#Automotive Composites Market Outlook

Text

Exploring the Ceramic Matrix Composites Market: Key Applications and Growth Trends

Composite materials are equipped with at least two parts: the strengthening, which offers superior mechanical properties including strength and stiffness, and the matrix material, which grips all together.

Ceramic matrix composites are a special kind of composite material in which both the strengthening and matrix materials are ceramics. In most cases, a similar type of ceramic is utilized for…

View On WordPress

#Aerospace#Automotive#Ceramic Matrix Composites#CMCs applications#energy#high-temperature environments#leading players#market outlook#performance#sustainability

0 notes

Text

Carbotanium Market Value to Reach US$ 59.2 Mn by 2031

The global carbotanium market is anticipated to grow at a CAGR of 16.0% during the forecast period from 2022 to 2031.

There has been a steady rise in demand for new raw materials from various end-use industries such as aerospace and automotive. Carbotanium has emerged as a suitable raw material in the manufacture several products for various end-use industries due to reduced specific weight and ability to withstand high temperatures.

Download a PDF sample copy of the report - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85297

Market Segmentation

The Carbotanium market can be segmented by service type, sourcing type, application, industry vertical, and region.

By Service Type: Manufacturing, Repair and Maintenance, Research and Development.

By Sourcing Type: Direct Procurement, Indirect Procurement.

By Application: Aerospace, Automotive, Sports Equipment, Medical Devices, Industrial Machinery.

By Industry Vertical: Aerospace and Defense, Automotive, Sports and Recreation, Healthcare, Industrial and Manufacturing.

By Region: North America, Europe, Asia Pacific, Latin America, Middle East and Africa.

Regional Analysis

North America

North America is anticipated to dominate the Carbotanium market due to significant investments in aerospace and defense, and a robust automotive sector. The presence of key manufacturers and a high adoption rate of advanced materials contribute to this dominance.

Europe

Europe follows closely, with Germany, the UK, and France leading the region’s market. The stringent regulations on emissions and fuel efficiency are driving the automotive industry's adoption of lightweight materials like Carbotanium.

Asia Pacific

Asia Pacific is expected to register the highest growth rate during the forecast period. The booming automotive and manufacturing sectors in countries like China, Japan, and India are the primary growth drivers.

Latin America and Middle East & Africa

These regions are gradually adopting advanced materials in various industries. Growth is expected to be steady, supported by increasing industrialization and infrastructure development.

Market Drivers and Challenges

Drivers

Performance and Efficiency: The superior performance characteristics of Carbotanium, including its high strength-to-weight ratio, drive its adoption across various sectors.

Technological Advancements: Continuous innovations in composite material technology enhance the production efficiency and application scope of Carbotanium.

Sustainability: The automotive and aerospace industries’ shift towards lightweight and fuel-efficient materials supports market growth.

Challenges

High Cost: The production and procurement costs of Carbotanium are relatively high, which can limit its widespread adoption.

Complex Manufacturing Processes: The specialized manufacturing processes required for Carbotanium can pose technical challenges and increase production time.

Market Trends

Increased R&D Activities: Extensive research and development are focused on enhancing Carbotanium properties and finding new applications.

Strategic Collaborations: Partnerships between material manufacturers and end-user industries are fostering innovation and market expansion.

Sustainability Initiatives: The drive towards more sustainable and eco-friendly materials is accelerating the adoption of Carbotanium.

Future Outlook

The future of the Carbotanium market looks promising with significant growth expected across all major regions. Innovations in manufacturing processes, cost reduction strategies, and expanding application areas will likely drive the market forward. The increasing emphasis on sustainability and performance efficiency will continue to bolster demand for Carbotanium.

Key Market Study Points

Analysis of current and future market trends.

Evaluation of the competitive landscape.

Assessment of technological advancements and their impact on market growth.

Identification of key market drivers and challenges.

Regional market analysis and growth forecasts.

Competitive Landscape

The Carbotanium market features a competitive landscape with key players focusing on innovation and strategic partnerships. Companies are investing in R&D to enhance product offerings and expand their market presence. Major players include:

Lamborghini

Ferrari

Boeing

Airbus

Toray Industries

Recent Developments

Lamborghini: Launched a new range of supercars utilizing Carbotanium for enhanced performance and reduced weight.

Toray Industries: Announced the development of an advanced Carbotanium production technique to reduce costs and improve efficiency.

Airbus: Integrated Carbotanium components in their latest aircraft models to improve fuel efficiency and structural integrity.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Automotive Roof System Market Growth Outlook Through 2024-2033

Overview and Scope

An automotive roof system refers to the structure or mechanism that covers the top of a vehicle, protecting its occupants from external elements such as rain, sun, wind, and debris.

Sizing and Forecast

The automotive roof system market size has grown strongly in recent years. It will grow from $31.34 billion in 2023 to $33.83 billion in 2024 at a compound annual growth rate (CAGR) of 7.9%. The growth in the historic period can be attributed to consumer demand for panoramic sunroofs, integration of advanced materials, regulatory standards for vehicle safety, consumer preference for convertible options, global expansion of premium and luxury vehicles.

The automotive roof system market size is expected to see strong growth in the next few years. It will grow to $45.6 billion in 2028 at a compound annual growth rate (CAGR) of 7.7%. The growth in the forecast period can be attributed to sustainability and lightweight design, increased adoption of electric vehicles, urbanization and parking challenges, customization and personalization trends, advanced safety standards. Major trends in the forecast period include integration of smart roof technologies, lightweight materials for improved efficiency, rise of convertible and retractable roof designs, increased adoption of solar roof technology, focus on aerodynamics and design.

Segmentation & Regional Insights

The automotive roof system market covered in this report is segmented –

1) By Type: Sunroof System, Panorama Roof System, Multi-Optional Roof System, Solar Roof System, Light Weight Roof System, Inbuilt Roof System, Other Types

2) By Material: Aluminium, Steel, Polycarbonate, Glass-Plastic Composite, Fiber-Plastic Composite

3) By Vehicle Type: Passenger Vehicles, Light Commercial Vehicles, Heavy Commercial Vehicles

4) By Sales Channel: Original Equipment Manufacturer (OEM), Aftermarket

Asia-Pacific was the largest region in the automotive roof system market in 2023. The regions covered in the automotive roof system market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa

Major Driver Impacting Market Growth

The increasing passenger car sales are expected to propel the growth of the automotive roof system market going forward. Passenger vehicles are motor vehicles that are used for the transport of passengers for commercial purposes. The automotive roof system provides effective ventilation, and enhanced driving experience for the rider in passenger vehicles, as a result, increasing sales of passenger cars increases the demand for the automotive sunroof system market. For instance, in January 2023, according to Eurostat, a Europe-based government agency, the number of electric passenger cars increased by 75% in 2021 with 2 million vehicles. Therefore, the increasing passenger car sales drives the automotive roof system market.

Key Industry Players

Major companies operating in the automotive roof system market report are Webasto SE, Magna International Inc., Valmet Automotive Inc., Inteva Products LLC, Covestro AG, Inalfa Roof Systems Group B.V., AAS Automotive Ltd., Aisin Corporation, ALUPROF S.A., Robert Bosch GmbH, The Haartz Corporation, JAC Products, CIE Automotive, U-Shin Ltd., Continental AG, Saint-Gobain Sekurit, GAHH LLC., CTS Automotive Products, Yachiyo Industry Co. Ltd., Minda KTSN Plastic Solutions GmbH & Co. KG, Mobitech Industries LLP, ACS Industries Inc., Kinugawa Rubber Industrial Co. Ltd., Roth North America, Eagle Ottawa LLC, RIMO GmbH, lkeda Manufacturing Co. Ltd., Tata Sons Private Limited, BOS Group, Carcoustics International GmbH, Hoerbiger Holding AG .

The automotive roof system market report table of contents includes:

1. Executive Summary

2. Automotive Roof System Market Characteristics

3. Automotive Roof System Market Trends And Strategies

4. Automotive Roof System Market — Macro Economic Scenario

5. Global Automotive Roof System Market Size and Growth

.

.

.

31. Global Automotive Roof System Market Competitive Benchmarking

32. Global Automotive Roof System Market Competitive Dashboard

33. Key Mergers And Acquisitions In The Automotive Roof System Market

34. Automotive Roof System Market Future Outlook and Potential Analysis

35. Appendix

Explore the trending research reports from TBRC:

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

0 notes

Text

Airless Tires Market Insights: Comprehensive Global Forecast (2023-2032)

The global demand for Airless Tires was valued at USD 1102.2 million in 2023 and is expected to reach USD 1709.8 million in 2032, growing at a CAGR of 5.00% between 2024 and 2032.

Airless tires market is a burgeoning sector within the broader automotive and transportation industry, characterized by the development and commercialization of tires that do not require air pressure to maintain their shape and functionality. These tires, also known as non-pneumatic tires (NPT), are constructed from durable materials like rubber and plastic composites, often featuring a unique spoke or honeycomb structure that provides support and flexibility. The market is driven by several key factors, including the increasing demand for maintenance-free and puncture-proof tires, which offer enhanced reliability and longevity compared to traditional pneumatic tires. Airless tires are particularly appealing for use in harsh environments and applications such as military vehicles, construction machinery, and agricultural equipment, where the risk of punctures is high and downtime is costly.

Despite the higher initial cost and some limitations in ride comfort and speed compared to conventional tires, the market is poised for significant growth, driven by the increasing emphasis on sustainability, safety, and cost-efficiency in vehicle operations. The adoption of airless tires is expected to expand as these technological and economic benefits become more pronounced, making them a viable alternative in various vehicle segments.

Airless Tires: Key Points

Construction:

Made from durable materials such as rubber and plastic composites.

Often feature a unique structural design, such as spokes or a honeycomb pattern, to provide support and flexibility.

Advantages:

Puncture-Proof: Eliminate the risk of flats and blowouts, enhancing safety and reliability.

Maintenance-Free: Require less maintenance compared to traditional pneumatic tires, as they do not need to be inflated.

Durability: Typically have a longer lifespan due to their robust construction.

Applications:

Ideal for use in harsh environments and demanding applications, such as military vehicles, construction machinery, and agricultural equipment.

Increasingly being explored for mainstream automotive use, including passenger cars and light trucks.

Performance:

Improved reliability in challenging conditions where traditional tires are prone to punctures.

Some limitations in ride comfort and speed performance compared to conventional pneumatic tires.

Market Drivers:

Growing demand for maintenance-free and puncture-resistant tires.

Advancements in materials and manufacturing technologies improving the feasibility and performance of airless tires.

Emphasis on sustainability, safety, and cost-efficiency in vehicle operations.

Higher initial cost compared to traditional tires.

Limited availability and adoption in the consumer market.

Ongoing development needed to enhance ride comfort and performance.

Future Outlook:

The market for airless tires is expected to grow as technological advancements continue and the benefits of airless tires become more widely recognized.

Potential for significant adoption in various vehicle segments as the technology matures and becomes more cost-effective.

Major Key Players-

Ameritire Corporation

Bridgestone Corporation

Continental AG

Hankook Tire & Technology Co., Ltd.

Michelin

Sumitomo Rubber Industries, Ltd.

The Goodyear Tire & Rubber Company

Toyo Tire Corporation

The Yokohama Rubber Co., Ltd.

Trelleborg

More About Report- https://www.credenceresearch.com/report/airless-tires-market

Airless Tires Market Trends-

Technological Advancements:

Continuous innovation in materials and design to enhance the performance and durability of airless tires.

Development of advanced manufacturing techniques to reduce production costs and improve scalability.

Increased R&D Investment:

Major tire manufacturers, including Michelin and Bridgestone, are heavily investing in research and development to refine airless tire technology.

Focus on improving ride comfort, load-bearing capacity, and speed capabilities.

Commercialization and Pilot Programs:

Several companies are conducting pilot programs and field tests in collaboration with automotive and industrial partners.

Early commercialization efforts targeting niche markets such as military, construction, and agriculture.

Sustainability Focus:

Growing emphasis on sustainability is driving interest in airless tires, which offer reduced waste and longer service life compared to traditional tires.

Potential for airless tires to be made from recyclable materials, further enhancing their environmental appeal.

Automotive Industry Adoption:

Increasing exploration of airless tires for use in passenger cars and light trucks, driven by the promise of maintenance-free operation and enhanced safety.

Potential integration with electric and autonomous vehicles, which require low-maintenance and reliable tire solutions.

Regulatory Support and Safety Standards:

Development of industry standards and regulatory frameworks to ensure the safety and performance of airless tires.

Government and industry initiatives to promote the adoption of innovative tire technologies.

Consumer Awareness and Acceptance:

Growing consumer awareness of the benefits of airless tires, including their puncture-proof nature and reduced maintenance needs.

Education and marketing efforts by manufacturers to highlight the advantages and address any concerns related to ride quality and cost.

Cost Reduction Efforts:

Ongoing efforts to reduce the manufacturing and material costs of airless tires, making them more competitive with traditional pneumatic tires.

Economies of scale expected as production volumes increase and technology matures.

Expansion into New Markets:

Exploration of new market opportunities in emerging economies where infrastructure development and industrial activities are growing.

Potential for significant market growth in regions with harsh operating conditions that benefit from the durability and reliability of airless tires.

Partnerships and Collaborations:

Collaboration between tire manufacturers, automotive companies, and technology firms to accelerate the development and deployment of airless tires.

Strategic partnerships to leverage expertise and resources, facilitating faster market penetration and innovation.

Segmentation

By Material Composition:

Rubber-based Airless Tires

Polyurethane-based Airless Tires

Plastic-based Airless Tires

Composite-based Airless Tires

Others

By Type of Airless Tires:

Radial Airless Tires

Bias Airless Tires

Belted Airless Tires

Non-Belted Airless Tires

By Application:

Military and Defense Vehicles

Off-road Vehicles (e.g., ATVs, UTVs, golf carts)

Commercial and Industrial Vehicles (e.g., forklifts, skid steers, construction equipment)

Lawn and Garden Equipment (e.g., lawn mowers, tractors, wheelbarrows)

Bicycles and Electric Scooters

Wheelchairs and Mobility Aids

Browse the full report – https://www.credenceresearch.com/report/airless-tires-market

Browse Our Blog: https://www.linkedin.com/pulse/airless-tires-market-projections-global-industry-hounf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Bulk Moulding Compound Revolutionizes Manufacturing Processes

Key Developments

Precision Mold Design: Manufacturers are investing in state-of-the-art mold design software and advanced machining technologies to create intricate and high-precision molds for BMC components. These molds ensure uniform material distribution, minimized defects, and enhanced surface finish, meeting the stringent requirements of modern applications.

Automated Molding Processes: Automation has revolutionized BMC molding operations, leading to faster production cycles, reduced labor costs, and improved consistency. Automated systems control material mixing, injection, compression, and curing processes with precision, resulting in superior part quality and increased throughput.

Advanced Material Formulations: Continuous research and development efforts have led to the formulation of BMC materials with enhanced mechanical properties, thermal stability, and flame resistance. Tailored formulations address specific application requirements, such as automotive under-the-hood components, electrical enclosures, and structural parts, expanding the versatility of BMC in diverse industries.

Integration of Sustainable Practices: With growing emphasis on sustainability, manufacturers are exploring eco-friendly additives and recyclable materials to enhance the environmental footprint of BMC products. Sustainable BMC formulations not only reduce waste but also contribute to regulatory compliance and corporate social responsibility initiatives.

Real-time Process Monitoring: Implementation of sensor-based monitoring systems allows real-time tracking of key process parameters during BMC molding. By monitoring variables such as temperature, pressure, and flow rates, manufacturers can identify deviations, optimize settings, and ensure consistent part quality, enhancing overall production efficiency.

Furthermore, collaboration between material suppliers, mold designers, equipment manufacturers, and end-users has fostered a collaborative ecosystem conducive to innovation and knowledge exchange. Through joint research projects, pilot trials, and technology transfer initiatives, stakeholders across the BMC value chain are driving continuous improvement and pushing the boundaries of what is achievable with composite materials.

Looking ahead, the outlook for BMC molding remains promising, with ongoing advancements poised to unlock new applications and markets. As industries embrace lightweight, durable, and cost-effective solutions, BMC stands out as a material of choice, offering unmatched performance and versatility in the ever-evolving landscape of composite materials.

0 notes

Text

Abrasives Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Abrasives Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Abrasives Market showcased a significant presence, boasting a valuation of US$ 53.41 billion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-abrasives-market/

Projected Growth: Projections suggest that the Abrasives Market will continue its upward trajectory, with a projected value of US$ 74.16 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4.8%, reflecting a steady and robust growth rate for the Abrasives Market over the coming years.

Technology Adoption:

In the Abrasives market, technology adoption encompasses the development and utilization of advanced abrasive materials, manufacturing processes, and surface finishing techniques. Abrasives are used for grinding, polishing, cutting, and shaping materials such as metals, ceramics, composites, and stones. Various abrasive types include bonded abrasives (e.g., grinding wheels, honing stones), coated abrasives (e.g., sandpaper, abrasive belts), and superabrasives (e.g., diamond, cubic boron nitride). Advanced technologies such as precision grinding, electroplated coatings, and laser machining enhance abrasive performance, precision, and efficiency in diverse applications across industries.

Application Diversity:

The Abrasives market serves diverse applications across industries such as automotive, aerospace, metalworking, construction, electronics, and healthcare. In manufacturing, abrasives are used for surface preparation, deburring, and precision grinding of components in automotive and aerospace production. Additionally, abrasives find applications in metal fabrication for cutting, shaping, and finishing metal parts in construction, machinery, and consumer goods. Moreover, abrasives are utilized in electronics manufacturing for wafer dicing, circuit board fabrication, and precision polishing of semiconductor materials.

Consumer Preferences:

Consumer preferences in the Abrasives market are influenced by factors such as abrasive performance, durability, surface finish quality, and cost-effectiveness. End-users prioritize abrasives that offer high material removal rates, consistent surface finish, and long tool life for efficient machining and finishing operations. Additionally, consumers value abrasives with low clogging tendency, heat resistance, and compatibility with specific materials and machining processes. Moreover, cost considerations, including abrasive price, availability, and overall process economics, play a significant role in consumer purchasing decisions.

Technological Advancements:

Technological advancements in the Abrasives market focus on improving abrasive material properties, manufacturing processes, and tooling technologies to enhance performance, productivity, and sustainability. Research efforts aim to develop new abrasive formulations with enhanced hardness, toughness, and self-sharpening characteristics for improved cutting and grinding efficiency. Additionally, advancements in abrasive coating technologies, such as nanostructured coatings and engineered grain geometries, enhance abrasive adhesion, wear resistance, and tool life in coated abrasive products. Moreover, integration with digital manufacturing technologies, such as CNC machining and robotic automation, enables precise control and optimization of abrasive processes for increased productivity and quality consistency.

Market Competition:

The Abrasives market is characterized by robust competition among abrasive manufacturers, distributors, and end-users, driven by factors such as product performance, quality, pricing, and customer service. Major players leverage their manufacturing scale, R&D capabilities, and global distribution networks to maintain market leadership and gain competitive advantage. Meanwhile, smaller manufacturers and specialty abrasive suppliers differentiate themselves through niche product offerings, customized solutions, and technical expertise in specific applications or industries. Additionally, strategic partnerships, acquisitions, and product innovations are common strategies for companies to expand market presence and enhance competitiveness in the dynamic Abrasives market.

Environmental Considerations:

Environmental considerations are increasingly important in the Abrasives market, with stakeholders focusing on sustainable sourcing, manufacturing processes, and waste management practices. Manufacturers strive to minimize environmental impact by using recycled and eco-friendly abrasive materials, reducing energy consumption, and optimizing water usage in abrasive production processes. Additionally, efforts are made to develop environmentally friendly abrasive coatings and surface treatments that minimize emissions, VOCs (volatile organic compounds), and hazardous waste generation during abrasive machining operations. Moreover, initiatives such as product life cycle assessment (LCA), eco-labeling, and certification programs promote sustainable practices and responsible consumption in the Abrasives market.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

3M Company

Saint-Gobain Abrasives

Robert Bosch GmbH (Bosch)

Norton Abrasives (A brand of Saint-Gobain Abrasives)

Klingspor AG

Tyrolit Group

Fujimi Incorporated

Deerfos Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Sia Abrasives Industries AG

Abrasiflex Pty Ltd

Hermes Schleifmittel GmbH

Abrasive Technology

Mirka Ltd.

The research report provides a comprehensive analysis of the Abrasives Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-abrasives-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Photopolymers Market Outlook: Emerging Applications in Biomedical Engineering and Flexible Electronics

The global photopolymers market is anticipated to reach USD 5.78 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 10.6% from 2023 to 2030. Rising demand for prototyping across the automotive industry and designs for understanding complex surgical procedures have increased the demand for photopolymer for 3D printing. Furthermore, increasing demand for artificial jewelry and prosthetics across the global population are further propelling the market growth.

Photopolymers Market Report Highlights

The European market was valued at USD 2.60 billion in 2022 and is expected to grow at a CAGR of 10.6% from 2023 to 2030

High-performance 3D printing refers to technologies that endure exceptional capabilities in terms of high speed, precision, material options, and the highest print quality. These high-performance 3D printing technologies include selective laser melting (SLM), electron beam melting (EBM), continuous liquid interface production (CLIP), and multi-material 3D printing

Stereolithography (SLA) is the most commonly used 3D printing technology across the world. It utilizes laser light sources to carry out 3D printing of objects. The global demand for SLA-based 3D printing has rapidly increased in recent years owing to its ability to print 25–300-micron components at a high XY resolution utilizing plastic resins and photopolymers

Photopolymers in 3D printing across the dental industry have witnessed a rise in demand in the past few years on account of their benefits, such as high-quality molds, perfect & precise designs, smoother surfaces, and higher durability, in comparison to the traditional process of manufacturing molds using thermoforming

For More Details or Sample Copy please visit link @: Photopolymers Market Report

Photopolymers are imaging compositions, based on polymers, oligomers, and monomers which can be polymerized accordingly and cross-linked upon image-wise exposure to light radiation such as ultraviolet (UV) rays. Photopolymers used across VAT polymerization in the 3D printing processes are used in liquid form and when exposed to UV rays in the form of a laser (SLA 3D printing technology) or scattered light source (DLP/cDLP 3D printing technology), undergo polymerization process which hardens them into the desired shape, as per the requirement of the final 3D printed product.

Photopolymers have gained traction from VAT polymerization-based 3D printing technologies, including stereolithography (SLA), digital light processing (DLP), and continuous digital light processing (cDLP) owing to their higher conversion from the liquid state to solid state, higher aesthetic component quality, enhanced versatility, material performance, and part longevity. The manufacturing of prototypes for jewelry, dental, and automotive, among others, are the market drivers for the market across the globe.

The market space is highly competitive with the introduction of new technologies for high-quality and high-speed 3D printing by various companies. For instance, in May 2022, Merit3D set a record for printing 60,000 parts in a time period of eight hours. The record was accomplished using Magna 3D printers for high-speed polymerization technology offered by Photocentric.

#PhotopolymersMarket#3DPrintingMaterials#PhotopolymerResins#UVcuringTechnology#AdditiveManufacturing#DigitalPrintingTech#HolographicMaterials#FlexibleElectronics#SustainableMaterials#InnovationInPrinting#AdvancedManufacturing#FutureOfMaterials

0 notes

Text

Exploring the Key Players in PF Resin Supply Chain: Suppliers, Innovations, and Market Trends

Introduction: Phenol-formaldehyde (PF) resin is a versatile and widely used synthetic resin with applications ranging from wood adhesives to molded products. As industries seek sustainable and high-performance materials, the demand for PF resin continues to grow. Central to meeting this demand are the suppliers who provide the raw materials, expertise, and innovations driving the PF resin market forward. This article delves into the world of PF resin suppliers, exploring their roles, innovations, and the evolving landscape of this essential industry.

The Role of PF Resin Suppliers: PF resin suppliers play a crucial role in the supply chain by providing manufacturers with the raw materials needed to produce Pf Resin Manufacturer in India adhesives, coatings, and other products. These suppliers typically offer a range of PF resin grades tailored to specific applications, including:

Adhesive Grade PF Resins: These resins are formulated to provide strong and durable bonds in wood products, laminates, and composite materials, making them indispensable in the furniture, construction, and automotive industries.

Molding Grade PF Resins: Molding grade PF resins are used in the production of molded products such as electrical components, appliance parts, and decorative items, offering excellent heat resistance and dimensional stability.

Coating Grade PF Resins: PF resins designed for coatings and surface treatments provide protection against moisture, chemicals, and abrasion, making them ideal for applications in marine, aerospace, and industrial sectors.

Innovations in PF Resin Technology: Driven by the demand for sustainable and high-performance materials, PF resin suppliers are continually innovating to improve product quality, environmental sustainability, and application versatility. Key innovations in PF resin technology include:

Low-Formaldehyde Formulations: Suppliers are developing PF resin formulations with reduced formaldehyde emissions to meet stringent regulatory requirements and address consumer preferences for eco-friendly products.

Bio-Based PF Resins: Bio-based PF resins derived from renewable feedstocks such as lignin or agricultural residues offer a sustainable alternative to traditional petroleum-based resins, reducing reliance on fossil fuels and mitigating environmental impact.

Waterborne PF Resins: Waterborne PF resin formulations provide improved safety, handling, and environmental benefits compared to solvent-based resins, contributing to lower VOC emissions and reduced environmental footprint in coating and adhesive applications.

High-Performance Additives: The integration of advanced additives such as crosslinking agents, antioxidants, and UV stabilizers into PF resin formulations enhances product performance, durability, and application versatility in various end-use industries.

Market Trends and Outlook: The PF resin market is characterized by steady growth driven by expanding applications in construction, automotive, electronics, and consumer goods sectors. Key market trends shaping the industry include:

Growing Demand for Engineered Wood Products: The increasing adoption of engineered wood products such as plywood, particleboard, and MDF (medium-density fiberboard) fuels demand for PF resins in wood adhesive applications, particularly in construction and furniture manufacturing.

Shift Towards Sustainable Materials: Consumer preferences for sustainable and environmentally friendly products drive the demand for bio-based and low-formaldehyde PF resin formulations, prompting suppliers to invest in green technologies and product development.

Technological Advancements in Manufacturing: Advances in resin synthesis, process Pf Resin Manufacturer in India optimization, and quality control enable suppliers to enhance product consistency, performance, and cost-effectiveness, driving competitiveness in the global PF resin market.

Conclusion: PF resin suppliers play a critical role in providing the raw materials and innovations that drive the growth and sustainability of industries reliant on synthetic resins. Through ongoing research, development, and collaboration with manufacturers, suppliers continue to push the boundaries of PF resin technology, offering solutions that meet evolving market demands for performance, sustainability, and regulatory compliance. As industries continue to prioritize environmental stewardship and product quality, the role of PF resin suppliers in delivering innovative and sustainable solutions will remain indispensable in shaping the future of materials science and manufacturing.

0 notes

Text

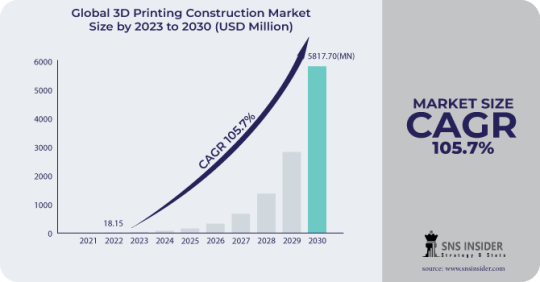

3D Printing Construction Market Analysis and Forecast 2031: Navigating Trends and Scope

3D Printing Construction market research is a valuable source of advice and information as it contains important information about global business. The research report includes a quantitative analysis of various aspects that have influenced the growth of the industry, such as country, supplier, market shape and size, and market characteristics. This study analyzes historical and forecast data to calculate the total market size based on global conditions. Tables and diagrams containing important data about the state of the industry are included in the overall business overview, along with tips and analysis for companies and consumers interested in the market.

Ask For Sample Report Here @ https://www.snsinsider.com/sample-request/1095

Primary and secondary procedures, approved research methods and services are crucial for 3D Printing Construction market research. The report covers all key market drivers and prospects, market constraints and their main competitors, company profile and general strategies to gain presence in the local and global level. This study looks at several countries to provide a qualitative and quantitative assessment of the world economy over the forecast period.

Segmentation View

By Construction Method

Extrusion

Powder Bonding

Others

By Material Type

Concrete

Metal

Composite

Others

By End-User

Building

Infrastructure

By Company

Apis Cor

COBOD International A/S, CyBe Construction

D-shape, Heidelberg Cement AG (Italcementi SpA)

LafargeHolcim

Sika AG

Skanska

Yingchuang Building Technique (Shanghai) Co., Ltd. (Winsun)

XtreeE

This Testing as a Service (TaaS) market research includes a detailed survey of vendors in the global market, along with an accurate analysis of the vendor market to determine the size of the market. The survey provides an overview of the market segments of the target sector and the many growth prospects that the sector faces. Buyers looking to increase their market share in recent and future business situations can benefit significantly from 3D Printing Construction market research.

Regional Developments

This study looks at current trends in these areas and the different options available to service providers worldwide. In a highly competitive environment, a global survey of the 3D Printing Construction market identifies all the key players operating in the automotive hose market and ranks them based on company strengths and products. The regions covered in this research report include Europe, North America, South America, Asia Pacific and others.

Competitive Outlook

This study examines the importance and predictive evidence of the field and its aspects. The report also includes information on the major global industry players in the 3D Printing Constructionmarket including company profile, specifications, product image, capacity, price, cost, and revenue. Market size, major methods of business performance, and company exposure in the region are all covered by market Research. It also includes expert opinions, information about the business environment, and marketing plans.

Buy This Report Here @ https://www.snsinsider.com/checkout/1095

This 3D Printing Construction market research evaluates the results of internal expert interviews, detailed secondary research, and primary interviews. Each service provider is evaluated using financial analysis, fundamental data, region participation, sales performance, and segment contribution. Upstream industry differences, market segments, business environments, demand developments, and cost and pricing structures are all included in the global study.

0 notes

Text

Ceramic Matrix Composites Market Is Expected To See Huge Growth Globally By 2033

Market Definition

The ceramic matrix composites (CMC) market focuses on advanced materials composed of ceramic fibers embedded in a ceramic matrix, exhibiting superior properties such as high strength, temperature resistance, and lightweight characteristics. These composites find extensive application in aerospace, automotive, energy, and other industries requiring materials with exceptional mechanical and thermal properties. CMCs offer advantages over traditional materials like metals and alloys due to their ability to withstand extreme temperatures and harsh environments while maintaining structural integrity.

Market Outlook

The ceramic matrix composites (CMCs) market holds a promising outlook with steady growth anticipated due to the burgeoning demand for high-performance materials across various industries. As industries increasingly prioritize lightweight, durable, and high-temperature-resistant materials, CMCs have emerged as a viable solution, especially in aerospace, automotive, and energy sectors. In aerospace, CMCs are utilized for components like engine parts, thermal barriers, and structural elements due to their ability to withstand extreme temperatures while reducing overall weight, thereby improving fuel efficiency. Moreover, the automotive industry is showing interest in CMCs to enhance fuel efficiency and reduce emissions by utilizing these composites in engine components and lightweight structural parts. Additionally, in the energy sector, CMCs are sought after for applications in gas turbines, nuclear reactors, and high-temperature processing equipment due to their superior thermal and mechanical properties.

To Know More:https://www.globalinsightservices.com/reports/ceramic-matrix-composites-market

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Sample: https://www.globalinsightservices.com/request-sample/GIS20317/

Market Segmentation

The market segmentation of ceramic matrix composites (CMCs) can be categorized based on material type, application, and end-user industry. Material type segmentation includes oxide-based, silicon carbide-based, and carbon-based CMCs, each possessing distinct properties suitable for different applications and industries. Application-based segmentation involves aerospace, automotive, energy & power, defense, and various industrial sectors, reflecting the diverse utilization of CMCs in components like turbine blades, engine parts, brake systems, heat exchangers, and structural components. Additionally, segmentation by end-user industry encompasses aerospace & defense, automotive, energy generation, and industrial sectors, catering to the specific requirements and applications of CMCs within each industry.

Request Customization:https://www.globalinsightservices.com/request-customization/GIS20317/

Major Players

The key players in the Global Ceramic Matrix Composites Market are Saint Gobain (France), Applied Thin Films Inc. (US), CeramTec GmbH (Germany), CoorsTek Inc. (US), Lancer Systems (US), Rolls-Royce plc (UK), Ultramet (US), Composites Horizons (US),COI Ceramics, Inc. (US), SGL Carbon (Germany)

Request Discounted Pricing: https://www.globalinsightservices.com/request-special-pricing/GIS20317/

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS20317/

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Nanocellulose Technology Market Size & Share to Surpass USD 2.2 billion by 2031

The global nanocellulose technology market was estimated to have acquired US$ 353.4 million in 2022. It is anticipated to register a 22.7% CAGR from 2023 to 2031 and by 2031, the market is likely to gain US$ 2.2 billion.

The exceptional mechanical strength and high surface area of nanocellulose make it suitable for water treatment applications. Nanocellulose based filters can provide an eco-friendly solution for water purification.

Integration of nanocellulose in smart packaging solutions, such as sensors and indicators for freshness and safety, can enhance the functionality of packaging materials.

Request Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1678

Market Segmentation

The nanocellulose technology market can be segmented based on service type, sourcing type, application, industry vertical, and region.

By Service Type:

Consulting and Development Services

Product Development and Testing Services

Maintenance and Support Services

By Sourcing Type:

Plant-Based Nanocellulose

Bacterial Nanocellulose

By Application:

Paper and Packaging

Composites and Plastics

Medical and Pharmaceutical

Electronics

Cosmetics and Personal Care

By Industry Vertical:

Automotive

Food and Beverage

Healthcare

Electronics

Textile

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Regional Analysis

North America: Dominates the market due to early adoption of technology, strong presence of key market players, and significant investments in research.

Europe: Follows closely with robust growth driven by stringent environmental regulations and high demand for sustainable materials.

Asia-Pacific: Expected to exhibit the highest growth rate due to rapid industrialization, increased research activities, and growing applications in packaging and electronics.

Latin America and Middle East & Africa: These regions are gradually adopting nanocellulose technology, with growth driven by increasing awareness and investments in the healthcare and packaging sectors.

Market Drivers and Challenges

Drivers:

Growing demand for sustainable and biodegradable materials.

Increasing applications in diverse industries such as automotive, electronics, and healthcare.

Advancements in nanotechnology and increasing R&D investments.

Challenges:

High production costs and scalability issues.

Limited technical expertise and awareness in developing regions.

Regulatory challenges and the need for standardization.

Market Trends

Sustainability Focus: Increased emphasis on using renewable and biodegradable materials in manufacturing processes.

Technological Advancements: Development of advanced manufacturing processes to reduce costs and improve the properties of nanocellulose.

Collaborations and Partnerships: Companies are increasingly collaborating with research institutions and other firms to enhance their product offerings and expand market reach.

Future Outlook

The future of the nanocellulose technology market looks promising, with significant potential for growth in various applications. Innovations in production techniques and increased investment in research will likely lower costs and expand the use of nanocellulose across more industries. The push for sustainability will continue to be a major driver, promoting the adoption of nanocellulose-based products globally.

Key Market Study Points

Evaluation of market size and growth from 2023 to 2031.

Analysis of market segmentation by service type, sourcing type, application, industry vertical, and region.

Insights into regional market dynamics and growth patterns.

Identification of market drivers and challenges.

Examination of current market trends and future outlook.

Assessment of the competitive landscape and recent developments.

Competitive Landscape

The nanocellulose technology market is highly competitive, with key players including CelluForce, Nippon Paper Industries, Borregaard, and American Process Inc. These companies are focusing on strategic partnerships, product innovations, and expansions to strengthen their market position. Recent developments include new product launches, collaborations with research institutions, and advancements in production technologies.

Buy this Premium Research Report @ https://www.transparencymarketresearch.com/checkout.php?rep_id=1678<ype=S

Recent Developments

Product Innovations: Introduction of new nanocellulose-based composites and coatings with enhanced properties.

Partnerships: Collaborations between nanocellulose producers and end-user industries to develop customized solutions.

Technological Advances: Improvements in nanocellulose production methods to increase efficiency and reduce costs.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

How Fiber Laser Cutting Machines Enhance Manufacturing Processes

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. Businesses are constantly seeking cutting-edge technologies to streamline their processes and stay ahead of the competition. One such innovation that has revolutionised manufacturing is the fiber laser cutting machine. Let's explore how these machines, particularly the ones offered by MadBytes, are enhancing manufacturing processes across industries.

Fiber Laser Machine: The Backbone of Modern Manufacturing

Fiber laser cutting machines have emerged as the go-to solution for precision cutting in various materials, including metals, plastics, and composites. Unlike traditional cutting methods, such as mechanical or plasma cutting, fiber lasers offer unmatched speed, accuracy, and versatility.

MadBytes, a leader in CNC machinery, offers state-of-the-art fiber laser machines designed to meet the evolving needs of manufacturers. These machines utilise advanced fiber laser technology to deliver superior cutting performance, whether it's intricate designs or large-scale production runs.

Flatbed Nesting CNC: Optimising Material Usage

One of the key features of MadBytes' fiber laser machines is their compatibility with flatbed nesting CNC systems. This integration allows manufacturers to maximise material utilisation by nesting multiple parts on a single sheet, thereby reducing waste and minimising production costs.

Auto-Nesting CNC Machine: Streamlining Workflow

MadBytes takes efficiency to the next level with their auto-nesting CNC machines. These automated systems intelligently arrange parts on the cutting bed, optimising cutting paths and minimising idle time. By automating the nesting process, manufacturers can significantly improve throughput without compromising quality.

Fiber Laser Cutting Machine: Precision Redefined

At the heart of MadBytes' manufacturing solutions lies the fiber laser cutting machine. These machines deliver unparalleled precision, thanks to their high-powered fiber lasers and advanced motion control systems. Whether it's intricate patterns or complex geometries, MadBytes' fiber laser cutting machines ensure precise cuts with minimal material distortion.

Benefits Across Industries

The benefits of MadBytes' fiber laser cutting machines extend across a wide range of industries. From automotive and aerospace to electronics and signage, manufacturers are leveraging these cutting-edge technologies to stay competitive in today's market. With faster turnaround times, reduced waste, and superior quality, businesses can meet the demands of their customers while maximising profitability.

Future Outlook:

As technology continues to evolve, the role of fiber laser cutting machines in manufacturing will only grow. MadBytes remains at the forefront of innovation, continuously refining their machines to meet the evolving needs of the industry. With a focus on reliability, performance, and customer satisfaction, MadBytes is empowering manufacturers to thrive in an increasingly competitive landscape.

In conclusion, the fiber laser cutting machines offered by MadBytes are revolutionising manufacturing processes worldwide. From precision cutting to material optimisation, these machines are driving efficiency and productivity across industries. With MadBytes' commitment to innovation and excellence, the future of manufacturing looks brighter than ever.

0 notes

Text

Automotive Composites Market 2024 is Booming Globally with Top Key Players

Global Automotive Composites Market research report published by Exactitude Constancy reveals the current outlook of the global and key regions from the following perspectives: Key players, countries, product types, and end industries. The report studies the top companies in the global market and divides the market into several parameters. This Automotive Composites Market research report pinpoints the industry's competitive landscape to understand the international competition. This report study explains the expected growth of the global market for the upcoming years from 2024 to 2030. This research report is accumulated based on static and dynamic perspectives on business.

The global Automotive Composites Market is expected to grow at 11 % CAGR from 2024 to 2030. It is expected to reach above USD 33.59 billion by 2030 from USD 5.16 billion in 2023.

Browse Complete Summary and Table of Content @ https://exactitudeconsultancy.com/ja/reports/13313/automotive-composites-market/

#Automotive Composites Industry#Automotive Composites Market 2024#Automotive Composites Market Analysis#Automotive Composites Market Research Report#Automotive Composites Market Demand#Automotive Composites Market Growth#Automotive Composites Market Insights#Automotive Composites Market Revenue#Automotive Composites Market Share#Automotive Composites Market Size#Automotive Composites Market Trends

0 notes

Text

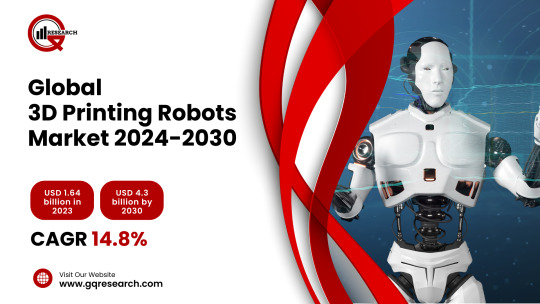

3D Printing Robots Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The 3D Printing Robots Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global 3D Printing Robots Market showcased a significant presence, boasting a valuation of US$ 1.64 billion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-3d-printing-robots-market-report/

Projected Growth: Projections suggest that the 3D Printing Robots Market will continue its upward trajectory, with a projected value of US$ 4.3 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 14.8%, reflecting a steady and robust growth rate for the 3D Printing Robots Market over the coming years.

Technology Adoption:

The 3D Printing Robots market involves the integration of robotics and additive manufacturing technologies to create automated systems capable of producing three-dimensional objects layer by layer. These robots utilize various 3D printing technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). They are equipped with advanced sensors, actuators, and control systems to precisely deposit or cure materials according to digital designs. Additionally, robotic arms and gantry systems are commonly employed to provide multi-axis movement and enable complex printing geometries.

Application Diversity:

The applications of 3D Printing Robots span across numerous industries, including manufacturing, construction, healthcare, aerospace, and automotive. In manufacturing, these robots are utilized for rapid prototyping, tooling production, and customized part manufacturing. In construction, they enable the fabrication of complex architectural components, building facades, and infrastructure elements. In healthcare, 3D printing robots produce patient-specific implants, prosthetics, and medical devices. Moreover, they are employed in aerospace and automotive industries for lightweight component manufacturing and rapid production of prototypes and spare parts.

Consumer Preferences:

Consumer preferences in the 3D Printing Robots market revolve around factors such as printing speed, accuracy, material versatility, and customization options. Customers seek robots capable of fast and precise printing to minimize production time and ensure quality output. Additionally, they prefer robots that support a wide range of materials, including plastics, metals, ceramics, and composites, to meet diverse application needs. Furthermore, customization features such as adjustable print parameters, scalable printing volumes, and compatibility with CAD software are valued by consumers seeking tailored solutions for their specific manufacturing requirements.

Technological Advancements:

Technological advancements in the 3D Printing Robots market focus on enhancing printing speed, resolution, material compatibility, and automation capabilities. Research efforts aim to develop faster printing processes, such as Continuous Liquid Interface Production (CLIP) and High-Speed Sintering (HSS), to accelerate production rates without compromising print quality. Additionally, advancements in material science enable the use of advanced materials with improved mechanical properties, thermal stability, and biocompatibility for diverse applications. Moreover, integration with artificial intelligence (AI) and machine learning algorithms enables robotic systems to optimize printing parameters, predict potential defects, and self-correct errors during printing processes.

Market Competition:

The 3D Printing Robots market is characterized by intense competition among robotics manufacturers, 3D printing companies, and solution providers, driven by factors such as technology innovation, product performance, pricing, and customer service. Major players leverage their expertise in robotics, additive manufacturing, and industrial automation to develop integrated solutions tailored to specific industry verticals and application requirements. Meanwhile, startups and niche players differentiate themselves through specialized printing technologies, proprietary software solutions, and targeted customer support services. Additionally, strategic partnerships, joint ventures, and acquisitions are common strategies for companies to expand market presence and gain competitive advantage in the dynamic 3D Printing Robots market.

Environmental Considerations:

Environmental considerations play a significant role in the 3D Printing Robots market, with stakeholders focusing on sustainability, resource efficiency, and waste reduction in manufacturing processes. Manufacturers strive to minimize energy consumption, material waste, and emissions associated with 3D printing operations by optimizing printing parameters, recycling unused materials, and adopting eco-friendly printing technologies. Additionally, efforts are made to explore bio-based and biodegradable materials for 3D printing applications to reduce dependence on fossil fuels and promote circular economy principles. Moreover, initiatives such as product life cycle assessment (LCA), eco-design principles, and environmental certifications contribute to promoting environmentally responsible practices throughout the 3D Printing Robots supply chain.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

ABB Group

KUKA AG

Stratasys Ltd

Mitsubishi Electric Corporation

Universal Robots

RobotLAB Inc

NACHI-FUJIKOSHI CORP

Dobot

Robot Factory

Ingersoll Machine Tools Inc

The research report provides a comprehensive analysis of the 3D Printing Robots Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-3d-printing-robots-market-report/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Stainless Steel Supplier

Stainless steel circles have become increasingly popular in various industries due to their versatility, durability, and aesthetic appeal. This article explores the properties, manufacturing process, applications, advantages, and market trends of stainless steel circles, along with maintenance tips and future outlook.

Introduction to Stainless Steel Circle

Stainless steel circles are disc-shaped metal sheets with a uniform thickness, made from stainless steel alloys. They are renowned for their corrosion resistance, high strength, and hygienic properties, making them ideal for a wide range of applications.

Properties of Stainless Steel Circles

Stainless steel circles exhibit exceptional properties such as:

Corrosion resistance

High strength-to-weight ratio

Heat resistance

Hygienic surface

Aesthetic appeal

Manufacturing Process of Stainless Steel Circles

The manufacturing process involves the following steps:

Melting: Raw materials like iron ore, chromium, nickel, and other alloys are melted in an electric arc furnace.

Casting: The molten metal is poured into molds to form slabs.

Hot Rolling: The slabs are hot rolled to achieve the desired thickness.

Circle Cutting: The hot-rolled coils are cut into circles using specialized machinery.

Annealing: The circles undergo annealing to improve their mechanical properties.

Applications of Stainless Steel Circles

Stainless steel circles find applications in various industries, including:

Cookware and kitchen utensils

Automotive components

Construction and architecture

Medical instruments

Aerospace industry

Advantages of Using Stainless Steel Circles

The advantages include:

Longevity and durability

Resistance to corrosion and stains

Easy to clean and maintain

Recyclability and sustainability

Factors to Consider When Choosing Stainless Steel Circles

When selecting stainless steel circles, consider factors such as:

Grade and composition

Surface finish

Thickness and diameter

Application-specific requirements

Market Trends and Growth Opportunities

The stainless steel circle market is witnessing growth due to:

Increasing demand in construction and infrastructure projects

Technological advancements in manufacturing processes

Rising awareness about sustainable materials

Environmental Impact of Stainless Steel Circles

Stainless steel circles have a low environmental impact due to their recyclability, durability, and energy-efficient production processes.

Maintenance Tips for Stainless Steel Circles

To maintain the quality and appearance of stainless steel circles:

Clean regularly with mild soap and water

Avoid abrasive cleaners and tools

Remove stains promptly

Apply protective coatings if necessary

Comparing Stainless Steel Circles with Other Materials

Stainless steel circles offer advantages over materials like aluminum and carbon steel in terms of corrosion resistance, strength, and aesthetics.

Cost Analysis of Stainless Steel Circles

While stainless steel circles may have a higher initial cost, their longevity and low maintenance requirements make them cost-effective in the long run.

Innovations and Developments in Stainless Steel Circle Industry

Innovations such as advanced surface treatments, alloy compositions, and precision manufacturing techniques continue to enhance the performance and versatility of stainless steel circles.

Future Outlook for Stainless Steel Circles

The future of stainless steel circles looks promising, with ongoing research and development aimed at improving properties, reducing costs, and expanding applications.

1 note

·

View note