#laser marking

Text

Are you into business of making doors, hinges, and other related accessories? Grow your business by laser-marking your brand. A fiber laser marking machine leaves fast, clear, and permanant marks and cuts over door hinges, nameplates, letters, and many others.

Know more by visiting us: https://www.hindcam.com/laser-marking-machine-in-delhi/

#laser marking#laser marking machine#laser machine#hinges marking#hindcam#fiberlaser#fiberlasermarkingmachine

2 notes

·

View notes

Text

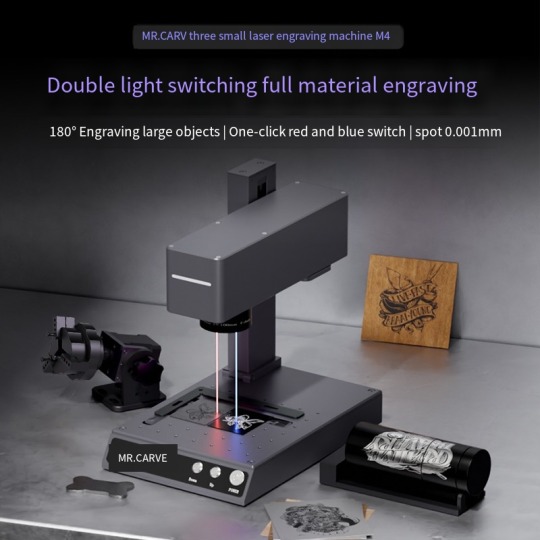

30W fiber laser machine, Carve a photo on a metal plate

2 notes

·

View notes

Link

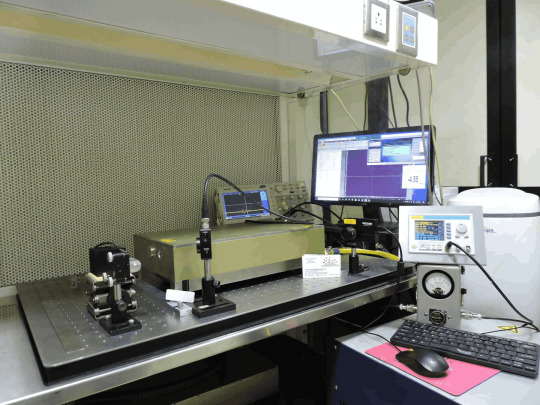

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion

MegaWatt Lasers

QPC Lasers

Amplitude Lasers (Continuum),

PhotoScribe

Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

Raycus Fiber Laser Source for Laser Marking, Engraving, and Cutting

Rycus Fiber Laser Source is an industrial-grade marking and micro-processing laser that provides high peak power, high single pulse energy, and variable spot diameter. The Q-switch pulsed fiber laser series is capable of marking metal, wood, plastic, and glass with a minimum spot size of 3mm. To learn more about the capabilities and applications of this laser, contact us.

#fiber laser#laser source#laser marking#laser#laser engraving#laser cutting#Rycus fiber laser source#fiber laser source

2 notes

·

View notes

Text

The most popular ShineRise fiber laser marking machine in 2024!

Let me solemnly introduce to you the reasons why our company’s desktop fiber laser marking machine will be the most popular in the global market from 2024 to now:

Compact design and lightweight structure without affecting power and use.

Whether it is metal, plastic, glass or jewelry and other delicate materials, high precision and accuracy of marking are guaranteed.

From industrial manufacturing to artistic creation, it can meet a wide range of application needs.

The intuitive interface, easy-to-master controls and user-friendly design can cover all user groups.

The use of high-quality materials ensures the durability and service life of the product, and can meet the needs of continuous, reliable and efficient use.

Most importantly, in order to thank our customers for their support of the company, we have decided to sell this product at the best price between May 1st and June 1st (i.e. 20w=1716 USD/unit, 30w=2000 USD /unit, 50w=2716 USD/unit), in order to express our sincerity and give back to all friends who are interested in this.

0 notes

Text

Revolutionizing Toy Design: Precision Mould Texturing for Irresistible Toy Car Wheels!

The world of toy manufacturing is undergoing a remarkable transformation, and at the heart of this evolution is the precision mould texturing that brings toy car wheels to life. With advancements in technology, particularly in affordable mould texturing in India, the art of designing and producing toy car wheels has reached new heights, creating products that are not just playthings but works of art.

Affordable Mould Texturing in India:

India has emerged as a hub for affordable and high-quality mould texturing services, offering manufacturers cost-effective solutions without compromising on precision. The accessibility of these services has opened doors for toy designers and manufacturers, enabling them to incorporate intricate and eye-catching textures on toy car wheels, setting a new standard for creativity and craftsmanship.

The Role of 3D Laser Engraving:

One of the key technologies driving precision mould texturing is 3D laser engraving. This cutting-edge technique allows for the creation of three-dimensional textures on the surface of moulds, providing an unprecedented level of detail and realism. Toy car wheels benefit immensely from 3D laser engraving, as it allows designers to replicate intricate patterns, tire treads, and even realistic textures like alloy spokes with unmatched precision.

Enhancing Aesthetics with Laser Marking:

In addition to mould texturing, laser marking plays a pivotal role in enhancing the aesthetics of toy car wheels. Laser marking allows for the application of logos, serial numbers, and other essential information directly onto the wheels. This not only adds a professional touch to the final product but also ensures that the markings withstand the rigors of play, maintaining their clarity and durability over time.

Precision Mould Texturing: A Game-Changer for Toy Design:

The level of precision achieved through mould texturing is a game-changer for toy design, especially when it comes to toy car wheels. Designers can now incorporate realistic textures that mimic the details found in real automotive wheels, providing children with a more immersive and engaging play experience. Whether it's the grooves of a tire or the intricate details of a custom wheel design, precision mould texturing brings these elements to life in miniature form.

Benefits of Precision Mould Texturing for Toy Car Wheels:

Realism and Detail: Precision mould texturing allows for the recreation of realistic textures and details, adding authenticity to toy car wheels.

Customization: Toy designers can customize mould textures to create unique and eye-catching designs, catering to diverse preferences and trends.

Durability: The precision achieved through advanced mould texturing techniques ensures that the textures withstand the wear and tear of play, maintaining their visual appeal over time.

Innovation in Design: Manufacturers can push the boundaries of toy car wheel design, introducing innovative and intricate patterns that were previously challenging to achieve.

The Future of Toy Manufacturing in India:

As affordable mould texturing services continue to flourish in India, the future of toy manufacturing looks exceptionally promising. The combination of precision mould texturing, 3D laser engraving, and laser marking is likely to inspire even greater creativity in toy design, setting the stage for a new era of visually stunning and technologically advanced toys.

Conclusion:

Precision mould texturing is ushering in a new era in toy design, particularly in the creation of toy car wheels. With affordable services available in India and the integration of advanced technologies like 3D laser engraving and laser marking, toy manufacturers can now bring unparalleled realism and customization to their products. The revolution in toy design is not just about play; it's about creating miniature masterpieces that captivate the imagination of both children and adults alike.

0 notes

Text

30W fiber laser machine, Carving a pattern on a teapot

0 notes

Video

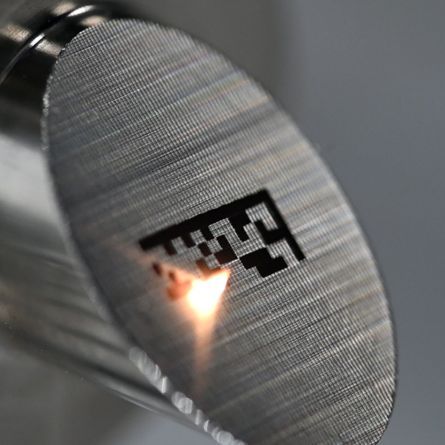

Laser Marking on Glass Bottle video from C. And C. Laser Engineering Whatsapp/Mobile: +91-9833105515.

Laser Marking on Glass Bottle - The above video shows Laser marking on glass Bottle using a nano-second UV laser.

Glass or Glass Bottle can only be marked with UV Laser. IR (1064 nm) laser gets reflected from the glass. UV laser (355 nm) and DUV (266 nm) get absorbed easily by the glass and hence are the ideal source for marking on Glass or Glass Bottle. In the video shown above, the glass bottle has been laser marked with a 355 nm 5 W UV laser with a Galvo-based marking system having a laser marking field of 100 X 100 sq. mm., using a rotary. Green (532 nm) laser and CO2 (10.6 µm) would fracture & crack the glass.

C. And C. Laser Engineering is popular for its job work services in laser marking, laser welding, laser cutting, and micro-machining.

For more details you can contact at:

Landline: +91-2249727168

WhatsApp: +91-9833105515

WeChat: +91-9833105515

Skype: sawanthb.205

#laser marking#laser marking job work#laser marking services#laser marking on glass#glass laser marking#laser welding#laser cutting

2 notes

·

View notes

Text

F – Theta Lens For Fiber Laser Marking Machine

High light transmittance, high output laser energy

Marking area is optional from 100mm to 300mm

High-quality coating, good protection, uniform laser light

Suitable for a variety of fiber laser marking machines with a laser wavelength of 1064nm

High quality, not easy to damage

#co2 laser engraving machine#laser marking machine#marking machine#dot peen marking machine#youtube#dot peen marking#dotpeenmarkingmachine#laser marking#heatsign#industrial marking machines

0 notes

Text

Permanent laser marking is an irreversible change in the color of the surface layer of the tool material. Get connected with Atesco Industrial Hygiene Ltd. for permanent food safety laser marking services.

0 notes

Text

Laser Marking of ECC 200 2D Matrix Codes on Printed Circuit Boards

Laser Marking of ECC 200 2D Matrix Codes on Printed Circuit Boards

Manufacturers of electronic devices, from home audio equipment to automotive keyless entry systems, are increasingly seeking a reliable, cost effective method for uniquely identifying and tracking products by the manufacturing cycle, sales dispensing and after-sale warranty verification. An independent, automated tracking system requires that a long-lasting, machine-readable code be applied to an…

View On WordPress

#laser marking#laser marking calendar#laser marking census#laser marking corvette#laser marking movies#laser marking nissan#laser marking presidential election#laser marking standard#laser marking suv#laser marking tax

0 notes