#laser machine

Text

Are you into business of making doors, hinges, and other related accessories? Grow your business by laser-marking your brand. A fiber laser marking machine leaves fast, clear, and permanant marks and cuts over door hinges, nameplates, letters, and many others.

Know more by visiting us: https://www.hindcam.com/laser-marking-machine-in-delhi/

#laser marking#laser marking machine#laser machine#hinges marking#hindcam#fiberlaser#fiberlasermarkingmachine

2 notes

·

View notes

Text

Maximizing the Capabilities of SLTL Laser Cutting Machines

SLTL laser cutting machines are cutting-edge tools that utilize laser beams to precisely cut through various materials. These machines offer several features that make them highly efficient and versatile. They are equipped with advanced control systems, high-power lasers, and intelligent software for optimal performance. Additionally, they often come with automated features like material handling systems and real-time monitoring capabilities.

The advantages of using SLTL laser cutting machines are numerous.

high precision and accuracy, allowing for intricate and complex designs

clean cuts with minimal material wastage

fast cutting speeds,.

can work with a wide range of metals, including Aluminum,Copper,Iron, Steel, Brass, Bronze, Silver, Gold, etc

Overall, SLTL laser cutting machines provide efficiency, flexibility, and quality in cutting.

youtube

To unleash the full potential of SLTL laser cutting machines, businesses can take several steps:

Upgrade the software and hardware

Keeping the machines up to date with the latest software and hardware upgrades ensures optimal performance. This includes installing the latest control systems, software updates, and laser sources. Upgrades can enhance cutting precision, speed, and overall efficiency.

Optimize the cutting parameters

Fine-tuning the cutting parameters, such as laser power, cutting speed, and focus, can improve the quality and efficiency of the cutting process. Conducting tests and experiments to find the optimal settings for different materials and thicknesses is crucial.

Train operators to maximize efficiency

Providing comprehensive training to operators is essential for utilizing the full potential of SLTL laser cutting machines. Operators should be well-versed in machine operation, maintenance, and troubleshooting. Continuous training and skill development can ensure efficient operation and minimize downtime.

SLTL laser cutting machines find extensive applications in various industries, including:

Automotive industry

These machines are used for cutting components like body panels, frames, and exhaust systems. The high precision and speed of SLTL laser cutting machines enable the automotive industry to achieve superior quality and efficiency in manufacturing processes.

Aerospace industry

SLTL laser cutting machines play a crucial role in aerospace manufacturing. They are utilized for cutting complex shapes in materials like aluminum, titanium, and composite materials. These machines enable the production of lightweight components with high structural integrity, meeting the stringent requirements of the aerospace industry.

Medical industry

SLTL laser cutting machines are employed in the medical field for cutting surgical instruments, implants, and medical devices. The precise cutting capabilities of these machines ensure accurate and reliable production of medical equipment, contributing to improved patient outcomes.

In conclusion, unleashing the potential of SLTL laser cutting machines can bring significant advantages to businesses across various industries. These machines offer high precision, clean cuts, and fast cutting speeds. By upgrading software and hardware, optimizing cutting parameters, and training operators, businesses can maximize the efficiency and productivity of these machines. Furthermore, SLTL laser cutting machines find applications in the automotive, aerospace, and medical industries, enabling superior quality and advanced manufacturing capabilities.

#cnc laser cutting machines#laser cutting machines#fiber laser cutting machines#laser machine#Youtube

2 notes

·

View notes

Text

Buy 35W RF co2 galvo laser machine Supplier

Shenzhen Sijiahua Keji offers a 35W RF co2 galvo laser machine at an affordable price. It is widely used for marking on wood, acrylic, leather, slate, etc. We have a wide range of laser marking machines for various industry uses. This laser machine has a long lifeline, a nonbreakable case design, and can be easy to operate. For more details call us at +86-18025348056.

0 notes

Text

Precision at the Speed of Light: The Revolution of Laser Machines in Industry

In the intricate dance of modern manufacturing, where every cut, weld, and engraving demands precision, laser machine have emerged as indispensable tools. These marvels of technology harness the power of focused light to perform a myriad of tasks with unmatched accuracy and efficiency. From automotive and aerospace to electronics and beyond, the applications of laser machines have reshaped the landscape of industrial production.

At the core of laser machines lies the principle of light amplification by stimulated emission of radiation (LASER). This coherent beam of light, precisely controlled and directed, allows for a level of precision unattainable by traditional machining methods. Whether it's cutting through tough metals, engraving intricate designs, or welding delicate components, laser machines excel in delivering results with unparalleled accuracy and speed.

One of the most significant advantages of laser machines is their versatility across a wide range of materials. Metals, plastics, ceramics, and composites can all be manipulated with equal ease using lasers, making them ideal for industries with diverse material requirements. In automotive manufacturing, for example, laser cutting has revolutionized the production of complex components, allowing for intricate designs and tight tolerances that enhance both performance and aesthetics.

Similarly, in the aerospace sector, where lightweight materials and complex geometries are commonplace, laser machines play a crucial role in precision manufacturing. From cutting intricate turbine blades to welding lightweight airframe structures, lasers offer capabilities that enable the production of aerospace components with unmatched precision and consistency. Moreover, the non-contact nature of laser machining minimizes the risk of contamination and damage to delicate materials, ensuring the integrity of critical components destined for high-performance applications.

In the healthcare industry, laser machines have enabled significant advancements in medical device manufacturing and surgical procedures. Laser cutting and welding techniques facilitate the fabrication of intricate implants, prosthetics, and surgical instruments with unparalleled precision, while laser-based surgical procedures offer minimally invasive alternatives that reduce patient trauma and recovery times.

The versatility of laser machines extends beyond traditional manufacturing applications into emerging fields such as additive manufacturing. Laser-based 3D printing techniques enable the fabrication of complex geometries and customized components with unprecedented ease and speed. This capability has sparked innovation in industries ranging from automotive and aerospace to fashion and architecture, where intricate designs and custom solutions are in high demand.

However, the evolution of laser machines is not without its challenges. As technology advances, so too do the demands for higher precision, faster speeds, and increased automation. Innovations such as fiber lasers, ultrafast lasers, and adaptive optics are pushing the boundaries of what's possible, driving further advancements in laser machining capabilities.

In conclusion, laser machines have ushered in a new era of precision manufacturing, offering unparalleled accuracy, versatility, and efficiency across a wide range of industries. From automotive and aerospace to healthcare and beyond, the revolution of laser technology continues to shape the future of industry, pushing the boundaries of what's possible and illuminating new possibilities for innovation and growth.

1 note

·

View note

Text

The Evolution of Laser Machines in Modern Industry

In the realm of modern manufacturing, precision is paramount. From intricate medical devices to robust automotive components, the demand for accuracy and efficiency drives innovation. Among the array of technological marvels revolutionizing production processes, laser machine stand out as beacons of precision, offering unparalleled capabilities across diverse industries.

Laser machines, once confined to the realm of science fiction, have seamlessly integrated into the fabric of contemporary manufacturing. These devices harness the power of light amplification by stimulated emission of radiation (LASER) to perform a myriad of tasks with remarkable accuracy and speed. From cutting and engraving to welding and marking, the versatility of laser machines knows no bounds.

One of the most compelling aspects of laser machines is their ability to operate across a broad spectrum of materials. Whether it's metals, plastics, ceramics, or even organic substances, lasers can manipulate these materials with surgical precision. This versatility has made laser machines indispensable in industries ranging from aerospace and electronics to jewelry design and healthcare.

In the automotive sector, laser cutting has revolutionized the production of complex components. High-powered lasers slice through metal with unparalleled precision, allowing for intricate designs and tight tolerances. This not only streamlines the manufacturing process but also enhances the performance and durability of automotive parts.

Similarly, in the field of medicine, laser technology has ushered in a new era of minimally invasive procedures. Laser cutting and welding techniques enable the fabrication of intricate medical devices with unmatched precision. From stents and catheters to surgical instruments and implants, these advancements have significantly improved patient outcomes while minimizing trauma and recovery time.

The electronics industry also benefits immensely from laser technology, particularly in the realm of microelectronics. Laser ablation and patterning enable the precise etching of circuit boards and semiconductor materials, facilitating the production of smaller, more efficient electronic devices. Additionally, laser marking provides a permanent, high-resolution method for branding and labeling electronic components.

In the realm of consumer goods, laser engraving has emerged as a popular choice for adding custom designs and personalization to products. From engraved jewelry and personalized electronics to intricate artwork on various materials, laser engraving offers limitless creative possibilities. This has fueled the growth of boutique businesses and custom manufacturing services catering to discerning consumers seeking unique and personalized products.

Beyond traditional manufacturing applications, laser technology is also making significant strides in emerging fields such as additive manufacturing (3D printing). Laser sintering and melting techniques enable the precise layer-by-layer deposition of metal powders, opening up new avenues for rapid prototyping and on-demand manufacturing.

However, the evolution of laser machines is not without its challenges. As technology advances, so too do the demands for higher precision, faster speeds, and increased automation. Innovations such as fiber lasers, ultrafast lasers, and adaptive optics are pushing the boundaries of what's possible, but researchers and engineers continue to explore new avenues for improvement.

Moreover, as laser technology becomes more accessible and affordable, the democratization of manufacturing capabilities is underway. Small businesses and entrepreneurs now have access to laser cutting and engraving services that were once exclusive to large-scale industrial operations. This democratization promises to fuel innovation and creativity across a diverse range of industries and applications.

In conclusion, laser machines have emerged as indispensable tools in modern manufacturing, offering unparalleled precision, versatility, and efficiency across diverse industries. From automotive and aerospace to healthcare and consumer goods, the applications of laser technology are boundless. As technology continues to advance and barriers to entry diminish, the future of manufacturing looks brighter than ever, illuminated by the brilliance of laser machines.

1 note

·

View note

Text

Laser Marking Machine

In the bustling halls of modern industry, where efficiency meets innovation, there exists a silent architect – the Laser Marking Machine. Often overlooked but omnipresent, these machines wield a profound influence, shaping the very fabric of manufacturing processes. In this exploration, we unveil the hidden intricacies of laser marking technology and illuminate its transformative role in industrial evolution.

The Symphony of Precision: Imagine a symphony where every note is meticulously crafted, every harmony perfectly orchestrated. Such is the essence of laser marking machines – masters of precision in a cacophony of manufacturing. With surgical precision, lasers etch intricate designs, alphanumeric codes, and identifiers onto a myriad of materials, ensuring flawless execution and unrivaled clarity. From aerospace components to medical devices, the symphony of precision resonates across industries, setting the standard for quality and reliability.

A Tapestry of Traceability: At the heart of every product lies a story waiting to be told – a journey from conception to consumption. Laser marking machines imbue each component with a unique identity, weaving a tapestry of traceability that spans continents and lifetimes. Through serialized codes, QR tags, and DataMatrix symbols, manufacturers can trace the origin, history, and authenticity of every item, safeguarding against counterfeiting and ensuring compliance with regulatory standards. In this digital age, where transparency reigns supreme, laser marking serves as the guardian of integrity and trust.

The Canvas of Creativity: In the hands of artisans, laser marking machines transcend utility, becoming instruments of creativity and expression. From bespoke artworks to personalized mementos, lasers transform mundane objects into cherished artifacts, imbuing them with meaning and significance. Whether it's engraving heartfelt messages on wedding bands or embellishing corporate gifts with company logos, the canvas of creativity knows no bounds. With lasers as their brush and imagination as their guide, artisans breathe life into every mark, leaving an indelible impression on hearts and minds.

Harmony in Sustainability: In a world grappling with environmental challenges, laser marking machines emerge as champions of sustainability, harmonizing efficiency with eco-consciousness. Unlike traditional methods that rely on chemical etchants and consumables, lasers operate with surgical precision, generating minimal waste and emissions. By embracing clean, contactless technology, manufacturers can reduce their environmental footprint, comply with stringent regulations, and meet the demands of eco-conscious consumers. In the symphony of sustainability, laser marking machines play a vital role, conducting harmony amidst chaos.

Conclusion:

As the curtain falls on our exploration of laser marking machines, one truth resonates clearly – they are the silent architects shaping the future of industry. From precision marking and traceability to creativity and sustainability, these unsung heroes embody the essence of innovation and progress. As we navigate the ever-evolving landscape of manufacturing, let us recognize and celebrate the profound impact of laser marking machines – the silent architects of our industrial renaissance.

0 notes

Text

youtube

For more details: please contact us at +91 9688881198 / 9087575750 / 7448800116. Visit us online: www.retechlasers.com Plotbot Plus: Plotbot Plus is a multipurpose laser engraver developed from scratch and equipped with a 40W CO2 laser tube, Plotbot can easily engrave and cut many things, and help to make surprises in daily life. For instance, making Customized Gifts, Engineering Laser Cut Components for technical needs, greeting cards for families, or engraving any kind of photos on wood for decoration, etc. Capability 1. Equipped with A 40W CO2 laser tube, Plotbot Plus is an independent XYZ Plotter with the efficiency to move 500mm/s with exact accuracy. Usually, it cuts up to 6mm of acrylic and up to 5mm of MDF sheets. 2. The main board has the capability to run both motors, but also very easy to use. Moreover, any can also control the speed and power of the motor and laser. 3. High-precision: Accurate up to 0.1 mm, carefully engraves every detail in an image. 4. Engraving area: 610mm×458mm (2×1.5 ft) with the compact machine size. =========================================================== Plotbot Pro: Plotbot Pro is a multipurpose laser cutting machine developed from scratch and equipped with a 100W CO2 laser tube, Plotbot Pro can easily engrave and cut many things, and help to make surprises in daily life. For instance, making Acrylic Sign Boards, Customized Gifts, Engineering Laser Cut Components for technical needs, greeting cards for families, or engraving any kind of photos on wood for decoration, etc. Capability 1. Equipped with A 100W CO2 laser tube, Plotbot Pro is an independent XYZ Plotter with efficiency to move 1000mm/s with exact accuracy. Usually, it cuts up to 12mm of acrylic and up to 8mm of MDF sheets. 2. The main board has the capability to run both motors, but also very easy to use. Moreover, any can also control the speed and power of the motor and laser. 3. High-precision: Accurate up to 0.1 mm, carefully engraves every detail in an image. 4. Engraving area: 1300mm×920mm (4×3 ft) with the enormous working area 5. Touch Screen: 7-inch touch screen with an attractive UI and custom #business #lasercutting #laserengraving #innovation #startup #startupbusiness #engineeringexcellence #businessideas #laseretching #personalizedgifts #giftideas #customized

#interiors#gardening#home decor#interior design#Business#small business#laser machine#best laser cutting machine#own business#Youtube

1 note

·

View note

Text

Laser optical mirror, output mirror, silicon mirror, copper mirror, molybdenum mirror

What mirrors is your best choise ?Tell us your requirement,we will make a good solution for you !

View On WordPress

0 notes

Text

Máy tẩy rỉ set laser cầm tay giá thấp là giải pháp tiên tiến cho việc làm sạch bề mặt kim loại. Với khả năng vệ sinh tẩy rỉ sét cùng các lớp phủ như sơn, dầu, xi mạ, bụi, máy này mang lại hiệu quả vượt trội trên nhiều loại vật liệu khác nhau như sắt, thép, inox, nhôm.

Tham khảo chi tiết hơn về máy tẩy rỉ cầm tay giá thấp tại Vlaser: https://www.vlaser.vn/tin-tuc/may-tay-ri-set-laser-cam-tay-gia-thap

#vlaser#fiber laser#lasertechnology#laser machine#lasercleaningmachine#tẩy rỉ#máy làm sạch#máy tẩy rỉ set giá thấp#máy tẩy rỉ laser

0 notes

Text

The Advanced Laser Marking Machine for Metal | Maxsell

A state-of-the-art metal laser marking machine from Maxsell offers remarkable precision and toughness. You can visit our website to learn more about our selection of premium laser machines created to satisfy the various marking needs of the metal sector. Our cutting-edge laser marking technology ensures permanent and readable marks on a variety of metal surfaces, whether you need to mark logos, serial numbers, barcodes, or complicated designs. Utilise the laser marking machine for metal from Maxsell to achieve higher performance and effectiveness. Visit our website now to view our inventory right away.

1 note

·

View note

Text

Column maintenance.

Now available for purchase on INPRNT

#cybernetics#cyberpunk#cyborg#retro#android#femalebody#foot#cables#machine#scanner#body#nudesketch#lab#computer#machinehead#love#takecare#laser#illustration#digitalillustration#digitalart#digitaldrawing#digitalsketch#digitalartwork#90s#monitor

4K notes

·

View notes

Text

The Benefits of Using a Laser Cutting Machine

Laser cutters are a unique tool used for cutting and engraving various materials such as wood, plastic, metal and more. Laser cutting machines provide a range of benefits, including cost savings and improved accuracy. At Ortur, we offer the best laser cutter engraver and laser cutter wood tool for metal available on the market, helping you create the best wood engraving projects. Here are just a few of the many benefits of using a laser cutting machine.

1. Accuracy & Precision: Laser cutting machines are known for their astounding accuracy and precision. When compared to traditional cutting tools, laser cutters are far more precise, producing intricate, detailed cutouts. This is especially beneficial for complex projects and intricate designs.

2. Cost Savings: One of the major benefits of using a laser cutting machine is the cost savings you can achieve. Since the cutting of materials is done with a laser, there is no need to purchase additional tools like saws or blades. This eliminates the need for additional materials, saving you time and money in the long run.

3. Safety: With a laser cutting machine, you don't have to worry about the potential hazards of traditional cutting tools. Laser cutters eliminate the need for sharp blades, meaning there is a much lower risk of injury.

0 notes

Text

100W Laser Cutting Machine at Reasonable Prices

Shenzhen Sijiahua Keji offers 100W Laser Cutting Machine at reasonable prices worldwide. It is designed and suitable for woodworking, textile cutting, industrial prototyping and marking, and Sign making, etc. It is also used for cutting leather, paper, cardboard, and plastic. To speed up your production, this one the perfect for your business. For more details call us at +86-18025348056.

0 notes

Text

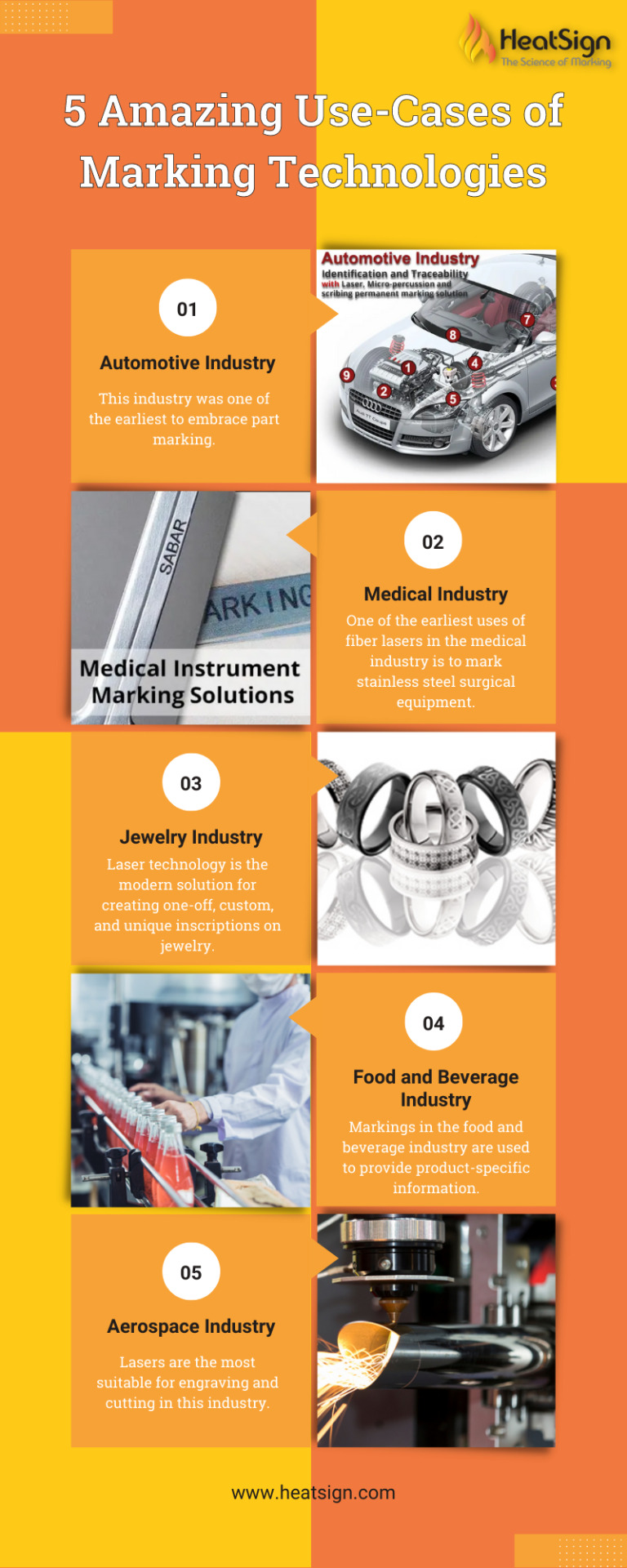

There have been many fantastic applications of marking in various technologies. But it is important for manufacturers to consider the quality of marks, the material type, the texture of the surface (roughness/softness), and the size of the part when choosing the right technology for their industry.

#laser marking#laser marking machine#marking machine#laser machine#dot peen marking#dot peen machine

1 note

·

View note

Link

We have told about all laser cutting machines. And it has also been told that for what work all these machines are used. Also tell the prices of all.

0 notes