#auto cnc lathe machine

Video

youtube

Auto CNC Groove Lathe Machine for PEM Hex Blind Standoff Self Clinching Rivet Nut Cabinet Metal Sheet Fasteners.

Whatsapp: +86 13431255254

#youtube#CNC Lathe machine#groove cutting machine#self clinching rivet nut#standoff rivet nut machine#cold forging#standoff rivet nut groove cutting machine#hex blind rivet nut#fasteners#auto cnc lathe machine#metal sheet rivet nut#rivet nut manufacturer#rivet nut supplier#self clinching rivet nut price#standoff self clinching nut#cnc machine#groove cutting machine supplier

2 notes

·

View notes

Video

youtube

How to use STARMA cnc wood turning lathe machine panel operation of 4 fu...

#youtube#How to use STARMA cnc wood turning lathe machine panel operation of 4 function About this 4 function with auto feeding cnc wood lathe machin

0 notes

Text

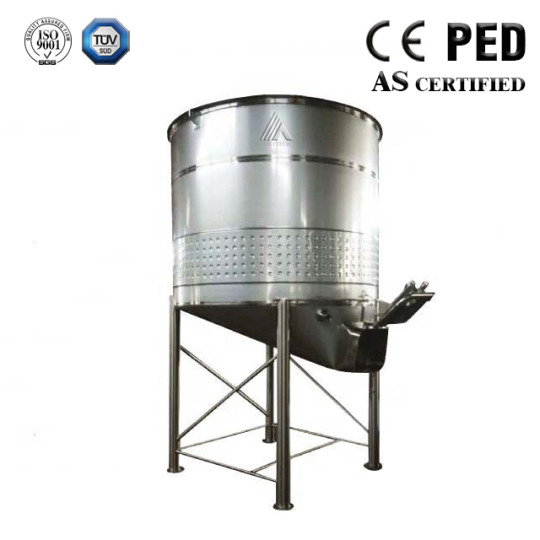

Stainless Steel Forkable Square Tank with Insulation

| Product Description

Presenting our Square Wine Tank – a specialized solution meticulously designed to meet the demands of small-capacity requirements. This tank is an ideal choice for the storage, transfer, and fermentation of limited quantities of pressed grapes, grape juice, and wine.

The square configuration of this tank optimizes space utilization, ensuring efficient handling and transportation. Engineered to be safely operated with forklifts, pallet jacks, and trailers, it offers convenience for storing, processing, and transporting full tanks of wine.

Crafted with precision and meticulous attention to detail, our Square Wine Tank adheres to the highest industry standards. Its robust construction guarantees durability and longevity, safeguarding your valuable wine throughout the storage and fermentation journey.

Whether you're a small winery aiming to enhance production capabilities or a wine enthusiast in search of a reliable storage solution for your collection, our Square Wine Tank stands as the perfect choice. Rely on its professional design and functionality to elevate your wine-making experience.

Make the investment in our Square Wine Tank today and elevate your wine storage and fermentation to unparalleled heights.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

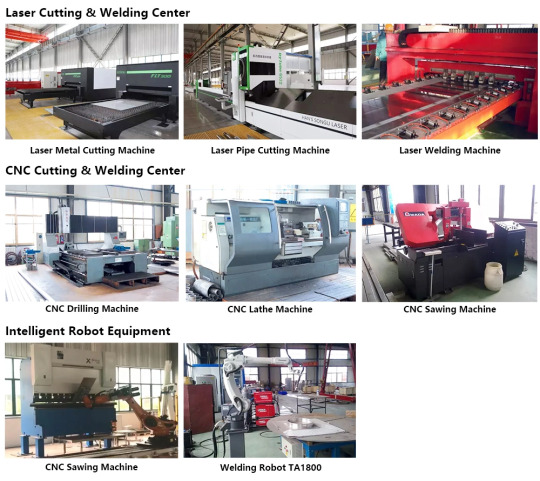

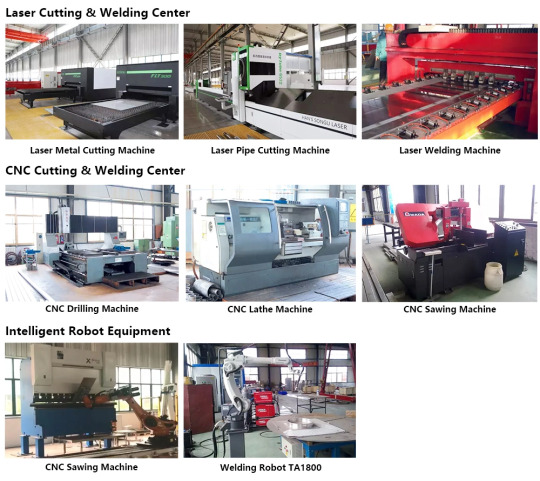

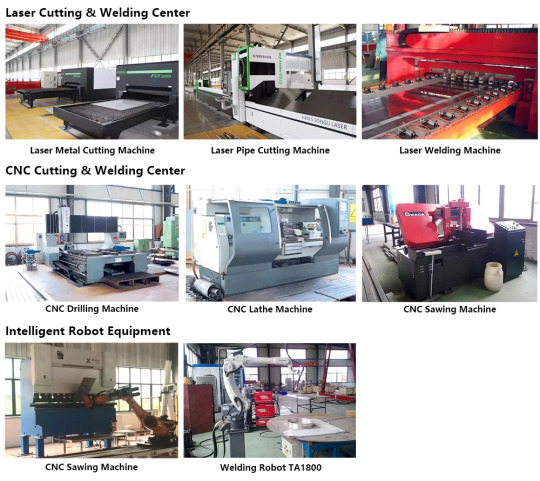

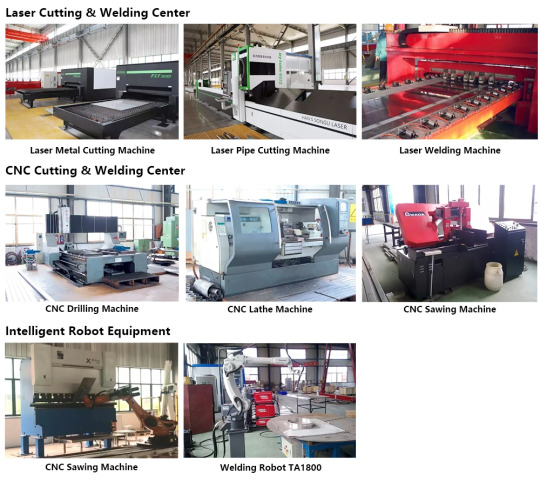

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| FAQ

1. Can you produce tanks with S.S.316L?

A: Yes we can, the wetted-parts are produced by S.S.316L to guarantee the corrosion resistance, the non-wetted parts are produced by S.S.304 to reduce cost.

2. What’s the lead time?

A: 35-50 working days depend on the order quantity.

3. How do you ship the goods?

A: We usually ship by sea in containers or flat rack.

4. Do you supply door to door shipping?

A: Yes we do, Pretank do ocean shipping, customs clearance, import procedures and deliver products to the appointed place.

5. What inspections will you do before delivery in your factory?

A: All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

0 notes

Text

Horizontal Fermentation Tanks

| Product Description

Introducing our horizontal fermenter tank, designed to enhance the winemaking process with its advanced features.

Crafted with precision, this tank offers a horizontal design coupled with a rotating stirring mechanism, maximizing the contact area between grape juice and skins. This innovative feature allows for optimal extraction of tannins and anthocyanins, resulting in a rich and flavorful wine.

Not only does our rotary wine fermentation tank deliver exceptional quality, but it also ensures efficiency in the winemaking process. With its fast batch turnover, you can produce wine in a shorter time frame, saving valuable resources and minimizing labor input.

Furthermore, this tank is equipped with automated controls, providing a seamless and hassle-free operation. Say goodbye to manual monitoring and adjustments, as our tank takes care of the fermentation process with precision and accuracy.

| Product Features

● The horizontal type and rotary mixing can increase the touching area of grape must and cap, tannin and anthocyan are macerated at max.

●Rapid turnover of batches with low labor input,automatic controlling.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it’s the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

Whatapp: +86-15295029678

Wechat: +86-15295029678

Email: [email protected]

0 notes

Text

automatic alligner machine

automated continuous 3d printing

automated transfer line

aligner machine

automatic wheel alignment machine

automatic tiptronic

automatic collect automatic correct

automatic tiptronic transmission

automatic servis

b automatic transmission

blue point alignment machine

bee line alignment machine

spark clear aligner system

conveyor belt self alignment system

ccd wheel alignment machine

direct drive vs overdrive transmission

e axle electric vehicle

fanuc socket messaging

fanuc control offset

john bean v2100 alignment machine

john bean v3400 wheel alignment system

auth0 machine to machine

john bean visualiner alignment machine

transmission electron microscope alignment

automatic transmission slide

john bean v3300 alignment machine

how to align a conveyor belt

auto insert machine

auto screw feeder machine

automatic bar feeder for cnc lathe

automatic snap button machine

automatic d1 d2 d3

automatic car d1 d2 d3

automatic transmission d d1 d2 d3

automatic service

automatic service reminder

automatic pick and place conveyor transfer using plc

automatic pick and place machine

automatic pick and place robot

qc automation

q matic machine

quantum dxi v5000

automatic transmission lining

automated vs automatic transmission

automatic transmission reverse delay

snap on alignment machine

automatic transmission testing machine

used wheel alignment machine

vx model alignment

vex auton selector

automatic haircut machine

automatic inspection system

z offset keeps changing

automatic transmission 1 2 3

quantum leap state machine

automatic 1 2 3 gears

2 post alignment machine

two and three wheeler technology

how to use 2 in automatic transmission

3d printed teeth aligners

3shape manual alignment

automatic z offset

automatic z offset calibration

4 wheel laser alignment

5d alignment machine

automatic wheel truing machine

automate shades programming

automatic alignment machine

8 track head alignment

automatic college bell system

#shshortsvideo

#shorts

#shortsfeed

#funny

#music

#technology

#technique

#viral

#foryou

#treanding

#Diplomagazine

#studysupportteam

#song

#dance

engineering all solutions

business customers

business proposal

business card design

welding machine

tiktokaahat

baby

balveer

0 notes

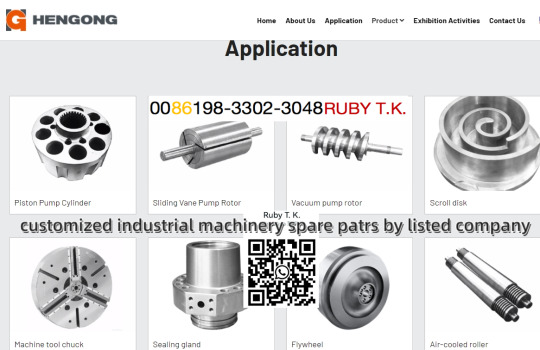

Text

I am from a Chinese listed company HGPE,Asia biggest continuous cast iron bar factory,and we also customized metal parts manufactured by our hundreds of CNC machines and lathes(hydraulic parts,air compressor parts,auto parts,robot parts,reducer parts…),OEM& ODM available.thanks®ards:) 🙏https://www.hengong-bar.com +8619833023048 [email protected]

#casting#iron bars#steel foundry#metalparts#reduceri#hydraulic cylinder#gears#skid and pump#auto parts

0 notes

Text

CNC Lathe Machine Manufacturer

This is a compact industrial slant bed lathe with 8 station programmable turret.

This can be integrated with automation components to create various configuration of Smart Factory Automation System.

This is offered with optional accessories such as CNCTrain software, eCNC e-learning, loading and unloading device, pneumatic chuck, auto door.

Its design replicates industrial machine features such as cast iron bed, precision grade grounded ball screws, LM guide ways, servo motors, coolant system, AC panel cooler for control box, full machine guard, etc.

Contact ELE for your School, College Civil and Mechanical Engineering Lab Instruments. We are the best and renowned engineering lab equipment exporter, chemical engineering lab equipments suppliers, chemical engineering lab instruments manufacturer, chemical engineering lab equipment manufacturer, chemical engineering lab equipments supplier, chemical engineering lab equipments manufacturers in Ambala, India.

This is a compact industrial slant bed lathe with 8 station programmable turret.

This can be integrated with automation components to create various configuration of Smart Factory Automation System.

This is offered with optional accessories such as CNCTrain software, eCNC e-learning, loading and unloading device, pneumatic chuck, auto door.

Its design replicates industrial machine features such as cast iron bed, precision grade grounded ball screws, LM guide ways, servo motors, coolant system, AC panel cooler for control box, full machine guard, etc.

0 notes

Text

Auto Die casting parts-E motor housing

Application &Purpose: mold is designed and produced in-house. This part is produced with 280tongs and/or 400tons famous brand casting machines and do the CNC center/lathe machining with specifications. It is used for new energy automotive application.

Material: Alloy ADC12 Etc ( customer specified)

Main Process: Alloy ingot melt-casting -punching-deburring-tumbling(shot pinning)-ultrasonic washing-CNC machining(needed)-anti oil spraying(needed)-packing

1 note

·

View note

Text

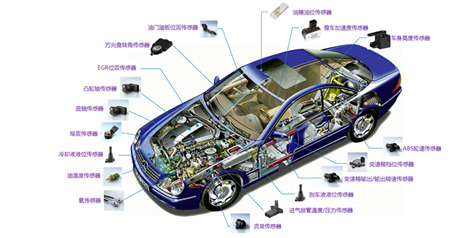

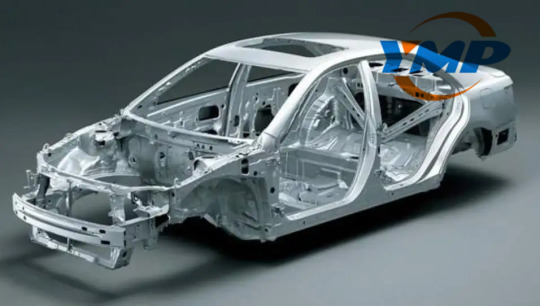

What positive impact does CNC machining have on the development of the automotive industry?

With the rapid development of the intelligent manufacturing industry, the high-efficiency, stable, and high-precision machining of major complex parts in automobile manufacturing will effectively shorten the product production cycle and improve enterprise efficiency and competitiveness. CNC machining technology will enable rapid prototyping and manufacturing of complex automotive parts. At the same time, virtual manufacturing technology, flexible production technology and numerical control technology will be widely used in modern automobile manufacturing.

Compared with traditional processing methods, modern cnc processing technology accelerates the realization of standardized auto parts manufacturing, which provides a solid foundation for the improvement of domestic auto parts production quality and operating efficiency.

CNC technology can provide a complete set of automation solutions for the manufacture of major automotive parts. In the process of processing, the processing data of big data monitoring and remote service based on the industrial Internet can be accepted.

CNC machining has the following characteristics in automobile modification parts:

1-Extremely fast production speed.

CNC machining can provide shorter and faster production times. This is because CNC machining is highly automated, eliminating the need for tedious, labor-intensive manual machining. Certain steps help to speed up and optimize the running time of machines in the production planning process;

2- High degree of automation. With its highly automated advantages, CNC machining can not only greatly shorten the production and processing time, but also make the automobile manufacturing process more streamlined. For example: If you send a part to a CNC machine for fabrication, a robotic arm can assist in removing the part after completion.

3- Highly repeatable. As a computer-controlled machining process, automotive CNC machining also brings repeatability assurance. This is a critical key element in any industrial-grade production environment. In the automotive manufacturing industry, the consistency of parts batches is very important. All CNC lathes will need to meet exactly the same standards and parameters.

4- High precision. CNC machining is capable of achieving tight tolerances for target parts while meeting repeatability requirements. Especially for the automotive sector, this reliable machining result meets the tolerances required for engines and other functional components. Therefore, you can get extremely precise auto parts through CNC precision machining.

5- Support customer customization. CNC machining can help automobile manufacturers customize production and processing parts. According to the actual needs of customers, we can formulate complete solutions to meet customer requirements. CNC custom processing enterprises can also meet the customer's delivery time at the same time. We accept customized processing and production needs of 1-10000+ pieces.

Therefore, CNC machining can supply the following parts for the auto modification industry:

1- Complex components (blades, pistons, connecting rods);

2- Body design: body frame, body parts, such as door handles, lamps, lathes, etc.;

3-Automotive electronic parts processing: industrial sensors, actuators, controllers and other parts;

4- Automobile welding: welding structure, welding joints;

0 notes

Text

The Global Brake Lathe Machine Market to Expand at a CAGR of 3.5% by 2025

Market Overview:

Brake lathe machine market is assessed to witness 3.5% CAGR during the figure time frame, 2022-2030.

The enormous expansion in the interest for present day vehicles like independent vehicles, associated vehicles, and electric vehicles are supposed to set out open doors in the worldwide market attributable to the expansion popular for vehicles. This is supposed to impact the interest for brake machines, including brake machine. Tracker Engineering Company, Hennessy Industries, Inc., Atlas Auto Equipment, and Pro-Cut International are the significant brake machine makers, which principally center around item improvement and key associations with car part produces in the Europe and Asia-Pacific. These advancements are supposed to set out worthwhile open doors on the lookout and further impact the venture open doors for the makers, during the conjecture time frame. In any case, the exorbitant costs of hard core brake machine machines are supposed to hamper the development of the worldwide brake machine market during the estimate time frame.

Get the sample copy of report here

Market Segmentation:

The global brake lathe machine market can be segregated on the basis of application, type, vehicle type, and regions.

On the basis of application, the global brake lathe machine market can be classified into Light-Duty, Heavy-Duty, and Medium-Duty.

On the basis of type, the global brake lathe machine market can be classified into Passenger Car and Commercial Vehicle.

On the basis of vehicle type, the global brake lathe machine market can be classified into Off-Car Brake Lathe Machine and On-Car Brake Lathe Machine.

On the basis of regions, the global brake lathe machine market can be classified into Asia–Pacific, North America, Europe, and the Rest of the World.

Key Players

The forefront players of the market are Hunter Engineering Company, Multipro Machines Pvt Ltd, BendPak Inc., ACCU−TURN, Hennessy Industries, Inc., Sino Star Automotive Equipment Co., Ltd, Atlas Auto Equipment, Pro-Cut International, Equipment Solutions, AUTOPRO-UP Co., Ltd, a Division of IDSC Holdings Inc.

Recent Developments:

March 2020: With north of fifty years of assembling experience, ATS ELGI has one of the vastest and most idealized scope of Wheel Service Equipment prepared for adjusting, adjusting, evolving, mounting, blowing up, dab seating and vehicle wellness testing. These items convey exhaustive and exact outcomes to guarantee greatest wellbeing out and about.

Explore trending research reports@

India Rice Milling Market

CNC Router Market

Snow Pusher Market

Bagging Machine Market

0 notes

Text

Get the precise results you need for your next project with nagualmetal CNC Machining Service. Our state-of-the-art equipment and experienced team of machinists will ensure that your parts are made to exact specifications.

1 note

·

View note

Video

youtube

auto feeding starma cnc wood lathe machine woodworking turning with 4 fu...

#youtube#auto feeding starma cnc wood lathe machine woodworking turning with 4 function turning engraving milling and burnish. The driver will use le

0 notes

Text

Horizontal Fermentation Tanks

Introducing our horizontal fermenter tank, designed to enhance the winemaking process with its advanced features.

Crafted with precision, this tank offers a horizontal design coupled with a rotating stirring mechanism, maximizing the contact area between grape juice and skins. This innovative feature allows for optimal extraction of tannins and anthocyanins, resulting in a rich and flavorful wine.

Not only does our rotary wine fermentation tank deliver exceptional quality, but it also ensures efficiency in the winemaking process. With its fast batch turnover, you can produce wine in a shorter time frame, saving valuable resources and minimizing labor input.

Furthermore, this tank is equipped with automated controls, providing a seamless and hassle-free operation. Say goodbye to manual monitoring and adjustments, as our tank takes care of the fermentation process with precision and accuracy.

| Product Features

● The horizontal type and rotary mixing can increase the touching area of grape must and cap, tannin and anthocyan are macerated at max.

●Rapid turnover of batches with low labor input,automatic controlling.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

0 notes

Text

Open Top Fermentation Tanks

| Product specification

The Open Top Fermentation Tanks is designed for the fermentation of red wine, offering unrestricted access to the grape cap while facilitating convenient cap submersion. Its spacious, inclined bottom ensures a seamless and effortless removal of skins and seeds post-fermentation.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it’s the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

#Open Top Fermentation Tanks#open top fermentation vessel#open top stainless steel fermenter#open top fermenter

1 note

·

View note

Text

Genmitsu CNC 3018-PRO Router Kit Milling Engraving Machine

- Brand: Genmitsu

Features

- What You Get: Genmitsu 3018-PRO CNC router kit; 1pcs CNC Spindle Motor with ER11 Collet. (Note: They will certainly be shipped independently)

- Premium Power Adapter: The 3018-PRO has actually brought security improvements to the adapter, with CE/FCC/UL-approved. Strong constructed for sturdy and also long use performance, making input/output stably also when benefit a long time or work with a laser module.

- Offline Controller: The 3018-PRO features an offline controller, you can manually change X, Y, Z-axis without connecting to the computer system as well as download data.

- Versatile: Capable of reducing all kinds of plastics, soft light weight aluminum, woods, acrylics, PVCs, and also PCBs, the Genmitsu can be made use of on a wide variety of jobs as well as products. Assembly instructions are provided, but if you obtain stuck, take a look at the SainSmart wiki page or call us with any kind of concerns that develop.

- 775 Motor: DC 24V; Speed: 20000/min. Pre-installed electric motor sound suppression PCB offers enhanced performance. It's compatible with Genmitsu 3018 Series CNC router. Applied to lathes, mills, auto hoists, pumps & & conveyors, and so on.

Read the full article

0 notes

Text

CNC Turning Parts

CNC Turning Parts

What makes Atlas metal different from other machining company is that Atlas metal is the label of superior quality and high efficiency. We have imported much high-tech equipment during these years, for example, 4 axis CNC machining center, which enables us to make complex and micro machine precision parts faster than ever.

Specifications of CNC Turning Parts

References According To Your Drawings (Size, Material, Thickness, Processing Content And Required Technology, etc.)

Tolerance丨Surface Roughness +/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Customize Available)

Materials Available Aluminium, Copper, Brass, Stainless Steel, Titanium, Iron, Plastic, Acrylic, PE, PVC, ABS, POM, PTFE etc.

Surface Treatment Polishing, General / Hard / Color Oxidation, Surface Chamfering, Tempering, etc.

Processing CNC Turning, Milling parts, Drilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc.

Testing Equipment CMM / Tool Microscope / Multi-joint Arm / Automatic Height Gauge / Manual Height Gauge / Dial Gauge / Roughness Measurement

Drawing Formats PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF

Our Advantages 1. 24 Hours Online Service & Quickly Quote / Delivery.

100% QC Quality Inspection Before Delivery, And Can Provide Quality Inspection Form.

15+ Years Of Experience In the CNC Machining Area And Have A Senior Design Team To Offer Perfect Modification Suggestions.

0 notes