Text

Revolutionizing Automotive Aesthetics The Automotive Paints and Coatings Market

Introduction: A Splash of Color and Protection

The automotive paints and coatings market is more than just colors on cars; it's a dynamic industry driving innovation in aesthetics, durability, and environmental sustainability. This article delves into the diverse landscape of automotive coatings, exploring its evolution, trends, and transformative impact on vehicle aesthetics and performance.

Exploring Automotive Paints and Coatings

Understanding Automotive Coatings

Automotive coatings encompass a wide range of products designed to enhance the appearance of vehicles while providing protection against corrosion, UV radiation, and environmental contaminants. These coatings are applied to various vehicle components, including exteriors, interiors, wheels, and underbodies, to achieve desired visual effects and performance characteristics.

Types of Automotive Paints

Basecoat: Basecoat paints consist of pigmented layers applied to the vehicle's surface to provide color and coverage. These paints are available in a myriad of hues and finishes, including metallic, pearl, and matte, allowing for customization and personalization according to consumer preferences.

Clearcoat: Clearcoat paints, also known as topcoats, serve as a protective layer over the basecoat, enhancing gloss, depth, and durability. These transparent coatings provide resistance against scratches, chips, and fading caused by sunlight and environmental factors, ensuring long-lasting shine and luster.

Primer: Primer paints are applied to bare metal or repaired surfaces to promote adhesion and corrosion resistance before the application of basecoat and clearcoat layers. These preparatory coatings provide a smooth and uniform surface for subsequent paint layers, ensuring optimal performance and finish quality.

Market Dynamics and Growth Trends

Technological Advancements

The automotive paints and coatings market is witnessing significant technological advancements, with innovations such as water-based paints, eco-friendly coatings, and self-healing materials gaining traction. These advancements address consumer demands for sustainable, low-VOC (volatile organic compound) solutions while delivering superior performance and durability.

Customization and Personalization

Consumers are increasingly seeking customized paint finishes and specialty coatings to differentiate their vehicles and express their individuality. Automotive OEMs and aftermarket suppliers offer a wide range of color options, effects, and textures, catering to diverse tastes and style preferences in the automotive market.

Applications and Use Cases

OEM Automotive Manufacturing

Automotive manufacturers utilize advanced paint systems and robotic painting technologies to achieve precise color matching, uniform coverage, and high-quality finishes during vehicle assembly. These automated painting processes enhance productivity, consistency, and cost efficiency in automotive production.

Automotive Refinishing and Restoration

Automotive refinishing shops and restoration specialists employ professional paint systems and refinishing techniques to repair and restore vehicle finishes damaged by accidents, corrosion, or aging. These services include color matching, surface preparation, paint application, and finishing, ensuring factory-like results and customer satisfaction.

Challenges and Opportunities

Environmental Regulations

Stringent environmental regulations and emissions standards pose challenges for automotive coatings manufacturers, driving the development of eco-friendly formulations and sustainable production practices. Companies are investing in R&D to reduce VOC emissions, hazardous waste generation, and environmental impact throughout the product lifecycle.

Innovation and Differentiation

In a competitive market, innovation and product differentiation are critical for automotive coatings manufacturers to stay ahead of the curve and meet evolving consumer demands. Companies are investing in advanced technologies, such as nanotechnology, ceramic coatings, and UV-curable paints, to develop high-performance coatings with unique properties and benefits.

#Automotive Paints and Coatings Market#Automotive Paints and Coatings Market Size#Automotive Paints and Coatings Market Share#Automotive Paints and Coatings Market Demand#Automotive Paints and Coatings Market growth#Automotive Paints and Coatings Market Outlook

0 notes

Text

Beyond Boundaries Exploring the Millimeter Wave Technology Market

The global millimeter wave technology market is projected to reach USD 11,912.1 million by 2030, advancing at a CAGR of 23.4% during the forecast period. This can be credited to the fact that this technology is vital in the healthcare, telecommunications, and aerospace industries. The growing acceptance of imaging devices, monitoring systems, progressive safety measures, tablets, smartphones, and electronic devices is propelling industry development.

Embark on a journey through the dynamic landscape of the millimeter wave technology market, where innovation meets connectivity at unprecedented speeds. Explore the latest advancements and applications driving the demand for high-frequency wireless solutions across various industries. From telecommunications to automotive radar systems, discover how millimeter wave technology is reshaping the future of communication and sensing capabilities.

Gain insights into market dynamics, key players, and emerging trends shaping the proliferation of this transformative technology. Uncover the intersection of engineering, telecommunications, and consumer demand as you navigate through this groundbreaking market segment.

The snowballing acceptance of data-intensive applications, the rising adoption of smart devices, and the advancing wireless technologies are the key reasons propelling the requirement for millimeter wave technology. Such applications need high-speed communication with quicker information transmission, high bandwidth, and the power to maintain huge quantities of information, specifically for high-resolution media. This technology is totally capable to fulfill such needs, which is why it is vital for the deployment of 5G networks.

Based on components, the antenna and transceiver components category generated the largest revenue share. This is mainly because mmWave radio lines are vital for backhaul solutions in the communications infrastructure, mainly for cellular wireless access. 5G utilizes millimeter waves with frequency bands 10 times more advanced than conventional networks.

In 2022, the telecommunications equipment category dominated the market, with a revenue share of 70%, based on product type, credited to the growing count of smartphone operators throughout the globe.

Furthermore, enterprise-level data centers are widely accepting this technology. A constant bandwidth of more than 24 GHz is required to fulfill the high-volume data needs of 5G services. R&D specialists have conducted tests and showed that this technology can get multigigabit-per-second data rates, therefore allowing high-speed wireless communication.

Based on the frequency band, the 24–57 GHz category is dominating the industry. This can be credited to the fact that the 24–57 GHz frequency spectrum range is typically utilized for radio and mobile services.

Worldwide, the APAC millimeter wave technology market is projected to lead the market by the end of the decade. This is because of the growing deployment of 5G networks, which offer advanced security and quicker data access to IoT devices and smartphone users.

Browse full report at: https://www.psmarketresearch.com/market-analysis/millimeter-wave-technology-market

Additionally, there has been a continuous rise in the need for high-speed networks to aid smart applications in both the residential and commercial sectors, therefore contributing to the market revenue development in the region.

North America is leading the market with the largest market share. This is due to the rising acceptance of progressive technologies, particularly 5G; the presence of numerous key industry players, and huge expenditure in the growth of 5G technology by telecom leaders, like Qualcomm, AT&T, T-Mobile, and Ericsson.

Hence, the growing acceptance of imaging devices, monitoring systems, progressive safety measures, tablets, smartphones, and electronic devices is propelling industry development.

#millimeter wave technology#market analysis#innovation#connectivity#high-frequency wireless#applications#telecommunications#automotive radar systems#communication#sensing capabilities#market dynamics#key players

0 notes

Text

#Ceramic Matrix Composites Market#Strength#Resilience#Lightweight#High-Temperature Resistance#Aerospace#Automotive#Energy#Market Trends#Innovations#Key Players#Emerging Technologies#Regulatory Factors

0 notes

Text

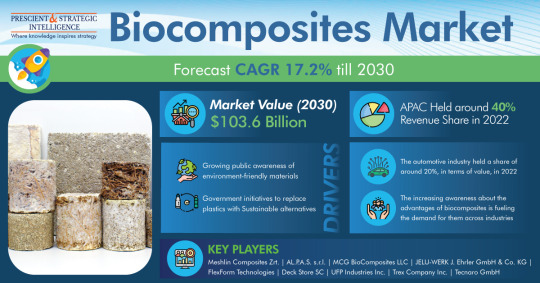

Biocomposites Market To Generate USD 103.6 Billion by 2030

Biodegradable polymer serves as the matrix material in biocomposites, which typically also contain bio-fibers as reinforcing elements. Moreover, biocomposites have the following characteristics: low cost, low density, high toughness, acceptable specific strength properties, good thermal properties, ease of separation, improved energy recovery, and biodegradability.

As per a report by P&S Intelligence, the biocomposites market is on track to reaching USD 103.6 billion by 2030. This is because more people are becoming aware of eco-friendly materials and because the government is taking steps to replace plastics with them. A further factor driving material demand is the car industry's growing desire to lighten and increase passenger safety.

NFCs are frequently employed in car interior components such as windows, driver cabins, doors, and dashboards. On the other hand, WPCs are mostly used in the construction of seat bases, back shelf trims for the spare tire and trunk, headliners, and inside door trims.

As a result, practically all European and North American OEMs have included them in their ambitious goals to reduce weight in order to comply with stringent environmental laws. This is due to the rising use of these materials in vehicles.

Due to its fast industrialization, APAC also represented the greatest value share in the worldwide market. Essentially, the rising requirement for such materials from the automobile and consumer goods sectors is what is driving market expansion in the region.

The market is also expected to be driven by the growing need in the building and construction sector for materials that are biodegradable, non-toxic, moisture- and thermally-resistant.

Furthermore, APAC is developing into a hub for producers of biocomposite materials, and it is anticipated that it will record a strong need for such materials in the years to come. Additionally, these materials are widely used in cooling tower units to prevent moisture-related corrosion.

For instance, as part of the Saudi Vision 2030 development plan, the Kingdom of Saudi Arabia is undertaking a number of large-scale infrastructure projects, such as the Red Sea Project, Qiddiya Entertainment City, King Abdullah Financial District, and Neom City, all of which are expected to support business and corporate expansion.

#Biocomposites Market#Biocomposites Market Size#Biocomposites Market Share#Biocomposites Market Trends#Biocomposites Market Outlook

0 notes

Text

Get a Wastewater Treatment Plant Installed and Become Wealthy

Enormous amount of Wastewater is treated each year in wastewater treatment plants all over the world. The municipal as well as industrial wastewater can comprise more than a few pollutants depending upon the source. Wastewater might comprise waste products, soap, human waste, food scraps, oils and even metals. The key goal of wastewater treatment is the preservation of the environment and keep the contaminants out of oceans and rivers.

Water is put to use in almost all of the industries for diverse purposes for example manufacturing, cooling, and heating as a solvent or rinse waters. This water becomes wastewater and can’t be discharged to a sewer without treatment.

Functioning of a wastewater treatment plant can be expensive because of the initial capital costs, reagents, spare parts, labor and even hazardous materials handling. In this blog, we will discuss about a rather interesting aspect that how you can become richer because of the functioning of a wastewater treatment plant.

Environmental

It is not a novel concept that industrial impact on the atmosphere is negative. Lack of appropriate wastewater treatment amenities and usage of outdated amenities running on old techs do not contribute to a justifiable future. More than a few wastewater treatment plants all over the globe are regulated to meet discharge limits and to comply with regulations imposed by the government.

Actually, more than a few nations don’t have any sort of regulations at all, or the implementation is not done. With regards to 'getting rich' in an ecological way, is referred to investment in the future of the upcoming generation and the only the environment of the earth. All the people are dependent on clean water to survive and if the necessary steps are not taken, it may be too late.

Social

The social image of a brand is always important. One can always try to push the effort to put into ecological stewardship and the treatment of industrial waste. An efficient wastewater treatment plant is something, that can make you fairly rich to say the least

Having a cutting-edge treatment tech ahead of all the competitors, may interest in a company and get the support of the local municipality. In the world of today where social media is well-thought-out the robust marketing tool, you can get richer literally by building the correct social image for a business.

Save and Earn

In the contemporary industrial world, there are two approaches to wastewater treatment. Some businesses dispose of contaminated water off site by hiring a disposal business, while others treat the waste onsite. Both approaches have their pros and cons up their sleeve.

Summing Up the Scene

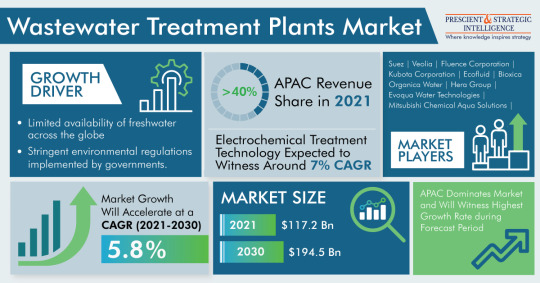

There is a limited availability of freshwater, and so there is a need to treat wastewater, in order to make it worth drinking. It is because of this reason the demand for wastewater treatment plants is on the rise, and the value will reach USD 194.5 billion in the years to come.

#Wastewater Treatment Plants Market#Wastewater Treatment Plants Market Size#Wastewater Treatment Plants Market Share#Wastewater Treatment Plants Market Growth#Wastewater Treatment Plants Market Trends#Wastewater Treatment Plants Market Outlook

0 notes

Text

Industrial Hemp Market To Reach USD 60,682.8 Million by 2030

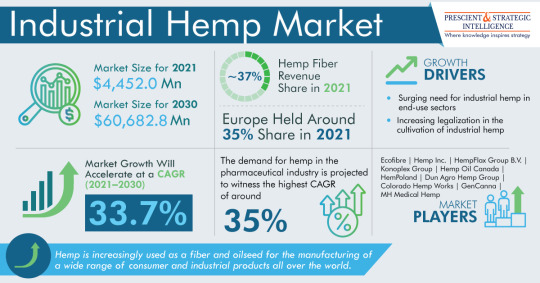

The industrial hemp market will progress at a considerable rate of 33.7% by the end of the decade to reach USD 60,682.8 million by 2030. In Europe, France had the highest revenue in the past, and it will grow significantly at a rate of rate of over 18%.

The industry is largely powered by the increasing requirement for industrial hemp in numerous sectors and the growing legalization of the farming of this crop to be used in industries.

The hemp oil category had the second-largest share in the industry, of about 30%. Hemp oil is chiefly valued by customers for its nutritious properties and benefits to health, as it is a comprehensive source of all vital fatty and amino acids.

Also, customers are more and more drawn to natural and organic products, and hemp oil is favored because it has caryophyllene, cannabidiol, and myrcene, which offer health benefits.

The food industry dominated the industrial hemp market with a share of above 25% in the past. Hemp is used by millennia as a source of fiber and oilseeds in numerous consumer and industrial products globally. Over 25 nations already are into the growing of industrial hemp as an agro commodity, and it is also traded globally. In Europe and APAC, hemp oil and seeds are a part of human diet for over 5,000 years.

Food products presently made at the industrial level with hemp oil and seeds include salad oils, non-dairy cheeses, health bars, non-soy tofu, non-dairy milks, additives for breads, biscuits, and cakes; butter pastes, along with whole seeds consumed in both roasted and raw forms.

The requirement for hemp in the pharma industry is will be the fastest in the years to come, with a rate of about 35%. Hemp provides a required omega-6-to omega-3-PUFA ratio, helping promote cardiac health, reduces osteoporosis symptoms, and eases the symptoms of eczema.

It also comprises CBD, which has pharmacological potentials, making it a possible therapeutic agent for ailments of the central nervous system, for example neurodegenerative ailments, and multiple sclerosis.

Furthermore, the requirement for this product for pharma applications will grow because of the aging and increasing population, on top of medical challenges for example neurodegenerative disorders, multiple sclerosis, and epilepsy.

The conventional type had the larger share, of over 50%, in the past, since conventionally grown hemp is priced low. Moreover, it does not need strict inspection or obedience to guidelines for meeting the certified organic standards, making the production procedure faster. Not only this, it is rich in fatty acids and also vitamins.

It is because of the increased use of industrial hemp in food industry, the demand for the same will be on the rise in the years to come.

#Industrial Hemp Market#Industrial Hemp Market Size#Industrial Hemp Market Share#Industrial Hemp Market Trends

0 notes

Text

Unveiling the Low VOC Adhesives Market Sustainable Solutions for Modern Bonding Needs

In today's environmentally conscious world, low VOC (Volatile Organic Compound) adhesives have emerged as a sustainable solution to meet the growing demand for eco-friendly bonding alternatives. As concerns about indoor air quality and environmental impact continue to rise, industries ranging from construction to automotive are increasingly turning to low VOC adhesives to address these challenges.

Understanding Low VOC Adhesives

Low VOC adhesives are formulated to contain minimal levels of volatile organic compounds, which are harmful chemicals that can off-gas into the air during and after application. By reducing VOC emissions, these adhesives contribute to healthier indoor air quality and help minimize the negative environmental impact associated with traditional bonding solutions.

Advantages of Low VOC Adhesives

Improved Indoor Air Quality: Low VOC adhesives emit fewer harmful chemicals, leading to healthier indoor environments for occupants.

Environmental Sustainability: By reducing VOC emissions, low VOC adhesives help minimize air pollution and contribute to a more sustainable future.

Regulatory Compliance: Many regions have implemented strict regulations regarding VOC emissions, making low VOC adhesives essential for compliance and avoiding fines.

Versatility: Low VOC adhesives are available in various formulations to suit different bonding needs, from construction to industrial applications.

Performance: Despite their eco-friendly nature, low VOC adhesives offer excellent bonding strength and durability, ensuring reliable performance in various conditions.

Applications of Low VOC Adhesives

Construction Industry

In the construction industry, low VOC adhesives are used for a wide range of applications, including:

Flooring Installation: Low VOC adhesives are ideal for installing flooring materials such as hardwood, laminate, and vinyl, providing strong and durable bonds without compromising indoor air quality.

Wall Paneling: Low VOC adhesives are also used for installing wall paneling and cladding materials, ensuring secure attachment while minimizing VOC emissions.

Insulation: Low VOC adhesives play a crucial role in bonding insulation materials, contributing to energy efficiency and thermal performance in buildings.

Automotive Sector

In the automotive sector, low VOC adhesives are utilized for:

Interior Trim Installation: Low VOC adhesives are commonly used for bonding interior trim components, such as dashboard panels, door panels, and headliners, ensuring secure attachment while reducing VOC emissions inside the vehicle.

Structural Bonding: Low VOC adhesives are also employed for structural bonding applications, such as bonding metal, plastic, and composite materials in vehicle assembly, providing strong and reliable bonds while meeting regulatory requirements.

Electronics Manufacturing

In electronics manufacturing, low VOC adhesives are indispensable for:

Electronic Component Assembly: Low VOC adhesives are used for bonding electronic components onto circuit boards, ensuring reliable connections without compromising the performance of sensitive electronic devices.

Display Panel Bonding: Low VOC adhesives play a crucial role in bonding display panels in electronic devices, such as smartphones, tablets, and televisions, providing secure attachment while minimizing VOC emissions during manufacturing.

Market Outlook

The low VOC adhesives market is expected to witness significant growth in the coming years, driven by increasing awareness of environmental issues, stringent regulatory standards, and the growing demand for sustainable bonding solutions across various industries. Manufacturers are focusing on developing innovative formulations and expanding their product portfolios to cater to diverse customer needs and stay ahead in this competitive market landscape.

#Low VOC Adhesives Market#Low VOC Adhesives Market Size#Low VOC Adhesives Market Share#Low VOC Adhesives Market Growth#Low VOC Adhesives Market Trends

0 notes

Text

Polyphthalamide Resin Market Insights and Growth Prospects

Introduction

In the dynamic landscape of polymer resins, Polyphthalamide (PPA) emerges as a key player, offering a myriad of applications across various industries. This article delves into the intricacies of the Polyphthalamide Resin Market, shedding light on its burgeoning growth, market dynamics, and future prospects.

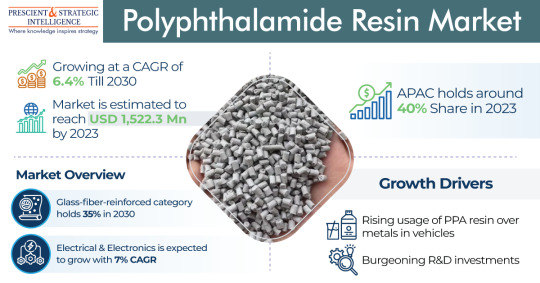

The polyphthalamide resin market witnessed a size of USD 1,522.3 million in 2023. Projections indicate a steady advancement with a compound annual growth rate (CAGR) of 6.4% anticipated during the period from 2024 to 2030. By 2030, it is forecasted to reach a substantial value of USD 2,320.6 million.

Understanding Polyphthalamide Resin

Polyphthalamide resin, a high-performance thermoplastic resin, exhibits exceptional mechanical, thermal, and chemical properties, making it suitable for demanding applications. With its superior strength, stiffness, and dimensional stability, PPA finds extensive usage in automotive, electrical, electronics, and industrial sectors.

Market Segmentation

1. Automotive Industry

Polyphthalamide Resin plays a vital role in the automotive industry, where lightweight, high-performance materials are essential for enhancing fuel efficiency and reducing emissions. From engine components to under-the-hood applications, PPA offers excellent heat resistance and mechanical strength, making it an ideal choice for critical automotive parts.

2. Electrical and Electronics Sector

In the realm of electrical and electronics, Polyphthalamide Resin serves as a reliable material for connectors, sockets, and circuit boards. Its ability to withstand high temperatures, moisture, and chemical exposure makes it indispensable for electronic devices, ensuring reliable performance and longevity.

3. Industrial Applications

In industrial settings, Polyphthalamide Resin finds diverse applications in machinery, equipment, and tooling components. Its exceptional mechanical properties, including high tensile strength and abrasion resistance, make it well-suited for demanding industrial environments, where durability and reliability are paramount.

Market Trends and Growth Drivers

The Polyphthalamide Resin Market is driven by several key trends and factors, including technological advancements, increasing demand for lightweight materials, and growing emphasis on sustainability. As industries strive for enhanced performance and efficiency, the demand for high-performance thermoplastics like PPA continues to rise, propelling market growth.

Challenges and Opportunities

While the Polyphthalamide Resin Market presents lucrative opportunities for manufacturers and suppliers, it is not without its challenges. Factors such as fluctuating raw material prices, regulatory compliance, and competition from alternative materials pose significant hurdles. However, proactive strategies, such as product innovation, market diversification, and strategic partnerships, can help industry players overcome these challenges and capitalize on emerging opportunities.

Polyphthalamide Resin Market: FAQs

What are the key properties of Polyphthalamide Resin? Polyphthalamide Resin exhibits exceptional mechanical, thermal, and chemical properties, including high strength, stiffness, and heat resistance.

What are the primary applications of Polyphthalamide Resin? Polyphthalamide Resin finds usage in automotive, electrical, electronics, and industrial sectors for components requiring high performance and reliability.

Is Polyphthalamide Resin recyclable? Yes, Polyphthalamide Resin is recyclable, offering sustainable solutions for various applications and industries.

What factors drive the growth of the Polyphthalamide Resin Market? Technological advancements, increasing demand for lightweight materials, and stringent regulatory standards contribute to the growth of the Polyphthalamide Resin Market.

How do manufacturers ensure the quality of Polyphthalamide Resin products? Manufacturers employ stringent quality control measures and testing protocols to ensure the quality and consistency of Polyphthalamide Resin products, meeting industry standards and customer expectations.

What are the emerging trends in the Polyphthalamide Resin Market?

Emerging trends include the development of bio-based Polyphthalamide Resins, advancements in compounding technologies, and expanding applications in emerging sectors such as 3D printing.

#Polyphthalamide resin market#Insights#Growth prospects#Automotive#Electrical and electronics#Industrial manufacturing#Mechanical properties#High temperature resistance#Chemical resistance#Product design#Market dynamics

0 notes

Text

Navigating the Acrylic Acid Market Trends and Opportunities

Understanding Acrylic Acid

Acrylic acid, a pivotal compound in the chemical industry, boasts diverse applications and promising market prospects. With its versatile nature and wide-ranging utility, acrylic acid continues to be a cornerstone of various industrial processes and consumer products.

Key Applications

1. Polymer Production

Acrylic acid serves as a fundamental building block in polymer production, contributing to the synthesis of acrylic polymers such as polyacrylic acid and polymethyl methacrylate (PMMA). These polymers find extensive usage in industries ranging from automotive to construction, owing to their exceptional durability and versatility.

2. Adhesive Formulations

In the realm of adhesives and sealants, acrylic acid-based formulations exhibit superior bonding properties and resistance to environmental factors. From automotive adhesives to construction sealants, acrylic acid plays a pivotal role in ensuring strong and long-lasting bonds in various applications.

3. Surface Coatings

Acrylic acid derivatives are commonly employed in surface coating formulations, imparting properties such as adhesion, weatherability, and chemical resistance. These coatings find application in industries such as electronics, aerospace, and marine, where protective coatings are essential for enhancing durability and performance.

Market Trends and Growth Outlook

The acrylic acid market is witnessing significant growth propelled by several key trends and factors. Rapid urbanization, infrastructure development, and increasing demand for eco-friendly materials are driving the adoption of acrylic acid-based products across various sectors. Moreover, technological advancements and product innovations are further fueling market expansion and diversification.

Challenges and Opportunities

While the acrylic acid market presents lucrative opportunities for industry players, it is not devoid of challenges. Fluctuating raw material prices, stringent regulatory frameworks, and market volatility pose significant challenges to market participants. However, proactive measures such as strategic partnerships, research and development initiatives, and market diversification can mitigate these challenges and unlock new growth avenues.

#Acrylic Acid Market#Acrylic Acid Market Size#Acrylic Acid Market Share#Acrylic Acid Market Demand#Acrylic Acid Market Growth

0 notes

Text

Clarity Unveiled: Exploring Trends and Innovations in the Anti-Reflective Coatings Market

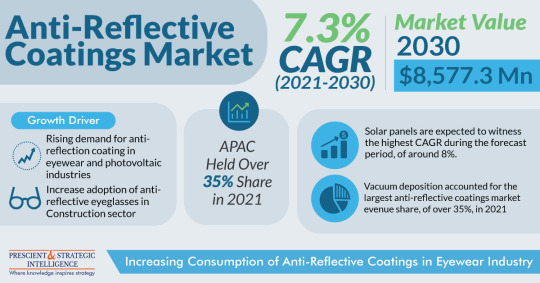

According to a statement by P&S Intelligence, the anti-reflective coatings market will generate USD 8,577.3 million, growing at a rate of 7.3%, by 2030.

The main factors boosting the growth of the industry include the increasing requirement for anti-reflection coats in the photovoltaic and eyewear industries, along with the rising implementation of anti-reflective eyeglasses in the construction sector.

Based on application, solar panels will witness the highest growth rate, of approximately 8%, in the years to come. This is credited to the growing requirement for low-cost solar cells with enhanced reliability and robustness, extensive adoption of these coatings in solar panels to rise their overall effectiveness, and the growing need to lessen photovoltaic surface reflection.

Furthermore, the electronics industry is the most-important end user in the industry because of the growing flat-panel displays popularity and increasing smartphone industry.

The growth of the anti-reflective coatings market is also driven by the increasing usage of these coatings in the eyewear industry, as the industry adopted such materials in high-light-transmitting products, for instance, eyeglasses and lenses.

Additionally, the advancement of technology in eyewear and the expansion of this industry because of the increasing prevalence of vision impairment, as well as the rising elderly populace, will further boost the growth of the industry.

In the past few years, vacuum deposition held the largest revenue share, of more than 35%, and it will propel with a significant growth rate throughout this decade. This is because of the extensive adoption of the deposition method in the application of antireflective coatings, because of its maximum adaptability, fast setting, affordability, and lesser environmental impact.

The APAC industry held the largest revenue share, of more than 35%, and it will propel at a significant rate because of the increasing requirement for logistics packaging and aerospace sector expansion.

Moreover, North America accounted for a significant share of the anti-reflective coatings industry. This is credited to the existence of a large number of reputable companies, rising discretionary expenditure by consumers, growing consciousness about the benefits of coated eyeglasses, booming automotive sector, and increasing construction industry.

#Anti-reflective coatings market#Trends#Innovations#Optical technology#Eyewear#Camera lenses#Solar panels#Displays#Market dynamics#Technological advancements#Investment prospects

0 notes

Text

Healing Innovations: Exploring Trends and Opportunities in the Medical Polymer Market

Chronic medical ailments such as cardiovascular issues, generic medical conditions, infections, and other ailments are becoming prevalent. This is demanding the expansion of cutting-edge pharmaceutical devices and sophisticated treatments.

Polymers is one of the most common used materials in medical applications. Natural polymers have been used for long for various purposes including medical.

The synthetic medical polymers have a big role to play in the pharma industry. This is because of the numerous beneficial properties including flexibility, permeability, and mechanical self-reinforcement, amongst others.

Tech Advancements in Polymer Industry

With synthetic polymers being used extensively for the creation of sophisticated materials, they are essential for the advent of new medical techs. So, an automated method of producing medical polymers is just fine for the development of advanced medical polymers designed to improve health. Robotics comes in handy for automating and increasing polymer production.

Polymer synthesis is an intricate process, because of the fact that chemical reactions are extremely oxygen-sensitive and usually needs to be removed during production.

PEEK Polymers Becoming Increasingly Popular

Polyether-ether-ketone polymers are also becoming increasingly popular all over the world recently, because of their resilience against a many solvents, lipids, , blood or body enzymes.

Other than that , these polymers are inert and resistant to heat, making them ideal for medical devices coming directly in contact with blood and tissue. These include comprise of pins, plates suture screws, bone screws, and tissue anchors.

#Medical polymer market#Trends#Innovations#Healthcare materials#Implants#Medical devices#Drug delivery systems#Tissue engineering#Market dynamics#Regulatory landscapes#Investment prospects

0 notes

Text

APAC Is Dominating the Fiberglass Market

The global fiberglass market is expected to reach an estimated USD 30.1 billion in 2023 and grow by 7.3% during the period between 2024 and 2030, reaching a value of USD 49.1 billion over that period. This is mainly due to the exclusive features of fiberglass, like high tensile strength, high resistance to chemicals, relatively low density, and non-flammable nature. Therefore, it has applications in many industries, like aerospace, construction & infrastructure, automobile, wind energy, septic tanks, boats, and water tanks.

During the projection period, the glass wool category holds the largest share of the fiberglass industry, and the category is also projected to advance at a CAGR of 7.5%. This is mainly because of the growing utilization of glass wool in the construction sector due to its good tensile strength, fire resistance, and insulative properties. It is mainly utilized for roof and ceiling insulation in halls and other huge areas as it blocks the gain or loss of heat. This is also why HVAC ducting systems are a vital application for this material.

In 2023, composites claim the majority share by application, primarily attributed to the numerous advantages of fiberglass composites when compared to conventional materials like wood and steel. These composites offer cost-effectiveness, resistance to corrosion, strong structural capabilities, and minimal maintenance needs. Consequently, the growing adoption of fiberglass composites in industries such as automotive, aerospace, and construction is anticipated to propel market growth throughout the forecast period.

Fiberglass finds extensive application in residential construction, particularly in insulation, owing to its durability and fire-resistant properties. Consequently, as governments strive to provide housing for all, the market is poised to encounter numerous opportunities, especially in densely populated nations such as India and China.

#Fiberglass Market#Fiberglass Market Size#Fiberglass Market Share#Fiberglass Market Growth#Fiberglass Market Demand#Fiberglass Market trends

0 notes

Text

Bio-Acrylic Acid Market is Led by APAC

The bio-acrylic acid market was USD 457.8 million in 2023, which will increase to USD 1,275.7 million, advancing at a 15.8% CAGR, by 2030.

This is because of the growing utilization of this chemical in surfactants, paints and coatings, adhesives and sealants, and textiles. In regard to paints, it is mainly employed for exterior walls because it has high adhesion, absorbance, and ultraviolet resistance.

The superabsorbent polymers category, based on derivative, was a significant contributor, because of their capability to absorb a substantial quantity of aqueous solutions. This is the major reason behind their use in incontinence pads, diapers, controlled-release medications, absorbent medical dressings, and more.

The butyl acrylate category is advancing at a significant rate, because of the rising investment of the governments in infrastructure projects, particularly in APAC. Silanes are extensively employed to defend buildings from deterioration.

In construction, silanes are an essential component of the coatings utilized in food & beverage production facilities, hospitals, pharmaceutical manufacturing areas, and kitchens.

Moreover, the increasing automobile demand, because of the rising urbanization level; the expanding oil & gas sector, and the rising construction activity are boosting the category expansion.

The surfactants category will advance at the highest rate, owing to the surging need for coatings in the automotive, paper, and aerospace sectors. The chemical is utilized in surfactants because it assists in penetrating the dye uniformly.

Moreover, constant expansion is being observed in the automobile sector, which will boost the need for bio-acrylic acid as an important element of automotive coatings in the coming years.

With the surging need for sealants and adhesives, the bio-acrylic acid industry will continuously propel in the coming years.

#Bio-Acrylic Acid Market#Bio-Acrylic Acid Market Size#Bio-Acrylic Acid Market Share#Bio-Acrylic Acid Market Demand#Bio-Acrylic Acid Market Growth#Bio-Acrylic Acid Market Outlook#Bio-Acrylic Acid Market Research Report

0 notes

Text

How is Manufacturing Sectors Driving Demand for Hard Coatings?

The dependence on machineries in industries has been growing since a while now. Manual labor is increasingly being replaced by advanced machines in the manufacturing sector for increasing productivity and efficiency. It is obvious then that such machines need to operate smoothly, which is why, hard coatings are used for protecting them against wear and tear.

These coatings further provide increased lifetime, greater functionality, enhanced energy efficiency, which, in turn, decrease lubricant requirements and fuel consumption. Therefore, the growth of the manufacturing industry is predicted to result in the expansion of the global hard coatings market.

One of the key applications of these coatings is lenses, where they are used for making lenses scratch resistant. Other than that, hard coatings also find applications in decorative coatings, gears, cutting tools, optics, cylinders, bearings, firearms, cylinders, hydraulic and pneumatic components, implants, and injection moulding dies. The two hard coatings processes are chemical vapor deposition (CVD) and physical vapor deposition (PVD). The CVD coating technique is atmosphere-controlled, where the solid state precursor is coated in a gaseous form in a CVD reactor. This is technique is utilized for surface coating process for producing fine grained, high purity, and impervious bulk materials which are utilized in several industries.

Coatings produced through this process are utilized in semiconductors, nanomachines, and optical fiber industry. Under the PVD technique, the base material is utilized for forming a thin coating layer on an object by condensing and evaporating the used material. The technologies used under this process are sputter deposition, electron beam, physical vapor deposition, evaporative deposition, cathodic arc deposition, and pulsed laser deposition. Due to its wear resistance and hardness, enhanced oxidation resistance, and decreased friction, the PVD technique is being demanded by a number of industries, including cutting tools, aerospace, and automotive.

Geographically, the Asia-Pacific (APAC) region is expected to emerge as a major hard coatings market in the years to come, which can be attributed to the surging demand for cutting tools and decorative coatings in the region. The requirement for cutting tool especially, in countries including Malaysia, China, and India, is creating high demand for hard coatings in APAC. In addition to this, the durability, steady application, and less time taking properties of the PVD technology is used in the cutting tools industry, and is leading to the replacement of traditional deposition technology.

In conclusion, the demand for hard coatings is growing due to the expansion of the manufacturing industry and rising demand for cutting tools.

#Hard Coatings Market#Size of Hard Coatings Market#Demand for Hard Coatings Market#Trends in Hard Coatings Market#Growth

0 notes

Text

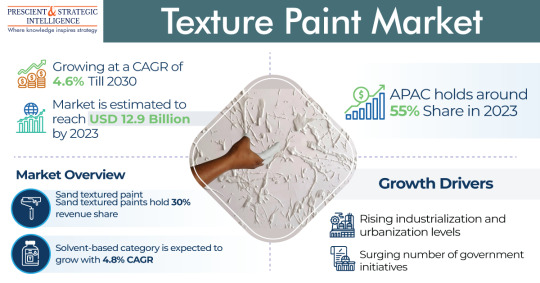

Making the Walls Glow with Textured Paints

Textured paint has become a new cool in the painting and renovation industry. It is an easy, quick and affordable way to add a new look to a space. Often used as a substitute to wallpaper, it is also a prodigious solution to cover up uneven walls. Textured painting is one of the most popular trends in home décor, and with the increase in DIY cases, many diverse styles are created with a variety of colors to choose from. The most difficult part of the project is determining which ones to put to use for best results.

What are the Different Options for Textured Paints?

Textured paint comes with different options. The premix has small, gravel like particles and is coarse in appearance. It is applied to ceilings where close scrutiny is not always probable.

Another variety, coming in a bucket and is smooth and thick requiring special application tools such as putty knives or trowels. Once applied, this paint looks like stucco. Most stores sell an agent that can be acquired separately. This material can be applied to control the roughness or smoothness.

Superior paint is the need of the hour, when you want a beautiful and striking textured look. A choice can be made between flat-finish latex and formulations with alkyd, or a sturdy synthetic resin. Latex versions are used on ceilings and don’t need a primer. Characteristically, they are durable to cover up the seams amid drywall.

What is Trending as Far as Textured Paints are Concerned?

The most popular trends in paint industry when it comes to the creation of textured finish contains metallic finishes in gold, copper, and silver. This option will allow to create a shiny, glossy look.

Textured paint can likewise be put to use for creating a faux finish. Common faux finishes comprise stone, marble, or wood, which can add texture and depth. Often this method needs tools, like sponges, special rollers, rags, trowels, and putty knives.

Visiting a paint store can become irresistible, as there are many different textures of paints to choose from. One can always check out diverse shades before making the final decision on the subject, what sort of look is wanted since removing the texture can be a little bit tough as compared to painting of a flat paint.

Touring the model houses can always be a good choice on the part of a person, who want to be very sure regarding the choice of the textured paint. Home improvement stores have different cards showing the diverse finishes.

#Texture Paint Market#market trends#technological advancements#key players#textured coatings#interior design#exterior applications#aesthetics#durability#transformative surfaces#market dynamics#innovative paint formulations#decorative finishes#textured wall coverings#architectural coatings

0 notes

Text

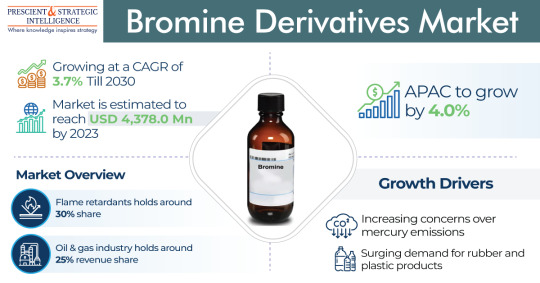

Elemental Elegance: Navigating the Bromine Derivatives Market

Sodium bromide is the most demanded derivative of bromine. It is white-colored, highly volatile, crystalline solid similar to common salt. This salt is used for the use of the bromide radical. There are many applications of the same, just as the other derivatives of Bromine in the drug industry.

Some chemical compounds are called chlorides, halides, and iodides also get extracted while withdrawing from the water of the ocean. Antiepileptic properties of the bromide salts are unveiled within the other salts resultant ocean water.

Structuring of Sodium Bromide

Sodium is a positively charged, extremely unstable because it is an extremely reactive metal. So, this reacts with the negative bromide radical to form an ionic bond together for the formation of a sodium bromide compound.

The structure of sodium bromide is linear, and polar because the negative and positive radicals create a polarity where electrons are shared on the more negative radical, that is the bromide liberal in the compound.

Where they Use sodium Bromide?

Just as any other bromides, it is put to use as a sedative. In numerous health problems, such as insomnia, sedatives come good for curing the same.

In the oil and gas drilling sector, sodium bromide is the main consumer because of its displacing properties, which can come in handy for oil extraction.

These are persistent with those which are projected from thermodynamics data and Kohler theory. At low level of humidity, 50cm-1 band centers of liquid water in bromine aerosols comparative to pure water are blue shifted. Also, particle structure and phase, in cooperation with atmospheric implications has also been discussed.

Summing Up the Scene

It is due to the increasing demand by rubber and plastic sector, the demand for bromide derivatives is on a high. The total demand of the industry will reach USD 5,614.1 million by the end of this decade.

0 notes

Text

Self-Healing Materials Market is Led by the Polymers Category

The self-healing materials market is experiencing significant growth and it will continue this trend in the years to come.

The growth of the industry is primarily attributed to the continuous inventions in the advanced material field intended for self-healing; surging acceptance of these materials in the healthcare, electronics, and automotive sectors; and their greater long-term financial advantages over conventional materials.

Self-healing materials assist in boosting the lifespan of systems, as they restore the damages and further lessen the growing entropy. The most substantial utilizations of such materials are in the aerospace, automotive, oil & gas, and building & construction sectors. The utilizations in the automotive sector comprise self-healing elastomers-based anti-scratch polyurethane coatings for vehicle bodies.

Moreover, the major application in the construction sector is self-healing asphalt. Capsules comprising oil are embedded in the bituminous binder to boost the asphalt roof covering lifespan. Therefore, the expansion in these sectors is resulting in the advancement of the industry.

Various innovations in self-healing materials have been observed, in the past few years, in the domain of advanced material. This advancement in technology has resulted in quicker healing and boosted the repair of the performance of these materials. This would cause a new era of environmental management and infrastructure preservation technologies. Therefore, research & development in cutting-edge materials has become a key trend in the industry.

In the past few years, the polymers category, based on material, accounted for the largest self-healing materials market share, and it will further advance at a considerable rate in the years to come. This is mainly because polymers imitate biological healing and heal themselves without requiring any external interference when they endure damage.

In the past few years, the building & construction category, based on application, accounted for the largest share of the self-healing materials industry. This is mainly because of the surging utilization of such materials in non-residential construction. These materials can restore early-stage damage, which, if unchecked, might result in material failure.

The European self-healing materials industry accounted for the largest share in the past few years, and it is likely to further advance at a substantial rate in the years to come.

#Self-Healing Materials market#materials science#market trends#global market outlook#innovative technologies#market dynamics#research and development#structural applications#market growth factors#construction materials#regulatory landscape#quality assurance#automotive coatings#biomimicry

0 notes