#vcipaper

Text

VCI Anti Rust Paper Market

Research Reports provides key analysis on the global market in a report, titled “VCI Anti Rust Paper Market by Types (VCI paper for ferrous metals, VCI paper for non-ferrous metals, VCI multi-metal papers), Applications (Metal Producing, Metal Forging and Die Casting, Metalworking, Finished Products, Others) and Region — Global Forecast to 2024” BrowseMarket data Tables and Figures spread through Many Pages and in-depth TOC on VCI Anti Rust Paper Market.

As report shows there will be trend of VCI paper in the market. You must be aware of the key feature as of VCI paper as below.

KEY FEATURES

Provides excellent processing ability (die cutting, folding, printing etc.) on all conventional as well as high-speed envelope lines

Customization in various colors and special surfaces for specific customer requirements

Water/moisture resistance

Much better tear strength

Elegant & lightweight

Excellent dimensional stability

Much improved durability & wet strength

Recyclable by mechanical separation with existing equipment

CONSTRUCTION

VCI Fabric Reinforced Metal wrap consists primarily of paper substrate that has an added layer of fabric and VCI materials that offer high moisture barrier and heat sealing technology.

APPLICATION

Used for protecting small metals and other parts from rust and moisture.

For Anti-rust VCI Paper Contact

Tel : +91–20–25560999 / +91–20- 25560400

1 note

·

View note

Text

Our VCI Paper Meets MIL-PRF-3420 Specifications

MIL-PRF-3420H WRAPPING MATERIALS, VOLATILE CORROSION INHIBITOR TREATED, OPAQUE

TREATED CARRIERS ARE FURNISHED IN THE FOLLOWING CLASSES AND STYLES

CLASSES

1. Heavy Duty

2. Medium Duty

3. Light Duty

STYLES

1. Kraft, flat: Single ply or laminated

2. Kraft, creped or embossed: Single ply or laminated

3. Greaseproof, waterproof, moldable: Laminated to carriers conforming to QQ-A-1876

The appearance of finished wrapping materials that are coated or impregnated shall not contain any voids in the coating or substrates (see 4.3.2.2). The material shall be clean and free from holes, tears, cuts, sharp creases, wrinkles, or other imperfections. The treated carrier shall be cut and trimmed of any selvage (see 4.3.2.1). On crepe material, bursting strength value shall be obtained with specimen stretched. Crepe requirements shall be 50 percent of flat.

At MAC Packaging we offer full-service government and mil spec packaging services and custom commercial packaging and export solutions. Contact us to learn more about our services or to request a free estimate.

See how we help companies like yours.

#Macpackaging#vcipaper#military#government#governmentbids#governmentcontracts#milspec#militaryspecifications#consulting#rfid solutions#rfid system#rfid#rfid tags#barcode#barcodes#esdlabels

0 notes

Link

#Suprabha#VCImanufacturer#Corrosiondoctors#VCI#Rustoil#Corrosionsolutionsprovider#VCIoil#Corrosionsolutions#Corrosionprevention#VCIpaper#VCIfilm#Rustpreventivepackaging#Seaworthypacking

0 notes

Text

Why use of Rust Preventive Oil is important in India?

Many times, you often come across a query from your end customers to not to use #Rust #Preventive #Oils on your Components or to use a Dry to Touch #Rust #Preventive #Oil.

Now the question comes, why is that you should always use a Rust Preventive Oil?

(a) In India, the temperature and #Humidity Variations are one of the major reasons for #Condensation which leads to #Oxidation on the #Metallic Components. When components are not packed immediately after production, they are subjected to Humidity and Temperature Variations thus causing the immediate reaction, i.e. #Corrosion. #Rust #Preventive #Oil takes care of this problem.

(b) Almost 99% of the industry uses Metal Working Fluids during production. When these Metal Working Fluids are not checked the time and again, the pH value of these Metal Working Fluids changes which can lead to immediate #Corrosion after it is taken out of the production process. Rust Preventive Oil takes care of this problem.

(c) During #Production, #Handling and #Packaging, the labour may forget to use Hand Gloves and thus Finger Prints can be left on the Metallic Components. These fingerprints later turn into #Acidic content and thus form #Corrosion. #Rust #Preventive #Oil takes care of this problem.

(d) During #Packaging, the components may be subjected to rest on #Corrugated #Box or #Wooden Surfaces which has a high amount of #Moisture Content. This moisture will penetrate into the components and thus #Rust. Rust Preventive Oil takes care of this problem.

(e) During Final Washing, the Metallic Components are sometimes subjected to Cold Air and Hot Air before final packaging. These air sometimes carry large amounts of #moisture which form patches on the component and later turn in #Rust. Rust Preventive Oil takes care of this problem.

Like ways, there are multiple reasons why you should use Rust Preventive Oil rather than avoiding it. Of course, we at #BENZ #Packaging can cater to your wide requirements of Rust Preventive Oil Requirements together with other Protective Packaging Solutions like #VCI #Paper, #VCI #Film, #Desiccants and #VCI #Emitters.

Contact us today. Click Here

#VCIPaper

#VCIFilm

#BENZ #Packaging #Solutions

#VCI #Film #Manufacturer

#VCI #Paper #Manufacturer

#Desiccants and Moisture Absorbers

BE Dry

C Dry

#VCI #Emitters

#Packaging #Solutions

#Rust #Preventive

#Corrosion #Inhibitor

#Gurgaon #Haryana #Chennai #Bangalore #Pune #Mumbai #Indore

0 notes

Link

Let's Fix Corrosion Problems - Suprabha

#vci#vcimanufacturer#suprabha#rustprevention#corrosionsolutions#Seaworthypacking#vcioil#vcipaper#vcifilm#vcipackagingmanufacturer#Rustpreventivepackaging#corrosionprevention#Corrosionsolutionsprovider

0 notes

Link

#rustpreventivepackaging#Packaging#vcipackaging#vcimanufacturer#Seaworthypacking#vcipaper#vcioil#vcifilm#vcipackagingmanufacturer#vcifilmmanufacturer#Rustprevention#VapourCorrosionInhibitors#Corrosionsolutionsprovider#Packagingmaterial

0 notes

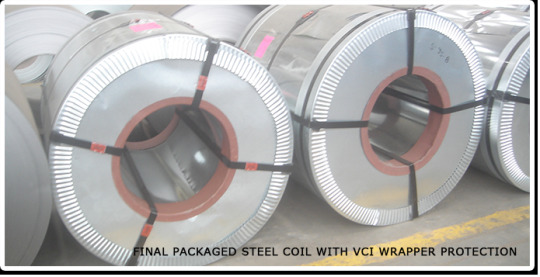

Photo

#rustpreventivepackaging#Packaging#vcipackaging#vcimanufacturer#Seaworthypacking#vcipaper#vcioil#vcifilm#vcipackagingmanufacturer#vcifilmmanufacturer#Rustprevention#VapourCorrosionInhibitors#Corrosionsolutionsprovider#Packagingmaterial

0 notes

Photo

#rustpreventivepackaging#vcipackaging#vcimanufacturer#vcifilm#vcioil#vcipaper#Rustprevention#Corrosionsolutionsprovider#Packagingmaterial#VapourCorrosionInhibitors

0 notes

Photo

#rustpreventivepackaging#Packaging#vcipackaging#vcimanufacturer#Seaworthypacking#vcipaper#vcioil#vcifilm#vcipackagingmanufacturer#vcifilmmanufacturer#Rustprevention#VapourCorrosionInhibitors#Corrosionsolutionsprovider#Packagingmaterial

0 notes

Photo

#rustpreventivepackaging#Packaging#vcipackaging#vcimanufacturer#Seaworthypacking#vcipaper#vcioil#vcifilm#vcipackagingmanufacturer#vcifilmmanufacturer#Rustprevention#VapourCorrosionInhibitors#Corrosionsolutionsprovider#Packagingmaterial

0 notes

Photo

Corrosion is Dangerous - Suprabha

#vcipackaging#vcimanufacturer#Seaworthypacking#vcipaper#vcioil#vcifilm#vcipackagingmanufacturer#vcifilmmanufacturer#Rustpreventivepackaging#Rustprevention#corrosionprevention#VapourCorrosionInhibitors#Rustopowder#SOVCI#Corrosionsolutionsprovider

0 notes

Photo

#vcifilmmanufacturer#vcipackaging#vcimanufacturer#Seaworthypacking#vcipaper#vcioil#vcifilm#vcipackagingmanufacturer#Rustpreventivepackaging#Rustprevention#corrosionprevention#VapourCorrosionInhibitors

0 notes

Photo

#Mondaybusinessmotivation#Suprabha#VCImanufacturer#vcipaper#vcioil#vcifilm#rustpreventionsolutions#seaworthypacking#vcipackaging#corrosionprevention

0 notes