#Valve Seat

Text

Mastering the Art of Fixing a Dripping Faucet: Your Ultimate Guide

When it comes to dealing with the pesky nuisance of a dripping faucet, we understand your frustration. That incessant, rhythmic drip not only wastes precious water but can also disrupt your peace of mind. In this comprehensive guide, we, the experts in plumbing and household maintenance, will empower you with the knowledge and skills to fix that dripping faucet like a pro.

The Irritating Symphony of a Dripping Faucet

A dripping faucet is not just a minor annoyance; it's a hidden source of water wastage that can significantly impact your utility bills and the environment. According to the Environmental Protection Agency (EPA), a single faucet dripping at a rate of one drop per second can waste over 3,000 gallons of water in a year! Moreover, the incessant sound can lead to sleepless nights and frayed nerves.

Tools of the Trade

Before we delve into the step-by-step process of fixing your dripping faucet, let's gather the essential tools and materials you'll need for this DIY plumbing endeavor. Having the right equipment on hand will make the task smoother and more efficient.

1. Adjustable Wrench

An adjustable wrench is your trusty companion for loosening and tightening various faucet components.

2. Replacement Parts

Depending on your faucet type, you may need replacement parts such as O-rings, washers, or cartridges. Make sure to identify your faucet model and purchase the necessary components.

3. Screwdrivers

Both flathead and Phillips screwdrivers are essential for removing screws and accessing hidden parts within the faucet.

4. Plumber's Tape

Also known as Teflon tape, plumber's tape is crucial for preventing leaks in threaded connections.

5. Bucket and Towels

Be prepared for some water spillage by having a bucket and towels nearby to catch and clean up any mess.

Identifying the Culprit

Understanding the anatomy of your faucet is the first step in resolving the issue. While there are various faucet types, most dripping faucets can be attributed to one of the following common culprits:

1. Worn-Out O-Rings

O-rings are small rubber gaskets that create a watertight seal within the faucet. Over time, they can deteriorate, leading to leaks.

2. Damaged Washers

Washers, located in the faucet handles, can wear down or become damaged, resulting in a constant drip.

3. Faulty Cartridge

Cartridges control the flow of water in modern faucets. If the cartridge is defective, it can cause leakage.

4. Corroded Valve Seat

A valve seat is the connection between the faucet and the spout. Corrosion in this area can lead to leaks.

The Fixing Process

Now that we've identified potential issues, it's time to roll up our sleeves and get to work. Follow these steps diligently to fix your dripping faucet:

Step 1: Turn Off the Water Supply

Before you begin, ensure that the water supply to the faucet is completely shut off. Look for shut-off valves under the sink or at the main water supply.

Step 2: Dismantle the Faucet

Using your adjustable wrench and screwdrivers, carefully dismantle the faucet. Be sure to keep track of the removed parts and their order to facilitate reassembly.

Step 3: Inspect and Replace Components

Examine the O-rings, washers, cartridge, and valve seat for signs of wear, damage, or corrosion. Replace any faulty components with the new ones you've gathered.

Step 4: Reassemble the Faucet

Reassemble the faucet in the reverse order of disassembly. Ensure that all parts fit snugly and securely.

Step 5: Turn On the Water Supply

Once the faucet is reassembled, slowly turn on the water supply to check for leaks. If there are no leaks, congratulations! You've successfully fixed your dripping faucet.

Preventative Maintenance

To avoid future faucet troubles, consider implementing regular preventative maintenance:

Periodically clean and lubricate the faucet to prevent mineral buildup.

Check for and address leaks promptly to prevent further damage.

Install water-saving aerators to reduce water wastage and save on utility bills.

By mastering these simple techniques, you can keep your faucets in optimal condition and enjoy a drip-free, peaceful home.

Conclusion

In this comprehensive guide, we've equipped you with the knowledge and skills to conquer the annoyance of a dripping faucet. By identifying the root causes and following our step-by-step fixing process, you can save water, money, and your sanity.

Looking for more tips on bathroom maintenance and fixtures? Check out these informative articles on BlissfulBathroom:

Easy Ways to Fix a Dripping Faucet: Dive deeper into faucet troubleshooting and repair techniques.

Is Your Bathroom Vanity High Quality?: Learn how to assess the quality of your bathroom vanity and make informed choices during renovations.

How to Clean Bathroom Taps: A Step-by-Step Guide: Discover a thorough guide to keeping your bathroom taps sparkling and functional.

Are Faucet Cartridges Universal?: Gain insights into faucet cartridges and whether they are interchangeable across different brands.

So, don't let that pesky drip continue to torment you. Take control and become a DIY plumbing pro. Fixing a dripping faucet is not just a household chore; it's a step towards a more sustainable and tranquil living environment.

A well-maintained faucet is a happy faucet.

#fix dripping faucet#how to fix dripping faucet#Dripping Faucet#Faucet Repair#Plumbing Tips#DIY Plumbing#Household Maintenance#Water Conservation#Faucet Components#O-Rings#Washers#Cartridge Replacement#Valve Seat#Preventative Maintenance#Bathroom Fixtures#Home Improvement#Sustainable Living#Water Efficiency#Home DIY#Plumbing Guide#Water Leak#Faucet Troubleshooting#Home Plumbing#Fixing Faucet Leaks#Faucet Maintenance#Plumbing DIY#Water-Saving Tips#Faucet Types#Home Repair#Water Waste

0 notes

Text

Bajaj Automobile Spare Parts | BLW Engine Valves

BLW Engine Valves Pvt. Ltd. was founded in 1974 with the sole purpose of offering top-notch automotive components to India and the rest of the world for use in various vehicle applications. At present, we serve different vehicle segments such as HCV, LCV, Tractor, Car, Two Wheeler, Three Wheeler, and Stationary Diesel Engines.

BLW is now a well-known brand in the automotive component industry. We were able to accomplish this by continuously improving the quality of our products and services. Our products are manufactured in our cutting-edge manufacturing plant in Bahadurgarh, Haryana, using automated equipment and machinery such as orgings, CNC machines, and the most recent German surface treatment. Before being dispatched to our customers, each component is subjected to the most rigorous quality checks and controls on fairly complex types of equipment such as spectrometers, optical scanners, and so on.

We are a certified ISO 9001-2015 Company by TUV Rheinland. We are fairly manufacturing and producing Engine Valves and Valve Seat Inserts for superior technology vehicles such as Toyota, Honda, Peugeot, Nissan, DAF, Rover, Mercedes Benz, Fiat, Perkins, Ford, and many more. We currently export 500 different types of engine valves to various parts of the world.

Our honest, ethical, and transparent business practices have made us a well-established and considered reliable brand in the market segments of Iran, Bangladesh, Myanmar, Egypt, and many other African countries.

Our Business Policy states total Customer Satisfaction through continuous effort, hard work, and improvement in the quality of our products and services.

Below the table Our firm has carved a niche in this respective domain with an excellent understanding of business and motivating guidance from our Directors, "Mr. Aditya Bhaskar" and "Mr. Gaurav Bhaskar," and a talented workforce. They have led our organization to greater success as a result of their professionalism.

for more information: http://blwenginevalves.com/

#bajaj genuine parts#bajaj parts#bajaj auto parts#bajaj 3 wheeler#engine valve#valve seat#valve seats#bajaj automobile spare parts#bajaj auto spare parts

1 note

·

View note

Text

Excellence in Flow Control: Butterfly Valve Manufacturers

Hf Valve specializes in crafting precision-engineered flow control devices. They produce a variety of butterfly valves, ranging from resilient-seated to high-performance designs, to suit diverse applications. These manufacturers adhere to industry standards, ensuring quality, reliability, and efficiency in managing fluid flow across industries such as oil and gas, water treatment, and HVAC systems.

#Butterfly Valve Manufacturers#Precision Engineering#Flow Control Devices#Resilient-Seated Valves#High-Performance Valves#Diverse Applications

2 notes

·

View notes

Text

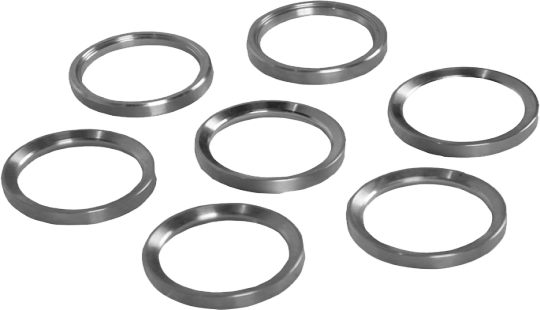

The Ultimate Guide to Choosing the Right Seats

Choosing the right valve seats is crucial for ensuring optimal performance and longevity of valves in various applications, including automotive engines, industrial machinery, and plumbing systems. Valve seats play a critical role in sealing, controlling flow, and withstanding high temperatures and pressures. Here’s a comprehensive guide to help you choose the best valve seats for your specific needs:

1. Understand Valve Seat Materials:

— Valve seats are typically made from materials like cast iron, steel alloys, bronze, and various types of hardened alloys. Each material offers specific advantages in terms of durability, heat resistance, and compatibility with different valve materials (e.g., steel, aluminum).

2. Consider Valve Seat Inserts:

— Valve seat inserts are replaceable components that can be installed in cylinder heads for improved durability and performance. Common insert materials include stellite, titanium, and tungsten carbide. Choose inserts based on the expected operating conditions and valve material compatibility.

3. Evaluate Operating Conditions:

— Consider the temperature, pressure, and chemical environment where the valve seats will be used. Select materials that can withstand these conditions without deformation, erosion, or degradation over time.

4. Assess Wear Resistance:

— Look for valve seats with high wear resistance to withstand repeated contact with valve components. Materials like stellite and tungsten carbide offer excellent wear resistance, making them suitable for high-performance applications.

5. Check Compatibility with Valve Materials:

— Ensure that the chosen valve seats are compatible with the materials used in the valve components (e.g., valve stems). Materials should have similar hardness and thermal expansion properties to prevent premature wear and ensure a reliable seal.

6. Evaluate Heat Dissipation:

— In high-temperature applications, heat dissipation is crucial to prevent overheating and valve failure. Choose valve seats with good heat conductivity to efficiently transfer heat away from the valve components.

7. Consider Seal Integrity:

— Valve seats must provide a reliable seal to prevent leakage and ensure optimal performance. Look for materials that can maintain a tight seal under varying temperatures and pressures without excessive wear.

8. Optimize Flow Characteristics:

— Valve seat design can impact flow characteristics and performance. Consider the shape and surface finish of the valve seats to minimize flow restrictions and turbulence, thereby optimizing efficiency.

9. Evaluate Cost vs. Performance:

— Balance performance requirements with budget constraints. Higher-performance materials like tungsten carbide may offer superior durability but come at a higher cost. Choose materials that provide the best value over the lifespan of the valve system.

10. Consult with Experts:

— If unsure about which valve seats to choose, consult with valve manufacturers or specialists who can recommend the most suitable materials and designs based on your specific application requirements.

Conclusion:

Choosing the right valve seats involves considering various factors, including material properties, operating conditions, compatibility, and performance requirements. By carefully evaluating these aspects and consulting with experts if needed, you can select valve seats that ensure reliable sealing, durability, and optimal performance in your application.

0 notes

Text

Budget-Friendly Bathroom Remodel Ideas

The Tapron blog post offers budget-friendly ideas for bathroom remodeling, focusing on achieving a luxurious look without exceeding financial constraints. It covers selecting appropriate shower sets, bathroom taps, towel radiators, and toilets, emphasizing cost-effectiveness without compromising on style or quality. The article aims to guide readers through enhancing their bathroom's functionality and comfort while sticking to a budget, showcasing Tapron's range of products as solutions for a stylish yet affordable bathroom makeover. For more details, visit the full guide here.

#Bathroom shower accessories#Shower enclosures#Matt black shower heads#Thermostatic shower valves#Modern bathroom taps#Traditional bathroom taps#Heated towel rail radiators#Towel radiator valves#Toilet seats#Rimless toilet technology

0 notes

Text

im watching chernobyl hbo (for barry) and honestly? this may be the most stressful tv show ive ever watched in my life

#Jesus did not die for your sins. those poor low-wage fuckers who had to wade into the middle of chernobyl to shut off the water valves did#this show has me shaking in my seat ngl

1 note

·

View note

Text

What is the adaptability of this type of gate valve to different environmental conditions?

The adaptability of BS5163 resilient seated gate valves to various environmental conditions can be assessed based on several factors:

Temperature Range: Resilient seated gate valves are generally designed to operate within specific temperature ranges. They might have limitations in extreme temperatures, both high and low, which could affect the flexibility and sealing capabilities of the resilient materials.

Corrosive Environments: The materials used in these valves are typically chosen for their resistance to corrosion. However, in highly corrosive environments, such as those with aggressive chemicals, additional protective coatings or specialized materials might be necessary.

Abrasive Media: Gate valves might encounter issues in environments with abrasive materials flowing through them. Over time, this could cause wear on the valve components, affecting their performance and lifespan.

UV Exposure and Outdoor Use: For outdoor applications, exposure to ultraviolet (UV) radiation can degrade the resilient materials used in the valve over time. Some valves might be equipped with UV-resistant coatings or materials to mitigate this issue.

Pressure Fluctuations: These valves might perform differently under varying pressure conditions. Fluctuations could impact the sealing properties of the valve, especially if the pressure exceeds the valve's design limits.

Moisture and Contaminants: Moisture ingress or the presence of contaminants in the operating environment can affect the functionality of the resilient seats, potentially leading to reduced sealing effectiveness.

Installation Conditions: Proper installation, including ensuring adequate support and alignment,bs5163 resilient seated gate valve is crucial for the valve's performance in different environmental conditions. Improper installation might lead to leaks or operational issues.

Regulatory Compliance: In certain environments, specific regulatory standards or certifications might be required. The adaptability of the valve to meet these standards could influence its suitability for use.

Overall, while BS5163 resilient seated gate valves offer resilience in various environments, their adaptability depends on the specific conditions and the materials used in their construction. In extreme or highly specialized environments, additional measures or alternative valve types might be more suitable. Regular maintenance and monitoring are essential to ensure their continued performance in different environmental conditions.

Are there any situations in which BS5163 gate valve is not suitable or recommended?

BS5163 resilient seated gate valves are versatile and commonly used in various industries, but there are scenarios where they might not be the most suitable choice:

High-Pressure Applications: In situations where extremely high pressures are involved, gate valves might not be the best option. Other valve types, like globe or ball valves, might offer better sealing capabilities under high-pressure conditions.

Throttling or Flow Control: Gate valves are primarily designed for on/off service. They might not provide precise flow control or throttling capabilities compared to valves specifically designed for those purposes.

Frequent Cycling: Gate valves might wear out more quickly if used frequently for opening and closing. In applications where frequent cycling is necessary, valves designed for such conditions, like ball valves, might be more suitable.

Handling Abrasive Media: Resilient seated gate valves might not be ideal for environments where the fluid passing through contains abrasive particles. The resilient seat might wear out faster, compromising the valve's sealing effectiveness.

Extreme Temperature Variations: In situations with extreme temperature fluctuations, the materials used in the valve's construction might expand or contract significantly, affecting the valve's performance and sealing capabilities.

Critical Shutdown Applications: For critical applications where absolute tight shut-off is crucial, gate valves might not offer the same level of leak-tightness as some other valve types. Double block and bleed valves or other specialty valves might be more appropriate.

Limited Space: In areas with space constraints or where a compact valve design is necessary, gate valves might not be the most space-efficient choice due to their linear design.

Regulatory Compliance: Certain industries or applications might require valves to meet specific standards or certifications that gate valves may not fulfill. In such cases, specialized valves meeting those standards might be recommended.

For these scenarios, it's essential to assess the specific requirements of the application and the operating conditions to determine the most suitable valve type. Gate valves have their strengths but might not be optimal for every situation.

0 notes

Text

Recon Control is one of The Leading Manufacturers - Suppliers of angle seated valves, angle seated valves in Ahmedabad, Gujarat, India. Find here address and contact details of angle seated valves Manufacturers in Ahmedabad, Gujarat, India.

#angle seated valves#angle seated valves exporter in India#angle seated valves supplier in ahmedabad#United states#canada#south korea#taiwan

0 notes

Text

WCB Gate Valve PN16

Body: WCB, Trim: 13Cr, Seat & disc: WCB+13CR

Handwheel operation

#WCB Gate Valve PN16#Body: WCB#Trim: 13Cr#Seat & disc: WCB+13CR#Handwheel operation#gatevalve#pn16gatevalve#wcbgatevalve#caststeelgatevalve#flangedgatevalve#industrialgatevalve#manualgatevalve

0 notes

Text

EWOM is a Chinese Top Valves manufacturer in 2009, exported to 84 countries worldwide They are committed to providing high-quality products Best Stainless Steel ,Metal Seated Ball Valve or Api 600 Gate Valve provider technical support and deliver the best results for our clients through our Quality remarkable valve is designed to provide optimal performance and efficiency for a wide range of Management System.

#gate valve manufacturers china#wafer check valve#cast steel gate valve#check valve china#swing check valve china#gate valve china#api 600 gate valve#forged steel gate valve#cast steel globe valve#forged steel globe valve#piston check valve#Double block and bleed valve#ball valve china#floating ball valve#fully welded ball valve#stainless steel ball valve#metal seated ball valve#flanged ball valve#top entry ball valve#trunnion mounted ball valve

0 notes

Text

Key Design Features and Working Principles of Resilient Seated Valve

Resilient seated valves are an essential component in various industrial systems, offering reliable and efficient flow control. Their design features and working principles play a crucial role in ensuring optimal performance and longevity. In this article, we will explore the key design features and working principles of resilient seated valves, shedding light on their functionality and benefits.

Body Construction:

Resilient seated valves are typically composed of a sturdy body made from materials such as ductile iron, cast iron, or stainless steel.

Resilient Seat:

One of the distinctive design features of resilient seated valves is the presence of a resilient seat. This seat, often made of materials like EPDM or NBR, provides a tight seal when the valve is closed, preventing leakage and ensuring effective shut-off. The resilience of the seat also allows it to compensate for minor misalignments, reducing the risk of damage during operation.

Disc and Stem:

The valve's disc, connected to the stem, is responsible for controlling the flow of fluid. It is typically designed with a streamlined shape to minimize flow resistance and pressure drop. The stem provides the necessary mechanical support for opening and closing the valve, ensuring smooth operation and precise control.

Actuation Options:

Resilient seated valves can be operated manually or through various actuation methods, such as electric, pneumatic, or hydraulic actuators. This versatility allows for remote and automated control, enhancing operational efficiency and system integration.

Opening and Closing:

When the valve is in the closed position, the resilient seat forms a tight seal against the disc, preventing the flow of fluid. To open the valve, the stem is turned or actuated, causing the disc to move away from the seat, creating a pathway for fluid to pass through. The valve can be closed by reversing this process, bringing the disc back into contact with the seat.

Flow Control:

Resilient seated valves offer excellent flow control capabilities due to their streamlined disc design and precise actuation. This feature is particularly valuable in applications where precise flow modulation is required.

Resilient Sealing:

The resilient seat of the valve ensures a tight seal, even when operating under varying pressures and temperatures. The flexibility of the seat material allows it to conform to the disc and maintain a secure closure, preventing leakage. This sealing ability reduces the risk of product loss, minimizes system downtime, and enhances overall safety.

Cair Euro Description:

Cair Euro is a renowned manufacturer and supplier of high-quality resilient seated valves. With a strong focus on innovation and reliability, Cair Euro has earned a reputation for delivering cutting-edge valve solutions for industrial applications.

Our resilient seated valves are meticulously designed to meet the stringent demands of modern industries. We prioritize durability, performance, and safety in every aspect of our valve construction.

At Cair Euro, we offer a wide range of resilient seated valve, catering to diverse industrial needs. Our valves are extensively used in sectors such as water treatment, HVAC systems, chemical processing, and power generation.

With a dedicated team of experienced professionals and a commitment to continuous improvement, Cair Euro strives to deliver exceptional products and excellent customer service. We are passionate about providing comprehensive technical support, ensuring that our clients have the necessary guidance and assistance throughout the valve selection, installation, and maintenance processes.

Conclusion: resilient seated valves are integral to industrial systems, and their design features and working principles significantly impact their performance. Cair Euro is a trusted provider of resilient seated valves, delivering reliable and high-quality solutions to meet the diverse needs of industries worldwide. By understanding the key design features and working principles of these valves, businesses can make informed decisions when it comes to implementing effective flow control solutions.

0 notes

Text

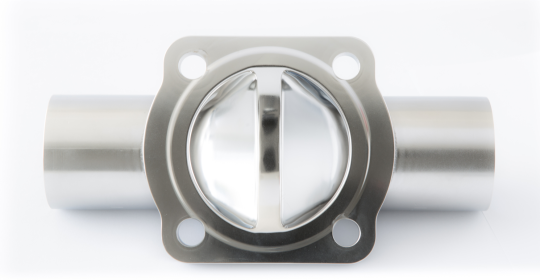

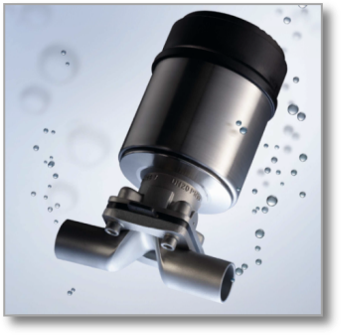

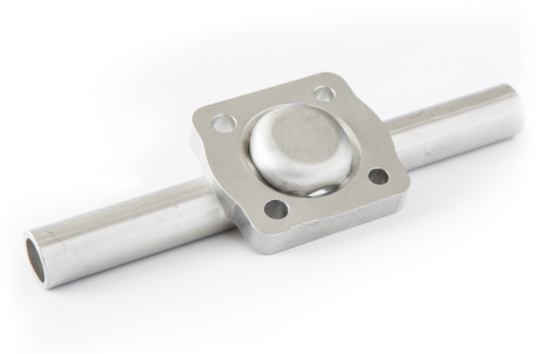

The New Benchmark of Efficient Hygienic Design | The Hydroformed Tube Valve Body for Diaphragm Valves

นวัตกรรมใหม่ ที่จะมาท้าทาย Forged Body & Cast Body ไดอะแฟรมวาล์ว หนึ่งในอุปกรณ์สำคัญที่ใช้กันในอุตสาหกรรมยา เครื่องสำอางค์ อาหาร และเครื่องดื่ม ด้วยลิขสิทธิ์เทคโนโลยีการดัดขึ้นรูปท่อ โดยใช้น้ำแรงดันสูงถึง 3000 บาร์ ร่วมกับ การเชื่อมเลเซอร์ ระหว่างส่วนของท่อที่ดัดขึ้นรูปมาแล้ว กับแป้นรองแผ่นไดอะแฟรม

💥💥 Burkert ขอนำเสนอ The New Hydroformed, Light-Weight Tube Valve Body ซึ่งนอกจากจะเข้าถึงมาตราฐาน และกฎเกณฑ์ขั้นสูง ของงานปลอดเชื้อแล้ว ในการใช้งาน ยังช่วยเพิ่มประสิทธิภาพของกระบวนการผลิตอีกด้วย

BENEFITS FOR YOU

ในการติดตั้ง

▪ Tube Valve Body เมื่อนำไปเชื่อมกับท่อ จะให้คุณภาพรอยเชื่อมที่ดีที่สุด! เพราะเป็น tube-to-tube welding เหมือนการเชื่อมท่อกับท่อ ที่เป็นวัสดุเดียวกัน

▪ Light-Weight Design น้ำหนักเบา ช่วยลดต้นทุนในการติดตั้ง สำหรับวาล์วขนาด 1”, 1.1/2” และ 2” จะเบากว่าแบบเดิมถึง 65-75%!

▪ Ra < 0.38µm, ได้มาตราฐาน FDA, EHEDG และ ฟรี Inspection Certificate 3.1

ในการใช้งาน

▪ Light-Weight Design น้ำหนักเบา มวลน้อย ไม่อมความร้อน! จึงช่วยลดเวลาในการ Heat-Up และ Cool-Down ระหว่างการ SIP/CIP เพิ่มประสิทธิภาพการผลิต และช่วยประหยัดพลังงานในการทำความร้อน

▪ ของไหลจะสัมผัสเฉพาะผิวของ 316L Tube Body กับแผ่นไดอะแฟรมเท่านั้น จะไม่ได้สัมผัสกับแป้นรองแผ่นไดอะแฟรม หรือบริเวณรอยเชื่อมเลเซอร์เลย

เพิ่มเติมที่เว็ปไซต์ : https://www.alphac.co.th/news/Burkert_-_Tube_Valve_Body_for_Diaphragm_Valves/71

👇👇👇👇👇👇👇

ALPHA CONTROMATIC CO., LTD.

📌 LINE ID: AlphaC.sales หรือ ClickLink 👉 http://line.me/ti/p/~alphac.sales

📲 084 330 6663

☎ 02 721 1801

🖨 02 721 2657

🌎 www.alphac.co.th

✨✨✨✨✨✨✨✨✨✨✨✨✨✨

#Sensors#Controller#วาล์วBurkert#valves#คอนโทรลเลอร์#จำหน่ายวาล์ว#BurkertThailand#Valveน้ำ#วาล์วน้ำ#Hygienic design#โซลินอยด์วาล์ว ราคา#Angle Seat Valve

1 note

·

View note

Text

Efficiency Redefined: Unraveling the Excellence of Wafer Type Centerline Butterfly Valves

Explore the pinnacle of fluid control with wafer type centerline butterfly valves. Boasting innovative design features, smooth finishes, and resilient seats, these valves redefine efficiency. Their centerline design ensures optimal face-to-face dimensions, making them indispensable for various applications.

#Wafer Type Centerline Butterfly Valve#center line#wafer type#design features#face to face#smooth finish#resilient seated butterfly valves

0 notes

Text

A Quick Guide to Know About Resilient Wedge Gate Valves

The use of gate valves have been prevalent for a long time and their usage is versatile as they are suited for use in all types of applications. Whether it is above-ground or underground installation, they just fit perfectly.

However, selection of the right type of a gate valve is of paramount importance. Today, in this blog we are going to focus on resilient wedge gate valves and all the essential aspects of it.

Keep reading until the end to learn all the basics about resilient wedge gate valves.

What are Resilient Wedge Gate Valves?

Resilient wedge gate valves, also known as resilient seated gate valves, are a type of gate valve designed to provide tight shut-off and efficient flow control. They are called "resilient" due to the flexible rubber or elastomer seat located at the valve's closure element.

This element allows for a reliable seal even under varying conditions. The design of the resilient wedge gate valve prevents leakage and ensures efficient performance over a long service life.

Key Features and Components

The resilient wedge gate valves have similar components as the standard gate valve parts. A few additional elements makes them capable of delivering some extra features. The key components of a resilient wedge gate valve includes -

Body: The valve body is typically made of ductile iron or cast iron, providing strength and durability.

Wedge: The resilient wedge is the key element responsible for sealing the valve. It is coated with rubber or elastomer, allowing it to conform to the seat and provide a tight seal.

Stem: The stem connects the gate to the valve actuator, enabling the control of the valve's opening and closing.

Bonnet: The bonnet encloses the valve stem and protects it from external elements.

Seating: The elastomer or rubber seat ensures a tight seal, preventing leakage.

How Does A Resilient Wedge Gate Valve Operate?

The resilient wedge gate valve operates using a simple design consisting of two main components: the body and the wedge (also known as the disc) assembly. The body houses the internal parts of the valve and provides support for the wedge assembly.

When the valve is opened, pressure builds up within the pipeline, causing the wedge assembly to move away from the body. This results in creating a gap through which liquid or gas can flow.

On the other hand, when the valve is closed, the pressure inside the pipeline decreases, resulting in a reverse action. This action helps dampen vibrations and compresses the resilient material against its seat.

Hence, forming a tight seal that prevents any contamination or leakage from occurring.

Metal Seated Gate Valve vs Resilient Wedge Gate Valve

Now when it comes to using gate valves that deliver sealing performance, resilient wedge gate valves are not the only type that is considered. A metal seated gate valve is also opted for the same purpose, however, both differ from one another in terms of sealing surface materials and other factors.

Let’s take a look at the strengths of both of them -

Metal Seated Gate Valve

Sealing Mechanism: Metal seated gate valves rely on the contact between metal surfaces to achieve a tight seal, ensuring minimal leakage.

Temperature and Pressure Resistance: These valves are suitable for applications involving high temperatures and pressures, making them ideal for industries such as oil and gas, petrochemical, and power generation.

Durability: Metal seated gate valves are highly durable and can withstand erosive and abrasive fluids. Hence, they are suitable for applications where the fluid carries solid particles.

Limited Tightness: While metal seated gate valves provide reliable sealing, they may not achieve the same level of tightness as resilient wedge gate valves, especially in low-pressure applications.

Resilient Wedge Gate Valve

Sealing Mechanism: Resilient wedge gate valves use a rubber or elastomer seat that conforms to the wedge. This ensures a tight seal even under varying conditions. Its design provides excellent shut-off capabilities, minimising leakage.

Versatility: These valves are versatile and find applications in water and wastewater systems, industrial processes, and fire protection systems.

Lower Operating Torque: Resilient wedge gate valves require less operating torque compared to metal seated gate valves, making them easier to operate.

Reduced Maintenance: The resilient seating materials contribute to a longer service life and require less maintenance, resulting in cost savings over time.

Limited Temperature and Pressure Range: Resilient wedge gate valves are not suitable for extremely high temperatures or pressures and may require careful consideration of operating conditions.

Conclusion

Now that we have covered some of the key basics of resilient wedge gate valves, it is time to make the right choice. From knowing exactly how it operates, its essential parts and comparative analysis with metal seated gate valves, we hope this guide gives you a decent roadway to make an informed decision.

Remember to consider the trusted

resilient seated gate valves suppliers

like the Dutco Tennant LLC to get your supply of gate valve solutions. Afterall, the quality of a product matters a lot for the efficiency of project outcomes.

0 notes

Text

What should the angle be for a ball valve seat?

It is estimated that the peek seat ball valve market, will reach $16.2 billion in the next five years and becomes an essential component in most applications. Several industries are involved in manufacturing peek seat ball valves for daily operations. Now we will see about the ball valve seat and the angle used for it.

0 notes

Text

#Linear density of yarn#Mass per unit area#Thickness of fabric#Synthetic blood penetration test#Splash reistance#Tensile strength and elongation#Tearing strength of the fabric by Trapezoid Procedure#Hydrostatic Head tester#Martindale piling test#Differential pressure test#Fit test#Total inward leakage test#Simulated wearing treatment#Temperature conditioning#Field of vision#Flammabillity of filtering half mask#Valve seat retention test#Mechanical strength test

0 notes