#conveyors

Text

6 Aesthetic And Practical Tips For Warehouse Optimization

A well-optimized warehouse can increase productivity, reduce labor costs, improve safety, and enhance overall performance. In this article, we’ll explore six aesthetic and practical tips for optimizing your warehouse.

2 notes

·

View notes

Text

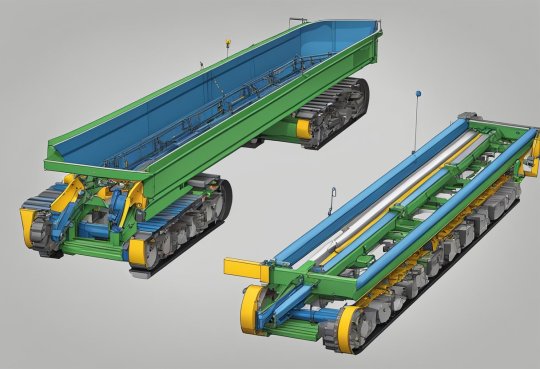

🦾 FLEXIBLE AUTOMATION. PALLETIZING SYSTEM

🦾 Automation ... Flexible palletising system with 6 pallet stations.

Automation Systems.

• 7-axis robot manipulator ... 6-axis + Linear Motion Track RTU Transfer Unit.

• 6 Conveyors for feeding plastic container boxes.

• 6 Centering system on each of the conveyors including load cells for automatic weighing "waiting position".

• 1 Gantry-type palletizing robot... to pick up and position the empty pallet at the appropriate station (1-6).

• 6 Automatic pallet stations (empty pallet loading / finished pallet unloading).

• PC - PLC - SCADA control system.

• Enclosures of the entire installation... preventing access to the different areas of workstation and guaranteeing protection (locking the position of guarding and fencing... electromagnetic technology...)

Remarks.

• Container detection in centering conveyor "waiting position".

• Empty Pallet Gantry Robot.

The Gantry-type palletizing robot picks up the empty pallet from the pallet stack and deposits it in the corresponding empty station (1-6).

Capacity to pick up to 3 pallets simultaneously.

If at a certain moment 2 or 3 stations are empty of pallets (e.g. empty stations 2-4-5-6), the robot will pick up 3 pallets from the stack and deposit them individually in stations 2-4-5... the next priority operation will be to position a pallet in station 6.

This increases the performance and efficiency of the system.

• Control system determines the destination pallet of each "waiting position".

• 7-axis robot decides the shortest and correct path for the next operation.

• Optimised movements of the robot in its transfer to the palletising area to ensure optimum CG (center of gravity) and maximum - optimum speed during its travel through the transfer unit.

• "Open system" for integration of a 2nd second manipulator... if req'd.

• Storage of all the robot operating data (times, weights, cycles...) with a view to making, if necessary, constant operational improvements.

🔧 Maintenance Program.

To improve maintenance operations, an exclusive maintenance zone "Zone 0" is planned in the Transfer RTU.

The transfer module (7th axis) positions the robot in this area when an anomaly is detected in its normal operation... and when any of the intervals specified in the maintenance program are reached (robot, RTU, stations...).

This program works independently ... collecting data from the palletizing station and the robot.

Some aspects or circumstances that are considered:

• Position deviation: if the robot operates outside the expected parameters.

• Repeatability problems: if the robot is unable to perform repetitive cycles or movements.

• Control software alterations.

• Safety issues... problems that may affect safety.

Data A014 - Flexible Palletising System

#TAEVision#engineering#automation#integration#robot#robotics#7th axis#RTU#RTU Robot Transfer Unit#RTU Transfer Unit#RTU Assembly Robotics#transfer unit#TransferUnit#7th axis transfer unit#position table#PositionTable#linear motion track#track motion#conveyors#automatic pallet stations#PC#PLC#SCADA#enclosures#guarding and fencing

2 notes

·

View notes

Text

Wire conveyor belts, Barbed Wire, Rubber Conveyor belts: versatile, durable & essential for various industries. Discover their advantages & applications. For more information visit: Wire Conveyor Belt

#Wire Mesh#Rubber Conveyor Belt#Conveyor Belt#Vibrating Screen#Wedge Wire Screen#Wedge Wire Panel#Barbed Wire#Chain Link Fencing#Perforated Sheet#Conveyors#Wire Conveyor Belt#Wire Mesh Manufacturers#Vibrating Screen Manufacturers#Wedge Wire Screen Manufacturers#Wedge Wire Panel Manufacturers#Chain Link Fencing Manufacturers#Perforated Sheet Manufacturers#Conveyor Belt Manufacturers#Wire Conveyor Belt Manufacturers#Rubber Conveyor Belt Manufacturers#Conveyors Manufacturers#Barbed Wire Manufacturers

0 notes

Text

Choosing the Right Conveyor Belt: PVC vs. Rubber

When selecting between PVC and rubber belts, several factors should be considered, including the specific requirements of your application, operational environment, and budgetary constraints. PVC belts are ideal for industries where hygiene, ease of maintenance, and cost-effectiveness are priorities, while rubber belts excel in applications demanding strength, durability, and traction.

0 notes

Text

Lifting Plough Assembly: Calculations for Conveyor System Loads and Forces

Lifting plough assemblies are a crucial component of conveyor systems that aid in the efficient transfer of bulk materials. These assemblies are used to divert materials from the conveyor belt to various discharge points, ensuring that the materials are delivered to their intended location. The design and calculation of lifting plough assemblies require a thorough understanding of the forces…

View On WordPress

#acceleration load#belt conveyor#conveyor motor#conveyor speed#conveyors#dead load#flat belt conveyor system#friction load#impact load#lifting plough assembly#live load

0 notes

Text

🌟 Revolutionize Your Material Handling Process with ITOH DENKI Conveyors! 🌟

Are you tired of inefficient material handling processes slowing down your operations? Say goodbye to delays and hello to seamless efficiency with ITOH DENKI Conveyors! 💼

🔹 Speed: Our conveyors are designed to maximize throughput, keeping your workflow moving at optimal speed. Say goodbye to bottlenecks!

🔹 Precision: With precise control and handling capabilities, our conveyors ensure accurate placement of materials, reducing errors and minimizing waste.

🔹 Flexibility: Adapt to changing needs effortlessly! ITOH DENKI Conveyors are highly versatile, accommodating various material types and handling requirements.

🔹 Reliability: Trust in reliable performance day in and day out. Our conveyors are built to withstand the rigors of continuous operation, keeping your business running smoothly.

🔹 Innovation: Stay ahead of the curve with cutting-edge technology. ITOH DENKI is at the forefront of conveyor innovation, constantly evolving to meet the demands of modern material handling.

Transform your material handling processes today with ITOH DENKI Conveyors! Contact us to learn more and take your operations to the next level. 🚀

https://youtu.be/QC4D8cGOKs0

0 notes

Text

Titan material handling pvt. Ltd provide Conveyors at best cost, It Is the best conveyors manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

#Conveyors#conveyors manufacturers#conveyor manufacturer in pune#conveyor manufacturer in India#AndhraPradesh#Visakhapatnam#SriCity#Guntur#Goa#Margao#Haryana#Gurugram#Faridabad#Gujarat#Ahmedabad#Ankleshwar#Bharuch#Gandhinagar#Jamnagar#Rajkot#Vadodara#Himachal Pradesh#Baddi#Karnataka#Bangalore#Belagavi#Tumkur#Manglore#Hubli#Maharashtra

0 notes

Text

Titan material handling pvt. Ltd provide Conveyors at best cost, It Is the best conveyors manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

0 notes

Text

DKT Engineering

Our PVC & PU Conveyor Belt Product line covers genral and food grade bekts that are used in nearly every industry abd come in a variety of sizes and varieties

#conveyor#conveyorbelt#conveyors#conveyorsystems#rubberbelt#belt#engineering#conveyorsystem#konvey#automation#industry#materialhandling#belts#manufacturing#conveyorrollers#quarry#industrial#beltconveyor#quarrylife#bearing#conveyorbelts#pvcbelt#beltsplicer#vulcanising#r#enduroply#qpiltd#fabrication#quality#conveyoridlers

0 notes

Text

Revolutionize your business operations by harnessing the power of warehouse conveyors. Streamline material handling, reduce labor costs, and eliminate bottlenecks in your workflow. From simple to advanced automation solutions, our conveyors optimize processes, enhance productivity, and maximize space utilization.

0 notes

Text

Conveyors Joint Belt Industrial Revolution

At Conveyors Joint, we take pride in being at the forefront of innovation in the world of Conveyors Joint Belt Industrial , playing a crucial role in transforming industries across the globe. Our mission is to revolutionize material handling, streamlining processes, enhancing efficiency, and ensuring optimal productivity for businesses of all sizes.

Why Choose Conveyors Joint?

Unparalleled Expertise:

With decades of experience in the industry, our team of seasoned professionals possesses extensive knowledge of belt conveyors, their design, manufacturing, installation, and maintenance. We stay up-to-date with the latest advancements, ensuring that you get the most cutting-edge solutions for your material handling needs.

Customization and Flexibility:

Recognizing that every industry has its unique requirements, we offer highly customizable conveyor solutions. From different belt types and widths to varying conveyor lengths and configurations, we tailor our products to meet your specific demands, enhancing operational efficiency.

Superior Quality:

At Conveyors Joint, we understand that durability and reliability are paramount for seamless operations. We source the finest materials and employ advanced manufacturing processes to create robust conveyor systems that withstand heavy loads and harsh environments, reducing downtime and maintenance costs.

Join the countless businesses worldwide that have experienced enhanced productivity and streamlined material handling processes by partnering with Conveyors Joint. Whether you require a standard Conveyors Joint Belt Industrial or a tailor-made solution for your unique application, we have the expertise and resources to fulfill your needs. For more details visit the site https://conveyorsjoint.com/

0 notes

Text

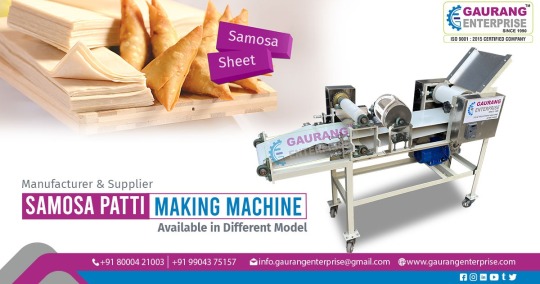

Manufacturer of Samosa Patti Making Machine

Gaurang Enterprise specializes in manufacturing Samosa Patti Making Machines, offering innovative solutions for efficient and precise production. Manufacturer of Samosa Patti Making Machine.

Our food-grade stainless steel machines are designed to reduce snack production costs for various food outlets.Samosa Patti Making Machines have a production capacity ranging from 700 to 2000 pieces per hour.

Our PLC-controlled machines feature a 360-degree dough-baking mechanism, and are equipped with essential components such as conveyors, gearboxes, and 1 HP motors.

These machines ensure uniform heating with excellent thermal insulation properties. The weight and size of the produced snacks can be adjusted according to specific production needs.Our snack-producing equipment is corrosion-proof, minimizes oil usage, maintains a contamination-free operation, and has low emission rates.Machine Details:

Machine Name: Samosa Patti Making Machine

Model: Available in Different Models

Electric Motor: 1 HP Single Phase

Production Capacity: Depends on Size and Shape

Machine Weight: 110kg

Usage/Application: Cutting Raw Samosa PattiFeatures:

Low operating cost and sturdy construction

PLC-based operation to reduce errors

Equipped with gearbox, conveyor, and motor

Excellent thermal insulation of heating components

Low maintenance design and fast operation

Gaurang Enterprise is a manufacturer of Samosa Patti Making Machines.

For more information, we invite you to have a professional conversation with our team.

Read the full article

#1HPmotors#360-degreedough-baking#conveyor#conveyors#GaurangEnterprise#gearbox#Lowmaintenancedesignandfastoperation#Lowoperatingcostandsturdyconstruction#ManufacturerofSamosaPattiMakingMachine#oilusage#PLC-basedoperationtoreduceerrors#SamosaPattiMakingMachine#snack-producingequipment

0 notes

Text

Screw Conveyor

Sodimate's screw conveyors use a rotating helical screw blade to efficiently transport bulk materials across diverse industries such as food, chemicals, and pharmaceuticals. Featuring a flexible design, they effortlessly access confined spaces, minimizing maintenance and maximizing productivity. We specialize in crafting efficient screw conveyor systems that precisely cater to your unique requirements. Reach out to us today for tailor-made solutions of unmatched quality.

0 notes

Text

Conveyors Manufacturers

Top-Notch Conveyors Manufacturers in Kolkata! Jeetmull Jaichandlall (P) Ltd. offers high-quality conveyors for all industries. Get a quote today!

#Conveyors Manufacturers#conveyors#Conveyors Manufacturers in Kolkata#Conveyors Manufacturers in India#conveyorbelt#wiremeshbelt

0 notes

Text

Enhancing Conveyor Performance with Sidewall Cleated Belts: The Nu T Link Belt

Conveyors play a pivotal role in various industries, facilitating the efficient movement of materials over distances. Among the different types of conveyor belts available, sidewall cleated belts have gained prominence for their ability to handle bulk materials effectively while navigating inclines and declines. One notable player in this arena is the Nu T Link Belt, renowned for its innovative design and superior performance.

0 notes

Text

Titan material handling pvt. Ltd provide Conveyors at best cost, It Is the best conveyors manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

0 notes