#AluminumExtrusions

Text

A EDELSTAHL VIRAT IBÉRICA é compradora e fornecedora de Extrusões de Alumínio!

Fornecemos extrusões de alumínio em todos os tamanhos de acordo com suas necessidades. Como extrusão a quente, extrusão a frio, extrusão a quente, extrusão por fricção e microextrusão e muito mais…

EDELSTAHL VIRAT IBERICA é um importador emergente - exportador, fornecedor de aço para ferramentas, aços para moldes de vários países. Também estamos envolvidos no comércio de ferrosos, ligas de aço, etc., com uma rede de parceiros em todo o mundo, somos capazes de atender rapidamente às necessidades do cliente.

Procuramos todos os fabricantes e fornecedores grossistas de sucata metálica como #HMS1, #HMS2, Extrusões de Alumínio, sucata ferrosa, sucata de motores eletrónicos e sucata triturada em #Portugal…

PARA SABER MAIS >>

https://moldsteel.eu/aluminum-extrusion-indl/

Chat WhatsApp: +351-920016150

E-mail: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#oportunidades#empresas#agricultura#b2b#AluminumExtrusions#alumínio#aviação#recycling#trabalho#moldsteel

2 notes

·

View notes

Video

youtube

Fenan aluminum -one of the vertical powder coating production lines and facility

What are the surface treatment processes of aluminum profiles? The surface treatment of aluminum profiles can be divided into three main ways: anodizing, electrophoretic coating and powder coating (in addition, fluorocarbon spraying, wood grain transfer, etc.), each Surface treatments all have different advantages. Powder Coated aluminum, as the most common aluminum, is recognized in many fields.

Powder spraying is to use powder spraying equipment (electrostatic spraying machine) to spray powder coating on the surface of the aluminum. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the aluminum to form a powder coating; Baking and leveling curing, it becomes the final coating with different effects (different types of powder coatings); the spraying effect of powder spraying is superior to the spraying process in terms of mechanical strength, adhesion, corrosion resistance, aging resistance, etc., and the cost is higher than Spray paint process.

The vertical spraying production line consists of powder spraying room, powder spraying equipment, powder curing furnace, gas heat exchange device, hanging conveyor, electrical control system and other parts. The working process is mainly divided into: pre-treatment → racking → spraying → curing → unloading → inspection-packaging

The main spray powder manufacturers:

Foreign Brand: Nippon, DuPont (Axalta), Tiger, AkzoNobel,etc.

China Domestic Brand: Wan An, Tu Yi, Ai Yue, Hong Ning,etc.

Relatively speaking, foreign spraying brands have absolute dominance, but they are more expensive. This mainly depends on the client's needs and budget.

In order to shape high-quality aluminum profiles, solar photovoltaic frames and brackets, Fen'an(FOEN) aluminum introduces the latest high-efficiency and high-quality vertical powder coating production line. The whole process adopts computer automation control and has excellent quality. The state-of-the-art production equipment has made Fen’an(FOEN) one of the top five aluminum profile manufacturers in the country. For this reason, we have the confidence in producing high-quality aluminum profiles in large quantities according to customer orders.

#anodizingaluminum #solarmountingsystem #oemservice #odm #oemfactory #oemsupplier #oemservice #industrialaluminum

#youtube#aluminum#alumnio#aluminumoxide#anodizedaluminum#aluminumtexture#aluminumextrusion#aluminumextrusions#aluminumprofile#aluminumwindows#extrudedaluminum#8020aluminum#FOENaluminum#fenanaluminum

0 notes

Text

What are the benefits of using aluminum extrusion?

In the world of modern manufacturing, efficiency and versatility are key. Among the various techniques and materials available, aluminum extrusion is a remarkably versatile and beneficial process. With a wide range of applications spanning from construction and transportation to electronics and consumer goods, aluminum extrusion offers many advantages that make it an attractive choice for various industries.

Strength

One of the foremost benefits of using aluminum extrusion is its inherent strength. Aluminum, when properly alloyed and processed, exhibits impressive structural integrity that can rival even traditional construction materials like steel. This is particularly significant in industries where durability and load-bearing capacity are paramount, such as in building frameworks and automotive components.

Lightweight Characteristic

Aluminum is renowned for its lightweight nature, making it an ideal choice in applications where weight reduction is crucial. Whether it's in aircraft design, automotive manufacturing, or even everyday consumer products, the use of aluminum extrusions contributes to achieving lower overall weight without compromising on strength or performance.

Resilience

Aluminum extrusions offer exceptional resilience in various environmental conditions. They are known for their ability to withstand extreme temperatures, making them suitable for applications ranging from industrial machinery operating in harsh environments to outdoor architectural structures enduring diverse climates.

High Strength-to-Weight Ratio

The combination of high strength and low weight results in an impressive strength-to-weight ratio for aluminum extrusions. This property is highly valued in industries where efficiency and performance are key considerations. By utilizing materials with an excellent strength-to-weight ratio, engineers can design products that are both robust and energy-efficient.

cCorrosion Resistance

Aluminum has a natural resistance to corrosion, thanks to its ability to form a protective oxide layer on its surface. This corrosion resistance makes aluminum extrusions a prime choice for applications in marine environments, outdoor structures, and even in food and beverage industries where cleanliness and hygiene are crucial.

Excellent Electrical Conductor

Aluminum's excellent electrical conductivity is another feather in its cap. It makes aluminum extrusions well-suited for applications in the electrical industry, such as power transmission lines and electrical enclosures. The material's ability to efficiently conduct electricity ensures optimal performance and reliability in various electrical systems.

Excellent Thermal Conductors

Beyond its electrical conductivity, aluminum also boasts impressive thermal conductivity. This property makes aluminum extrusions invaluable in applications that require efficient heat dissipation. Heat sinks, for example, which are commonly used in electronics to manage thermal energy, often rely on aluminum extrusions due to their exceptional thermal conductive abilities.

Fast-to-Market

In today's fast-paced market landscape, time-to-market is a critical factor. Aluminum extrusion offers a streamlined manufacturing process that facilitates rapid production. The simplicity of the extrusion process, from design to final product, means that products can be developed and brought to market more swiftly compared to other manufacturing methods.

Easy Fabrication and Assembly

The malleability of aluminum simplifies the fabrication process. Extrusions can be easily cut, shaped, and machined to meet specific design requirements. This flexibility allows for intricate and complex designs, enabling engineers to turn their creative visions into reality. Furthermore, assembling components made from aluminum extrusions is a straightforward process, reducing manufacturing complexities and costs.

Non-sparking

Certain industries, such as those involving flammable materials or explosive atmospheres, require non-sparking materials to ensure safety. Aluminum's non-sparking property makes it a suitable choice for such applications, providing an added layer of security in environments where sparks could lead to catastrophic consequences.

Sustainable

In an era of growing environmental consciousness, sustainability is a crucial consideration. Aluminum is a highly sustainable material due to its recyclability. It can be melted down and reused without a significant loss of quality, reducing the demand for virgin resources and minimizing the environmental impact of production. Choosing aluminum extrusions aligns with sustainable practices, making it an eco-friendly option.

Non-magnetic

Certain industries, such as electronics and medical devices, require non-magnetic materials to prevent interference with sensitive equipment. Aluminum's non-magnetic nature makes it an appropriate choice for such applications, ensuring that the material won't disrupt the functioning of nearby electronic components.

Final Words

The benefits provided by aluminum extrusions are far-reaching and diverse. From its remarkable strength and lightweight characteristics to its resistance to corrosion and exceptional thermal and electrical conductivity, aluminum extrusions prove their worth across numerous industries. Their versatility, coupled with advantages like ease of fabrication, non-sparking properties, and sustainability, positions aluminum extrusions as a frontrunner in modern manufacturing.

Read the full article

0 notes

Text

Aluminum Extrusion: Shaping the Future of Manufacturing

Introduction

Aluminum extrusion involves the shaping of aluminum profiles through a process called extrusion. The process begins with a solid cylindrical aluminum billet, which is heated and pushed through a die to form the desired shape. Aluminum extrusions find wide use in industries such as construction, transportation, electronics, and more.

What is aluminum extrusion?

Aluminum extrusion is a manufacturing process in which aluminum billets are forced through a shaped opening in a die, thereby creating a continuous profile. These profiles can have complex cross-sectional shapes and are produced with high accuracy. Extruded aluminum profiles are then cut to the desired length and used in a variety of applications.

Aluminum extrusion process

The aluminum extrusion process involves several steps to convert a raw aluminum billet into a finished profile. Let's look at each stage in detail:

Billet preparation

The first step in the extrusion process is the billet preparation. Aluminum billets are generally manufactured from high-quality aluminum alloy, selected based on the specific application requirements. These billets are preheated to ease the extrusion process and ensure uniform temperature distribution.

Heating and homogenization

Once the billets are prepared, they are heated to a specific temperature to increase their ductility. Heating is very important to reduce the strength of the material and increase its ductility, making it easier to extrude. The billets then undergo a process called homogenization, which ensures a uniform chemical composition throughout the material.

Extrusion Process

Heated billets are loaded into a chamber and pressed against a specially designed die. The die determines the shape and size of the final extruded profile. Pressure is applied to force the softened aluminum through the die, resulting in the desired shape. This continuous extrusion process allows long profiles with consistent dimensions to be produced.

Cool and Subdued

After the extrusion process, the newly formed aluminum profile cools and quenches. Cooling is essential to stabilize the structure of the profile and prevent deformation. Rapid cooling is quenched to further enhance material properties like strength and hardness. A variety of cooling methods can be used, including air or water discharge, depending on the specific requirements.

Advantages of Aluminum Extrusion

Aluminum extrusion offers many advantages that make it a preferred choice in various industries. Let's know some of its key benefits:

Design Flexibility

One of the primary benefits of aluminum extrusions is its exceptional design flexibility. The process allows complex cross-sectional shapes to be created, enabling designers to bring their innovative ideas to life. From intricate profiles to customized geometries, aluminum extrusions offer endless possibilities for creative and unique designs.

Lightweight and Powerful

Aluminum is famous for its lightweight properties without compromising on strength. Extruded aluminum profiles exhibit a high strength-to-weight ratio, making them ideal for applications where weight reduction is critical. This benefit is especially beneficial in industries such as automotive and aerospace, where lightweight materials contribute to fuel efficiency and improved performance.

Cost Effective

Aluminum extrusion offers cost-effective manufacturing solutions. The process allows the production of complex shapes in a single operation, reducing the need for additional machining or assembly processes. This streamlined manufacturing process leads to cost savings in terms of materials, labor, and overall production time.

Corrosion Resistance

Aluminum extrusions have inherent corrosion resistance. A natural oxide layer forming on the surface provides a protective barrier against environmental elements, making them resistant to rust and corrosion. This feature makes aluminum extrusions well suited for outdoor applications, where exposure to moisture and harsh weather is a concern.

Durability

Aluminum extrusion aligns with sustainable practices because of its recyclability. Aluminum is 100% recyclable with no loss in its physical properties. Recycling aluminum requires significantly less energy than primary production, making it an environmentally friendly choice. The recyclability of aluminum extrusion contributes to reducing carbon emissions and conserving natural resources.

Future Trends in Aluminum Extrusion

The field of aluminum extrusion is constantly evolving, driven by technological advancements and changing industry demands. Let's explore some of the future trends in aluminum extrusion:

Advanced Alloys

The development of advanced aluminum alloys with enhanced properties is an ongoing area of research. These alloys offer improved strength, corrosion resistance, and other desirable characteristics. By utilizing advanced alloys in the extrusion process, manufacturers can expand the application range of aluminum extrusions and meet the evolving needs of industries.

Energy Efficiency

Energy efficiency is a key focus in various industries. Aluminum extrusion processes are being optimized to reduce energy consumption, waste, and carbon emissions. Advanced heating and cooling techniques, as well as process control systems, are being implemented to achieve higher energy efficiency and sustainability.

3D Printing and Additive Manufacturing

The integration of 3D printing and additive manufacturing technologies with aluminum extrusion holds great potential. This combination allows for the creation of complex and customized profiles with intricate internal structures. By leveraging these technologies, manufacturers can further enhance design freedom, reduce material waste, and optimize resource utilization.

Conclusion

Aluminum extrusion is a versatile manufacturing process that offers exceptional design flexibility, lightweight properties, cost-effectiveness, and corrosion resistance. Its applications span across various industries, including architecture, automotive, aerospace, electronics, and consumer goods. With customization options and surface finishing techniques, aluminum extrusions can be tailored to specific requirements. While challenges exist, advancements in alloys, energy efficiency, and additive manufacturing are paving the way for future innovations in the field. Aluminum extrusion continues to shape the future of manufacturing with its unique combination of properties and endless possibilities.

#AluminumExtrusion#ExtrusionTechniques#AluminumFabrication#DIYProjects#AluminumProfiles#Metalworking

0 notes

Video

youtube

#SolarPanel #RenewableEnergy #CleanEnergy #Sustainability #SolarPower #GreenTechnology #SolarEnergy #SolarPV #SolarIndustry #cleantechnology #AluminumProfile #AluminumExtrusion #AluminumIndustry #AluminumProducts #AluminumFabrication #AluminumSolutions #AluminumDesign #ExtrudedProfiles #AluminumSystems #AluminumArchitecture

#youtube#SolarPanel RenewableEnergy CleanEnergy Sustainability SolarPower GreenTechnology SolarEnergy SolarPV SolarIn

0 notes

Photo

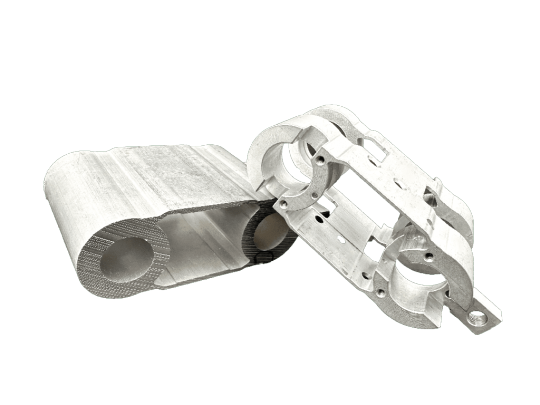

Discover The Best Aluminum Panel Extrusions Online

Discover The Best Aluminum Panel Extrusions Online with “Aluminum Extrusion & Fabrication”. One of the most effectual procedures for molding and shaping metal has to be the process of extrusion. These are done on the metal that is most used and is known by the name of aluminum. To know more about Aluminum Panel Extrusions, Aluminum Extrusions please visit the given URL.

0 notes

Photo

Aluminum extrusion is the process of shaping aluminium by forcing it through a small opening, commonly known as a die. Extruded aluminium has the same profile as die and is elongated. Because of its light weight, corrosion-free, and excellent conductivity properties, aluminium extruded has a wide range of applications in industries such as automotive and aircraft. The aluminium extrusion market is experiencing high demand as a result of the automotive industry's rapid adoption. Read more @ https://cmiaspireblog.blogspot.com/2022/04/aluminum-extrusion-market-analysis-size.html

#coherentmarketinsights#coherentmarketinsightsreports#AluminumExtrusion#AluminumExtrusionMarket#AdvancedMaterials

0 notes

Photo

I went back and got 50 pounds of the aluminum extrusion. #aluminumextrusion #ttrack #scrap There’s a little bit left. (at Sunshine Steel Enterprises Corp) https://www.instagram.com/p/Cbu5XepLFH1/?utm_medium=tumblr

0 notes

Link

0 notes

Photo

High end Office desk aluminum profile cover . Good quality and tasted !😍 Do you like it ? #aluminum #aluminumdiecasting #aluminumfabrication #aluminumextrusion #aluminumprofile #aluminumcasting #aluminumprocessing #aluminumproducts https://www.instagram.com/p/CHsGB9ehtYa/?igshid=1kqtg51vg0jqd

#aluminum#aluminumdiecasting#aluminumfabrication#aluminumextrusion#aluminumprofile#aluminumcasting#aluminumprocessing#aluminumproducts

0 notes

Link

#tslot#tslotaluminumextrusionprofile#Aluminum Extrusion#aluminumtubing#AluminumWindows#aluminum#aluminumtube#aluminumextrusion#aluminiumextrusion#aluminumextrusionbillet#specialaluminumextrudedprofiles

0 notes

Text

A EDELSTAHL VIRAT IBÉRICA é compradora e fornecedora de Extrusões de Alumínio!

Fornecemos extrusões de alumínio em todos os tamanhos de acordo com suas necessidades. Como extrusão a quente, extrusão a frio, extrusão a quente, extrusão por fricção e microextrusão e muito mais…

EDELSTAHL VIRAT IBERICA é um importador emergente - exportador, fornecedor de aço para ferramentas, aços para moldes de vários países. Também estamos envolvidos no comércio de ferrosos, ligas de aço, etc., com uma rede de parceiros em todo o mundo, somos capazes de atender rapidamente às necessidades do cliente.

Procuramos todos os fabricantes e fornecedores grossistas de sucata metálica como #HMS1, #HMS2, Extrusões de Alumínio, sucata ferrosa, sucata de motores eletrónicos e sucata triturada em #Portugal…

PARA SABER MAIS >>

https://moldsteel.eu/aluminum-extrusion-indl/

Chat WhatsApp: +351-920016150

E-mail: [email protected]

#porto#portugal#europe#din2738#edelstashlviratibrica#viratsteels#oportunidades#b2b#empresas#agricultura#AluminumExtrusions#AÇORÁPIDO#alumínio#trabalho#aviação

2 notes

·

View notes

Video

youtube

FenanFOEN aluminum Aluminum extrusion of various cross sections and size...

Having been in this line of business for more than 30 years,Fenan(FOEN)aluminum has had rich experience in the production of Aluminum extrusion of various cross sections and sizes(small to big),and we also offer OEM&ODM as your request at competitive price .

Looking forward to your inquiries,just grant us an opportunity to cooperate and develop together with you

Our site: www.foenalu.com

Charles is at your service: [email protected]

#aluminum #alumnio #aluminumoxide #anodizedaluminum #aluminumtexture #aluminumextrusion #aluminumextrusions #aluminumprofile #aluminumwindows #aluminumprofile #extrudedaluminum #8020aluminum #anodizingaluminum #solarmountingsystem #fenanaluminum #anodizingaluminum #oemservice #odm #oemfactory #oemsupplier #oemservice

#youtube#aluminum#aluminum profiles#alumnio#aluminumoxide#anodizedaluminum#aluminumtexture#aluminumextrusion#aluminumextrusions#aluminumprofile#aluminumwindows#anodizingaluminum#8020aluminum#oemservice#oemfactory#oemsupplier

0 notes

Photo

Building a Faux Retro Portable Computer #all-in-one #AluminumExtrusion #ComputerHacks #PortableComputer https://t.co/oOV5OfIUOO http://twitter.com/iAndroideu/status/1201501619218608128

Building a Faux Retro Portable Computer #all-in-one #AluminumExtrusion #ComputerHacks #PortableComputer https://t.co/oOV5OfIUOO

— iAndroid.eu (@iAndroideu) December 2, 2019

0 notes

Photo

a little #showcase progress... #aluminumextrusion #8020compatable #lexan (at WhirlyPig Design) https://www.instagram.com/p/B3J2lbdpfmg/?igshid=225o1q15cqmz

0 notes

Photo

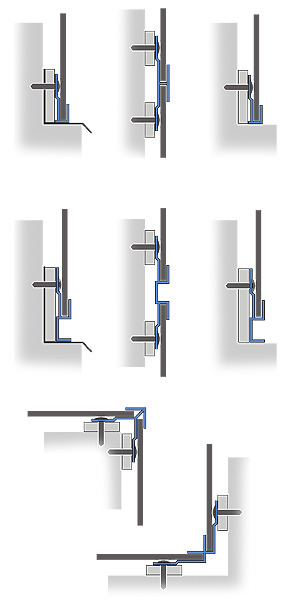

Find The Best Industrial Aluminium Profiles Online

Find The Best Industrial Aluminium Profiles Online with “Aluminum Extrusion & Fabrication. They serve you with the best Aluminum Products and services that too by professionals at reasonable prices. To know more about Industrial Aluminium Profiles, Aluminum Extrusions, Aluminium Extrusion Manufacturers please visit the given URL.

https://aluminum-extrusions.com/aluminum-profiles/

0 notes