#customized packaging

Text

Explore Top Sustainable Packaging Trends in 2023

Introduction:

Sustainable packaging has become a significant concern for businesses and consumers alike, as the world continues to prioritize environmental consciousness.

With the increasing focus on sustainability, it’s crucial to explore the top sustainable packaging trends that will shape the packaging industry in 2023. This article delves into the various sustainable packaging trends that are expected to make a significant impact in the coming year.

Importance of Sustainable Packaging:

Sustainable packaging plays a prime role in minimizing waste, conserving resources, and minimizing environmental impact.This doesn’t only prioritize eco-conscious consumers but also is very beneficial for businesses in the long run.

Sustainable packaging can enhance brand reputation, attract environmentally conscious customers, and lead to cost savings through optimized material usage and streamlined logistics.

Sustainable Packaging Trends:

Read below to know more about the top Sustainable Packaging Trends that are shaping the future of packaging industry.

Eco-Friendly Packaging Materials:

To achieve sustainable packaging goals, businesses are increasingly turning to eco-friendly materials that have minimal impact on the environment. Three prominent options are:

Biodegradable Packaging: Biodegradable packaging materials are designed to decompose naturally over time, minimizing the piling of waste in landfills. They are formed from plant-based polymers, such as PLA (polylactic acid), which can break down into harmless elements with the help of microorganisms.

Compostable Packaging: Compostable packaging goes a step further by not only breaking down but also providing valuable nutrients to the soil during the composting process. These materials are made from organic matter, such as cornstarch or bagasse, and contribute to a circular economy by turning into compost that can enrich agricultural lands.

Recyclable Packaging: Recyclable packaging materials includes cardboard, glass, and certain types of plastics, can be gathered, refined, and reused to create new packaging or other products. Recycling preserves resources, reduces usage of energy, and minimizes the demand for virgin materials.

Minimalistic Packaging:

One of the emerging sustainable packaging trends is minimalistic design. This approach focuses on eliminating excess packaging and using the bare minimum required to protect and present the product.

Minimalistic packaging not only reduces waste but also enhances the product’s visual appeal, creating a sleek and modern aesthetic.

Packaging Reduction and Lightweighting:

To further minimize the impact of packaging on the environment, companies are vigorously. seeking ways to minimize the amount of material used. Packaging reduction involves optimizing the size and dimensions of packaging to minimize waste, transportation costs, and storage requirements.

Lightweight, on the other hand, aims to decrease the weight of packaging materials without compromising their integrity, leading to energy savings and reduced emissions during transportation.

Smart Packaging Solutions:

Advancements in technology have paved the way for smart packaging solutions that offer enhanced functionality while remaining environmentally friendly. Two notable examples are:

Intelligent Labels: Intelligent labels comprise of RFID (Radio Frequency Identification) or NFC (Near Field Communication) technology to impart real-time insights about the product, such as its origin, ingredients, and expiration date. By enabling consumers to make informed choices, intelligent labels promote transparency and minimize food waste.

Active Packaging: Active packaging involves the integration of active substances or components into the packaging material to extend the shelf life of the product. Oxygen absorbers, moisture control packets, and antimicrobial films are examples of active packaging solutions that help maintain product freshness, reduce spoilage, and minimize food waste.

Plant-Based and Renewable Packaging:

As the demand for sustainable packaging grows, there is a rising focus on plant-based and renewable materials. Packaging created from renewable resources, such as bamboo, sugarcane, or hemp, offers a viable substitute to traditional petroleum-based plastics.

These materials are not only biodegradable or dispensable but also have a lower carbon footprint during production.

Packaging Innovations:

In addition to the aforementioned sustainable packaging trends, packaging innovations continue to drive sustainable practices. Three noteworthy innovations include:

Edible Packaging: Edible packaging materials, often made from natural polymers like seaweed or starch, can be consumed along with the product. This eliminates the need for additional waste and offers a unique, eco-friendly packaging experience.

Water-Soluble Packaging: Water-soluble packaging is created to dissolve when it comes into contact with water, minimizing the amount of waste produced. This type of packaging is particularly applicable for single-use items like detergent pods or dishwasher tablets.

Mushroom Packaging: Mushroom packaging is also known as mycelium packaging, it makes use of the root structure of mushrooms to create a biodegradable and compostable material. It offers a sustainable alternative to foam-based packaging materials, minimizing reliance on non-biodegradable options.

Packaging for E-commerce:

With the emergence of e-commerce, sustainable packaging solutions are crucial to minimizing the environmental impact of shipping and handling.

Sustainable Packaging Trends in the Food Industry:

The food industry is actively adapting to sustainable packaging practices to address the challenges of food waste and environmental impact.

From compostable food containers to eco-friendly food wraps, innovative packaging solutions are being developed to ensure the freshness and safety of food products while reducing the ecological footprint.

Sustainable Packaging Trends in the Beauty and Personal Care Industry:

Sustainable Packaging Trends in the Fashion Industry:

Sustainable Packaging is gaining popularity in the Fashion Industry, as various brands realize the need to minimize environmental impact of products.

Packaging that is created using recycled materials, biodegradable garment bags and innovative ideas such as seaweed-based packaging is becoming increasingly popular.

Sustainable Packaging Trends in the Electronics Industry:

The electronics industry is notorious for its excessive packaging and e-waste. However, manufacturers are now adopting to sustainable packaging trends such as corrugated cardboard, molded pulp, and plant-based plastics to minimize waste generation and improve recycling rates.

Collaboration for Sustainable Packaging:

Collaboration between stakeholders is crucial to drive sustainable packaging initiatives forward. Brands, packaging manufacturers, consumers, and policymakers need to work in harmony to develop and implement effective strategies that boost sustainable practices throughout the supply chain.

Conclusion – Sustainable Packaging Trends:

In conclusion, the packaging industry is witnessing a shift towards sustainability, driven by the growing awareness of environmental issues and consumer preferences.

In 2023, the top sustainable packaging trends will revolve around eco-friendly materials, minimalistic design, packaging reduction, smart solutions, plant-based alternatives, and innovative packaging options.

By adapting to these sustainable packaging trends, businesses can align with consumer values, minimize their carbon footprint, and contribute to a more sustainable future.

FAQs:

Why is sustainable packaging important?

Sustainable packaging is crucial as it helps to minimize waste, preserve resources, and minimize environmental impact. It also improves brand reputation and attracts eco-conscious consumers.

What are some eco-friendly packaging materials?

Eco-friendly packaging materials such as biodegradable packaging, compostable packaging, and recyclable packaging. These materials have minimal impact on the environment and promote a circular economy.

How can minimalistic packaging benefit businesses?

Minimalistic packaging not only reduces waste but also enhances the visual appeal of products, creating a sleek and modern aesthetic. It can attract consumers and differentiate brands in the market.

What are some packaging innovations in sustainability?

Some packaging innovations in sustainability include edible packaging, water-soluble packaging, and mushroom packaging. These innovations offer biodegradable or compostable alternatives to traditional packaging materials.

How can collaboration drive sustainable packaging initiatives?

Collaboration between brands, packaging manufacturers, consumers, and policymakers is crucial to develop and implement effective strategies for sustainable packaging. By working together, stakeholders can drive positive change throughout the supply chain.

2 notes

·

View notes

Text

Custom Packaging Boxes at Verdance Packaging

Custom Packaging plays an important role in increasing the targeted audience for business products. It also increases product market value. Now Verdance Packaging is offering custom packaging boxes at a 30% discount, get it now and Unlock The Creativity!

#Custom Packaging#Custom Boxes#custom printed boxes#Custom Packaging Boxes#Custom box Packaging#Packaging box printing#customized boxes#customized packaging#packaging company#packaging supplies#Tuesday Tips

5 notes

·

View notes

Text

We are providing All Custom Printed Products with free shipping at affordable rates. Our custom Packaging Boxes are available in different sizes used to keep the products safe.

#business#packaging#packaging solutions#packaging designs#custom packaging#customized packaging#customized packaging boxes#printed boxes#custom printed boxes

2 notes

·

View notes

Text

#business#packaging#packaging solution#packaging designs#Custom Printed Packaging#Custom Printed Packaging Supplier#Custom Printed Packaging Supplier USA#All Custom Boxes Wholesale#Customized Packaging

2 notes

·

View notes

Text

Efficient Packaging Solutions for Air Flow Valves

When it comes to packaging airflow valves, efficiency and reliability are key. Pre-opened bags on a roll are a perfect solution, offering a convenient and effective package of these essential components.

Pre-opened bags on a roll are designed to simplify the packaging process, especially for airflow valves. The bags are pre-opened and perforated, allowing for quick and easy packaging without the…

View On WordPress

#bagsforpackaging#compostablebags#custom packaging bags#customized packaging#preopenedbags#preopenedbagsforvalves

0 notes

Text

Efficient Packaging Solutions for Air Flow Valves

When it comes to packaging airflow valves, efficiency and reliability are key. Pre-opened bags on a roll are a perfect solution, offering a convenient and effective package of these essential components.

Pre-opened bags on a roll are designed to simplify the packaging process, especially for airflow valves. The bags are pre-opened and perforated, allowing for quick and easy packaging without the need to stop and open individual bags. This saves time and reduces the risk of contamination, ensuring that the valves remain clean and protected.

One of the main advantages of pre-opened bags on a roll for airflow valves is their convenience. The roll format allows for continuous packaging, minimizing downtime and increasing efficiency. This is particularly beneficial in industries where speed and reliability are crucial.

Additionally, pre-opened bags on a roll provide excellent protection for airflow valves during storage and transportation. The durable bags are resistant to punctures and tears, ensuring that the valves arrive at their destination in perfect condition.

Overall, pre-opened bags on a roll are an ideal packaging solution for airflow valves, offering convenience, reliability, and protection in one package.

#pre-openedbags#preopenedbagsforvalves#bagsforpackaging#clear packaging bags#customized packaging#custom packaging bags

0 notes

Text

Efficient Packaging Solutions for Air Flow Valves

When it comes to packaging airflow valves, efficiency and reliability are key. Pre-opened bags on a roll are a perfect solution, offering a convenient and effective package of these essential components.

Pre-opened bags on a roll are designed to simplify the packaging process, especially for airflow valves. The bags are pre-opened and perforated, allowing for quick and easy packaging without the need to stop and open individual bags. This saves time and reduces the risk of contamination, ensuring that the valves remain clean and protected.

One of the main advantages of pre-opened bags on a roll for airflow valves is their convenience. The roll format allows for continuous packaging, minimizing downtime and increasing efficiency. This is particularly beneficial in industries where speed and reliability are crucial.

Additionally, pre-opened bags on a roll provide excellent protection for airflow valves during storage and transportation. The durable bags are resistant to punctures and tears, ensuring that the valves arrive at their destination in perfect condition.

Overall, pre-opened bags on a roll are an ideal packaging solution for airflow valves, offering convenience, reliability, and protection in one package.

#pre-openedbags#preopenedbagsforvalves#bagsforpackaging#compostablebags#clear packaging bags#customized packaging#custom packaging bags

0 notes

Text

The Perfect Influence with Customized Packaging

This packaging is a crucial aspect of modern business strategies. This approach involves tailoring packaging materials to suit a particular brand's identity and products. This packaging has become a cornerstone in the world of marketing and branding. In this era of fierce competition, the significance of this packaging cannot be overstated. One of the most prominent benefits of Customized Packaging is the opportunity it provides to improve brand recognition. Besides, by joining a company's logo, color scheme, and exclusive design elements, a package becomes a prompt advertisement. Customers are possible to recall a brand when they meeting its distinct packaging.

How Customized Packaging Influences Customers

This recognition goes a long way in building client loyalty and trust. This packaging also allows companies to take their message effectively. Furthermore, the wrapping serves as a canvas to tell the story of the brand and its goods. Companies can use original graphics, taglines, and even QR codes to engage customers. Indeed, this storytelling aspect of packaging can create an emotional connection with customers. Another benefit of Customized Packaging is its ability to improve the perceived value of a product. High-quality and sole packaging suggests that an invention is worth the asset. It can make even an everyday item feel like a best purchase.

The Significance of Customized Packaging

This apparent value can justify higher values and lead to augmented sales. This packaging also allows companies to offer limited edition or seasonal packaging. Besides, sustainability is a growing concern for both businesses and consumers. This packaging can be tailored to be environmentally friendly. This eco-friendly approach can not only attract environmentally conscious customers but also reduce a brand's carbon footprint. Besides, brands that prioritize sustainability and promote it through their packaging receive positive feedback. In the age of e-commerce, Customized Packaging has taken on a new equal of meaning.

Customized Packaging is a Maintainable Branding Choice

Businesses can opt for maintainable materials and designs that decrease waste and environmental impact. This reverberates with the rising demand for eco-conscious goods, contributing to a positive brand image. Additionally, the rise of e-commerce has augmented the meaning of this packaging. With products shipped straight to customers' entrances, the wrapping becomes the first palpable interaction between the brand and the customer. Truthfully, eye-catching, modified packaging can leave a lasting imprint. Customized Packaging is a tailor-made answer designed to meet the specific needs of a product and brand image. Whether it's a luxury item, food creation, electronics, or any other customer goods, this goods allows trades to stand out on the retail shelf.

Lift Your Brand with Cosmetic Packaging Boxes

They are a vital constituent of the beauty industry, playing a double role of functional protection and aesthetic allure. Besides, they are intended to safeguard cosmetic goods, which can range from lipsticks to skincare creams, while also serving as a means of graphic appeal and branding. In a sector driven by aesthetics and allure, the belongings of cosmetic products holds a unique rank. First and foremost, they must ensure the defense and preservation of their contents. Besides, many cosmetic products are sensitive to ecological factors like light and air, which can principal to product deterioration. Well-designed Cosmetic Packaging Boxes act as a fence against these elements, spreading the shelf life of the products and maintaining their effectiveness. Additionally, they defend against physical damage during transport and handling.

Boost Branding and Visual Impact Through Cosmetic Packaging Boxes

Beyond functionality, they are essential in establishing a brand's individuality and setting the stage for a customer's experience. The design, color, and touch of they often tailor to imitate the brand's image and appeal to its board audience. For high-end luxury brands, goods exudes wealth with the use of premium materials like embossed paper, metallic accents, and intricate designs. In contrast, more affordable brands may opt for minimalist, eco-friendly products to convey affordability and sustainability. The visual appeal of Cosmetic Packaging Boxes is key to capturing consumer attention in a crowded marketplace. When a product stands out on the shelf or online, it has a higher chance of being noticed and ultimately purchased. Colors, typography, and graphics are thoughtfully chosen to evoke certain emotions or associations, which can impact a consumer's purchasing decision.

Unforgettable Customer Experience from Cosmetic Packaging Boxes

The right combination of these elements can make a product memorable and desirable. Cosmetic Packaging Boxes also contribute to the overall user experience. They design not only to be attractive but also practical. Easy-to-open designs and useful compartments can make using the creation more convenient. In the case of beauty goods like palettes and compacts, mirrors and applicators often mix into for added user convenience. Lastly, in recent years, the beauty industry has also saw a shift towards sustainability.

#Customized Packaging#Cosmetic Packaging Boxes#Customize Boxes#Custom Boxes#Cosmetic Boxes#Cosmetic packaging#Custom Cosmetic Packaging#Boxes of Cosmetic#Wholesale Custom Boxes#Wholesale Cosmetic Boxes

0 notes

Text

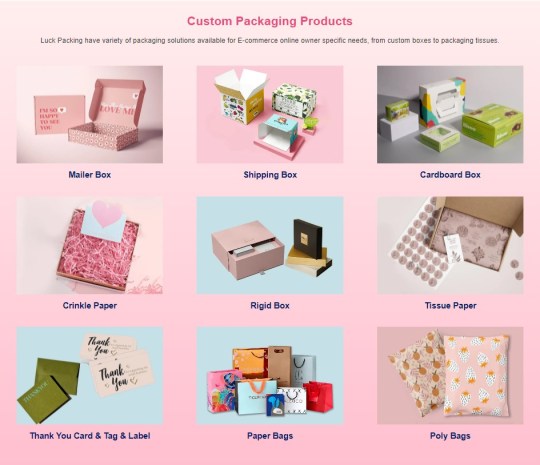

Luck Packaging is a luxury packaging box manufacturer. We cater to a wide range of industries, We offer customization options to suit your requirements.

Our team closely works with you to create exceptional boxes. Contact us to know more about packaging boxes.

#packaging#premium packaging#packaging boxes#packaging designs#packaging box manufacturer#packaging materials#luxury packaging#customized packaging

0 notes

Text

dgscprinting.com

#factory#china#supplier#paper#box#carton box#paper box#customized packaging#packaging#printing#OEM#ODM

1 note

·

View note

Text

https://unboxit.in/

#packaging designs#packaging box manufacturer#premium packaging#packaging boxes#customized packaging#packaging

0 notes

Text

What Is The Significance Of Customized Packaging In The Textile Industry?

The textile industry is highly competitive, with countless businesses vying for consumers' attention. In this crowded landscape, textile brands need to find ways to stand out from the crowd and differentiate their products from those of their competitors. One way to do this is through customized packaging. By creating unique, visually appealing packaging and easy to use, textile businesses can enhance the overall customer experience, protect their products during transportation, and build brand recognition and loyalty over time. Read more: https://paolawooduk.livejournal.com/297.html

0 notes

Text

What Is The Significance Of Customized Packaging In the Textile Industry?

The textile industry is highly competitive, with countless businesses vying for consumers' attention. In this crowded landscape, textile brands need to find ways to stand out from the crowd and differentiate their products from those of their competitors. One way to do this is through customized packaging. By creating unique, visually appealing packaging and easy to use, textile businesses can enhance the overall customer experience, protect their products during transportation, and build brand recognition and loyalty over time. Read more: https://generousmuse.livejournal.com/654.html

0 notes

Text

#pharma pet bottles#bottle pet#hdpe bottle manufacturer#transparent plastic bottles wholesale#customized packaging

0 notes

Text

The Customized Packaging market size is estimated to be close to USD XX Billion in 2022 and is projected to grow at a CAGR of XX% till 2027. Key factors driving market revenue growth are rising demand for convenience packaging and innovation in packaging technologies. In addition, creating brand awareness, personalized experience for customers, and better customer engagements are other key factors expected to drive demand for custom packaging, and support market revenue growth.

The market for Customized packaging is expected to be driven by the demand from Asia Pacific. Growth in Customized industry in economies such as China and India and in the South East Asian region, is expected to translate into a rise in the demand for packaging in the region. Rise in the population is also expected to drive end-use purchases which in turn is expected to drive the growth of the Customized packaging over the next five years.

Few of the key players in the global personalized packaging market include Owens Illinois Inc., Salazar Packaging, Inc., Design Packaging, Inc., PrimeLine Packaging, International Packaging Inc., Elegant Packaging, Pak Factory Inc., ABOX Packaging, ACG Ecopak, CB Group, SoOPAK Company, Huhtamaki Oyj, The Mondi Group plc., Smurfit Kappa Group, Glenroy Inc. and ProAmpac LLC., The Box Factory Limited, Owens Illinois, CBS Packaging, Huhtamaki and others.

#Customized Packaging Market#demand for custom packaging#Customized Packaging#Sales for Customized Packaging#Demand for Customized Packaging#Personalized Packaging Market#Personalized Packaging#Personalized Packaging Industry#Personalized Packaging Market Size#Personalized Packaging Market Report#Custom Packaging Market#Custom Packaging#custom packaging bags#custom packaging tape#custom packaging uk#custom packaging canada#canadian custom packaging#custom jewelry packaging#custom eyeshadow palette packaging#custom clothing packaging bags#Customized Packaging Market Share#Customized Packaging Market Forecast#Customized Packaging Market Report

1 note

·

View note

Text

Introduction To Thermoforming And Thermoform Packaging Design Considerations

When a thermoplastic sheet is heated to its softening point, the process is known as thermoforming. The resultant sheet can be molded and manipulated according to the desired/required shape. Vacuum-forming, pressure-forming, and twin-sheet forming are the most commonly used methods implemented for thermoforming. Creating custom plastic designs becomes so much more convenient with the help of thermoforming. To create such customized packaging designs, air pressure must be contained in a designated box. Talking about the applications, thermoforming can be implemented in several industries and sectors.

Key Terminologies

Apart from thermoforming, there are a few specific terminologies that you need to familiarize yourself with. Knowing the difference between these terms, you can create a successful project.

Thermoplastics - This particular type of plastic is created using polymer resins that become homogenized when heated to a specific temperature.

Vacuum forming - By using vacuum, a part of the plastic sheet is heated and then stretched across a mold. On most occasions, the mold is left open. The force required to form the sheet is restricted to around 15 psi.

Pressure forming - For this process, a pressure box is added to the tooling package. It makes use of both positive air pressure and vacuum. This generates about four times the forming pressure as compared to vacuum forming. It permits fine details (such as surface textures) to get formed on the mold without incurring additional costs.

Twin sheet forming - Tow molds are used for this process; placed at the top and bottom. For this, two plastic sheets are simultaneously heated and formed to get the desired results. Twin sheet forming is excellent for creating hollow parts that require a distinctive upper and lower shape.

Thermoforming Design Considerations

Quality Design

Design plays a pivotal role in creating excellent thermoforming packaging. Design encompasses several crucial items for the process, such as tools and materials required. You need to have a one-on-one discussion with the packaging design team to discuss your expectations from the project, and anything else you have in mind. You can also discuss with them the specifics about your product they must be fully aware of during the course action of the design phase. With your input, the design team would be able to come up with suggestions and solutions to ensure the highest level of protection for the basic structure of the project.

Material Selection

The team will then choose the most feasible plastic material for the project. PET and PETG plastics are commonly used by businesses to create thermoformed components. Both are FDA-approved plastic materials. You may opt for other materials according to your specific needs.

Quality Tooling

Once the design and material selection considerations get sorted, the hired team would then create customized tooling to create the package. Consider an all-inclusive company to make this specific step an easier process.

Plug Design

The next consideration would be to develop a plug design. In the case of a stock packaging project, there may already be a plug design available for use. For Customized Packaging designs, it would demand a unique plug form design.

Speed to Market

Packaging designs must be expedited to make sure products reach the market on time. In the absence of an efficient timeline, things may turn south, which can take a hit on the timely delivery of the products. This means products can lose their popularity with consumers or clients.

Choosing Indepak

Indepak has a wide range of production equipment to meet nearly every need for thin plastic and foam applications. With continuous effort and performance, Indepak has now become a leading thermoforming company in the Northwest U.S. The services we cater to include development, production, package fulfillment, quality, inventory management, and shipping

0 notes