#CNC Lathe machine

Video

youtube

Auto CNC Groove Lathe Machine for PEM Hex Blind Standoff Self Clinching Rivet Nut Cabinet Metal Sheet Fasteners.

Whatsapp: +86 13431255254

#youtube#CNC Lathe machine#groove cutting machine#self clinching rivet nut#standoff rivet nut machine#cold forging#standoff rivet nut groove cutting machine#hex blind rivet nut#fasteners#auto cnc lathe machine#metal sheet rivet nut#rivet nut manufacturer#rivet nut supplier#self clinching rivet nut price#standoff self clinching nut#cnc machine#groove cutting machine supplier

2 notes

·

View notes

Text

WHAT IS CNC LATHE MACHINING? PARTS, OPERATIONS, & PROCESSES

A CNC lathe(CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer. Multiple stages may be set simultaneously, avoiding the need for your component to leave the lathe between producing and ensuring accurate cut placement.

Parts of the CNC Lathe Machine and their functions

Click here to know more about - https://phillipscorp.com/india/what-is-cnc-lathe-machining-parts-operations-processes/

0 notes

Text

Practical Tips On Buying A Sewing Machine

That describes an important question - a person you obtain an offshore drilling rig job before this appears in an ad? The simplest way is to go shopping for all the small offshore drilling contractors that the create the large offshore drilling companies like Halliburton, Schlumberger, Transocean, give up. Most of these small oil service companies usually tend to cluster around two types of places - the headquarters of big companies that subcontract to them; and around the area where your offshore oil rigs can be (in the US, these would become Gulf Coast states of Alabama, Louisiana, Mississippi and Texas).

The Craftsman CNC router is aimed towards the woodworker and dabbler. Anyone basically who has a need to create a one-of-a-kind masterpiece in their backyard and from wood, this machine has been designed these.

Toys -- there certainly variety of toy projects you can create with a CNC Wood router. Obtain make checkers and checker boards, elaborate chess sets, game pieces for a variety of video. These projects merely limited by your imagination.

From routers to mills, laser cutters, plasma cutters and more, there is really a CNC machine that you may incorporate in to your hobby which can help you not waste time and be a little more creative. Sculpting, tapering, cutting, and engraving are a totally of the features that these appliances can a person to do. Wouldn't it be nice to have a machine to in order to taper the ends persons chair legs in far less time computer system would call for to carried out manually? Or, how about cutting wings for that model airplane that an individual been enhancing?

Forstner bits are top for drilling flat bottom holes that don't go right up through the wood. For instance, chair legs that don't to help come through the seat. https://www.mskcncmachine.com/Boring-Tapping-Tleeve-Flat-Radial-Drilling-Machine-pd42701701.html have a pilot to steer the bit, it uses a fluke from the outside that cuts a nice clean edge as the chips are cut released. These bits cost above and beyond twist or paddle bits but substantial the excellent for good finish work.

The rotary core and wire line is the two main regarding diamond drilling techniques. Rotary drilling is when boreholes have with regard to dug though coring in rocks. Wire line drilling is used to treat mineral discovery. Here radial drilling machine is not just in dig a dent but and get a core small sample.

We sometimes call this emotional fat. Emotional baggage comes in the form of trapped emotional energies created relation as may be now finished external situations or imagined events. We have not completed the internal emotional release cycle connected them locations causes in order to remain alive inside of us; you would like as though these things are still happening now.

#cnc lathe machine#5 axis cnc machine#stand drill machine#bench drilling machine#radial drilling machine

1 note

·

View note

Text

Top 7 CNC Lathe Machines And Conversion Kits In 2022

While there are endless choices for CNC lathes and lathe conversion kits on the market, choosing the right one is never so easy. That’s so since machining capabilities and cost are some factors that you’re most likely to consider for your lathe.

Nevertheless, you should also keep in mind your precise requirements and go for a CNC lathe that meets them all. You see, every workshop and machinist has a different requirement altogether, meaning you can’t apply a one-size-fits-all approach. And not to forget, the longevity and sturdiness of a do dictate the choice. After all, you want your lathe to last for a long time, don’t you?

If you’re looking for your ideal lathe and CNC lathe conversion kit, you can reach out to us. We have top-of-the-line lathes from leading manufacturers like Grizzly and Shop Fox at the most cost-efficient prices. And we can deliver your ideal lathe to your workshop for free.

0 notes

Text

CNC Lathe Machine Parts

To use a Lathe Machine Parts effectively, it is crucial for the operator to feel at ease with the tool and comprehend how it operates. Look for the benefits of the lathe machine for more assistance and guidance.

0 notes

Text

Buy used WIAP - CNC Lathe - DM4 - C in Germany - Zatpatmachines

Stay Updated with our latest machines download our app:https://play.google.com/store/apps/details?id=com.zatpatmachines

For detailed specifications visit: https://bit.ly/3ddZi1A

#Used CNC Lathe for sale#CNC Lathe for sale in Germany#CNC Lathe Machine#Used CNC#1600diametercncfor sale#Zatpatmachines#Usedmachines#Old CNC for sale

0 notes

Text

6 Sets of Yornew CK140 Micro CNC Lathe, finished and ready to ship to Philippines for education purpose.

Visit our website to see more: https://www.miumachine.com/ck140.asp

0 notes

Text

CNC Conversion Kits for Mill and Lathe - CNC Conversion Plus

Convert your mill or lathe to CNC with our CNC conversion kits. Whether you are looking for Harbor Freight Mini Mill CNC Conversion Kit or just a Lathe CNC conversion kit

#cnc lathe conversion kit#cnc conversion kit#cnc conversion#diy cnc lathe conversion#lathe cnc conversion#harbor freight mill cnc conversion kit#mill cnc conversion#cnc lathe machine#benchtop cnc mill#cnc lathe machine price#benchtop cnc lathe

0 notes

Link

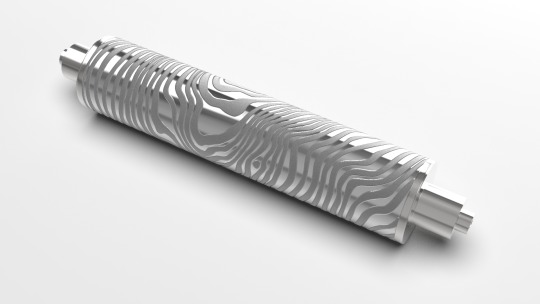

Anar Rub Tech Pvt. Ltd is engaged in the manufacture of the finest textile roller for the past 30 years. We are supported by a team of highly skilled professionals who contribute to make us the chief rubber roller suppliers in India.

Our product range includes Heavy Nip Roller, Bow Roller, a Sanforizing belt, Tube Roller, Teflon Coated Roller, Trough Roller, and S.S. Roller, etc. Our high-quality roller are fabricated employing supreme-grade raw materials and advanced technology under the guidance of our highly experienced professionals.

To eliminate any defects or flaws our quality control department checks the quality of the products before their dispatching. They are precisely engineered as per the norms of the International quality standards.

These roller are available in different sizes & models and are also offered in customized versions. They are also available in different colors and thicknesses as per desired customer needs.

Our Flexo Printing Roller in India is the highest selling product of the related supplies. We offer them at very competitive rates in the market.

These roller have extensive usage in the Textile Industry.

#cnc lathe machine#manufacturer#india#roller#textile embossing#embossing roller#exporter#indiamart#tradeindia#anarrubber

1 note

·

View note

Text

Cnc Torna

Talaşlı imalat

Fason üretim

2 notes

·

View notes

Text

I'm the lathe queen

11 notes

·

View notes

Text

How do you process carbon fiber brake discs?#carbonfiber #brakedisc #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

4 notes

·

View notes

Text

Powermatic

Powermatic is a well-known brand of woodworking machinery that has been producing high-quality tools and machines since 1921. The company is known for its wide range of products, including table saws, bandsaws, jointers, planers, lathes, and dust collection systems. Woodworking professionals and enthusiasts around the world trust Powermatic machines due to their precision and accuracy.

One of the key features that sets Powermatic machinery apart from others is the use of cast iron in their construction. This material provides stability and durability to their machines, making them reliable and long-lasting.

Powermatic machinery is designed with safety in mind. They incorporate various safety features in their machines such as blade guards and safety switches to prevent accidents in the workshop.

Overall, Powermatic is a reputable brand that offers high-quality woodworking machinery. Their precision, durability, and safety features make them a popular choice for both professional woodworkers and hobbyists alike.

Powermatic product line

Powermatic is a renowned brand that specializes in crafting top-quality woodworking machinery and tools. The brand offers a diverse product line that caters to the varying needs of woodworkers, from novice hobbyists to seasoned professionals.

Table Saws - Powermatic's table saws are engineered for precision, power, and durability. The brand offers cabinet saws designed for heavy-duty use, featuring large table surfaces and robust motors. Contractor saws are more portable and suitable for job site use, while hybrid saws combine features of both cabinet and contractor saws.

Bandsaws - Powermatic's bandsaws are designed to make accurate cuts in wood and other materials. They come in different sizes, from benchtop models suitable for small jobs to floor models capable of handling larger wood pieces. Powermatic's bandsaws are renowned for their precision, ease of use, and smooth operation.

Planers - Powermatic's planers are designed to smooth rough lumber and make it usable for woodworking projects. The brand offers a variety of sizes, with larger models capable of handling wide boards and thick wood pieces. Powermatic's planers are known for their precision and user-friendliness.

Jointers - Powermatic's jointers are used to straighten and flatten wood surfaces. They come in benchtop and floor models, with larger ones capable of handling wider wood pieces. Powermatic's jointers are known for their accuracy and ease of use.

Sanders - Powermatic's sanders include both belt and drum sanders, designed to make sanding jobs quick and straightforward. They come in different sizes, with larger models capable of handling more substantial wood pieces. Powermatic's sanders are renowned for their accuracy, speed, and ease of use.

Dust Collectors - Powermatic's dust collectors are designed to ensure workspace cleanliness and safety by removing dust and debris from the air. They come in different sizes, with larger models capable of handling multiple machines at once. Powermatic's dust collectors are known for their efficiency and reliability.

Lathes - Powermatic's lathes are used for turning wood and other materials. They come in benchtop and floor models, with larger ones capable of handling more significant wood pieces. Powermatic lathes are known for their precision and ease of use.

Mortisers - Powermatic mortises are used to make precise mortises in wood. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's mortises are renowned for their accuracy and user-friendliness.

Drill Presses - Powermatic's drill presses are used to drill accurate holes in wood and metal. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's drill presses are known for their precision and ease of use.

CNC Machines - Powermatic's CNC machines are used for computer-controlled manufacturing processes. They come in different sizes, with larger ones capable of handling larger wood and other materials. Powermatic's CNC machines are known for their precision and efficiency.

In conclusion, Powermatic's product line is designed to cater to the needs of woodworkers at all levels, offering high-quality woodworking machinery and tools that are durable, efficient, and user-friendly.

#powermatic#CNC Machines#Drill Presses#Mortisers#Lathes#Dust Collectors#Sanders#Jointers#Planers#Bandsaws#Table Saws

2 notes

·

View notes

Text

Everything You Should Know About A Benchtop CNC Lathe

If you’re looking to grow your manufacturing business, then a benchtop CNC lathe should be your go-to solution.

You see, not only such a machine helps to attain a high degree of precision, but also increase your profitability manifold by bringing about efficient machining and reducing waste generation.

0 notes

Text

Everything You Should Know Regarding CNC Lathe Machines

There are several types of CNC machining processes available today. CNC turning Parts, for example, employ a helix route to cut through the material, whereas CNC milling uses rotary cutters to remove the extra material. All of these need the use of specialized machining tools for the workpiece to perform the appropriate function. A CNC lathe is one such essential piece of equipment. The lathe is regarded as the first metal-cutting machine.

Let's take a closer look at the operation, characteristics, and different types of CNC lathe machines.

Introduction

A lathe machine with CNC lathe parts is primarily used to shape the material into the required shape by eliminating extra material from a particular workpiece (generally cylindrical). A lathe is used to accomplish sophisticated operations such as knurling, deformation, metal spinning, woodturning, thermal spraying, metallurgy, and more, in addition to cutting and facing.

The manual lathe was invented by reformers in Ancient Egypt and Greece, according to machine historians. The European nation commonly used the two-person lathe variant, with the former rotating the workpiece (wood) and the latter cutting off the extra material with a single-point cutting tool. The modern lathe arrived with the Industrial Revolution; it was sophisticated, quick, and better!

How Does a CNC Lathe Machine Work?

A standard lathe consists of a bed, headstock, tailstock, chuck, tool turret, carriage, and a spindle for feeding purposes, as detailed in the previous section. The following steps describe how this machine works:

· First, a cylindrical workpiece is mounted to the chuck after the machine has been checked for operational flaws. Its location might change depending on the situation.

· Second Step: We now adjust the spindle to the desired speed, causing the chuck and workpiece to rotate. The spindle speed must be monitored closely since any variation might result in cutting mistakes. Examine if the workpiece is rotating correctly.

· Third, move the tool turret and carriage to place the cutting tool at the appropriate feed. Pay close attention to the feeding rate. Remove any superfluous metal by moving the carriage to obtain the completed result in CNC machining parts.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes