Text

DAMASCUS WATCH CASE

The case is Damascus steel made for us by a forge in the states that uses these enormous Nazel Hammers to smash the different steels together. The design chosen for the Obscura moves away from the ubiquitous wavy form that so many associate with Damascus and appears more cellular. Which is exactly what I wanted. Something more akin to alien skin. After we receive the raw material, the recognisable Schofield case shape is fully machined in England, Then it comes back to Schofield where I finish all the cases by hand. Using high-strength Hydrochloric acid to etch the surface, less for colour but more for texture.

In a more recent update we added bronze bushings around the strap bar holes. This contrasting material acts like a friction bearing but also frames the steel strap bar screws, creating an obvious boundary and shadow line.

British watches

1 note

·

View note

Text

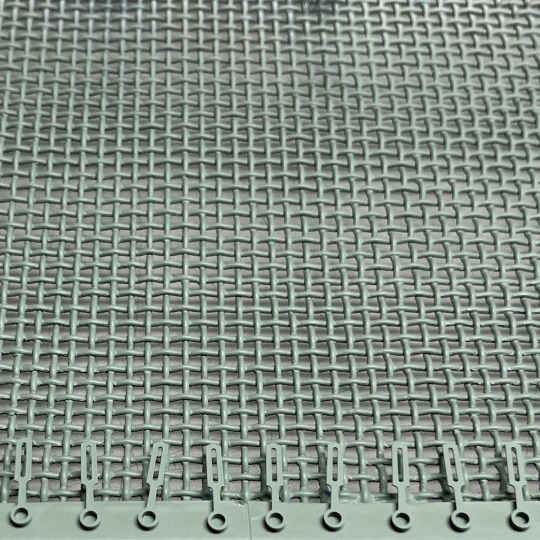

OBSCURA BUCKLE

This buckle was designed for the Obscura but also retro-fitable to all other Schofields, this is why the Obscura buckle is not Damascus, that was too cheesy and watch specific. Overall, it is slightly bigger than the old types, an appropriate shift in the visual balance of weight between the watch and the buckle. The one shown is the blasted type - there are others coming and you will see those soon.

17 notes

·

View notes

Text

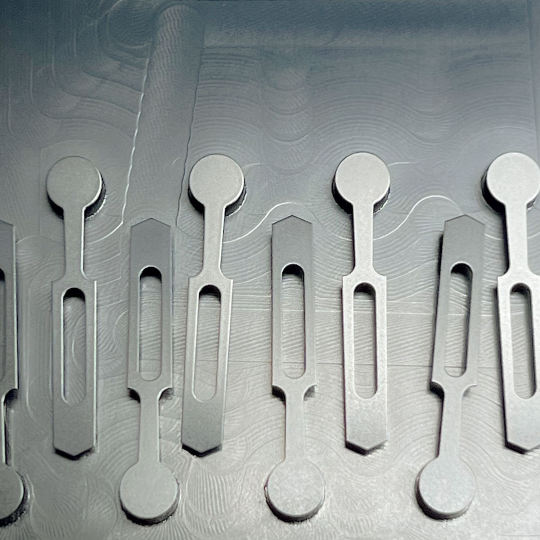

OBSCURA HANDS

These are the hands in progress; hours, minutes and seconds, milled, ground, plating, polishing, luming, colleting and finishing. Fully machined in Germany, there is no finer process for manufacturing the best watch hands in the world than this.

Obscura Watch

1 note

·

View note

Text

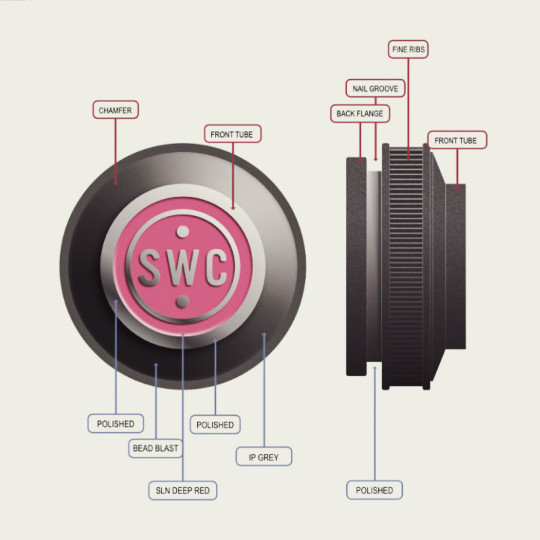

CROWNS

The real Obscura crown on its tod. A quick 'n dirty factory shot, but wow, right? It is these details which will make this watch berserk!

1 note

·

View note

Text

OBSCURA BLANK

Here is a dial blank, a dial in the early stages, un-plated and not yet filled with Super-LumiNova, and that is what those outer channels are for - serious lume! Individually filled with a hypodermic syringe. This is the Obscura dial, an extremely complex, multi-levelled affair with runnels of awesome glow.

If after reading all about it you would like one then email in and get on the list! :-) Schofield Watches

1 note

·

View note

Text

OBSCURA CROWN

Let’s look at the crown. It is oversized like all Schofield crowns, better for leverage and easier to handle. PVD black with double O rings. It is the screw down type. It has fine knurling and our nail groove, it has multiple steps and different finishes but the real fun is with the red/pink Super-LumiNova fill in the engraved front face. A glowing dot under your cuff, a concept we introduced with the Blacklamp.

Visit https://schofieldwatchcompany.com/

1 note

·

View note

Text

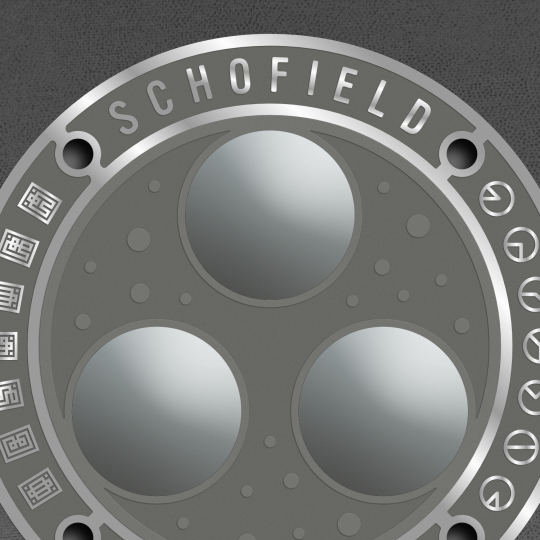

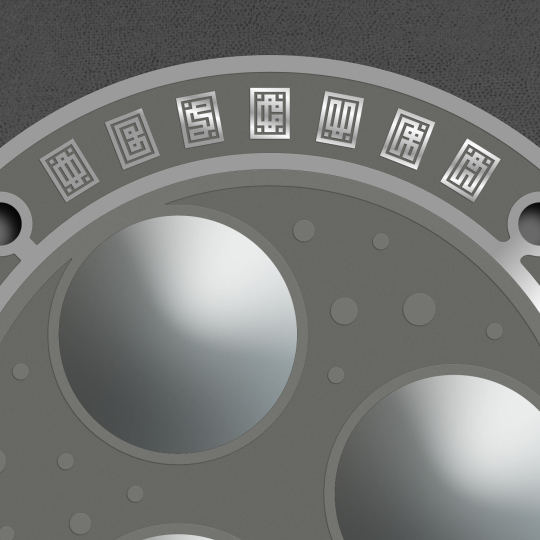

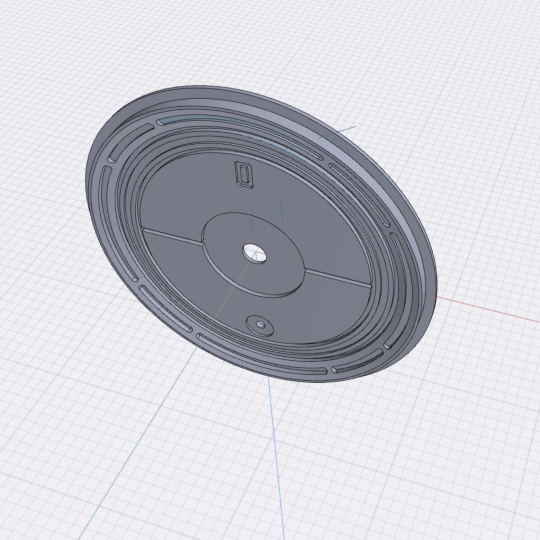

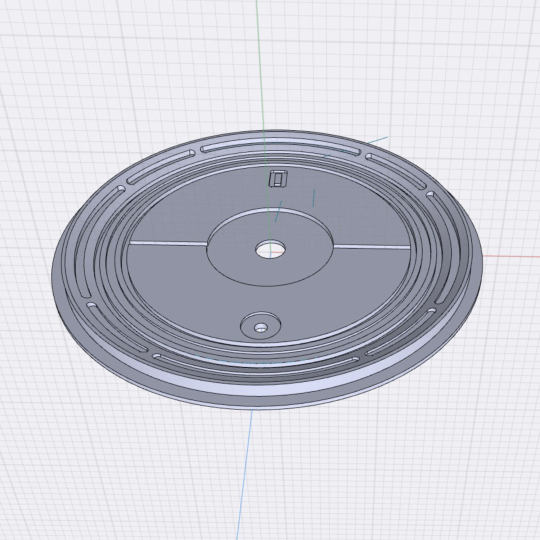

OBSCURA CASE BACK

A first look at the case back, clearly this is a drawing but I have the real thing in my mitts and to say it is a level up is an understatement! The design is built around the three smoked crystals in the centre. Smoking a crystal is the term used to describe a graduated coating on the underside. We are using a grey coating to partially obscure the manual wind Unitas movement beneath. These crystals slightly magnify elements on the movement, like the blued screws, which scintillate as they catch the light.

The overall theme of the watch continues here with the brief that the Obscura should be akin to a timing device and less an obvious watch, even though it has central hands and tells the time conventionally. It should be an object of suspicious origins, military perhaps or alien?

The three circles in a triangle is a classic Sci-fi meme (think Predators tri-beam laser gun sight), but they also represent planets among the stars. The fonts are interesting, below is a font I have used before for Schofield and really love, there is something about its ambiguous vibe. It could be Mayan, Chinese, Witcher or Incal – who knows? I would not rank it for legibility – can you make out what it says?

The other is a font representing semaphore flag positions. A contracture of the N and the D makes the CND logo, a masterpiece of design by Gerald Holtom in 1958. Peace!

Visit Schofield for cool British made watches.

1 note

·

View note

Text

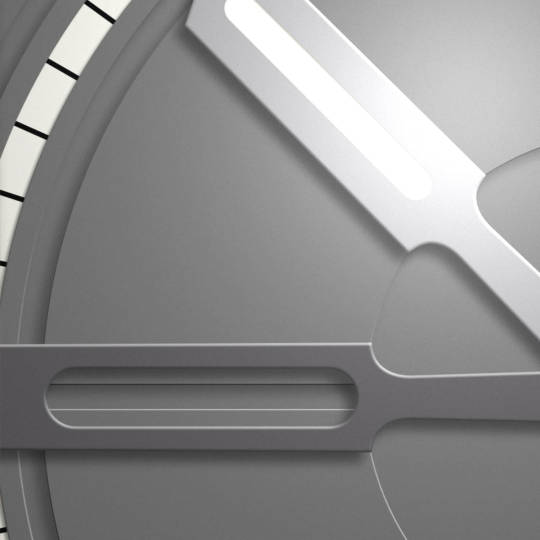

OBSCURA DIAL

Soon I will explain what is happening here. For now, these images show a dial made from a single piece of metal. The complete 3D topography is achieved through milling alone (which is why there are no internal corners), the voids and rebates are then filled with various Super-LumiNova colours.

See more very cool watches here...

1 note

·

View note

Text

OBSCURA HAND INTERACTIONS PT 2

More hand and dial interactions – a vital part of watch design, quite often overlooked. The Obscura has to be obscure right? By building in obscurity into the relationship between the dials and the hands we can some interesting interactions.

These images only seen in this watch club show the minute hand blocking (obscuring) the lume ring below whilst the hour hand is too short – which is why it is lumed. So the hour hand is visible at night whilst the minute hand is visible via the absence of lume below it. Nice!

The term Designing Interactions is not mine, coined by the great Bill Moggridge who wrote a book with same title, it is a study includes UX, cultural behaviours, but really starts with how humans interact with objects.

This is not relevant as the watch is already defined. I am concerned with how one designed element interacts with all the others in an assembly beyond the mechanical necessities. It goes further than just dials and hands and would include all framing parts like the bezel and crystal, the depth of the dial, textures and reflections. All is considered for the Obscura 🙂

See more at Schofield Watches

1 note

·

View note

Text

OBSCURA HAND INTERACTIONS

Hand interactions are studies of all possible combinations of the hands and dial. I do these exhaustively because they define the poetry of watch design. The intangible harmony which is only obvious when absent. When hand interactions are not considered then quite often there is something wrong with the whole project, something you cannot put your finger on and I’m telling you – it is because the designer has not played with hand interactions!

When designing the Obscura the question was how can this be interesting and a touch obscure within the constraints of using ‘normal’ hands that rotate around a central point? You will notice that the hour and minute hands are different colours, the minute hand skeletonised, the hour hand lumed. You will see that the neck of the hands lines up with a dial step. The minute hand obscures the lume ring in the dial, thereby marking time at night with an absence of luminescence so no lume on the hand is required. The hour hand being shorter is lumed, this asymmetry fulfils the overarching brief that the watch is to look like a timing device and less watchy. At 12 O’clock the hands align to reveal the lume strip through the window of the minute hand. At six we see a pleasing alignment with the sub seconds, the arrangement looks like a rail or a slot on which the seconds hand could slide up and down. See more at Schofield Watch Company.

1 note

·

View note

Text

OBSCURA

One of the big launches late in 2023 is the Obscura – a watch I have been working on for way too many years. In summery, the Obscura is an artefact. Something that if discovered in the undergrowth should probably be left alone, or handed in. It was designed specifically within all the normal design constraints to look less like a conventional watch and more like a timing device.

What I can reveal now is that the case is a special Damascus steel, less wavy and more cellar in texture. Acid and oil finished to achieve a mid contrast mat surface with a texture you can feel. The movement a Unitas manual-wind 6498-2, like the Blacklamp, a three hander with sub seconds. All the other details will be revealed as the project is finalised. Price wise we are looking at approximately £7500 + VAT. This may change (and already has because of an unbelievable case back!) depending on what gets added along the way. If you want on the list then please email us. Be sure to sign-up to the Pips if you haven’t already. Otherwise click here to go to our British Watches page.

1 note

·

View note

Text

BRITISH MADE TITANIUM WATCHES

Let's talk titanium watches and more specifically - titanium. Discovered in Cornwall in 1791, and there we have a nice link to the Blacklamp Carbon watch we made which has a structure akin to the crazy geology of the cliffs of Milook Haven near Bude. Titanium was named after the Greek Titans. It is the 7th most abundant metal in the Earth's crust. It has been detected in the sun, M-type stars, meteorites and it makes up 12.1% of moon rock composition. But that is generally an oxide because pure metallic titanium is very rare. 95% of all titanium ore is refined into titanium dioxide, a white pigment used in pretty much everything that is white - paint, sunscreen, toothpaste, paper, plastics, etc... Seen here is the Blacklamp Carbon, not for sale.

So why is titanium such a cool material for watches? Titanium reacts immediately with air to form a thin non-porous passivation layer that continues to grow for about 4 years to a thickness of 25nm. A shield that protects the body of metal. This makes titanium watches as corrosion resistant as platinum ones. It is non-magnetic, it has the highest strength to weight ratio of any metal. Titanium is roughly 40% lighter than steel but just as strong. Twice the strength of aluminium but only 60% heavier and it is here that we have the titanium watches paradox. Whilst it is a commonly accepted metal for watch cases it falls short for luxury heft. On paper it should be the number one metal for cases but alas, if it is not heavy it is not precious. It is more expensive than steel as a raw material and is more difficult to machine but within the luxury sector cost is not the limiting factor in its ubiquity, it is weight.

That said, and thanks the Citizen X-8 in 1970 who were the first to use it, we see more titanium watches on the market every year, so perhaps the on-paper specs make more sense than our senses. Rolex launched its first ever commercially available full titanium watch in 2022 marking an important milestone for the metal's luxury value. Even though every other watchmaker of note has had to make a titanium watch, very few are vaulted and coveted like their steel counterparts. As of 2023, you could look at Audemars Piguet, Grand Seiko and Vacheron Constantin for some stellar examples.

Where does the Strange Lights fit in? For starters the case, including the case back are fully machined and finished in the UK, the cases are machined in Dorset and we do the finishing here in Sussex. The laser engraving is done between the two counties in Hampshire. We use Grade 5 Ti-6AL-4V (similar to the Rolex Sea Dweller RLX and the same as Richard Mille), an alloy with 6% aluminium and 4% vanadium. It is an expensive alloy favoured for its hardness and machining capabilities. However, titanium has poor thermal conductivity so heat builds up between the surface of the part and the cutting tool, thus creating a characteristic chatter in the cut as the tool expands and shrinks, so you will also see greater tool wear. We use state-of-the-art 5 axis CNC mills with skilled engineers who work with titanium all day long, especially within the military sector. In short, they know what they are doing and that mitigates the difficulties of working with this metal. So, to see the quality of finish as we do on the Strange Lights is testament to the quality of the case machining and precision.

The Strange Lights brings together the Schofield themes of sea and space. Titanium has so many specialist applications both in marine and space exploration. The International Space Station is estimated to have 22,226 Kg of titanium onboard comprising 7% of its total mass. So, the Strange Lights had to be titanium as soon as the idea took hold. The case back features a romantic look at these notions with the use of a 1950s UFO shining its light/beam on Smeaton's Tower Lighthouse, a strange light that would be! But we also see a star circle, not just showing the passing of time but also a map or a guide. The fact that this design is like a mission patch is no coincidence. SWC SL-1 (indicating that one day they may be more iterations of this watch) is mechanically engraved on the side giving us this ship's identity.

The Strange Lights is a limited watch in two dial colours; Not Quite Green and Not Quite Red, port and starboard lights. In the sky or on the water?

Schofield Titanium Watches

Schofield British Watchmakers

#watches#Schofield#Cool#horology#design#metal#titanium#science#technology#minimalist#menswear#mensfashion#best watches#modern watches#luxury#style

27 notes

·

View notes

Text

CONSIDERATIONS OF A BLACK WATCH PT 1

Navigating the details on modern black watch materials, coatings and finishes can be a confusing undertaking. Ambiguous science with misleading figures all contribute to the marketing nonsense that spews from our beloved and often hyperbolic industry. Many manufacturers will offer black variants in their collections because black is cool and has been since the 14th century! As many of you know black is my go-to and has been since 2012 (after giving up the madness that is premium denim so thick you can't bend your knees!). This was also the time Schofield was thinking about the Blacklamp, which was named for many reasons one of which is a play on lamp black, a black pigment made by collecting the fine soot from the inside of an incandescent lamp.

Black means a surface that absorbs visible light and does not reflect it. Ultimately it will have an albedo of 0 (fully reflecting surfaces have an albedo of 1). In 2008 researchers at Rensselaer Polytechnic Institute created the blackest material ever - reflecting just 0.1% of light from carbon nanotubes stood on end. By comparison black paint reflects 5-10%. Since that time the same team have improved the coating to reflect only 0.03%. Vantablack developed by Surrey Nanosystems is at 0.045%. Both outfits argue theirs is the blackest.

As black dials go, using Vantablack is certainly cool if you are H. Moser & Cie. Schofield spoke to Vantablack before they had made a watch dial but I felt that as soon as you cover it with a sapphire crystal, that reflects light regardless of the coatings, then it's all rather pointless.

Black watches are a recent development because there were no readily available black materials or coatings until the mid 1970s other than oxidising, anodising, powder coating or painting and most of these don’t sit comfortably beside platinum, gold or stainless steel in a chart of premium materials.

When designing watches we are limited to the materials used because of machining, safety and cost constraints. So when I say black, I also mean dark grey and sometimes with hues of brown, blue or green. I also look at all the material surface characteristics - colour, texture, slickness, temperature and sheen, finding ways to exploit these attributes favourably. These subtleties bring differentiation and make our ‘black’ watches interesting.

#black watches#Schofield#Watches#Science#Black#Schofield watches#design#horology#Mechanical watch#minimal#Giles Ellis#Made in Britain#Made in England

6 notes

·

View notes

Text

CONSIDERATIONS OF A BLACK WATCH PT 2

Let's look more closely at the materials and the language used to describe them in an attempt to make an informed decision on whether the material can work for us.

When considering a watch case, texture is generally either rough or smooth depending on the surface irregularities. We should also consider waviness and lay of the texture or whether or not the case has been engraved like the amazing Linde Werdelin Octopus Tattoo.

Slickness is synonymous with smoothness but not exclusively so. A watch case can have a rough surface finish and a DLC coating. Aluminium magnesium boride (BAM) has a record low co-efficient of friction (COF) of 0.02, DLC of 0.05 and Teflon in third place at around 0.4. These three surfaces are the only ones a gecko cannot stick to. Steel by comparison has a COF of 0.8.

Temperature is interesting because different materials feel warm or cold to touch because of varying degrees of heat conduction. Steel will take on changes in ambient temperature much more quickly than carbon fibre for example.

Sheen is the complex qualities of reflected light and colour. Tantalum for example will look black in artificial light but like blue steel in sunlight. Metal case finishes are generally limited to polished, micro-bille (bead blasted) and linished (brushed). If we were comparing to paint finishes the sheen of these would equate to gloss, matt and eggshell.

All of these factors contribute to the tactile qualities of your watch. It is after all an object you handle every day and because of this I would place as much emphasis on the visual as the tactile.

The physical properties of materials and coatings mainly only affect the longevity of the finish which would include hardness, scratch resistance and toughness.

Hardness can be measured in a few ways but we will concern ourselves mainly with Vickers (HV). This test can be done on most materials and involves impressing a pyramidal diamond (the load) into a surface and measuring the plastic deformation of the surface. To put this into perspective, stainless steel (316L) is between 150 - 500 HV. Sapphire Crystal is around 2500 HV. This is relevant because it indicates how dent resistant your watch is.

Scratch resistance is different to hardness because it involves shear and load, whereas hardness is just load. Basically scratch testing is measured by drawing a point (load) over (shearing) a surface at pressure and measuring depth and displacement of the substrate. We all know sapphire crystals to be scratch proof, right? Not quite, scratch resistant! All materials can be scratched.

Toughness is the ability of a material to absorb energy and deform not fracture, dent not break.

The ideal black material would be one that is luxurious, exotic, durable and tough, has beauty and depth of blackness with a subtle hue depending on the light, and has tactility and heft that constantly pleases. A material that so utterly compelling that you just have to have it!

I think there are six practicable surfaces that have these desirable qualities - one metal, one ceramic, one composite and three coatings. They are fairly accessible with all in use across many brands. With all there is a compromise, mostly cost. The unexpected cost of repair and re-finishing of these materials could make the purchase of a black watch much more expensive in the long run.

Tantalum is a rare transition metal, bluish grey and very dense. In sunlight it is truly wonderful. Most of it comes from Australia and one of its main uses is in the electronics industry in electrolytic capacitors. It has a hardness of around 1900HV and is very scratch resistant. It is not easy to machine and the dust can combust spontaneously on exposure to air. The rarity and difficulty in machining makes this an expensive material for use in watch cases. I intend to use Tantalum one day.

Zirconium dioxide is the most common ceramic used in watches. There are others and ceramic technology moves fast with companies concocting their own recipes, like Hublot’s Magic Gold and Rado’s Silicon Nitride. Zirconium dioxide has a density similar to aluminium and is very scratch resistant with a hardness in excess of 2000 HV, but it has a low fracture toughness. It is this last fact that has caused some concern with consumers over the risk of the case shattering or splitting in two. It is the Achilles heel in what would be an almost perfect material. Ceramic watches are sintered, which is a way of making a solid object from powders, done by moulding and heating. IWC and Redo introduced it to us in the late 1980s. Chanel then widened its appeal in 2000 with the introduction of the J12. Schofield continues to experiment with and prototype full ceramic cases but has for some time concentrated on ceramic coatings. These are more resilient in real world tests than most coatings outlined in this article.

Carbon fibre is generally known to be associated with Formula One racing and sports equipment. It has a very high strength to weight ratio. Not until recently has it caught on for watch case production and for good reason. It just does not have the homogenous density to be machined or moulded to complex shapes with small tolerances. It also lacks toughness and has a relatively low surface hardness. Over the last 10 years more and more companies use it well by experimenting with the ingredients that make the composite. The Audemars Piguet Royal Oak Concepto Carbon, Hublot’s All Black Carbon, The Bell and Ross Carbon and the Ellicott Mach One Skymaster are watches that pioneered carbon fibre.

We like to think that Schofield has played a small part in the carbon watch world with the development of our own material for the Blacklamp. We developed Morta, a special carbon fibre that is incredibly dense making it really tough, hard and scratch resistant, negating all of the downsides associated with the material. After all we don’t need it to be light weight - think Richard Mille. Morta is a textured black-grey material reflecting light with a sparkle like waves on the sea. It is autoclaved one watch sized billet at a time which gives each piece a unique textural grain. Schofield is looking to introduce a new carbon watch, a Blacklamp Evo.

PVD (Physical Vapour Deposition) is a group of coating methods that deposit thin film coatings, usually between 5-10 microns thick. It should be said that DLC (Diamond Like Carbon) is a material that is applied with the PVD process. The watch industry however has split the two with PVD generally being regarded as the inferior coating. It is not always inferior but is often cheaper. Coating watches successfully depends on a particular ‘art’. It takes experienced technicians to combat the quirks of the equipment and variations in the environment, target, compounds, processes and cleanliness to guarantee consistent results.

PVD deposits a layer of material by condensation of vapour in a high temperature and vacuum environment. It is often applied by line of sight meaning it is sprayed on. On angular shapes sometimes the crevices won’t get coated. The other issue is that PVD when applied at high temperatures can anneal the steel target and make it softer therefore more prone to denting. What is the point of having a super hard coating if the supporting structure is soft? If this is so, then the coating is nothing more that cosmetic. The coating compounds are made up of various elements such as carbides, nitrides, borides and silicides; confusingly these coatings are most often hard ceramics. PVD has had a reputation of pealing or flaking but this is occasional and is not symptomatic to the method. Coatings applied with PVD range in hardness from 1000-4000 HV. PVD is ubiquitous in the market-place, a brand example that uses particularly good PVD with different substrate textures was/is Romain Jerome.

DLC, as the name suggests, is just that. Like PVD it can be done well or cheaply and badly. The diamond like structure of DLC can be more or less diamond like depending again on variations in the process - cleaning, compounds, catalysts, temperature, vacuum etc. Really good DLC (like we use) is not only very expensive and time consuming to apply but is harder than most other PVD coatings. With a surface hardness over 4500 HV it is extremely scratch resistant. DLC like this has very few hydrogen atoms ensuring the carbon atoms bond strongly with each other in what is known as amorphous sp3 bonded carbon, A good example of ADLC is the Cartier Santos 100 carbon.

DLC is mainly used as a tribological coating, e.g. in engine parts or cutting tools to reduce wear and friction. Even your Gillette razor blades are treated this way. When handled it imparts an unusual greasy, slippery feel. The colour of DLC coatings used for watch cases range through dark grey to jet black. The Schofield Signalman DLC and Silvertop is black with subtle brown tones when viewed in daylight. We bead blast the steel prior to coating to give a matt finish which makes the case look darker. It also work-hardens the steel improving its hardness. We have been DLC coating watches since 2010 and still do on request, though we currently favour ceramic coatings.

Titanium Nitride coatings like Aluminium Titanium Nitride (AltiN) are tribological coating used to reduce wear to machine tools. I would argue that there are better coatings for mechanical properties, but it can look good especially when Urwerk use it. A variant of PVD is that containing Titanium Carbide (TiC). Tudor uses this on the Black Bay. It is very hard and less brittle than DLC - Schofield is playing with this finish to achieve new textures on our cases.

There are other exotic materials in usage like Arcap and Alusic. Also the use of femto pulsed lasers to blacken any metal. When designing watches a decision has to be made based on a materials cost, scientific pros and cons and whether it fits with the projects aesthetic nature. As consumers we can engage further with the things we touch through knowledge and for me it’s about the integrity in design that includes the science but also art. The question I ask is how can I take this thing and make it cool.

To celebrate black watches, of which there will be more from Schofield, I have made a new sticker.

2 notes

·

View notes

Text

Limited edition, Ceramic Beater.

6 notes

·

View notes