#Aluminium Honeycomb Panels

Text

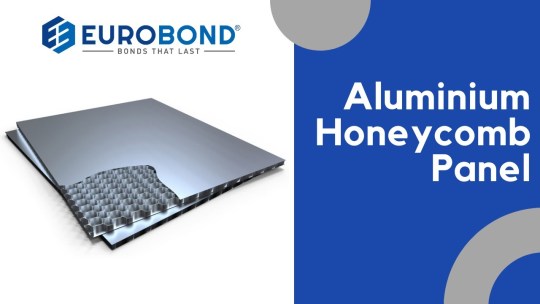

Exploring the Versatility: The Benefits of Aluminum Honeycomb Panels Across Industries

Innovation in construction materials has paved the way for revolutionary solutions in architecture, transportation, and various industrial sectors. One such advancement is the utilization of aluminum honeycomb panels. These lightweight yet sturdy structures offer a multitude of benefits across diverse applications, ranging from aerospace to interior design. In this blog, we delve into the…

View On WordPress

#ACP panels#ACP sheet#Aluminium composite panels#Aluminium Honeycomb Panels#Eurobond#Eurobond ACP#Eurobond ACP panels#Honeycomb Sandwich Panel

0 notes

Text

#aluminium composite panel#Honeycomb Panels#Aluminium Honeycomb Panels#Aluminium Honeycomb Core#Lightweight Honeycomb Panels

0 notes

Text

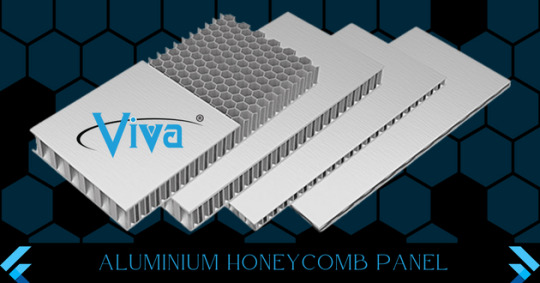

If you are interested in purchasing one, select from the Viva ACP, they have one of the highest ranges in design and colours for honeycomb panels. Tested from the top institutions nationally and internationally these panels from Viva are the ones for your construction.

0 notes

Text

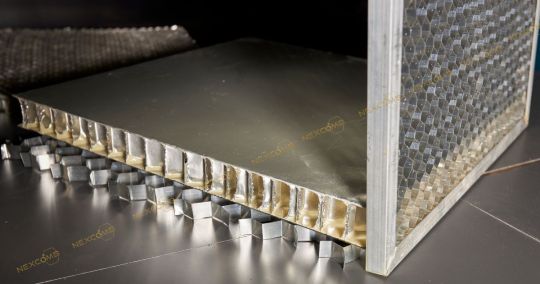

Aluminium honeycomb panels India are lightweight construction materials consisting of a honeycomb core sandwiched between two aluminum sheets. They are widely used in industries such as aerospace, automotive, marine, and architecture.

0 notes

Text

Aluminium honeycomb sandwich panel are a type of composite material used in construction and manufacturing. They consist of two thin sheets of aluminum, bonded to a lightweight honeycomb core made of aluminum or other materials.

0 notes

Text

Aluminium Honeycomb Composite Panel is a type of sandwich panel consisting of two thin aluminium sheets bonded to an aluminium honeycomb core. This combination results in a lightweight and strong panel with excellent thermal and acoustic insulation properties. Ecocomb Aluminium honeycomb composite panels are commonly used in the construction, aerospace, and transportation industries due to their durability, stability, and resistance to corrosion. The panels can be customised in terms of size, shape, and color to meet the specific requirements of various applications. They are also easy to install and maintain, making them a popular choice for various structures, partitions, and cladding systems.

0 notes

Text

3 Excellent Reasons to Use Aluminum Composite Panels

Aluminum composite panels by ACP Sheet manufacturers can give buildings an edgy, modern appearance. Aside from its aesthetic value, aluminum composite panels have a variety of other benefits.

#ACP Sheet manufacturers#ACP Sheet Manufacturer#Aluminium Composite Panel Manufacturers#Aluminum Honeycomb Panel

0 notes

Text

How Does Composite Wall Cladding Perform In Extreme Weather Conditions?

You would be happy to know that composite wall cladding is a popular choice for architects, builders, and property owners looking for an attractive and durable cladding material that can withstand a range of weather conditions. But have you ever thought that how does composite wall cladding perform in extreme weather conditions?

Heat: Composite wall cladding and shiplap wall panels are designed to resist heat and is often used in hot and humid climates. These wall panels have a high resistance to UV rays, which can cause fading and discoloration in other materials.

Cold: In cold weather, composite wall cladding is less likely to crack or warp than other building materials like wood or vinyl. You would be happy to know that this wall panel can also withstand freeze-thaw cycles without damage.

Wind: Similarly, composite wall cladding has excellent wind resistance and can withstand strong winds without becoming dislodged or damaged easily.

Rain: At the same time, composite wall cladding is water-resistant and will not absorb moisture like wood or other organic materials. Due to this reason, this wall cladding also resists mold and mildew growth.

Hail: On the other hand, the aluminum corrugate panel can withstand hail impact without denting or breaking, making it a good choice for areas prone to hailstorms.

Composite wall cladding from HONGZAN Building Materials Co., Ltd is an excellent choice for extreme weather conditions. The durability, and resistance to heat, cold, wind, rain, and hail, make these wall claddings a reliable and low-maintenance option for any building project.

Get to know more us :-

Aluminum Honeycomb | Decorative Wall Panels | Aluminium Komposit | Aluminum Honeycomb Panel | Aluminium Panel | Honeycomb Aluminum Panel | Stone Veneer Panels | Aluminium Wall Panels

Contact us :-

Company Name: Hongzen Building Materials Co., Ltd.

Address: Mayi Village, Shiling Town, Nanhai District, Foshan City, Guangdong Province, China.

Country: China

Mobile: 0086 139 2319 2421

Email: [email protected]

Website: https://chinahoneycombpanel.com/

0 notes

Photo

Urs Fischer (Swiss, b. 1973), Office, 2021. Aluminium composite panel, aluminium honeycomb, polyurethane adhesive, epoxy primer, gesso, solvent-based screen printing paint, water-based screen printing, 243.8 x 194.9 cm

426 notes

·

View notes

Text

The Space Shuttle's vertical tail is 27 feet high and 22 feet long at the base. It ensures the stability and the direction of the orbiter in flight. It supports the mobiles elements which are used to oriente the orbiter or to slow down (areobreak). These last ones are jointed with four pieces and controlled by an electrical engine. The box of the vertical stabilizer is made of two strengten pieces mashin-finished from one piece, panels. The box is settled to the rear part of the fuselage by ten bolts. The mobile parts (direction and aerobrake) are made of aluminium alloy and panels in honeycomb structure.

All were built by Fairchild Republic Company, in Long Island, New York.

source

Boeing Images: B1230615

43 notes

·

View notes

Photo

Ian Davenport, Untitled (Circle Painting: blue/green/blue), (household gloss paint on aluminium honeycomb panel), 2003 [© Ian Davenport]. From: Colour is, Waddington Custot, London, March 1 – April 28, 2017

56 notes

·

View notes

Text

EuroComb: Aluminium Honeycomb Panels Processing Demystified

Remember the internal tug-of-war when smartphones arrived, and we held on to our trusted push-button mobiles? Today we have long since bid them goodbye, having overcome our initial misgivings about smartphones.

Innovations are accompanied by apprehensions, which once demystified, open up a world of benefits! It’s the same with Aluminium Honeycomb Panels (AHPs). This blog will therefore focus on bursting the bubbles of doubt surrounding AHP processing, to promote informed decisions that help reap the amazing benefits of this lightweight

EuroComb Panel – a great boon for Clean Room Systems, Commercial Facades, Ceilings, Coach Bodies, and Aerospace Applications.

A word about Aluminium Honeycomb Panels: Inspired by nature, EuroComb is a sandwich panel with a hexagonal honeycomb structure at its core that contributes to its lightweight, while simultaneously augmenting stiffness and stability. Built on the principles of safety and environment-friendliness, EuroComb incorporates fire-retardant properties and are fully recyclable. Added advantages are their superior flatness, exceptional stiffness, and sound insulation. Our PVDF coating makes EuroComb weatherproof, UV resistant, waterproof and dust-proof.

Now let’s deal with the deceptive doubts.

Myth: EuroComb processing is complex and difficult, requiring highly skilled labour.

Reality: EuroComb processing employs normal tools with specific tool extensions to make processing easy – ensuring a smooth finished product with minimum effort.

So, let’s explore each process to demystify the AHP Processing myth.

Cutting – employs two simple tools:

Pitch Router/Hand Router

Common Blade

The Pitch Router affixed with the Common Blade is effortlessly guided across the length of the AHP that is to be cut. That’s it – the job is done!

Edging – involves four tools:

Electric Router

Rectangular Groove Bit

Pitch Router/Hand Router

Common Blade

The Electric Router affixed with the Rectangular Groove is guided across the bottom edge, keeping the EuroComb’s top cover intact. The Pitch Router’s Common Blade is then guided across to make a groove on the Top cover, enabling it to be manually bent over the smoothened edge, to conceal it. Voilà, you have a smooth finished product with edges neatly and safely covered!

Folding – uses the same four tools as Edging:

Electric Router

Rectangular Groove

Pitch Router/Hand Router

Common Blade

The Electric Router affixed with the Rectangular Groove when guided across the area to be folded, will efficiently scoop off the bottom cover and honeycomb core, keeping the top cover intact. The Pitch Router’s Common Blade is then run across the top cover to make a groove, enabling the desired manual folding. Hey presto! – You have a safe, smooth finished product accurately and impeccably folded at 90°.

Innovation is the avenue through which the world progresses, and hence at Eurobond, we are proud to be India’s first ACP brand to manufacture EuroComb – Aluminium Honeycomb Panels in-house. Our 15-year warranty exudes our confidence because we leverage the best quality control procedures that test our EuroComb with advanced equipment – to secure your safety.

#acp sheet#eurobond acp#eurobond acp panels#acp cladding#acp panel#eurobond#Aluminium Honeycomb Panels#Honeycomb Panels#Honeycomb acp Panels

0 notes

Text

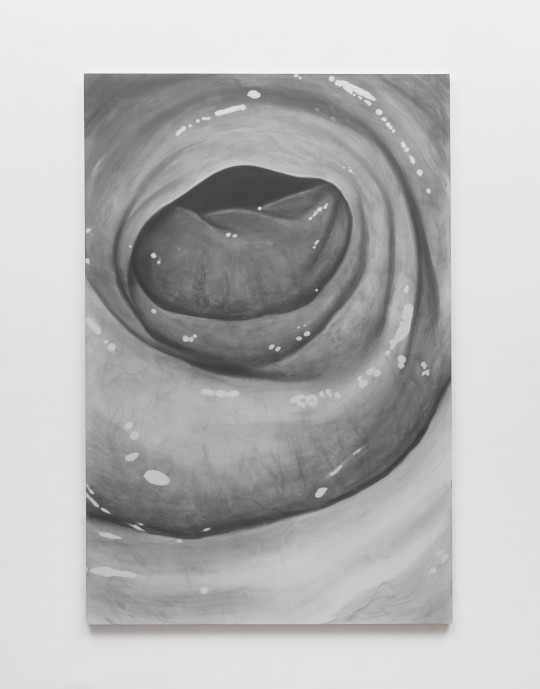

by Juan Antonio Olivares

Untitled (endoscopy), 2023

Acrylic and graphite powder on aluminium honeycomb panel

122 x 183 x 2.5 cm

source: collectionarchive.tumblr.com

6 notes

·

View notes

Photo

The honeycomb panel sheet of Viva is inspired by a natural hexagonal honeycomb structure that is 100% recyclable. This makes the sheets a sustainable choice for the environment. The structure of the honeycomb panels is like any other Aluminium Panel Sheet (ACP sheet) from the outside, while the interior has a hexagonal shape where the panels are connected in the same way I-beam are connected.

0 notes

Text

Aluminium honeycomb panel suppliers are companies that produce and distribute high-quality honeycomb panels made from aluminium. These panels consist of a core material made of hexagonal cells that are bonded between two layers of aluminium sheets, providing strength, durability, and lightness.

0 notes

Text

Aluminium honeycomb sandwich panels are a type of composite material used in construction and manufacturing. They consist of two thin sheets of aluminum, bonded to a lightweight honeycomb core made of aluminum or other materials.

0 notes