#fly ash bricks making business

Text

The Ultimate Startup Guide for Fly Ash Brick Manufacturing

🔥 Wanna be your own boss? Start by mastering the art of Fly Ash Brick Manufacturing! 🧱💼 Let's unlock your entrepreneurial potential! 💥 #SmallBusinessTips #flyashbrickmachine #manufacturingbusiness #flyashbricksmakingmachine

With India’s construction industry adopting sustainable practices, the popularity of eco-friendly fly ash bricks is rising. Previously, clay bricks dominated the market; however, cement bricks have gradually become favoured, and now fly ash bricks are gaining traction. Fly ash is a coal combustion byproduct, and India has it in abundance, making it ideal for brick production. Launching a fly ash…

View On WordPress

#automatic fly ash bricks machine#best business ideas#business ideas#fly ash brick machine#fly ash brick making#fly ash bricks#fly ash bricks business#fly ash bricks business plan#fly ash bricks machine#fly ash bricks making business#fly ash bricks making machine#fly ash bricks manufacturing process#how to start a fly ash brick manufacturing business#how to start fly ash brick business#manufacturing business ideas 2024#manufacturing business ideas in india#mini manufacturing business ideas#new business ideas#new business ideas 2024#small business ideas

0 notes

Text

Brick vs Block: Which Construction Material Is Right for You?

Introduction

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

Seeds

At first they return as softness, whispers in the wind, barely making their presence known The nostalgia is just the beginning, until the memories of you start aching in my bones They always come but are never welcome, intrusive, manipulative, controlling everything you always were, so discreetly So much so, I tried to tell my […]

47 notes

·

View notes

Video

youtube

Fly Ash Bricks Making Machine से कमाई ₹ 2.5 लाख हर महीना! Small Business...

#youtube#Fly Ash Bricks Making Machine से कमाई ₹ 2.5 लाख हर महीना! Small Business... https://youtu.be/Pq9UYnuz7yk via @YouTube FlyAshBricksMakingMach

0 notes

Text

Things you must know about the Fly Ash Brick Making Machine

I would like to sketch a fly ash brick making machine as a new revelation because it makes the construction easier. This disruptive technology converts industrial waste into structurally sound and aesthetically appealing bricks that can replace traditional clay ones.

The most notable fact is that fly ash bricks are an important element of environmentally friendly construction. They may assist in easing the pressure exerted on raw materials, and they also contribute to the conservation of carbon emissions in construction. This brick making machine makes bricks that eliminate the buildup of waste in landfills and reduce the use of clay and destroy topsoil.

The method of making fly ash bricks is more energy efficient than the normal methods of brick making. These machines are gaining acceptance globally due to their high productivity, low cost of production and enhanced quality of the bricks. The need for brick making machine in India is still on the rise and there is no doubt that they will be part of the future construction industry.

Composition of Fly Ash Bricks

Fly ash bricks are made of fly ash (50–70%), cement (10–20%), sand or stone dust (10–20%), or other materials. The specific proportion may slightly differ but the outcome is a brick that is light in weight, high strength and sustainable. The fly ash brick making machine compels and shapes these materials to develop bricks of superior quality.

Environmental Benefits

Another advantage of fly ash bricks is the reduction of waste products that affect the environment in industries. Another positive impact of fly ash bricks on the environment is that fly ash is considered industrial waste and using it in the production of bricks helps minimize waste. These bricks aid in the handling of waste from coal fired power plants by using fly ash in the production of the building bricks. The fly ash brick manufacturing process also needs less energy than other bricks as it does not involve high temperatures like kilns for baking clay bricks.

How Fly Ash Brick Making Machines Work

Fly ash brick making machine work on a closed cycle system with its essential components to mix and mold the bricks from raw materials.

Hopper: This component stores the raw material requirements used in the production such as fly ash, gypsum and sand.

Mixer: The mixer plays a key role in the whole process of producing the final product as it helps in mixing all the raw materials in the proper manner.

Conveyor: This is initiated by a conveyor belt that takes the mixed material to the brick mold.

Brick Mold: This is the final step whereby the resultant mixture is shaped into the required brick forming through high pressure.

Step-by-Step Process:

Feeding: Materials have to be supplied to the hopper, which is the entry point into the mill.

Mixing: They move to the mixer to be well blended with the other materials.

Conveying: The blended mixture then goes through the inclined conveyor to the brick mold.

Molding: The produce is compacted into the brick mold to produce bricks.

Curing: Molded bricks are then cured with water or steam so as to gain the required strength of the bricks.

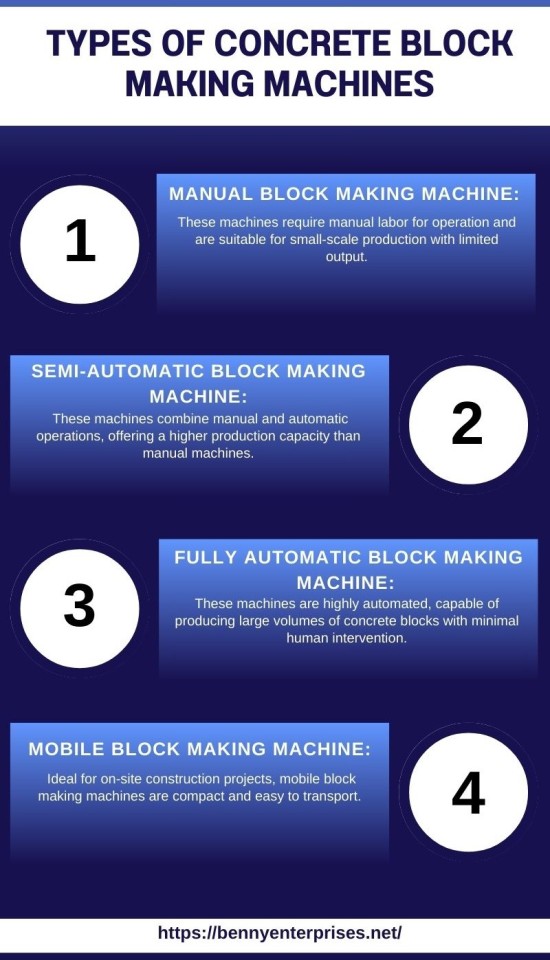

Types of Fly Ash Brick Making Machines

Manual Brick Making Machine:

Pros: Affordable, easy to use, and efficient for small scale production.

Cons: Slow production, requires many workers, bricks are not of uniform quality and have less production capability.

Semi-Automatic Brick Making Machine:

Pros: Sustained cost, enhanced productivity, and more uniformity in the quality of bricks produced.

Cons: Needs manual effort, suitable for moderate volumes of production.

Fully automatic brick making machine:

Pros: Large production capacity, low dependence on labor, high degree of uniformity of bricks, numerous features.

Cons: Higher initial cost involved, need for skilled personnel for running and controlling the machinery.

Which Fly Ash Brick Making Machine is best for your business?

Scale: First of all, you need to define the scale of production you want to achieve. Do you intend to carry out a small project or a big project that requires industrial-level infrastructure? Semi-automatic machines may help with small-scale operations while fully automatic machines would serve large-scale production purposes with better accuracy and productivity.

Features: Now that we have already discussed some types of brick making machine, it is now for us to determine the special features that we require for the machine. Some of the common types of bricks to produce include hollow bricks, solid bricks and interlocking bricks. It is advisable to look for machines that have variable mold characteristics and those that make it easier to operate and maintain the machine. Based on the operational capacity or labor availability, automation types like manual, semi-automated or automated should also be incorporated.

Budget: First of all, estimate the initial cost that might be required for starting the business. It is a well-known fact that fully automatic machines are generally costlier than partially automatic ones, but in the long run, it saves money on labor as well as time. Compare the prices of various machines to one another and factor in how much you could save in the future.

Consider possible methods of funding the purchase like loans, leasing or installment purchases. Most suppliers provide payment options that allow you to make a functioning initial installment. This will also help in discovering the return on investment (ROI) which will indicate the time it will take for the machine to start generating its own value in terms of efficiency and the reduction of costs.

Supplier Reputation: It is vital that one conducts research on the potential suppliers to make sure that they are okay in the market. Search for opinions on the specific topic, the number of stars given to the product or service and other people’s experiences that they may have written about on a blog, social media, etc.

Brick Machinery is popular for being a recognized company, producing standard machines, and good customer service. We want you to get the most out of your purchase which is why we offer a good after-sales service such as installation support, training for your staff and we are always ready to offer our assistance in case of a technical hitch.

Why choose brick machinery?

Brick Machinery is among the best companies in the market and has made a name for itself in the market. Brick Machinery aims to provide the best quality products with advanced technologies in its machinery. We have provided excellent quality of our products in the form of fly ash brick making machine that can be witnessed from the above specifications.

Technologically, our machines utilize advanced automation in the process of producing bricks, thereby decreasing human intervention. We provide client-oriented solutions to satisfy all project characteristics and provide you with the ideal machine.

How Brick Machinery Plans to Stay Ahead in the Industry

Brick Machinery is striving continually to be at the forefront of brick making technologies and products. Brick Machinery aims at directing resources to advanced research and development to bring in new high technology fly ash brick making machine that offer the best quality and competence in the market. They work with the market, customer feedback, and other industry players. They make sure that their machines are fit for the current demand.

Further, it has a social responsibility towards the environment, that it is involved in the establishment of fly ash bricks also in the practice of eco-friendly manufacturing techniques. The technological advancements and laid down policies on sustainable development put brick machinery in the right place to lead the market in the future in terms of Brick Making Machine both nationally and internationally.

Are you ready for a change and to bring the best brick making technology to your construction projects? You can also read more about our products and their specifications in the brick making machine portal of our website.

#fly ash brick making machine in gujarat#fly ash brick plant#fly ash brick making machine#brick making machine#brick making machine in India

0 notes

Text

8 inch aac block price

Introduction to AAC Blocks

Autoclaved Aerated Concrete (AAC) blocks have won reputation in the building industry due to their lightweight, thermal insulation properties, and environmental benefits. These blocks are manufactured the usage of a combination of sand, cement, lime, and aluminum powder, which undergoes a chemical response to create air bubbles, ensuing in light-weight concrete blocks.

Importance of AAC Blocks in Construction

8 inch AAC block price provide severa blessings over usual clay bricks and concrete blocks. They are lightweight, lowering the general weight of the shape and permitting for less complicated coping with and transportation. Additionally, AAC blocks supply splendid thermal insulation, supporting to hold relaxed indoor temperatures and minimize electricity consumption.

Factors Affecting AAC Block Prices

Raw Material Costs

The costs of uncooked substances such as cement, sand, lime, and aluminum powder can substantially have an effect on the standard fee of AAC blocks. Fluctuations in these cloth costs can have an effect on the ultimate product cost.

Manufacturing Process

The manufacturing manner of AAC blocks includes autoclaving, a approach that requires specialized tools and energy. The effectivity of the manufacturing technique can have an impact on the manufacturing price and, consequently, the costs of AAC blocks.

Transportation Costs

The place of the manufacturing facility and the distance to the development web site can have an effect on transportation costs. Suppliers placed nearer to the website online can also provide decrease expenditures due to decreased transportation expenses.

Market Demand

Supply and demand dynamics play a essential position in figuring out AAC block prices. Higher demand for AAC blocks can lead to elevated prices, specifically throughout height development seasons.

Comparison of eight Inch AAC Block Prices

When evaluating 8-inch AAC block prices, it is crucial to think about a number of factors, including:

Local Suppliers vs. National Suppliers

Local suppliers can also provide aggressive expenses due to decreased transportation costs, whilst country wide suppliers may also grant a broader vary of picks and higher-quality products.

Quality Variation

Price editions amongst unique suppliers may also mirror variations in block quality. Hyderabad Builders It's quintessential to think about elements such as compressive strength, density, and thermal conductivity when evaluating prices.

Tips for Buying eight Inch AAC Blocks

To make certain you get the excellent price for your cash when buying 8-inch AAC blocks, think about the following tips:

Researching Suppliers

Take the time to lookup and examine AAC block suppliers. Look for reliable businesses with a tune document of imparting top notch merchandise and super consumer service.

Requesting Quotations

Obtain quotations from more than one suppliers to examine costs and product specifications. Be positive to inquire about any extra costs, such as transport costs or taxes.

Checking Quality Certifications

Verify that the AAC blocks meet applicable great requirements and certifications, such as IS 2185 (Part 3) for AAC blocks. Quality-certified blocks make certain sturdiness and structural integrity.

Cost-Effective Alternatives to eight Inch AAC Blocks

If 8-inch AAC blocks exceed your budget, think about exploring choice development substances such as fly ash bricks or concrete blocks. These choices provide comparable advantages at doubtlessly decrease costs.

Conclusion

AAC blocks provide a versatile and sustainable answer for modern-day development projects. Understanding the elements influencing AAC block fees and following first-class practices when buying can assist make certain a profitable and within your budget constructing process.

FAQs

Are AAC blocks appropriate for all kinds of building projects?

Yes, AAC blocks can be used in a number applications, together with residential, commercial, and industrial buildings.

What is the common lifespan of AAC blocks?

When top mounted and maintained, AAC blocks can remaining for decades, with a lifespan comparable to that of usual masonry materials.

Can AAC blocks face up to seismic activity?

Yes, AAC blocks have exquisite seismic resistance due to their light-weight but long lasting nature.

Are AAC blocks environmentally friendly?

Yes, AAC blocks are regarded environmentally pleasant due to the fact they use much less material, minimize electricity consumption, and produce fewer emissions for the duration of manufacturing.

How do AAC block costs examine to ordinary constructing materials?

While AAC block fees may also at first appear greater than standard materials, the long-term benefits, such as electricity financial savings and durability, frequently outweigh the preliminary investment.

0 notes

Text

AAC Bricks: Its application in different sectors

Introduction:

Are you in search of an innovative and sustainable solution for your construction work? Then, bricks made of AAC are the only ideal option! These Autoclaved Aerated Concrete blocks offer a range of advantages over traditional building materials, from energy efficiency to durability. Plus, with versatile applications in various sectors, AAC bricks are becoming increasingly popular among architects and builders alike. In this blog post, We'll discuss the advantages of employing AAC bricks and why they're a wise choice for your upcoming project.

What are AAC Bricks?

AAC, or Autoclaved Aerated Concrete, is a lightweight and eco-friendly building material used in construction projects globally. Natural ingredients including cement, lime, fly ash, water, and an expanding agent that causes bubbles to form in the mixture during curing are used to make AAC bricks.

The resulting product is a strong and durable block that has excellent insulation properties thanks to the entrapped air within its structure. This feature makes it perfect for minimizing temperatures in buildings and enhancing sound insulation.

Another advantage of AAC bricks is their versatility in design. They come in various sizes and shapes to fit any project's needs. Additionally, they're easy to cut and shape on-site without specialized tools.

AAC blocks are environmentally friendly compared to other traditional building materials like concrete blocks or clay bricks because they produce fewer carbon emissions during production due to their lightweight nature.

Contrary to other forms of building materials, AAC blocks are stronger, more resilient, and enable various design options.

Advantages of Using AAC Bricks

Due to their many benefits, Autoclaved Aerated Concrete blocks are rising in popularity in the building sector.

Their many advantages are-

Minimal Expenses : One of the biggest advantages of using AAC bricks is that they are lightweight, making them easier to transport and handle during construction projects. This also means that less structural support is needed, which can save money on building costs.

Resistant to Heat : Another advantage is that AAC bricks have excellent thermal insulation properties, helping to keep buildings cool in hot climates and warm in cold climates. This can reduce energy costs associated with heating and cooling.

Sound Proof : In addition, AAC bricks offer superior sound insulation compared to traditional clay bricks. They absorb more sound waves, leading to a quieter indoor environment for occupants.

Eco-friendly Building Material : AAC bricks are also environmentally friendly as they require much less raw material than traditional clay or concrete blocks. The production process emits fewer pollutants into the air and reduces carbon footprint.

Durable : AAC brick structures tend to last longer as they are highly durable and resistant to fire damage, pests such as termites and mold growth.

It is obvious that using AAC bricks instead of other building materials has several advantages, including lower prices, better energy efficiency, and environmental friendliness.

Application of AAC Blocks in Different Sectors

With their wide uses in various fields, AAC blocks, often referred to as Autoclaved Aerated Bricks, have revolutionized the construction business. These cutting-edge building materials are strong yet lightweight, making them perfect for a variety of tasks.

Due to their versatility and durability, AAC blocks are a great option for a variety of architectural applications. And they are discussed below:

Shopping Complexes : These locations continue to be packed with large crowds almost always. Yet again, they must project an image of more affluent, decorous, and solid. Thus, choosing AAC blocks for such projects works in a perfect way.

How?

AAC blocks feature properties that make them tolerant to both temperature and unwanted noise. Due to the tiny air gaps, it also has great heat insulation potential. In other words, depending on the season, it maintains a cool or warm temperature. Furthermore, visitors are also no longer concerned by the noise from outside.

Residential Sector: AAC blocks can be used to construct homes, apartments, and other small-scale structures. They offer excellent insulation properties, which ensure energy efficiency and reduce energy consumption costs.

Commercial Sector: AAC blocks are commonly used in constructing office buildings, hospitals, schools, and shopping malls. Their lightweight property makes them easy to handle during construction while still providing structural integrity that is necessary for such large buildings.

Industrial Sector: Industrial buildings also benefit from using AAC bricks since they provide thermal insulation when constructing factories or warehouses. This helps regulate temperatures inside these facilities hence making them more comfortable work environments for employees.

Transportation Infrastructure: Transportation frameworks such as bridges and tunnels can also benefit from using AAC blocks due to their strength-to-weight ratio making it easier to transport materials on-site with ease thus reducing transportation costs.

Conclusion:

Hence, there’s no denying that the application of AAC bricks in different sectors has been a game-changer offering cost-effective solutions without compromising on quality. They have revolutionized the construction industry with their numerous applications in different sectors. These innovative building materials are lightweight yet sturdy, making them ideal for a wide range of projects.

In the residential sector, AAC blocks are extensively used for constructing homes due to their thermal insulation properties and energy efficiency. The low-density nature of these bricks allows for cost-effective construction while maintaining structural integrity.

Furthermore, in commercial buildings such as offices and shopping malls, AAC installations provide excellent soundproofing capabilities that enhance the overall comfort and ambiance of the space.

Another significant sector where AAC blocks find application is industrial construction; they are widely utilized in factories and warehouses owing to their fire-resistance properties and durability against harsh environmental conditions.

Moreover, these versatile bricks can be easily cut or shaped according to specific project needs, enabling architects to unleash their creativity while ensuring efficient use of resources. Whether it's creating greenhouses or public infrastructure like schools and hospitals, AAC blocks offer a sustainable solution that combines strength with eco-friendliness.

As technology continues to advance in the realm of building materials, it is clear that AAC blocks have emerged as a game-changer across various sectors by providing exceptional performance characteristics combined with aesthetic appeal.

1 note

·

View note

Text

youtube

Watch the American Climate Leadership Awards 2024 now: https://youtu.be/bWiW4Rp8vF0?feature=shared

The American Climate Leadership Awards 2024 broadcast recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by active climate leaders. Watch to find out which finalist received the $50,000 grand prize! Hosted by Vanessa Hauc and featuring Bill McKibben and Katharine Hayhoe!

#ACLA24#ACLA24Leaders#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental justice#environment protection#environmental health#Youtube

17K notes

·

View notes

Text

Locate Top-Quality Fly Ash Bricks Near Me for Sustainable Construction

Welcome to the era of sustainable construction, where every choice you make can contribute to a greener and eco-friendly environment. If you're embarking on a construction project and have sustainability on your mind, you've come to the right place. In this blog, we'll delve into the world of fly ash bricks, an eco-conscious alternative to traditional bricks, and guide you on how to locate top-quality fly ash bricks near you for your next construction venture.

Understanding Fly Ash Bricks

What are Fly Ash Bricks?

Before we dive into the "near me" aspect, let's understand what fly ash bricks are. These bricks are made from fly ash, a byproduct of coal combustion in thermal power plants. Unlike conventional clay bricks, fly ash bricks are considered environmentally friendly as they recycle waste material and reduce the demand for clay, preserving natural resources.

Advantages of Fly Ash Bricks

Environmental Friendliness: The production of fly ash bricks consumes less energy and reduces carbon emissions compared to traditional bricks.

Strength and Durability: Fly ash bricks exhibit high compressive strength, making them a durable and reliable choice for construction.

Cost-Effective: These bricks are often more affordable than conventional bricks, contributing to cost savings in your construction project.

Insulation Properties: Fly ash bricks offer excellent thermal insulation, helping maintain a comfortable temperature inside buildings.

Why Choose Fly Ash Bricks for Sustainable Construction?

Sustainability is at the forefront of modern construction practices, and fly ash bricks align perfectly with this ethos. Here are some compelling reasons to opt for fly ash bricks:

1. Reduced Carbon Footprint

By using fly ash bricks, you contribute to reducing the carbon footprint of your construction project. The process of manufacturing these bricks generates significantly lower greenhouse gas emissions compared to traditional brick production.

2. Waste Utilization

Fly ash is a byproduct that would otherwise end up in landfills. Choosing fly ash bricks helps repurpose this waste material into a valuable building component, promoting a circular economy.

3. Energy Efficiency

The production of fly ash bricks requires less energy compared to conventional bricks, further supporting sustainable construction practices.

How to Find Top-Quality Fly Ash Bricks Near You

Now that you're convinced about the benefits of fly ash bricks, let's explore how you can locate high-quality fly ash bricks in your vicinity.

1. Local Suppliers and Hardware Stores

Start your search by exploring local suppliers and hardware stores. Many suppliers are embracing eco-friendly construction materials, including fly ash bricks. Visit or contact these establishments to inquire about the availability of fly ash bricks near you.

2. Online Directories

In the digital age, finding construction materials has become easier with online directories. Utilize online platforms that connect buyers with sellers in the construction industry. Enter relevant keywords like fly ash bricks near me to narrow down your search.

3. Construction Material Aggregators

Consider reaching out to construction material aggregators in your area. These businesses specialize in sourcing and supplying a variety of construction materials. Inquire about their stock of fly ash bricks and request information on quality certifications.

4. Connect with Construction Professionals

Networking is a valuable resource in the construction industry. Connect with architects, builders, and construction professionals in your community. They often have insights into reliable suppliers of sustainable construction materials, including fly ash bricks.

Chhikara Builders

Chhikara Builders is your trusted partner in construction excellence. With a commitment to quality and sustainability, we offer top-quality fly ash bricks for your eco-friendly projects. Our bricks are meticulously crafted to ensure strength, durability, and adherence to industry standards. Conveniently located, we provide easy access to fly ash bricks near you.

As a reputable name in the construction industry, Chhikara Builders prioritizes customer satisfaction and eco-conscious practices. Choose us for your next project and build with confidence. Sustainable construction begins with Chhikara Builders – building a greener future, one brick at a time.

Evaluating Quality

Locating fly ash bricks near you is just the first step. Ensuring you get top-quality bricks is equally important. Here are some factors to consider when evaluating the quality of fly ash bricks:

1. Certifications and Standards

Check if the fly ash bricks meet industry standards and certifications. Look for certifications from relevant authorities that guarantee the quality and eco-friendliness of the bricks.

2. Supplier Reputation

Choose suppliers with a positive reputation for providing quality construction materials. Customer reviews and testimonials can be valuable resources in gauging the reliability of a supplier.

3. Sample Testing

If possible, request a sample of the fly ash bricks before making a bulk purchase. Conduct tests for strength, durability, and other specific requirements relevant to your construction project.

Conclusion

As you embark on your journey towards sustainable construction, the choice of materials plays a pivotal role. Fly ash bricks offer a greener alternative to traditional bricks, contributing to a more eco-friendly construction industry. By following the tips in this guide, you can easily locate top-quality fly ash bricks near you and build with a conscience.

0 notes

Text

Govind Industry - https://govindindustry.com/

Title- Machinery Manufacturer | Rice Mill | Fly Ash Bricks | Katghora |Chhattisgarh

Description: "Govind Industry" is a distinguished Manufacturer of a wide array of Brick Making Machine, Fly Ash Brick Making Machine, Paper Dona Machine, etc. Our range is available in various specifications as per the client’s requirements. We have successfully created a niche in the market in the last few months by bringing forth a matchless range of products. We work as a team in understanding the needs of the customers, keeping each other’s business interest intact so that we can deliver products at the right time and at the most competitive rates.

Keywords - Govind Industry, Machinery Manufacturer , Service, Pan India, Best, Katghora, Chhattisgarh

Social Media -

0 notes

Text

Revolutionizing Construction with Fly Ash Blocks: The Sustainable Choice

The construction industry is at a crossroads, with sustainability becoming a top priority. Fly ash block manufacturers in bangalore, often sought after by fly ash block dealers, have emerged as a game-changer in sustainable construction. These blocks, which are manufactured by utilizing fly ash, a waste product from coal combustion, offer a host of benefits that go beyond traditional construction materials.

Fly Ash Blocks: The Eco-Friendly Alternative

Fly ash blocks are environmentally friendly, as they help reduce the disposal of fly ash waste in landfills. Fly ash block dealers in tamil nadu and traders play a pivotal role in ensuring the efficient distribution of these eco-friendly construction materials. By using fly ash in the manufacturing process, this waste product is repurposed into a valuable construction material, significantly cutting down on environmental pollution and resource depletion.

Energy Efficiency

Manufacturing fly ash blocks requires significantly less energy compared to traditional clay bricks or concrete blocks. Fly ash blocks suppliers in hyderabad these energy-efficient building materials, and fly ash block dealers make them accessible to builders, further contributing to a smaller carbon footprint. This makes fly ash blocks an excellent choice for environmentally conscious builders and developers.

The Advantages of Fly Ash Blocks: Fly ash blocks are known for their high compressive strength, making them a durable choice for construction. They can withstand extreme weather conditions and have a longer lifespan compared to traditional building materials. Fly ash block dealers ensure that builders have access to this strong and dependable construction material.

Fly ash blocks offer excellent thermal insulation properties. They help regulate indoor temperatures, reducing the need for excessive heating or cooling, which leads to energy savings. Fly ash block traders can assist in the supply of these thermally efficient blocks to construction projects.

The Growth of Fly Ash Block Manufacturers in tamil nadu and Dealers: The demand for fly ash blocks is on the rise as more builders and developers recognize the value of sustainable construction. Manufacturers have responded to this demand by expanding their production capacity and improving the quality of fly ash blocks, making it easier for fly ash block dealers and traders to meet the market's needs. This growth has led to increased availability and competitive pricing in the market, ultimately benefitting builders and construction projects.

Quality Assurance: Ensuring that your manufacturing process consistently produces high-quality fly ash blocks is essential to gain the trust of builders, contractors, and fly ash block dealers.

Fly ash blocks are rapidly gaining popularity in the construction industry due to their eco-friendliness, strength, durability, and cost-effectiveness. As the world continues to prioritize sustainability, fly ash block manufacturers, dealers, and fly ash block traders in anantapur are poised to play a significant role in revolutionizing the construction sector. The growth of this industry not only benefits businesses but also contributes to a more sustainable and environmentally responsible future for construction, meeting the needs of fly ash block dealers and the broader construction community.

#fly ash blocks suppliers in hyderabad#fly ash block dealers in tamil nadu#fly ash block manufacturers in bangalore#fly ash block dealers in hyderabad#fly ash block traders in anantapur#fly ash blocks in tirupati

0 notes

Text

Supplier of Hollow Block Making Machine Maharashtra

Akshar Precast Industries is an emerging Indian Engineering Company. Akshar Precast Industries was Established in the year 2018.Supplier of Hollow Block Making Machine Maharashtra.We are offering Semi Automatic Fly Ash Brick Machine, Manual Bricks Making Machine, Block Making Machine, Paver Block Vibrating Table, Cement Brick Making Machine, etc.The business is promoted by a young team of engineers having a very rich domain experience in the manufacturing and marketing of engineering products for the construction industry.A hollow block-making machine is a machine that is used to produce hollow concrete blocks. These blocks are used in construction for a variety of purposes, including walls, partitions, and foundations.Hollow blocks are made by mixing cement, sand, water, and aggregate. The mixture is then poured into a mold and vibrated to remove air bubbles.Hollow block-making machines are available in a variety of sizes and capacities. The size of the machine will depend on the size of the blocks that you want to produce.

The capacity of the machine will depend on how many blocks you want to produce per hour.Benefits of Hollow Block-Making MachineIncreased productivity: Hollow block-making machines can produce more blocks per hour than manual methods. This can save you time and money.

Improved quality: Hollow block-making machines can produce blocks with consistent dimensions and strength. This can improve the quality of your construction projects.

Reduced labor costs: Hollow block-making machines can reduce the need for manual labor. This can save you money on labor costs.

Environmental benefits: Hollow block-making machines can reduce the amount of waste produced in construction.We Provide Supplier of Hollow Block Making Machine Maharashtra Including Mumbai, Pune, Nagpur, Nasik, Aurangabad, Bhiwandi, Malegaon, Kolhapur, etc.

If you are interested then contact us, and we will offer you our best quality product.

Read the full article

#AksharPrecastIndustries#HollowBlockMakingMachine#SupplierofHollowBlockMakingMachine#SupplierofHollowBlockMakingMachineMaharashtra

0 notes

Text

Selecting the right concrete block making machine for your construction business is a significant decision that can impact your productivity, profitability, and overall success. Benny Enterprises is the best choice for all your needs, we are the finest Concrete Brick Making Machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Video

youtube

Fly Ash Bricks Making Machine से कमाई ₹ 2.5 लाख हर महीना! Small Business...

0 notes

Text

Top 3 Profitable Unlisted Shares & Pre IPO To Buy in 2023

Best opportunity to invest in top 3 profitable Unlisted Shares & Pre IPO. Investing in these shares is a good option for the most people who really want to make more and more money from their investments. There can we be various methods of doing this and if you will pick the right company, it could gives you Execellent Returns on your investments. But many people don't know the process of finding profitable companies that can gives us best return on inventsments. This makes it diffcult for them to invest in shares without wasting too much time on ressearch. For getting amazing returns you have to know about the right company. Here, I will sugeest you to take consultation form Planify. Planify Team at Share Investor has put together an informative article today will help you to understand how to choose an Unlisted Shares that is going to give you Best return in 2023.

Here are Top 3 Profitable Unlisted Shares & Pre IPO :

1. Mohan Meakin

Mohan Meakin Upcoming Initial Public Offering (IPO) : The 163-year-old corporation is considering re-listing its equity shares on the Delhi and Calcutta stock exchanges, some 16 years after they were de-listed. They have filed documents to re-list on the exchanges with the Metropolitan Stock Exchange (MSE). The company has not filed any DRHP for the IPO as of now.

Mohan Meakin Share Price : Currently the Mohan Meakin Share Price is ₹1,470.00/Share. Mohan Meakin Limited (MML) is a large conglomerate that began with Asia's first brewery, manufacturing alcoholic and non-alcoholic beverages is the company's main business. The company’s alcoholic products include whiskies, beers, brandies, gins, rums, and vodka. Its non-alcoholic products comprise apple juices, brewed and non-fruit vinegars, and mineral water; and breakfast foods, such as corn flakes, wheat porridge, wheat flakes, and wheat dalia, as well as malt extracts.

2. NCL Buildtek

NCL Buildtek Upcoming Initial Public Offering (IPO) : The plans of the company for IPO has been kept on hold for the time being. In view of the sub-optimal performance due to covid, the company feels it is not the correct time to approach the market with a share issue.

NCL Builtek Share Price : Currenlty the NCL Buildtek Share Price is ₹209.00/Share. NCL Buildtek Ltd. ("NCL Buildtek"), formerly known as NCL Alltek & Seccolor Ltd. is a part of the NCL Group. The company is primarily involved in manufacturing and selling spray plasters, paints, skim coat, steel profiles, doors, windows (steel, ABS & uPVC) and fly ash bricks.

3. NCL Holdings

NCL Holdings Upcoming Initial Public Offering (IPO) : The company is not planning IPO so far. Its main revenue comes from their subsidiaries companies.Company's objective are to make and hold investment in corporate and non-corporate entities engaged in manufacturing, trading or provision of services, either as pure investment with right to participate in management of such facilities. It's main products are Hydro Power, Real estate & Construction, Seeds, and Chemicals. NCL Holdings is a Telangana based company. NCL holdings formed on 05th Jan. 2018.

NCL Holdings Share Price : Currently the NCL Holdings Share Price is ₹66.00/Shares. NCL Holdings is a investment holding company having three subsidiaries i.e. NCL Green Habitats Pvt. Ltd and Eastern Ghat Renewable Energy Limited and Suncrop Science. The company operates an investment company to make the investment in majorly, building materials, construction, agro, chemicals and renewable power projects(majorly hydro). Moreover, company was incorporated too acquire non-building materials asset held by NCL Buildtek Limited along with equivalent reserves vide NCLT Demerger order dated 24th January 2019.

To find out more Unlisted shares that are waiting to give you great returns in 2023.

Here is Our Official App Download Link Download and Check : https://play.google.com/store/apps/details?id=com.planify

#Unlisted Share#Pre IPO#IPO#Upcoming IPO#Share price#Mohan Meakin SHare Price#Mohan Meakin Pre IPO#Mohan Meakin IPO#NCL Holdings Share Price#NCl Holdings IPO#NCL Holdings Unlisted SHares#NCL Buildtek SHare Price#NCL Buildtek IPO#NCL Buildtek Pre IPO

0 notes

Text

Do you intend to enter in fly ash brick plant manufacturers?

If you are interested in getting involved in the industry of fly ash brick making machine business with the aim of generating big profits, it’s important to be aware of certain key factors that will determine the success of your future business. Every step of the process needs thorough planning and execution. The process starts with the sourcing of the right materials and ends with the implementation of a robust quality assurance program.

Fly ash brick manufacturers play a significant role in supplying fly ash bricks for sale to the booming market. People love this product due to its environment-friendly nature and because it is also pocket friendly.

Developed over the years, the cement industry has evolved to unleash the potential of innovation. These manufacturers are enhancing the build process by incorporating the latest technologies and streamlining production. They are remodeling the way we build.

Key Considerations to Establish a Successful Fly Ash Brick Plant

First of all, finding a reliable source for a constant supply of fly ash as the main raw material is the main priority. Develop good relationships with power plants in order to get a constant supply of this necessary component. Keeping various supply sources varied can also help you face and deal with any possible disruptions.

Second, purchase appropriate and expensive machines that are mainly designed for the production of fly ash bricks. These types of machines do the job in a better way and they also reduce waste and improve quality. Do market research, get advice from industry experts and make sure that your plant is run with the most advanced technology available.

Why is Brick Machinery the top fly ash brick plant manufacturer?

Brick Machinery is a pacesetter in push forward fly ash brick manufacturing model and this gives us an upper hand in the market. Every business has unique needs that must be met. You provide customized arrangements that work for small start-ups and industrial scale plants, regardless of the size of the case.

Brick Machinery is a reliable fly ash brick plant manufacturers with a good reputation in the market. We are working on innovations and precise quality controls to produce the finest quality brick. With Brick Machinery, you will realize that our machines are high quality compliant, which means that the fly ash bricks you will get are durable, reliable and marketable.

#Fly Ash Brick plant manufacturers#Brick plant manufacturers#Fly Ash Brick plant#Brick#Brick making machine#brick making machine in India

0 notes

Text

Light Weight Bricks: Revolutionizing Construction Industry in Hyderabad

In the bustling metropolis of Hyderabad, the place urbanization is at its peak, the demand for environment friendly and sustainable development substances is ever-growing. One such innovation that has been making waves in the building enterprise is the creation of light-weight bricks, mainly light-weight cement bricks.

These bricks now not solely provide sturdiness however additionally grant an eco-friendly answer to normal brick development methods. In this article, we delve into the intricacies of light-weight bricks, their benefits, and their have an impact on on the development panorama in Hyderabad.

Understanding Lightweight Bricks

What Are Lightweight Bricks?

Lightweight bricks, as the title suggests, are bricks that are notably lighter in weight in contrast to ordinary clay bricks. They are generally made the use of light-weight aggregates such as multiplied clay, shale, or fly ash, which are blended with cement or lime.

The Composition of Lightweight Cement Bricks

Lightweight cement bricks are a unique type of light-weight brick made predominantly from cement. These bricks contain light-weight aggregates into the cement mixture, ensuing in a closing product that is sturdy but lightweight.

The Benefits of Using Lightweight Bricks

Enhanced Thermal Insulation

One of the key benefits of light-weight bricks is their optimum thermal insulation properties. Due to their composition, these bricks provide higher insulation in opposition to warmth transfer, assisting to preserve a relaxed indoor temperature all through the year. In a town like Hyderabad, the place temperatures can jump at some point of the summer time months, this attribute is enormously desirable.

Reduced Structural Load

Traditional clay bricks are heavy, which can exert huge strain on the building's basis and structural framework. In contrast, light-weight bricks exert much less load on the structure, thereby lowering the typical structural burden. This now not solely contributes to price financial savings all through building however additionally enhances the durability of the building.

Ease of Handling and Installation

Being lighter in weight, light-weight bricks are less complicated to manage and transport in contrast to traditional bricks. This interprets to quicker development instances and decrease labor costs. Moreover, their uniform measurement and form facilitate unique installation, ensuing in neater finishes and decreased wastage.

The Impact on Construction Practices in Hyderabad

Sustainable Construction Solutions

In latest years, there has been a developing emphasis on sustainable development practices in Hyderabad, pushed via worries over environmental degradation and aid depletion. Lightweight bricks provide a sustainable choice to regular clay bricks, as they are manufactured the usage of recycled substances and devour much less strength throughout production.

Meeting Regulatory Standards

With stricter guidelines governing the development industry, builders and builders in Hyderabad are increasingly more turning to light-weight bricks to meet stringent security and environmental standards. These bricks are regarded for their fire-resistant properties, making them a favored desire for complying with constructing codes and regulations.

Architectural Versatility

Lightweight bricks come in a range of sizes and finishes, presenting architects and designers in Hyderabad increased flexibility in realizing their innovative visions. Whether it is for present day residential initiatives or business developments, light-weight bricks can be tailor-made to swimsuit numerous architectural patterns and requirements.

Conclusion

In conclusion, light-weight bricks, specially light-weight cement bricks, have emerged as a game-changer in the development enterprise in Hyderabad. With their severa benefits, which include stronger thermal insulation, decreased structural load, and sustainability, they are revolutionizing building practices and placing new requirements for effectivity and quality. As Hyderabad continues to urbanize and expand, the adoption of light-weight bricks is poised to accelerate, using innovation and ushering in a new generation of sustainable construction.

FAQs (Frequently Asked Questions)

Despite being lighter in weight, light-weight bricks are regarded for their sturdiness and strength, making them a dependable desire for development projects.

Lightweight bricks provide finest thermal insulation, lowering the want for synthetic heating and cooling structures and thereby advertising strength efficiency.

Yes, light-weight bricks are appropriate for each load-bearing and non-load-bearing applications, relying on the particular necessities of the project.

While the preliminary price of light-weight bricks can also be barely higher, the long-term financial savings in phrases of development time, labor, and strength consumption regularly outweigh the preliminary investment.

0 notes

Text

ALL ABOUT FLY DEBRIS BLOCKS

Fly debris blocks are hey tech all around superior quality blocks utilized for development of block workmanship structures. They are utilized as swap for ordinary mud blocks and has preferable properties over it. Fly ash bricks manufacturers in Vijayawada serious in contrast with the regular earth blocks and give colossal backhanded benefits. The usage of fly debris blocks brings about preservation of regular assets as well as insurance of climate.

Structure of Fly Debris Blocks

The significant structures of fly debris blocks are:

Fly debris

Concrete

Sand

Water

Wellsprings of Fly Debris

72% of India's power plants are coal based. These power stations produce almost 40 million tones of fly debris yearly. Fly debris contains Co2 radiated from Nuclear energy stations, businesses involving coal as a fuel discharges undesirable debris and smoke from which fly debris is created. In all the power plants and ventures, they separate the fly debris by utilizing the typhoon converter. This fly debris is then utilized as a natural substance for production of blocks.

Nature of Contamination Brought about by Fly Debris

Fly debris causes extreme contamination of air and water, and its removal eats up huge lots of land. Very much arranged programs for legitimate administration of fly ash block suppliers in vijayawada are in this way being embraced to improve the utilization of fly debris in different applications, so our generally hazardously imbalanced climate can be secured

Assembling of Fly Debris Blocks

The fly debris block is only a sluggish setting pozzalona concrete blend. The cycle is same as making concrete in concrete plants though the earth and limestone are ignited with coal and gypsum. What's more, it is blended and ground to solidify. In fly debris blend likewise the fly debris, which is singed earth particles (oxides of dirt) got from consuming coal, which contains mud from the mines. At the point when hydrated lime powder, gypsum are blended and ground in a skillet, the combination gives a sluggish setting pozzalona concrete. While the blend is squeezed at low tension at low dampness content in water powered machine, which is extraordinarily intended to give high strain load at a sluggish rate, in the request for 350kg/square inch. At this of pace of strain and with holding the tension for an ideal time frame invigorates extreme fly debris blocks.

Flowchart Showing the Production of Fly Debris Blocks

Fabricating cycle of Flydebris Blocks

Advantages of Fly Debris Blocks for Climate

The expansion in ozone depleting substances, out of which CO2 is one of the significant constituents, expands the an Earth-wide temperature boost a large number of years, causing dry spell and floods. The all out CO2 Emanations worldwide record for 24,960 million tons at 1990 levels. Concrete and building materials industry is one of the major contributors. Fly debris blocks uses The CO2 emanation is around ninety million tons out of concrete and 49 million tons out of dirt blocks creation in India. According to the continuous practices in India, every million earth blocks consume around 200 tons of coal (or some other fuel with equivalent amount of warm qualities) and emanate around 270 tons of CO2. Fly ash building blocks in Vijayawada creation in sans energy course saves the discharges thoroughly, befitting the venture to qualify under Clean Improvement System (CDM), as visualized by Kyoto Convention towards the government assistance of Mother Earth.

0 notes