’, or the standard equipment of a grave knight.

(Or, have a set of gothic inspired magic items for equipping graveyard knights. Not necessarily paladins, just any poor sod who wound up having to deal with undead a lot, and asked the help of the local travelling knightly order to tool up for the task. Brought to you by my sister pointing out that a lot of the more elaborate wrought iron railing toppers you see in graveyards would make boss gothic weaponry).

GRAVE IRONS

Weapon (Mace), Rare

The signature weapon of the grave knights, grave irons were maces made from grave iron, the wrought iron surrounds of sanctified or hallowed graves. Typically the mace heads were formed either by wrapping bands of reshaped grave iron around a wooden or iron ball, or, more ornately, by strengthening the elaborate wrought iron railing tops to withstand impacts. The heads were then affixed to sturdy wooden or metal hafts for use.

The wielder of a grave iron gains a +1 bonus to attack and damage rolls with this magic weapon. Additionally, on a successful hit against an undead creature with a grave iron, the creature takes an additional 2d6 bludgeoning damage, and its movement speed is halved until the end of the wielder’s next turn, as the iron attempts to bind the undead creature back into its earthly grave.

GAUNTLETS OF GENTLING

Wonderous Item, Rare

These worn steel gauntlets also bear a thin band of grave iron at the wrist, and grant a +1 bonus to AC while worn. The gauntlets have six charges, and regain all spent charges every day at dawn. While wearing the gauntlets, the wearer can use an action to expend a charge and cast the Gentle Repose spell, without the need for material components.

EERIE OINTMENT

Potion, Rare

Grave knights carried small, sturdy earthenware jars containing a silvery ointment. A knight could use an action to smear the ointment beneath their eyes, granting them the ability to see 60ft into the ethereal plane while on the material plane, and vice versa, for 1 hour after application. The jars typically held enough ointment for 10 applications, after which a new batch of ointment would need to be made or purchased.

KNIGHT’S ASPERGILLUM

Wonderous Item, Rare

One of the finest tools in the grave knights’ armoury, the knight’s aspergillum is a small, hollow, perforated metal ball on a wooden handle. The ball contains an internal silvered reservoir which can be filled with water. Any water which is kept in the aspergillum for 24 hours becomes holy water. A knight can use a bonus action to flick holy water from the aspergillum towards a fiendish or undead creature within 10ft, making a ranged attack roll against that creature, which deals 2d6 radiant damage on a hit. The aspergillum’s reservoir holds enough water to make three such attacks before it must be refilled.

8 notes

·

View notes

Text

youtube

NASA's innovative rocket nozzle paves way for deep space missions

NASA recently built and tested an additively-manufactured—or 3D printed—rocket engine nozzle made of aluminum, making it lighter than conventional nozzles and setting the course for deep space flights that can carry more payloads.

Under the agency's Announcement of Collaborative Opportunity, engineers from NASA's Marshall Space Flight Center in Huntsville, Alabama, partnered with Elementum 3D, in Erie, Colorado, to create a weldable type of aluminum that is heat resistant enough for use on rocket engines. Compared to other metals, aluminum is lower density and allows for high-strength, lightweight components.

However, due to its low tolerance to extreme heat and its tendency to crack during welding, aluminum is not typically used for additive manufacturing of rocket engine parts—until now.

Meet NASA's latest development under the Reactive Additive Manufacturing for the Fourth Industrial Revolution, or RAMFIRE, project. RAMFIRE focuses on advancing lightweight, additively-manufactured aluminum rocket nozzles. The nozzles are designed with small internal channels that keep the nozzle cool enough to prevent melting.

With conventional manufacturing methods, a nozzle may require as many as thousand individually joined parts. The RAMFIRE nozzle is built as a single piece, requiring far fewer bonds and significantly reduced manufacturing time.

NASA and Elementum 3D first developed the novel aluminum variant known as A6061-RAM2 to build the nozzle and modify the powder used with laser powder directed energy deposition (LP-DED) technology. Another commercial partner, RPM Innovations (RPMI) in Rapid City, South Dakota, used the newly invented aluminum and specialized powder to build the RAMFIRE nozzles using their LP-DED process.

"Industry partnerships with specialty manufacturing vendors aid in advancing the supply base and help make additive manufacturing more accessible for NASA missions and the broader commercial and aerospace industry," Paul Gradl, RAMFIRE principal investigator at NASA Marshall, said.

NASA's moon to Mars objectives require the capability to send more cargo to deep space destinations. The novel alloy could play an instrumental role in this by enabling the manufacturing of lightweight rocket components capable of withstanding high structural loads.

"Mass is critical for NASA's future deep space missions," said John Vickers, principal technologist for STMD advanced manufacturing. "Projects like this mature additive manufacturing along with advanced materials, and will help evolve new propulsion systems, in-space manufacturing, and infrastructure needed for NASA's ambitious missions to the moon, Mars, and beyond."

Earlier this summer at Marshall's East Test Area, two RAMFIRE nozzles completed multiple hot-fire tests using liquid oxygen and liquid hydrogen, as well as liquid oxygen and liquid methane fuel configurations. With pressure chambers in excess of 825 pounds per square inch (psi)—more than anticipated testing pressures—the nozzles successfully accumulated 22 starts and 579 seconds, or nearly 10 minutes, of run time. This event demonstrates the nozzles can operate in the most demanding deep-space environments.

"This test series marks a significant milestone for the nozzle," Gradl said. "After putting the nozzle through the paces of a demanding hot-fire test series, we've demonstrated the nozzle can survive the thermal, structural, and pressure loads for a lunar lander scale engine."

In addition to successfully building and testing the rocket engine nozzles, the RAMFIRE project has used the RAMFIRE aluminum material and additive manufacturing process to construct other advanced large components for demonstration purposes. These include a 36-inch diameter aerospike nozzle with complex integral coolant channels and a vacuum-jacketed tank for cryogenic fluid applications.

NASA and industry partners are working to share the data and process with commercial stakeholders and academia. Various aerospace companies are evaluating the novel alloy and the LP-DED additive manufacturing process and looking for ways it can be used to make components for satellites and other applications.

12 notes

·

View notes

Text

Rubber Elastomer Washers

Specializing in quick turnaround of thin-gauge components, Mercer Gasket & Shim provides world-class laser chopping providers for applications where precision is a high precedence and quality is essential. Metal gaskets is a term often used to describe any measurement of gasket, shim or washer that is manufactured from elemental metals or alloys such as metal, brass or titanium. Specialist metal alloys such as Inconel, which is composed of nickel, chromium and iron, have properties suited to processes that endure excessive pressures or temperatures. They have offered superior performance and products for our doors as properly and lots of of weird requests from us making an attempt to care for our prospects. The employees are very hardworking and professional and can do what it takes to get the job done.

Goodrich Gasket delivers premium quality gaskets that ensures performance, safer operation and reliability. Regardless the kind, the gaskets are personalized to specifically go nicely with the client specifications and space of utility to speed up the efficiency with usage of the best materials. Polyurethane products often are called “urethanes”, they're a particularly numerous product as a end result of multiple ways it can be configured during manufacturing. Polyurethane materials are a fantastic selection when pondering of your next sealing product utility.

Custom Gasket Manufacturing also presents custom rubber molding and extrusion companies for extra complicated, 3D geometries. It’s necessary to notice that rubber just isn't a single material, however instead a broad class of elastomers with totally different bodily traits. Industrial purchasers should contemplate any needed corrosion and temperature resistance properties and select a rubber accordingly. Available in 10 metre rolls, metre lengths, strips, washers or cut to order in normal or non commonplace gaskets. Industrial Gaskets manufactures commonplace Imperial rubber washers as nicely as Metric rubber washers.

Mercer Gasket & Shim is provided with new, state-of-the-art router slicing tools. Mercer Gasket & Shim’s waterjet cutting service presents a fast, versatile, and correct technique for fabricating advanced or difficult components while maintaining the integrity of the material. We proceed to attempt to boost and increase the range of companies we provide our prospects. AG’s extrusion services embody using injection, cold and hot becoming a member of strategies which allows us to offer a variety of sections, sizes and shapes made from a big selection of materials. Our big selection of standard items at the aspect of our varied methods of manufacture will ensure you get the right seal every time, reduced lead times assured. A gasket is a mechanical seal that fills the area between two mating surfaces, generally to prevent leakage from or into the joined objects whereas underneath compression.

Today, it is established as a quantity one supplier of piping systems for the safe and dependable transport of liquids and gases. Despite the constant change, customer-centric innovation and sustainability stay the defining values for GF Piping Systems. Often used as a seal for steam and scorching valves, taylor ring gaskets are reduce from a variety of sheet metals and fashioned into corrugated concentric rings.

As a manufacturer of a broad range of flange gaskets, including metallic gaskets, semi-metallic gaskets, and sheet gaskets, we pride ourselves on helping our customers supply the best product for any utility. At Mercer Gasket & Shim, our staff has the information to promptly and accurately finish any custom gasket order. In addition, we are geared up with cutting-edge equipment to precisely manufacture gaskets from numerous materials. We are additionally committed to offering the very best quality gaskets to our clients by adhering to relevant industry standards and specifications. Our expert group of engineers at Mercer Gasket & Shim aids customers all throughout the whole gasket production course of.

metallic gaskets

We additionally provide custom gasket solutions to ensure that you get the most effective answer for your needs. Our in depth range includes, 100% Pure, Expanded and Modified PTFE products available in sheet, tape, completed components, gaskets and washers. Covering a wide range of applications, our brands include Gylon, Klinger’s Topchem & Teflex.

#durlon sealing products#durlon gaskets#industrial gaskets#sheet gaskets#metallic gaskets#sustainable gasket materials#high-quality gaskets#PTFE sheet gaskets

2 notes

·

View notes

Text

Understanding Aluminum PCB Prototypes

Aluminum PCB prototypes utilize aluminum as the base material instead of traditional fiberglass or FR4. This unique choice offers superior heat dissipation, making them ideal for high-power applications like LED lighting, power electronics, and automotive electronics.

Advantages of Aluminum PCB Prototypes

Superior Thermal Performance: Aluminum's high thermal conductivity allows for more efficient heat dissipation, leading to lower operating temperatures and increased component reliability.

Enhanced Electrical Performance: Aluminum PCBs offer better electrical performance due to their lower dielectric constant and loss tangent, reducing signal attenuation and crosstalk.

Lightweight and Compact: Aluminum PCBs are significantly lighter and smaller than FR4 PCBs, making them ideal for weight-sensitive applications.

Durable and Corrosion-Resistant: Aluminum PCBs are more durable and corrosion-resistant than FR4 PCBs, suitable for harsh environments.

Applications of Aluminum PCB Prototypes

Aluminum PCB prototypes find applications in various industries, including:

LED Lighting

Power Electronics

Automotive Electronics

Aerospace

Medical Devices

Their advantages make them a preferred choice for weight-sensitive, high-performance, and durable applications.

Fabrication of Bare Aluminum PCB Prototypes

Bare aluminum PCB prototype fabrication involves several steps:

Material Selection: Choosing the right type of aluminum, such as 6061 or 5052.

Surface Preparation: Cleaning, degreasing, and etching the aluminum surface.

Copper Deposition: Electroplating copper onto the aluminum surface.

Patterning: Using a photoresist and etching process to pattern the copper layer.

Drilling: Creating holes for vias.

Plating: Applying a protective metal layer like gold or nickel.

Aluminum PCB fabrication requires different processing steps and considerations compared to traditional PCBs due to aluminum's unique properties.

Assembly of Aluminum PCB Prototypes

Assembly of components onto bare aluminum PCBs involves:

Component Selection: Choosing components compatible with the aluminum substrate.

Solder Paste Application: Applying solder paste to the PCB pads.

Component Placement: Placing components onto the PCB.

Reflow Soldering: Heating the PCB to melt the solder paste and form a bond.

Inspection: Checking for proper soldering.

Assembly of aluminum PCB prototypes is similar to traditional PCBs but requires consideration of aluminum's properties.

Choosing the Right Aluminum PCB Prototype Manufacturer

When selecting a manufacturer, consider:

Experience and Expertise: Look for a manufacturer with extensive experience and technical expertise in aluminum PCB fabrication.

Quality Control and Testing: Verify the manufacturer's quality control and testing procedures.

Lead Time and Pricing: Compare lead times and pricing from multiple manufacturers.

Customer Service and Support: Ensure the manufacturer offers responsive customer service and support.

Additional factors like location, value-added services, and sustainability practices should also be considered.

In conclusion, aluminum PCB prototypes offer numerous advantages and are suitable for a wide range of applications. By selecting the right manufacturer and considering key factors, you can ensure the success of your aluminum PCB prototype project.

2 notes

·

View notes

Text

Your Trusted Ammonium Hepta Molybdate Manufacturer, Supplier, and Exporter in India

Introduction:

PalviChemical stands as a pioneer in the chemical industry, providing high-quality products to meet diverse industrial needs. With a commitment to excellence and customer satisfaction, we have established ourselves as a leading manufacturer, supplier, and exporter of Ammonium Hepta Molybdate in India. In this blog, we delve into the significance of Ammonium Hepta Molybdate, its applications, and why PalviChemical is your go-to source for this essential chemical compound.

Understanding Ammonium Hepta Molybdate:

Ammonium Hepta Molybdate, also known as Ammonium Paramolybdate, is a vital chemical compound widely used in various industrial processes. It is a white crystalline powder with the chemical formula (NH4)6Mo7O24•4H2O. This compound is valued for its versatility and unique properties, making it indispensable in industries such as agriculture, metallurgy, and chemical synthesis.

Applications of Ammonium Hepta Molybdate:

Agriculture: Ammonium Hepta Molybdate plays a crucial role in agriculture as a source of molybdenum, an essential micronutrient for plant growth. It is used as a fertilizer additive to enrich the soil with molybdenum, promoting healthy plant development and increasing crop yields. Farmers rely on this compound to address molybdenum deficiencies in soils, ensuring optimal nutrient uptake by crops.

Metallurgy: In the metallurgical industry, Ammonium Hepta Molybdate is utilized in various processes, including metal surface treatment, corrosion inhibition, and alloy production. It serves as a corrosion inhibitor in metal coatings, protecting surfaces from degradation and extending their lifespan. Additionally, this compound is a key component in the production of specialty alloys with enhanced strength, durability, and corrosion resistance.

Chemical Synthesis: Ammonium Hepta Molybdate finds application in chemical synthesis, particularly in the synthesis of other molybdenum compounds and catalysts. It serves as a precursor for the preparation of molybdenum oxide catalysts used in organic synthesis, petroleum refining, and chemical manufacturing. The versatility of this compound makes it a valuable resource for chemical researchers and manufacturers worldwide.

Why Choose PalviChemical?

Superior Quality: At PalviChemical, quality is our top priority. We adhere to stringent manufacturing standards and quality control measures to ensure that our Ammonium Hepta Molybdate meets the highest industry specifications. Our state-of-the-art facilities and experienced team of professionals ensure consistency and purity in every batch of product we deliver.

Reliable Supply: As a trusted manufacturer, supplier, and exporter of Ammonium Hepta Molybdate in India, PalviChemical maintains a robust supply chain network to fulfill the diverse needs of our customers. Whether you require small-scale quantities or bulk orders, we guarantee timely delivery and uninterrupted supply to keep your operations running smoothly.

Customized Solutions: At PalviChemical, we understand that every customer has unique requirements. That is why we offer customized solutions tailored to your specific applications and preferences. Whether you need a specialized grade of Ammonium Hepta Molybdate or assistance with product customization, our team is dedicated to meeting your needs with precision and efficiency.

Competitive Pricing: We believe in offering competitive pricing without compromising on quality. PalviChemical strives to provide cost-effective solutions that add value to your business while maintaining affordability and accessibility. Our transparent pricing policies ensure that you receive exceptional value for your investment, making us the preferred choice for Ammonium Hepta Molybdate in India.

Conclusion:

As a leading manufacturer, supplier, and exporter of Ammonium Hepta Molybdate in India, PalviChemical is committed to excellence, reliability, and customer satisfaction. With our superior quality products, reliable supply chain, customized solutions, and competitive pricing, we have earned the trust of customers across diverse industries. Whether you are in agriculture, metallurgy, or chemical synthesis, trust PalviChemical to be your partner in success. Contact us today to learn more about our Ammonium Hepta Molybdate offerings and how we can fulfill your chemical needs with distinction.

#Ammonium Hepta Molybdate exporter in India#Ammonium Hepta Molybdate supplier in India#Ammonium Hepta Molybdate manufacturer in India#India

5 notes

·

View notes

Text

Did you know that what is Die Steel?

Die steel, also known as tool and die steel, is a specialized type of steel designed for use in the production of dies, molds, and other tooling used in manufacturing processes. Dies and molds are used to shape, cut, or form materials such as metals, plastics, and ceramics in various industrial applications. Die steel needs to have specific properties to withstand the harsh conditions of these processes.

Key characteristics of die steel include:

Hardness: Die steel is typically hardened to resist wear and deformation. This is crucial because dies and molds are subjected to repeated cycles of stress, pressure, and friction during manufacturing processes.

2. Toughness: In addition to hardness, die steel must also possess toughness to resist cracking or chipping under high impact loads. This is important for maintaining the integrity and longevity of the dies.

3. Heat resistance: Many manufacturing processes involve high temperatures, so die steel must be able to withstand elevated temperatures without losing its hardness or other mechanical properties.

4. Wear resistance: Die steel should have good wear resistance to maintain its shape and effectiveness over time, especially when used in high-volume production settings.

5. Corrosion resistance: Although not always a primary concern, some die steels may also be designed to resist corrosion, especially when used in environments where exposure to moisture or corrosive substances is a concern.

Die steels are often classified based on their intended use and specific properties, and different grades of die steel may be chosen based on the requirements of a particular application. The selection of the appropriate die steel is crucial for achieving high-quality and cost-effective manufacturing processes.

VIRAT SPECIAL STEELS is leading Tool Steel & Die Steel Importer, Exporter, Stockiest, Distributor and Supplier in India.

Product List

HOT WORK STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteels.com/

Any further queries feel free to contact us :

Email: [email protected] or Call: +91 98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#diesteels#diesteelsuppier#diesteel#die steels#diemouldsteels#db6 steel#h13steel#h11steel#p20steels#p20

2 notes

·

View notes

Text

Exploring the Screen Printing Mesh Market: Ink & Weave

The screen printing mesh market involves the manufacturing and supply of woven or synthetic mesh materials used in screen printing processes. These meshes serve as a crucial component in the creation of screen printing screens, enabling the transfer of ink onto various substrates such as textiles, paper, plastics, metals, and more. The adoption of mesh screen printing is widely rising among various end-use industries such as electrical, packaging, ceramics, and electronics are driving the market revenue. The growth and evolution of these sectors, including changes in consumer preferences and packaging trends, can influence the demand for screen printing meshes.

Increasing printing of mesh materials used for fabric print is eye-catching for beautiful printing designs in the textile sector, which is gaining immense popularity. Manufacturers offer polyester screen printing technologies in the textile industry to strengthen the cloth without affecting or upsurging the market growth. On the other hand, construction and architecture sectors are choosing advanced and cutting-edge technologies to reduce additional costs of printing methods and capture end users' needs. Advancements in digital printing technologies and the adoption of alternative printing methods may impact traditional screen printing processes, potentially influencing the demand for screen printing meshes.

Demand for custom-made screen printing meshes to suit specific applications or industries, such as high-resolution graphics or unique substrate printing, could drive market growth in specialized niches. Consumers are looking for effective and high-quality printing solutions for special event presents, increasing the market revenue. Manufacturers are focused on shifting consumers' preferences, changing lifestyles, and enhancing product quality with printing technologies. Manufacturers are developing new technologies to strengthen touchscreen production for electronic components to boost the global market.

3 notes

·

View notes

Text

I think everyone has heard the term “supply chain crisis” at this point. Manufacturing centers were first hit in late 2019 and most to the global lockdowns were in effect by the second quarter of 2020. It is now third quarter of 2022 and we are into year three of this “interruption”, it is time to discard this outdated and frankly wrong from the start system of manufacturing and distribution. Americans in particular were already caught in a state of duality in which much of the public laments that nothing is made domestically, while also discarding anything made by local shops as “overpriced hipster gear”. I have previously stated that for true domestic production to return to America there would need to be enough demand for the products to cause more competition and drive the prices down as domestic supply increased.

That is the current situation as I see it, so now what do we do about it? In the last decade one particular technology has taken off, once a novelty and hyper expensive tool for industrial prototyping, 3D printers have become affordable, commonplace, and surprisingly capable. While still used by many to produce novelty items and in industrial roles, this technology is akin to the movable-type printing press of the mid-1400s in that it represents an upset to the established order if utilized effectively. Now before this is dismissed I am aware of the limitations of what can be printed at home. More exotic and expensive versions are used to produce high strength items. But this is where it gets interesting, because it isn’t about everyone having a printer. It’s about everyone using home printers to get a head start on skills, hobbies, and trades they couldn’t afford to break into otherwise and then using those skills to work with each other.

Lathes or milling machines are both often said to be machines that make machines. 3D printers should be included in that list. Now there is nothing made on this machine that can’t be done with other tools and methods, but few that allow the low cost of entry and ease within a home settings. Open source software and thousands of free files allow anyone and everyone to make tons of tools, dies, forms, jigs, stencils, etc. as needed. I've seen sheet steel stamped on dies made from common PLA on a cheap press from Harbor Freight, or even just stuck with hammers. My cousin makes brackets for electronics with an entry level printer while his wife makes custom cookie cutters for various events on the same machine.

And that’s the thing about this, the broad range of applications combined with people’s varied and personal interests. With the addition of a chop saw and drill for extruded or tubular metal you can make strong supports for printed pieces to form a much larger machine. If you can make a drill press or milling machine, you can make a lathe, manually operated or CNC. I’ve seen people make large format CNC router tables that can quickly and efficiently cut and trim an entire sheet of plywood for assembly. If within a community most people have the ability to make their own simple plastic or resin tools and utensils, while someone has a garage metal shop, another a carpentry shop, a couple down the road a leather shop and sewing studio, someone else a pottery studio, even a small foundry for smelting and casting, you would have a far more self-reliant community than anything seen in a hundred years in much of the western world.

I was originally going to link a bunch of videos showing the possibilities and I still might add some later on about specific applications. But I really want everyone to give this some serious thought on their own. Is there a hobby or trade you are interested in but you’re concerned about the investment? Look at what the essential components are. Can the more complex ones be found used? The cheaper ones made at home? We, as in all of us, are in a massive web of unsustainable distribution and centralized manufacturing. I don’t believe the key is to change where that center is, but to replace it with local and regional decentralized networks of skilled individuals whom own their own tools and shops.

#self reliance#sustainability#decentralisation#3d printer#trades#hobbies#skill set#new skills#casting#welding#machining#carpentry#pottery

38 notes

·

View notes

Photo

metal additive manufacturing - metal 3d printing services in india

#metal additive manufacturing additive manufacturing process additive printing additive manufacturing design additive metal 3d printing addit#metal additive manufacturing applications#metal additive manufacturing companies#metal additive manufacturing in india#metal additive manufacturing machine#metal additive manufacturing materials#metal additive manufacturing post processing#metal additive manufacturing service providers#3d metal printing companies 3d metal printing machine 3d metal printing machine manufacturers 3d metal printing near me 3d metal printin#3d metal printing companies#3d priniting post processing services#3d printing in defence industry#additive manufactured products#additive manufacturing companies in bangalore#additive manufacturing company in india#additive manufacturing material#additive manufacturing metal parts#additive manufacturing service in india#additive metal 3d printing#dmls printer manufacturers#materials for additive manufacturing#metal 3d printing bangalore#metal 3d printing companies in bangalore#metal 3d printing companies in india#metal 3d printing in mumbai#metal 3d printing in rapid prototyping#metal 3d printing india#metal 3d printing manufacturing#metal 3d printing post processing#metal 3d printing process

1 note

·

View note

Text

Recycling the non-recyclable: New epoxy resin resists flames and reduces waste

Empa researchers have developed an epoxy resin that can be repaired and recycled, in addition to being flame-retardant and mechanically strong. Potential applications range from coating for wooden flooring to composites in aerospace and railways.

Epoxy resins are tough and versatile polymers. In combination with glass or carbon fibers, they are used, for example, to manufacture components for aircraft, cars, trains, ships and wind turbines. Such epoxy-based fiber-reinforced polymers have excellent mechanical and thermal properties and are much lighter than metal. Their weakness: They are not recyclable—at least not yet.

Now Empa researchers led by Sabyasachi Gaan at Empa's Advanced Fibers laboratory have developed an epoxy resin-based plastic that is fully recyclable, repairable and also flame retardant—all while retaining the favorable thermomechanical properties of epoxy resins. They have published their findings in the Chemical Engineering Journal.

Read more.

#Materials Science#Science#Recycling#Epoxy#Resins#Flames#Waste#Flame retardants#Polymers#Thermosets#Vitrimers

11 notes

·

View notes

Text

Epoxy Floors in Oklahoma City: The Ultimate Flooring Solution

When it comes to durable, attractive, and long-lasting flooring options, epoxy floors in Oklahoma City are gaining popularity. Whether you're a homeowner looking to upgrade your garage or a business owner seeking a practical and aesthetically pleasing solution for your commercial space, epoxy flooring is a versatile choice that offers numerous benefits.

Epoxy Flooring Basics

Epoxy flooring is a type of surface coating that combines resin and hardener to create a strong, seamless, and highly resilient floor. It's a popular choice in various settings, from industrial facilities and warehouses to retail stores and homes. In Oklahoma City, epoxy floors are appreciated for their ability to withstand the city's variable weather conditions and heavy foot traffic.

Advantages of Epoxy Floors

Durability: Epoxy flooring is incredibly durable and can handle heavy loads without cracking or chipping. It can withstand the weight of vehicles, making it an ideal choice for garages and auto shops.

Easy Maintenance: Epoxy floors are effortless to clean and maintain. They are resistant to stains, chemicals, and moisture, making them perfect for areas prone to spills and accidents.

Aesthetically Pleasing: Epoxy floors are available in a wide range of colors and patterns, allowing you to customize your flooring to match your style and space. They can also be enhanced with decorative elements like flakes, metallic pigments, or quartz.

Longevity: When properly installed and maintained, epoxy floors can last for many years, making them a cost-effective investment.

Safety: Epoxy floors can be customized to include anti-slip additives, making them safer for areas where slip and fall accidents are a concern.

Applications of Epoxy Flooring in Oklahoma City

Residential Garages: Many homeowners in Oklahoma City are choosing epoxy flooring for their garages. It not only enhances the appearance of the space but also protects the concrete underneath from oil, grease, and other stains.

Commercial and Industrial Spaces: Epoxy flooring is a popular choice for commercial and industrial spaces in Oklahoma City. It can withstand heavy machinery, high foot traffic, and chemical exposure, making it suitable for manufacturing facilities, warehouses, and factories.

Retail Stores: Retailers appreciate the clean and polished look of epoxy floors, which can elevate the ambiance of their stores. The customizable design options allow for branding elements to be incorporated into the flooring.

Restaurants and Bars: Epoxy flooring's resistance to spills and easy cleaning make it a practical choice for the food and beverage industry. It also offers an opportunity for creative designs to enhance the dining experience.

Installation Process

Professional installation is crucial to achieving the full benefits of epoxy flooring. The process typically involves the following steps:

Surface Preparation: The existing concrete floor is thoroughly cleaned and prepared, which may include repairing cracks and imperfections.

Primer Application: A primer is applied to ensure proper adhesion between the epoxy coating and the concrete surface.

Epoxy Coating Application: The epoxy mixture is applied to the prepared surface, and it can be customized with various colors and patterns.

Additional Design Elements: If desired, decorative elements like flakes, metallic pigments, or quartz can be added during the epoxy application.

Topcoat Application: A clear topcoat is applied to provide additional protection and enhance the floor's shine.

Conclusion

Epoxy flooring installation offer a durable, attractive, and low-maintenance flooring solution for residential, commercial, and industrial spaces. With their customizable design options, resistance to stains and chemicals, and long lifespan, epoxy floors have become a top choice for those seeking a practical and aesthetically pleasing flooring solution in the vibrant city of Oklahoma. Whether you want to upgrade your garage or enhance your commercial space, epoxy flooring is a versatile option that can meet your needs and exceed your expectations.

https://mtcustomconcrete.com/epoxy/

2 notes

·

View notes

Text

Brazil exports first shipment of green lithium

The mineral used to manufacture products such as batteries for electric vehicles was extracted in Minas Gerais and sent to the Chinese company Yahua. The vice president of Brazil accompanied the sending.

The vice president and minister of Development, Industry, Commerce, and Services of Brazil, Geraldo Alckmin, accompanied, this Thursday (27), the shipment for export of the first batch of Brazilian “green lithium” extracted in the Jequitinhonha Valley in Minas Gerais. The event occurred in the port of Vitória, the capital city of Espírito Santo.

The mineral is essential for producing batteries, metal alloys, medical devices, and drugs, among other applications. The highlight is the manufacture of long-lasting batteries for electric vehicles, an industry driving the energy transition.

The shipment sent this Thursday to Chinese company Yahua includes 15,000 tonnes of high-purity lithium and 15,000 tonnes of ultrafine waste. Until the end of the year, expectations are for exports around 130,000 tonnes.

The pre-chemical lithium technological input was produced by the Brazilian company Sigma Lithium. It was named “green lithium” or zero-carbon because the exploration plant does not have a tailings dam. In addition, the company recycles the water used in the lithium purification process, which does not involve chemical agents. The tailings are dry stacked and sold for the recovery of residual minerals.

Continue reading.

2 notes

·

View notes

Text

Unleashing Power and Precision: Beretta M9A1 CO2 Gun Review

Beretta M9A1 Co2 gun

**Introduction**

In the world of firearms, few names evoke the same level of recognition and admiration as Beretta. The renowned Italian arms manufacturer has a legacy of crafting exceptional firearms for over five centuries. Among their iconic creations is the Beretta M9, a popular semi-automatic pistol adopted by various military forces around the globe. Building on the success of the M9, Beretta introduced the M9A1, an advanced variant designed to meet the needs of modern-day shooters and enthusiasts. In this blog, we'll delve into the features, performance, and why the Beretta M9A1 CO2 gun is a standout choice among airsoft and training replicas.

**1. A Brief Overview of the Beretta M9A1**

The Beretta M9A1 is a semi-automatic, full-sized pistol designed for military and law enforcement use. It's an evolution of the M9, incorporating several enhancements to improve handling, reliability, and ergonomics. The real steel M9A1 is chambered in 9x19mm Parabellum and is the standard sidearm of the United States Armed Forces since the 1980s.

The CO2 version of the Beretta M9A1 replicates the iconic design and functionality of the original firearm, making it an ideal choice for airsoft players, collectors, and those looking to practice their shooting skills in a safe environment.

**2. Key Features of the Beretta M9A1 CO2 Gun**

* **Realism**: The Beretta M9A1 CO2 gun is meticulously crafted to mirror the look and feel of the authentic M9A1. From the metal slide, polymer frame, and realistic controls, every detail contributes to an authentic shooting experience.

* **CO2 Powered**: The M9A1 CO2 gun utilizes 12-gram CO2 cartridges to propel BBs, offering consistent power and performance during extended shooting sessions. The accessibility of CO2 cartridges makes it easy to keep the gun running without the need for external power sources or frequent recharging.

* **Blowback Action**: One of the standout features of the Beretta M9A1 CO2 gun is its blowback action. This means that the slide reciprocates with every shot, giving the shooter a satisfying recoil sensation similar to the real firearm. It enhances the overall shooting experience and adds an element of realism.

* **Drop-Free Magazine**: The CO2 gun comes with a drop-free magazine, allowing for quick and straightforward reloads. The magazine capacity typically holds around 18 BBs, providing ample shots before needing to reload.

* **Safety Mechanisms**: The M9A1 CO2 gun includes multiple safety features, such as a manual safety, decocker, and a functional slide catch, making it a safe option for training and recreational use.

* **Accurate Performance**: With a smooth trigger and adjustable sights, the Beretta M9A1 CO2 gun delivers impressive accuracy. This makes it a reliable choice for target shooting, training, and competitive airsoft play.

**3. Applications of the Beretta M9A1 CO2 Gun**

* **Airsoft Gaming**: The M9A1 CO2 gun is a popular choice for airsoft enthusiasts due to its realistic design and blowback action. Whether engaging in milsim events or casual skirmishes, this pistol performs exceptionally well, providing an immersive gaming experience.

* **Training and Practice**: For those looking to improve their shooting skills, the M9A1 CO2 gun offers a safe and cost-effective training tool. Its resemblance to the real M9A1 allows shooters to practice fundamental techniques without live ammunition.

* **Collectors**: Firearms enthusiasts and collectors appreciate the Beretta M9A1 CO2 gun for its attention to detail and historical significance. It's a prized addition to any firearms collection.

**Conclusion**

The Beretta M9A1 CO2 gun stands as a testament to Beretta's commitment to crafting high-quality firearms. With its exceptional realism, reliable performance, and versatility, it has earned its place as a top choice for airsoft gamers, training purposes, and firearm collectors alike. Whether you're a seasoned shooter or just beginning your journey into the world of firearms, the Beretta M9A1 CO2 gun is sure to provide countless hours of enjoyment and skill-building in a safe and controlled environment.

2 notes

·

View notes