Text

Prospects of Trenchless Rehabilitation Technology

https://www.pipedetect.com/prospects-of-trenchless-rehabilitation-technology.html

At present, there are three kinds of trenchless rehabilitation technology for underground drainage pipeline collapse in the world (including more than 10 kinds of process technologies). One is to use resin curing to form a new drainage pipe inside the pipe, such as CIPP, on-site curing and other processes. The other type is to use small pipes to pass through large pipes, and insert small drainage pipes inside the original pipes to solve urgent problems, such as short pipe lining, U-shaped pipe dragging and other processes. The last type is to use the spiral pipe method to form a new pipe inside the original pipe by winding method, such as spiral winding method.

The overall advantage of the trenchless rehabilitation is that the negative impact of the rehabilitation is small, the space occupied is relatively small, and the impact on the ground, traffic, environment and surrounding underground pipelines is very weak. Therefore, it is imperative to promote the application of trenchless rehabilitation technology in the field of drainage pipeline rehabilitation.

The difficulty of the promotion of trenchless rehabilitation technology lies in the high rehabilitation cost, which is prohibitive for many small and medium-sized cities. In fact, considering the traffic, the risk of surrounding pipeline excavation and the quality of life of citizens, the cost of trenchless rehabilitation is acceptable. And the main reason for the high cost is that the materials are completely imported. In the near future, this technology will be accepted by the drainage and municipal industries, and it will be widely used in the rehabilitation of urban pipelines.

As an important branch of trenchless technology, pipeline trenchless rehabilitation technology plays an important role in solving the problems of existing pipelines. At present, pipeline repair technology is still in its infancy in some countries and is still far from the mature stage. There are still many problems to be solved, in particular, relevant technical and management institutions should formulate some practical standards and specifications as soon as possible.

Pipeline rehabilitation technology has great advantages in terms of economic cost, social cost and environmental cost, and has a wide range of applications. We look forward to seeing a better development of pipeline trenchless rehabilitation technology in the near future.

0 notes

Text

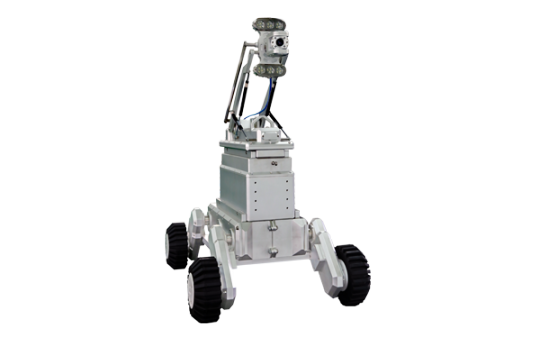

X5-HS CCTV Inspection Crawler

https://www.pipedetect.com/products/x5-hs-robotic-crawler-pipe-inspection-system/

X5-HS is a high-definition pipeline CCTV inspection robot. It can use a tablet, a laptop or a dedicated industrial controller as the main control, freely choose wireless or wired connection and control, and display and store high-definition inspection videos in real time.

X5-HS CCTV Inspection Crawler Main Parts

X5-HS Crawler

Suitable for pipe DN300-3000

6-wheel-drive

IP68 up to 10m water depth

Include pressure sensor, inclination sensor, roll and pitch sensor

Power supply: cable reel

Motor: 2x90W DC Speed: Max 32m/min Inclination: Max 45°

Light source: forward light 12X10W LED; backward 2X10W LED

Working ambient temperature: -10℃~50℃

Material: Brass nickel-plating stainless steel

Compatible with X5-H series camera

Dimension( LxWxH): 580x175x225mm

Weight: about 18.5 kg

Cable Reel

Cable length: 150m

Motor-driven

4-pin cable, drawing anti-Kevlar 300 kg, imported polyurethane sheath, cable diameter <6mm, waterproof, wear, acid, corrosion.

Cable retracting automatically or manually

Accurate cable counter, devition within 1mm

Compatible with Easy-Sight X5-H series crawlers and X4 sonar inspection system

Protection class: IP63

Dimension( LxWxH): 570x395x475mm

Weight: about 67 kg( with 300m cable)

Main Controller

The main controller is pre-installed with PipeCCTV pipeline inspection and evaluation report software, which can control and operate the robot, video surveillance and recording, fill in the inspection records on site and interpret by screenshots, automatically evaluate, calculate and output inspection and evaluation reports that meet industry standards and local standards. It equipped with PipeSight pipeline inspection video evaluation report software, which can perform playback interpretation and evaluation report output, and archive output data according to project classification, for archiving or GIS system data connection. Besides, it equipped with PipeTracer pipeline detection positioning and tracking software, Draw pipe bottom slope curve and pipeline path curve in real-time measurement, and can derive longitudinal section diagram of pipeline deposition status.

HD P&T Camera

Pixel quality: ≥2 million pixels

IP68 up to 10m water depth

Working ambient temperature: -10℃~50℃

Light source: 4x 3W LED light

The radial rotation 360°,horizontal rotation ±135°,one click to reset

10X optical, 12X digital

Laser measurement for crack

Lens: color 1/3”, 2592*1520, CMOS, viewing angle 6.7°-68°,sensitive 0.1 lux, auto-focusing

Dimension( LxWxH): 155x95x90mm

Weight: about 1.5kg

0 notes

Text

PT-C Video Jetting Nozzle

https://www.pipedetect.com/products/pt-c-video-jetting-nozzle/

The PT-C Video Jetting Nozzle is equipped with a camera on the body of the cleaning sprinkler, which has the function of cleaning the drainage pipe while also performing pipe video inspection. The visual sprinkler does not need a cable, and the image is transmitted from the visual sprinkler to the control terminal by radio, and you can choose to watch the live video in front or behind the visual sprinkler.

PT-C Video Jetting Nozzle Main Parts

Model: PT-C

Applicable pipe diameter: above 250mm

Effective transmission distance of wireless signal: 100m

Battery life: more than 8 hours

Video: 200W color HD

Signal transmission: wireless

Weight: 20 kg

The high-pressure water flow is 160L/min, and the maximum working pressure of the high-pressure pump is 120bar

0 notes

Text

Pipe Rehabilitation System

https://www.pipedetect.com/products/pipe-rehabilitation-system/

UV curing repair technology is the most effective and fast solution for pipe rehabilitation. Because of its high efficiency and low cost, UV curing repair technology is now widely used in the pipe rehabilitation industry. Easy Sight's UV LED light curing rehabilitation system can work for pipe DN200-1600 (CIPP) and DN200-600 (spot CIPP).

X120-D UV Spot Repair System

X120-D is an efficient equipment for repair, only taking 8 minutes for one spot to be repaired.

X120-CIPP UV Light Curing Repair System

With different size of light train, this system can work for pipe DN200-1600.We can not only provide the system, but also the liner customised according to your project demand.

WHAT IS PIPE REHABILITATION?

Pipe rehabilitation is the basic element of operating any asset or pipeline to maximize operational efficiency and therefore maximize profits. It enables asset owners to maintain the maximum flow through the pipeline without losing product due to leakage, reducing flow due to clogging, accumulation or debris, and ensuring high-quality products.

Clearing blocked sewer pipes is an indispensable process in pipeline repair, which has significant benefits for the service life of the pipeline and the quality of the medium in the pipeline.

Professional pipeline rehabilitation companies can provide assistance in pipeline inspection, repair and cleanup at the same time. After the pipeline inspection, if the debris and accumulation are removed, and the problem is found and corrected, the product quality can be improved and the flow rate can be increased. All of this leads to better products with higher yields and ultimately higher profits.

EASY-SIGHT CIPP REHABILITATION (CURED IN PLACE PIPE LINING)

Easy-Sight uses Trenchless Rehabilitation Technology to change the traditional concept of large-scale excavation and replacement of roads, avoiding long-term traffic jams on road traffic, and reducing secondary pollution to the surrounding environment.

In the case of partial pipeline cracks, leakage, or damage, there is no need to repair the entire section of the pipeline, or when an urgent repair is required due to partial damage of the pipeline, short-distance lining can be used to repair the pipeline.

CIPP Process Characteristics

1. Curing the resin at the damaged point to increase the strength of the pipeline to achieve the purpose of repair and provide a certain structural strength.

2. In the trenchless repair of drainage pipes, it is usually combined with soil grouting technology.

3. Protect the environment and save resources. No road excavation, no rubbish generation, no traffic jams, greatly improving the image of pipeline repair construction. The overall social and economic benefits are good.

UV-CIPP

It is a kind of trenchless CIPP. UV-CIPP is a CIPP that woven glass fiber into a hose impregnated with resin, and then pull it into the original pipe to inflate and expand to close to the original pipe. Under the action of ultraviolet light, the resin is cured to form a CIPP with a certain strength of the lined pipe.

0 notes

Text

Jetting Nozzle

https://www.pipedetect.com/products/jetting-nozzle/

Jetting Nozzle Main Parts

FL-100

FL-100

Model: FL-100

For 8" to 12" pipe

Designed to remove debris from sanitary & storrm liners

50 - 120 GPM to 2,500 PSI

6 stainless steel replaceable jets

Available in 1" or 1 1/4"

Stainless steel screen available to keep orifices free from obstruction

Weight: 10 ibs

FL-200

FL-200

Model: FL-200

For 12" to 24" pipe

Designed to remove debris from sanitary & storrm liners

50 - 120 GPM to 2,500 PSI

8 stainless steel replaceable jets

Available in 1" or 1 1/4"

Weight: 12.5 ibs

FL-300

FL-300

Model: FL-300

For 12" to 36" pipe

Designed to remove debris from sanitary & storrm liners

50 - 120 GPM to 2,500 PSI

16 stainless steel replaceable jets

Available in 1" or 1 1/4"

Weight: 20 ibs

P1-5

P1-5

Model: P1-5

1" NPT

1 Forwarder Jet

5 Rear Jets

55 GPM, 2000 PSI

R-100/R-125

R-100/R-125

Model: R-100/R-125

For 6" to 18" pipe

Optional front penetrator tip 3 Rear stainless steel jets

50 - 120 GPM to 3,000 PSI

1" NPT

Available in 1" or 1 1/4"

Weight: 9 ibs

P1-6

P1-6

Model: P1-6

1" NPT

6 Rear Jets

55 GPM, 2000 PSI

0 notes

Text

Grab All

https://www.pipedetect.com/products/grab-all/

The Grab-All is designed to remove sticks, stones, concrete, and other debris. It's ideal for grease traps, septic tanks, lift stations, manholes, and excavation holes.

Grab All Main Parts

Grab All Parts

The Grab-All is made completely out of stainless steel and aluminum. Its powerful jaws can grab items from 100mm to 480 mm in size.

This compact unit is only 990mm in height and weighs only 5.5kg. It can reach up to 9 meters in depth, and additional rope can be added to reach unlimited depths.

The Grab-All can save the operator costly downtime and PPE expenses to avoid entering confined work spaces, and is a must have on every service truck.

0 notes

Text

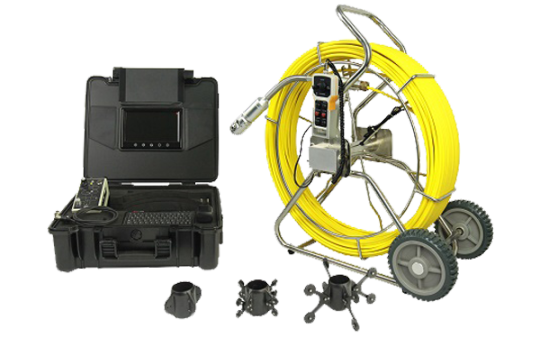

X3-M50 Push Rod Camera

The X3-M50 push rod type pipeline endoscope is composed of three parts: an integrated main controller, a flexible push rod cable reel, and a high-precision durable camera. The front-end camera is pushed into the pipeline by a flexible push rod cable to image the inside of the pipeline. Preview and record to achieve the purpose of detection.

Push rod camera is suitable for surveying and testing the interior of residential, small-scale commercial sites, special factories and municipal engineering pipelines, including slender, narrow, and curved pipelines that cannot be accessed by other testing instruments. Its operation is simple, powerful, and widely applicable.

X3-M50 Push Rod Camera Main Parts

Cable Wheel

Wheel size: 768L*369W*820Hmm

Cable material: Fiberglass rod

Cable length: 60m-120m

Cable diameter:φ9.5mm, 9 cores

Wheel material: Stainless steel

Meter counter & handle-brake

Counter accuracy: 0.1m

Fiberglass color: Yellow

Camera Head

Camera sizw: φ50mm*L107mm

Sensor size: 1/3 inch CCD

View angle: 90°

Manual focus & self-levelling

Camera light: 6pcs highlight LEDs

Resolution: 960TVLine

Glass material :Sapphire glass

Shell material: Aluminum alloy

Scope of focus: 20mm-infinite

Control Box

Work supply: DC 12V

Storage medium: SD card &USB stick(max 256G)

DVR Total pixels: 720X576(D1)

Video record(mp4) & picture snap(jpg)

10 levels digital zoom

Microphone Audio record

Stereo earphone output

Digital clock& digital calendar

https://www.pipedetect.com/x3-m50-push-rod-camera/

0 notes

Text

X7 CCTV & Sonar Pipe Inspection

The CCTV detection sonar floating system adopts sonar imaging technology and CCTV video detection technology. The underwater scanning unit (sonar head) and the water detection unit (rotating lens) are placed on the water surface inside the pipeline (full pipe or half pipe). Using crawler or manual drag method to drive (glide, float) to move in the pipeline. Using personal laptop or special controller as the main control.

X7 CCTV & Sonar Pipe Inspection Main Parts

Sonar Probe

Size: total length: 485mm, diameter: 70mm;

Material: aluminum alloy shell;

Waterproof: IP68;

Operating temperature: 0~40℃;

Storage temperature: -20~70℃;

Weight in air: 2.7kg;

Acoustic frequency: 1MHz;

Beam width: 1.1deg (-3db), conical beam;

Range resolution (0.125m range) : 0.5mm;

Maximum applicable pipe diameter: 6000mm;

Transmitting pulse width: 4~20us;

Receiving bandwidth: 500KHz;

Power supply: 48V dc;

HD P&T Camera

IP68 up to 10m water depth

Working ambient temperature: -10℃~50℃

Light source: 4x 3W LED light

The radial rotation 360°,horizontal rotation ±135°,one click to reset

10X optical, 12X digital

Laser measurement for crack

Lens: color 1/3”, 2592*1520, CMOS, viewing angle 6.7°-68°,sensitive 0.1 lux, auto-focusing

Dimension( LxWxH): 155x95x90mm

Weight: about 1.5kg

Cable Reel

Cable length: 150m

Motor-driven

2-pin cable, drawing anti-Kevlar 300 kg, imported polyurethane sheath, cable diameter <6mm, waterproof, wear, acid, corrosion.

Cable retracting automatically or manually

Accurate cable counter, devition within 1mm

Compatible with Easy-Sight X5-H series crawlers and X4 sonar inspection system

Protection class: IP63

Dimension( LxWxH): 570x395x475mm

Weight: about 45 kg( with 150m cable)

Main Controller

Regular computer or tablet can be used at main controller with build-in inspection collection software. Both main controller and joystick can control the crawler forward, back and turn, camera rotating, light and so on. Equipped with PipeCCTV pipeline inspection and evaluation report software and PipeSonar pipeline sonar imaging analysis report software. The former is used to control and operate the robot, video surveillance and recording, fill in inspection records on site and take screenshots for interpretation; the latter is used to display and collect inspection images in real time during the inspection process, and can perform contour extraction, interpretation analysis, 3D reconstruction and report output .

Floating Boat

UPVC material,suitable pipe width: DN500mm~6000mm;

Size:870mm * 458mm * 300mm;

Weight:8kg;

Flotage:15kg;

https://www.pipedetect.com/products/x7-cctv-sonar-pipe-inspection/

0 notes

Text

X5-HW Pipeline CCTV Inspection Robot

X5-HW pipeline CCTV inspection robot adapts to the pipe diameter range of 800mm-4000mm, and the detection distance can reach 2000 meters. It is a product designed for large long-distance drainage pipelines. Its most notable feature is the long single detection distance, which solves the problem that traditional pipeline inspection robots cannot detect long-distance pipelines.

X5-HW Pipeline CCTV Inspection Robot Main Parts

Crawler

Suitable for pipe DN800-4000

IP68 up to 10m water depth

Powerful eight-wheel drive (steerable)

Automatic removable elevator

Include pressure sensor, inclination sensor, roll and pitch sensor

Integrated rear-view camera

Electrical adjustable clutch Power supply: cable reel

Speed: Max 12m/min Inclination: Max 15°

Light source: forward light 6X10W LED; backward 2X10W LED

Material: Brass nickel-plating stainless steel

Minimum dimension( LxWxH): 780x580x490mm,

Maximum dimension( LxWxH): 1400x860x2355mm

Minimum weight: 180KG Maximum weight: 300KG

Cable Reel

2050m cable, diameter 8.5mm, 96.28g/m

Accurate meter counter: ±0.01m

Multi-pin cable, strong 500kg Kevlar reinforced

Automatic rewinding, maximum speed:30m/min

Protection Class: IP63

Dimension: 1050X830X830mm

Weight: 300KG

HD P&T Camera

IP68 up to 10m water depth

Working ambient temperature: -10℃~50℃

Light source: 4x 3W LED light

The radial rotation 360°,horizontal rotation ±135°,one click to reset

10X optical, 12X digital

Laser measurement for crack

Lens: color 1/3”, 2592*1520, CMOS, viewing angle 6.7°-68°,sensitive 0.1 lux, auto-focusing

Dimension( LxWxH): 155x95x90mm

Weight: about 1.5kg

https://www.pipedetect.com/products/x5-hw-sewer-inspection-robot/

0 notes

Text

X5-HR Screw Type Crawler

The X5-HR all-terrain pipeline robot consists of three parts: a spiral propeller crawler, a cable reel, and a display and control terminal. It is suitable for environments where conventional CCTV detection robots cannot detect siltation above DN600mm and higher water levels. It can be used for municipal drainage pipelines, detection of box culverts, culverts, river channels, etc.

X5-HR Screw Type Crawler Main Parts

X5-HR Crawler

Suitable for pipe diameter: above 600mm

Cable length: standard 350m

Power supply: battery /AC220V

Battery life: 1-2 hours

Video: 200W pixel color HD, 10x zoom, 360° horizontal and 180° vertical

Rear view: 200W pixels

Light : the front 4 groups and the back 1 group of LED lights

Weight: 15kg

Speed: downstream environment 0.5m/s, upstream environment 0.2m/s

Sensor : IMU unit, positioning sensor system, pipeline deformation inspection system, sonar inspection (optional)

Cable Reel

Cable length: 150m

Motor-driven

2-pin cable, drawing anti-Kevlar 300 kg, imported polyurethane sheath, cable diameter <6mm, waterproof, wear, acid, corrosion.

Cable retracting automatically or manually

Accurate cable counter, devition within 1mm

Compatible with Easy-Sight X5-H series crawlers and X4 sonar inspection system

Protection class: IP63

Dimension( LxWxH): 570x395x475mm

Weight: about 45 kg( with 150m cable)

Sonar Probe

Size: total length: 485mm, diameter: 70mm;

Material: aluminum alloy shell;

Waterproof: IP68;

Operating temperature: 0~40℃;

Storage temperature: -20~70℃;

Weight in air: 2.7kg;

Acoustic frequency: 1MHz;

Beam width: 1.1deg (-3db), conical beam;

Range resolution (0.125m range) : 0.5mm;

Maximum applicable pipe diameter: 6000mm;

Transmitting pulse width: 4~20us;

Receiving bandwidth: 500KHz;

Power supply: 48V dc;

Main Controller

Regular computer or tablet can be used at main controller with build-in inspection collection software. Both main controller and joystick can control the crawler forward, back and turn, camera rotating, light and so on.

HD P&T Camera

IP68 up to 10m water depth

Working ambient temperature: -10℃~50℃

Light source: 4x 3W LED light

The radial rotation 360°,horizontal rotation ±135°,one click to reset

10X optical, 12X digital

Laser measurement for crack

Lens: color 1/3”, 2592*1520, CMOS, viewing angle 6.7°-68°,sensitive 0.1 lux, auto-focusing

Dimension( LxWxH): 155x95x90mm

Weight: about 1.5kg

https://www.pipedetect.com/products/x5-hr-sewer-robot-camera/

0 notes

Text

X5-HMA CCTV Inspection Crawler

X5-HMA pipeline CCTV inspection robot is a high-definition pipeline CCTV inspection robot, which can be controlled by a personal notebook computer or a dedicated controller. A laptop computer or a dedicated controller is connected to other parts of the system through a wireless (wired) method, and displays and stores high-definition detection videos in real time.

X5-HMA CCTV Inspection Crawler Main Parts

X5-HMA Crawler

Suitable for pipe DN150-300

6-wheel-drive IP68 up to 10m water depth

Include pressure sensor, inclination sensor, roll and pitch sensor

Power supply: cable reel Motor: 2x25W DC

Speed: Max 15m/min Inclination: Max 45°

Working ambient temperature: -10℃~50℃

Material: Brass nickel-plating stainless steel

Compatible with X5-H series camera

Dimension( LxWxH): 385x120x102.5mm

Weight: about 11.5 kg

Cable Reel

Cable length: 150m

Motor-driven

2-pin cable, drawing anti-Kevlar 300 kg, imported polyurethane sheath, cable diameter <6mm, waterproof, wear, acid, corrosion.

Cable retracting automatically or manually

Accurate cable counter, devition within 1mm

Compatible with Easy-Sight X5-H series crawlers and X4 sonar inspection system

Protection class: IP63

Dimension( LxWxH): 570x395x475mm

Weight: about 45 kg( with 150m cable)

Main Controller

Regular computer or tablet can be used at main controller with build-in inspection collection software. Both main controller and joystick can control the crawler forward, back and turn, camera rotating, light and so on.

HD Axial Camera

Working ambient temperature: -10℃~50℃

Light source: 6x 3W LED light

Lens: color 1/3”, 2592*1520, CMOS, viewing angle 6.7°-68°,sensitive 0.1 lux, auto-focusing

Dimension( LxWxH): 100x75x75mm

Weight: about 0.6kg

https://www.pipedetect.com/products/x5-hma-pipe-crawler-robot/

0 notes

Text

X1-H4 Pipe Periscope

X1-H4 pipeline periscope is mainly used for rapid detection and diagnosis of the internal conditions of industrial vessels or pipelines. Put the camera probe with its own searchlight light source into the pipe mouth or the inside of the industrial container through the operating lever. The digital high-definition camera is used with the focus and zoom and pitch adjustment functions to clearly display the structural defects and functionality of the pipe and the container. Defects will be recorded and saved, and the inspection information will be filled in on-site and taken screenshots for interpretation.

X1-H4 Pipe Periscope Main Parts

X1-H4

Suitable for pipe DN100-2000;

Working Temperature:-20℃~50℃;

Image sensor:Color 1/2.8 Progressive scanning CMOS

Image resolution:PAL. 1920*1080,2.1 megapixel

Rotation angle:up 35°,down 25°

Zoom:30x optical,manual or auto focusing;

luminous sensitivity (minimum illumination): 0.01LX

Waterproof: IP68;

Distance-measuring precision: ±0.001mm

Distance-measuring range: 0.2m~80m;

Telescopic pole length: standard 8.8m, can customize up to 25m

Main control: Windows or Android tablet, or Android phone can be used

Lighting: can move along with camera probe.With main and auxiliary lighting. Main lighting is with2X 10W LED. There are 8X3W LED as auxiliary lighting. Effective irradiation distance is 40-80 meters;

https://www.pipedetect.com/products/x1-h4-pipe-periscop/

0 notes

Text

X120-D UV Spot Repair System

The X120-D UV Spot Repair System is mainly used for the repair of point defects in drainage pipes. According to different pipe diameters, the corresponding airbags are selected to accurately repair the damaged points. It is mainly composed of a main control system and an airbag. Its main characteristics are high efficiency, stability, precision, and controllability. It can repair a damaged point in 8 minutes.

X120-D UV Spot Repair System Main Parts

Main Control System

Control function: The physical button can not only achieve the automatic take-up of the cable reel and adjust the take-up speed; but also control the air inflation and deflation as well as the switches of the ultraviolet lamp;

Status display: State of the light source; airbag type; pressure value; traveled distance of the airbag; states of air inflation and deflation; and restoration time;

Cable length: Length of the standard cable is 80m

Cable parameters: The cable interior adopts the air pipe of 6mm, four cores of 1.5mm and two wires of the diameter <15mm, showing the characteristics of water resistance, abrasive resistance, acid fastness, alkali resistance and corrosion resistance;

Automatic winding displacement: Ensure the regular distribution of the cable on the cable reel in the course of take-up and pay-off;

Counting: Adopt the high-precision encoder with the counting resolution ratio of 1mm ;

Power supply: AC220V input, with the maximum instantaneous power of 3KW.

https://www.pipedetect.com/products/x120-d-uv-spot-repair-system/

0 notes

Text

Pipe Inspection System

Easy Sight as a well-known pipe inspection system producer, can provide a complete series of inspection products. Include HD CCTV inspection robots, HD pipe periscope, sonar inspection system, CCTV & Sonar inspection system, push rod camera, 3D manhole scanner and so on.

Featured Pipeline Maintenance Products

Pipe CCTV Inspection Robot

CCTV inspection robots, as the most effective and accurate tools to access the pipeline, play a very important role in the sewer and drainage industry. With state-of-the-art technology, Easy-Sight CCTV inspection robots can provide best-quality inspection with HD video and images.

X1-H4 Pipe Periscope

The portable pipe periscope is designed for pre-survey of pipe condition. With laser measurement and high definition camera, it can give you a basic knowledge of what is going on inside the pipe and where is the defect.

X3-M50 Push Rod Camera

X3-M50 is an easy-handle self-propelled camera, with 60m or 120m cable, can easily reach the location where the defection is in your drainage.

X4 Pipe Sonar System

Sonar system is designed to inspect condition under water mainly for the deposit and sediment.

X7 CCTV & Sonar Pipe Inspection

With a high definition camera above and a sonar probe below water lever, the X7 CCTV & Sonar pipe inspection system is the best solution for condition where you can't drain the water.

Drainage pipelines are one of the important infrastructures in cities, but many hidden dangers caused by serious aging of pipelines have a huge impact on the quality of life and safety of people. Therefore, it is very important to carry out inspection of drainage pipes, to grasp the structure and functional safety of pipes in time, and to use scientific methods to guide maintenance and repair work.

But underground pipe inspectors are inconvenient for manual work.

ADVANTAGES OF VIDEO ENDOSCOPIC PIPE INSPECTION SYSTEM

Pipeline video endoscopic inspection systems have a wide range of applications. Their designs that meet the characteristics of the industry are often used by special pipeline inspection engineers, maintenance engineers, municipal drainage maintenance engineers, and plumbers to detect areas that are difficult to reach or enter.

The lens of the pipeline video endoscopic inspection system can enter and explore the urban sewage drainage system, rainwater drainage system, petrochemical process pipelines and other areas that are difficult to reach and detect. In this way, we can find problems and determine whether standard pipe dredging is required, or whether other measures need to be taken, such as removing tree roots.

When you don't want to waste too much time, energy and investment to guess which parts of the pipeline have problems, the pipeline video endoscopic inspection system is your best choice. It can directly reach the inspection area, presenting defects and failures clearly and intuitively in front of your eyes, which is helpful for the formulation of the next maintenance and repair plan.

CCTV PIPE INSPECTIONS

CCTV (Closed Circuit Television) pipe inspections are currently the most advanced and effective method for pipeline condition inspection in the world. Compared with traditional pipeline inspection technology, it has high safety and clear and intuitive images, which provides powerful help for scientific decision-making of pipeline repair programs.

Our CCTV inspection crawler has the most advanced high-resolution digital inspection camera with recorder, crawler and lighting system, which can see the situation in the pipeline at a glance. It is completely controlled by a monitor with a remote control joystick, easy to operate and easy to move. It can perform image processing, record the rotation and positioning of the camera, and have high-quality image recording and text editing functions.

The main work part is a four-wheel-drive camera car and a computer. According to different pipe diameters, different models can be selected. In the project, when it is really impossible to know the inside of the pipe, automated visual inspection equipment is used to inspect the pipe section.

EASY-SIGHT'S VIDEO DETECTION SOLUTION

According to different construction conditions, we have developed a variety of video detection solutions.

As a top pipeline inspection company, we suggest and provide you with a pipeline video inspection system that meets your inspection requirements and capital budget. No matter what industry it is used in, we can provide corresponding products to meet the different requirements of users.

WHY CHOOSE ROBOT EASY-SIGHT VIDEO INSPECTION

Lenses with different diameters, push rods with different working lengths and different types of pipeline robots;

The entry type tube video endoscope is easy to operate;

It can not only detect the municipal drainage system, but also analyze the damage of the pipeline and repair it with a mechanical arm;

All of our pipeline video inspection products are equipped with high-resolution CMOS imaging chips and integrated high-brightness LED lighting systems to provide good auxiliary lighting for the inspection area, and can store endoscopic images and videos in the memory for later pictures Analysis and management.

EASY-SIGHT PIPE SONAR INSPECTION SYSTEM

Pipeline CCTV inspection is currently an effective means of drainage pipeline inspection, but based on this video camera inspection system, if the pipeline is full of water, the visibility is almost zero as in "smoggy" weather.

The pipeline sonar detection system uses an acoustic method to detect the internal conditions of the pipeline with water without draining the liquid inside the pipeline. It can form a cross-sectional view of the pipeline and intuitively understand the general situation of the pipeline inner wall and deposition. It is a powerful supplement to the CCTV detection method.

Sonar imaging devices combine with pipeline sonar inspection imaging analysis software to collect and display high-resolution contour pictures in real-time. By analyzing the contour characteristics, the deposits, condensation or structural diseases of the pipe wall can be determined.

The pipeline sonar detection system can accurately detect many structural defects of the pipeline (such as deformation, collapse, rupture, fouling, hidden connection of branch pipes, etc.) and pipeline functional defects (such as deposits, floating objects).

If you have any questions about the operation and use of our CCTV inspection products, please contact us as soon as possible, Easy-Sight will provide you with timely and effective support and advice.

https://www.pipedetect.com/products/pipe-inspection-system/

0 notes

Text

Pipe Cleaning System

WHY DO WE NEED MAIN LINE CLEANING SERVICE REGULARLY?

Unscheduled removal of foreign matter in the pipeline will cause the pipeline to be blocked. In the long-term used pipeline, the solidification of sludge and rust in the pipeline will cause the original pipe diameter to become smaller. The hydrogen sulfide gas generated by the sludge precipitation in the pipe will cause environmental pollution, and easily cause acid and alkali substances in the combustion and explosion wastewater, which is easy to corrode the pipe wall.

In the process of manufacturing, storage, transportation and installation, the pipeline will produce various impurities such as rust and slag on the pipeline, dust, sand, cement and other impurities. Rust, rust inhibitor, sediment, etc. will seriously affect the normal use of the pipeline.

After cleaning the pipeline, a dense chemical passivation film is formed on the clean metal surface. The passivation film can effectively prevent the re-formation of dirt and effectively protect the equipment, which can effectively ensure the safety of the equipment and extend the service life of the equipment.

If the piping system is not severely clogged, the standard sink plunger can easily solve the problem. But the blockage of the main pipeline or worse situation requires the help of professional technicians.

PROBLEMS WITH USING CHEMICALS WHEN CLEANING UNDERGROUND DRAIN PIPES

Many people choose dredging chemicals that can be easily found on store shelves. Pipe dredging chemicals can indeed dissolve certain organic substances. But in fact, chemicals may not function as expected, and may cause great damage to people and objects:

1. It is highly toxic and should not be near the skin or eyes.

2. Some chemicals may even damage the pipeline, make the pipeline wear faster and shorten the service life of the pipeline.

PRINCIPLES OF UNDERGROUND PIPE CLEANING

Use artificial methods to increase the water head difference in the pipeline, increase the water flow pressure, increase the flow rate and flow to clean the sediment in the pipeline. In other words, use a larger flow rate to disperse or wash away the sediment that can be moved by the sewage in the pipeline, and use a larger flow to transport the suspended matter that can be deposited in the sewage.

When the pipeline silt deposits are too much or even cause blockage, the cleaning method cannot be solved. At this time, the pipeline must be dredged, digging and removing the mud blockage. That is, the machine is used to directly act on the sediment to loosen it and be carried away by the sewage or directly manually removed from the pipeline.

BEST WAY TO CLEAN OUT DRAIN PIPES

When there is a serious blockage in the sewer pipeline, you need professional pipe dredging tools.

For example, the nozzles of Easy-Sight are made of special steel, which is particularly strong and durable, and can effectively remove all kinds of deposited dirt, hard dirt, tree roots, etc. in the sewer. The PT-C visual sprinkler is equipped with a camera on the body of the cleaning sprinkler, which can clean the drainage pipe while also performing pipeline video inspection.

Our pipe dredging tools grab all, jetting nozzle and PT-C video jetting nozzle will make your cleaning work easier.

https://www.pipedetect.com/products/pipe-cleaning-system/

0 notes

Text

Pipe CCTV Inspection Robot

CCTV inspection robots, as the most effective and accurate tools to access the pipeline, play a very important role in the sewer and drainage industry. With state-of-the-art technology, Easy-Sight CCTV inspection robots can provide best-quality inspection with HD video and images.

Pipe CCTV Inspection Robot

X5-HMA CCTV Inspection Crawler

small pipe inspection

high definition

X5-HT Pipeline CCTV Inspection Robot

electrical lift

6-wheel-driven

X5-HS CCTV Inspection Crawler

removable electrical lift

two-motor driven

Clutch

X5-HW Pipeline CCTV Inspection Robot

large pipe inspection

2000m cable

HD camera

X5-HR Screw Type Crawler

Motor-driven

screw type crawler

combined with CCTV

sonar and radar

https://www.pipedetect.com/products/pipe-inspection-robot/

0 notes

Text

Easysight Reliable Pipeline Cleaning/ Inspection/Rehabilitation Equipment

Easy-Sight provides a whole series of innovative tools and solutions for pipe cleaning, inspection, and rehabilitation to ensure your pipeline in good condition. Including HD CCTV inspection robots for pipe DN150-4000, wireless portable HD pipe periscope, Sonar inspection system, fast curing UV repair system, video nozzle, and so on. The management of pipeline system could be easier with intelligent pipeline solutions from Easy-Sight. In 2019, Easy Sight sold more than 800 sets of pipe inspection robots all over the world.

Grab All

Jetting Nozzle

PT-C Video Jetting Nozzle

Pipe Cleaning System

With powerful pump and HD camera, Easy Sight Video inspection nozzle PT-C offers a solution for our customers to clean sewer and storm pipeline while recording video.

Pipe Inspection System

Easy-Sight provides a variety of inspection products including push rod camera, pipe periscope, CCTV inspection robots, sonar pipeline inspection system, CCTV-sonar inspection system, and manhole scanner. With state-of-the art technology, our inspection system can ensure you accurate pipeline condition assessment

X120-D UV Spot Repair System

X120-CIPP UV Light Curing Repair System

Pipe Rehabilitation System

UV curing repair technology is the most effective and fast solution for pipe rehabilitation.

https://www.pipedetect.com/products/

0 notes